PEX Pipe Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 441023 | Date : Feb, 2026 | Pages : 248 | Region : Global | Publisher : MRU

PEX Pipe Market Size

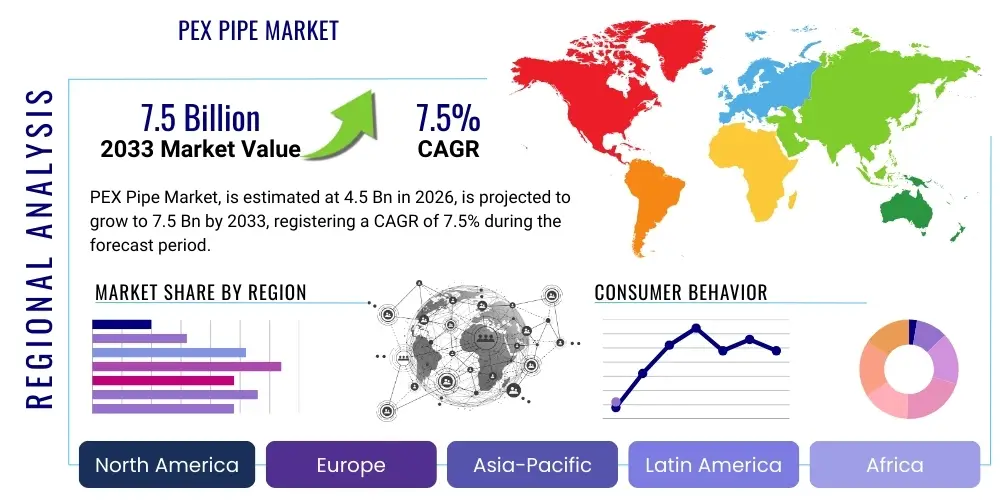

The PEX Pipe Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.5% between 2026 and 2033. The market is estimated at USD 4.5 billion in 2026 and is projected to reach USD 7.5 billion by the end of the forecast period in 2033.

PEX Pipe Market introduction

The PEX (Cross-linked Polyethylene) Pipe Market is characterized by the production and distribution of flexible plastic tubing utilized predominantly in plumbing, radiant heating and cooling systems, and specialized industrial applications. PEX piping systems have experienced substantial adoption globally, largely supplanting traditional materials such as copper and galvanized steel, owing to their inherent resistance to corrosion, scalability in installation, and superior thermal properties. This market includes various types of PEX, specifically PEX-a, PEX-b, and PEX-c, distinguished by their manufacturing processes (Engel method, Silane method, and Electron Beam method, respectively), which dictate their cross-linking density and flexibility. The primary applications span residential and commercial construction sectors, driving demand through infrastructure development and the increasing global focus on energy-efficient building standards.

The key product description centers on high-density polyethylene (HDPE) that undergoes a chemical or physical cross-linking process to enhance its durability, temperature resistance, and pressure bearing capacity. Major applications encompass domestic hot and cold water distribution (potable water systems), hydronic radiant floor heating, chilled water conveyance, and outdoor snow and ice melting systems. The core benefits driving market penetration include installation cost reduction due to flexibility and fewer required fittings, prevention of mineral buildup (scaling), and a significantly longer service life compared to metallic alternatives. PEX is also notably resistant to freeze damage, an important consideration in diverse climatic regions, further solidifying its value proposition in modern construction practices.

Driving factors propelling market expansion are fundamentally linked to sustained growth in the global construction industry, particularly in emerging economies undergoing rapid urbanization, coupled with stringent environmental regulations mandating sustainable and durable building materials. Furthermore, the increasing consumer preference for radiant floor heating systems, recognized for their energy efficiency and comfort attributes, provides a significant boost to PEX demand. Regulatory approvals and standardization efforts by organizations such as ASTM and NSF International have fostered confidence in PEX systems, accelerating their acceptance among contractors, engineers, and municipal authorities globally. The inherent efficiency of PEX in reducing water waste and energy consumption aligns perfectly with modern green building codes and standards.

PEX Pipe Market Executive Summary

The PEX Pipe Market Executive Summary reveals robust growth trajectory anchored by infrastructural investments and technological advancements in cross-linking methodologies. Business trends highlight a strong shift toward pre-assembled PEX systems (manifolds and prefabricated distribution units) which reduce on-site labor time and costs, enhancing contractor efficiency. Consolidation among major manufacturers through mergers and acquisitions is evident, aiming to capture larger market share and optimize global supply chains. Furthermore, sustainability reporting and the use of bio-based additives in PEX manufacturing are emerging business imperatives, responding to increasing corporate social responsibility demands.

Regional trends indicate that North America and Europe remain the dominant markets, driven by established regulatory frameworks supporting PEX use in residential and commercial plumbing upgrades, especially related to lead abatement programs. However, the Asia Pacific (APAC) region is demonstrating the highest growth potential, largely fueled by massive urbanization projects in China, India, and Southeast Asian countries where PEX provides a durable, cost-effective alternative to traditional plumbing materials. The Middle East and Africa (MEA) are also showing promising signs of adoption, particularly in large-scale residential community developments where water quality management and corrosion resistance are critical concerns. Demand in Latin America is tied closely to public infrastructure investments and housing initiatives.

Segmentation trends illustrate that the PEX-b segment, utilizing the reliable Silane method, maintains the largest market share due to its cost-effectiveness and broad regulatory acceptance for potable water applications. Concurrently, the radiant heating application segment is experiencing accelerated growth, driven by the expanding smart home technologies and energy management systems that integrate hydronic solutions. By material, high-barrier PEX pipes (those incorporating an oxygen diffusion barrier, typically EVOH) are becoming standard, especially in hydronic heating circuits, to prevent system corrosion and maintain warranty compliance, signifying a shift toward higher-performance products across key end-use sectors.

AI Impact Analysis on PEX Pipe Market

User inquiries concerning the impact of Artificial Intelligence (AI) on the PEX Pipe Market frequently center on optimizing manufacturing processes, enhancing supply chain transparency, and utilizing predictive maintenance for installed systems. Common user questions probe how AI can improve the quality control of PEX-a cross-linking consistency, whether generative design can optimize pipe layout for complex building geometries, and the role of machine learning in forecasting material demand fluctuations influenced by volatile construction cycles. Analysis indicates key themes revolve around efficiency gains in production (minimizing material waste), predictive logistical management (reducing lead times), and leveraging smart monitoring in end-use applications (ensuring system longevity and identifying potential failures before they occur).

The direct impact of AI implementation is initially focused on the manufacturing floor. Machine learning algorithms are increasingly being deployed to monitor extrusion parameters—temperature, pressure, and cross-linking radiation dosage—in real-time. This sophisticated monitoring ensures uniformity in polymer cross-linking, resulting in fewer defects and higher product reliability, crucial for minimizing warranty claims and maintaining regulatory compliance. Furthermore, AI-driven simulations allow manufacturers to rapidly prototype new PEX formulations, potentially integrating recycled materials or specialized additives while maintaining performance integrity, accelerating product innovation cycles.

Beyond manufacturing, AI significantly influences market strategy and installation. For contractors and large construction firms, AI platforms can optimize the procurement of PEX systems by predicting regional material shortages, analyzing optimal routing for delivery, and even assisting in generating precise material take-offs from Building Information Modeling (BIM) data. In the final installation phase, AI-powered image recognition and sensor data analysis can verify correct jointing techniques and system pressures, ensuring that installations meet stringent quality standards. This move towards intelligent installation practices enhances overall system reliability and reduces the margin for human error, fundamentally transforming how PEX systems are deployed.

- Implementation of predictive maintenance algorithms for large-scale hydronic PEX systems, optimizing flow and temperature control.

- AI-driven quality control in extrusion processes, ensuring precise cross-linking density (PEX-a, PEX-b).

- Optimization of supply chain logistics using machine learning to forecast regional material demand and minimize inventory holding costs.

- Generative design tools assisting architects and engineers in optimizing PEX pipe layout for maximum thermal efficiency and minimal material use.

- Automated defect detection during manufacturing using computer vision systems.

DRO & Impact Forces Of PEX Pipe Market

The PEX Pipe Market is fundamentally shaped by the dynamics of its Drivers (D), Restraints (R), and Opportunities (O), which collectively define the Impact Forces influencing market direction. Key drivers include the ongoing global construction boom, particularly in residential and commercial sectors seeking cost-effective and long-lasting plumbing solutions, and the strong regulatory push towards energy-efficient building infrastructure, favoring PEX for radiant heating and cooling applications. Restraints primarily involve the continued, albeit diminishing, regulatory hurdles in certain regions that still mandate traditional metallic piping for specific high-pressure applications, alongside the inherent limitations regarding PEX’s UV degradation susceptibility which necessitates protected storage and specialized installation practices in exposed areas. Opportunities lie in developing advanced multilayer PEX pipes (e.g., PEX-AL-PEX composites) that offer superior performance barriers and rigidity, expanding into new niche markets like industrial fluid transport, and aggressively targeting developing economies where plumbing infrastructure modernization is nascent. These forces create high pressure for innovation, requiring manufacturers to continuously improve product performance and compliance.

The major impact forces stem from the competitive pressure exerted by substitute materials and the fluctuating costs of raw materials, predominantly high-density polyethylene (HDPE). The competition from PVC, CPVC, and PP-R pipes, particularly in non-potable and lower-pressure applications, acts as a significant restraint on pricing power. Simultaneously, the volatility of global petrochemical markets directly affects HDPE procurement costs, squeezing profit margins for PEX manufacturers. Successfully managing these cost pressures while simultaneously investing in advanced cross-linking technologies (like electron-beam PEX-c for higher purity and flexibility) is critical for maintaining market leadership and achieving scalable growth. Regulatory alignment, particularly in addressing concerns related to chemical leaching in older PEX formulations, is another critical force that requires continuous monitoring and investment in material science research.

Strategic opportunities include leveraging the global trend toward smart buildings and IoT integration. PEX piping systems are foundational components of hydronic systems which can be easily monitored and controlled by smart thermostats and energy management platforms. Manufacturers who successfully integrate sensor technology or provide pre-fabricated, smart-ready PEX manifold systems will capture significant value. Furthermore, the rising awareness of water conservation and quality in drought-prone and developing regions provides a substantial opportunity for PEX, given its resistance to corrosion and scaling, ensuring long-term water purity and system integrity. Overcoming existing geographical installation biases through aggressive education and certification programs for contractors remains a necessary strategic imperative to fully capitalize on these expansion opportunities.

Segmentation Analysis

The PEX Pipe Market segmentation provides a granular view of market dynamics based on type, application, and end-use sector. This structured analysis is essential for understanding differentiated growth vectors and specific market needs. Key segmentation categories include the three main PEX types (PEX-a, PEX-b, PEX-c), which are defined by their distinct manufacturing processes and resulting performance characteristics. Application segmentation focuses heavily on the two primary uses: potable water systems (hot and cold plumbing) and radiant systems (heating and cooling), which exhibit different growth rates based on regional regulatory acceptance and climate. Finally, end-use analysis differentiates between residential, commercial, and industrial construction sectors, reflecting varied volume requirements and specification standards.

The product type segmentation reveals a mature competition between PEX-a, which offers superior flexibility and ease of installation, and PEX-b, which is often favored for its lower manufacturing cost and widespread regulatory acceptance. PEX-c, utilizing the electron beam process, holds a smaller but growing niche market due to its clean manufacturing process and specific material properties appealing to high-purity applications. Within application segments, while residential plumbing remains the volume leader, the fastest growth is observed in the radiant heating and cooling segment, fueled by technological advancements in heat pumps and the push for floor-integrated comfort systems in high-end new construction. This application requires specialized barrier PEX to prevent oxygen ingress and subsequent system damage.

Analysis by end-use sector shows that the residential segment, encompassing both single-family and multi-family dwellings, accounts for the majority of the market, primarily driven by new housing starts and extensive re-piping activities in older homes. The commercial segment, including office buildings, hospitals, and educational facilities, demands high volumes of pipe meeting stringent fire and safety codes, favoring products with robust flame resistance. The industrial segment, while smaller, typically requires highly specialized PEX formulations capable of handling aggressive chemicals or extreme temperatures, representing a high-value, low-volume opportunity for specialized manufacturers. Understanding these segment behaviors is crucial for allocating marketing resources and tailoring product development strategies.

- By Type:

- PEX-a (Engel Method)

- PEX-b (Silane Method)

- PEX-c (Electron Beam Method)

- By Application:

- Potable Water Plumbing

- Radiant Heating and Cooling

- Snow and Ice Melting

- Industrial and Agricultural

- By End-Use Sector:

- Residential Construction

- Commercial Construction

- Industrial Infrastructure

Value Chain Analysis For PEX Pipe Market

The value chain for the PEX Pipe Market begins with upstream activities focused on the procurement and conversion of raw polymeric materials. The primary upstream input is High-Density Polyethylene (HDPE) resin, derived from petrochemical processes, often sourced from global commodity chemical producers. Manufacturers must ensure a reliable and cost-effective supply of virgin polymer, along with specialized additives, stabilizers, and cross-linking agents (peroxides for PEX-a, silanes for PEX-b). Price volatility in crude oil and natural gas directly impacts raw material costs, necessitating sophisticated hedging and procurement strategies. The manufacturing stage involves extrusion and the critical cross-linking process, which defines the final product quality and type (a, b, or c).

The midstream phase focuses on manufacturing, quality assurance, and initial logistics. PEX pipe producers convert the resin into finished tubing, often applying additional barriers (like EVOH oxygen barriers) or protective coatings. Quality control testing, including burst strength, flexibility, and longevity evaluations (e.g., chlorine resistance testing), must adhere to global standards like ASTM F876/F877 and NSF. Distribution channels are highly fragmented but critical for market reach. Direct channels often involve large original equipment manufacturers (OEMs) or major infrastructure projects where the manufacturer supplies the material directly. Indirect channels rely heavily on a network of national and regional distributors, specialized plumbing wholesalers, and large retail home improvement centers (Big Box Stores).

Downstream activities center on installation, system integration, and end-user consumption. Contractors, plumbers, and specialized HVAC technicians are the direct users who purchase the pipe and associated fittings (crimp, expansion, or compression) through the wholesale channel. The efficiency of installation, including access to specialized tools and training, significantly influences contractor preference. The final downstream consumer is the property owner or developer who ultimately benefits from the system's performance. The indirect distribution channel dominates the residential and small commercial market due to the convenience and inventory breadth offered by wholesalers, while direct sales are common in major commercial and industrial segments requiring technical support and bulk purchasing agreements. The overall value chain success hinges on maintaining quality consistency from resin to installed fitting.

PEX Pipe Market Potential Customers

The primary end-users and potential buyers in the PEX Pipe Market span across the entire construction ecosystem, encompassing residential, commercial, and infrastructure development stakeholders. Residential builders and remodeling contractors constitute the largest volume consumers, utilizing PEX extensively for potable hot and cold water distribution due to its flexibility and corrosion resistance, which simplifies installation in both new construction and renovation projects (re-piping). Demand from this segment is highly sensitive to housing starts, interest rates, and consumer confidence indices, requiring manufacturers to maintain scalable production capacity and broad distribution coverage.

Commercial property developers and institutional facility managers represent another major customer group. This includes buyers for large-scale projects such as hospitals, schools, hotels, and high-rise office buildings. In these environments, PEX is predominantly specified for hydronic radiant heating/cooling systems, aiming for optimal energy efficiency and uniform comfort control across vast spaces. These customers often require detailed technical specifications, robust fire-rated assemblies, and long-term warranties, prioritizing specialized PEX products like PEX-AL-PEX composites or fire-resistant versions of PEX tubing. Procurement decisions in this sector are driven less by material cost and more by performance longevity and compliance with strict engineering standards.

A growing segment of potential customers includes specialized contractors focused solely on sustainable building technologies and energy management solutions. These contractors deploy PEX for geothermal heating loops, thermal energy storage systems, and advanced snow melting systems for critical infrastructure like airports and medical facilities. Additionally, municipal water authorities and agricultural enterprises occasionally represent buyers for specialized large-diameter PEX pipes used in non-potable water conveyance and irrigation systems, where the material’s durability and resistance to chemicals are highly valued. Targeting these diverse customer segments requires differentiated marketing strategies and specialized product offerings tailored to specific performance requirements.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 4.5 billion |

| Market Forecast in 2033 | USD 7.5 billion |

| Growth Rate | 7.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Uponor Corporation, The Lubrizol Corporation, RWC (Reliance Worldwide Corporation), Rehau AG, Pexco LLC, Viega GmbH & Co. KG, Georg Fischer Ltd., Roth Industries GmbH & Co. KG, Zurn Industries, Inc., Boway Group, Aqua-Therm LLC, Advanced Drainage Systems, Inc. (ADS), MrPEX Systems, Hebei Huiguan Pipe Industry Co., Ltd., Maincor AG, NIBCO Inc., Watts Water Technologies, Inc., SharkBite Plumbing Solutions, Vanguard Pipe & Fitting, Inc., Uponor Infra Oy. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

PEX Pipe Market Key Technology Landscape

The PEX Pipe Market technology landscape is dominated by advancements in cross-linking chemistry and composite material engineering aimed at improving performance characteristics such as barrier properties, chlorine resistance, and high-temperature tolerance. The fundamental technologies are PEX-a (peroxide method, offering the highest degree of cross-linking and 'memory' effect), PEX-b (silane method, prevalent due to cost-efficiency and chemical stability), and PEX-c (e-beam method, utilized for cleaner processing without chemical residuals). Recent technological shifts involve enhancing the resilience of PEX-b to chlorine degradation, a major factor in municipal water systems, through proprietary stabilization packages and specialized polymer formulations, effectively extending the service life of the pipe in challenging conditions. Furthermore, the integration of multilayer technology, specifically PEX-AL-PEX, where an aluminum core is sandwiched between PEX layers, provides superior dimensional stability, oxygen barrier properties, and higher working pressures, positioning these composites as key technological differentiators in high-demand heating applications.

Beyond the core pipe manufacturing, the technology ecosystem includes specialized connection systems, which significantly impact installation speed and reliability. The market sees ongoing competition between established crimp ring connections and modern, cold expansion systems (like Uponor’s ProPEX or Viega’s PureFlow), which rely on the elastic memory of PEX-a pipe for a secure, leak-proof seal. Technological innovations in fittings are moving towards lead-free brass or engineered polymer fittings to comply with increasingly strict potable water safety regulations (e.g., the US Safe Drinking Water Act amendments). Digital integration is also influencing the landscape, with manufacturers developing IoT-enabled monitoring systems that can be integrated into PEX manifolds, providing real-time data on water flow, temperature, and potential system anomalies, leveraging predictive maintenance capabilities.

Another crucial area of technological development involves fire safety and flame resistance. Standard PEX pipes typically require protection when installed in plenums or exposed areas. Manufacturers are investing in research and development to incorporate advanced flame retardant technologies directly into the PEX polymer matrix. This innovation aims to create PEX products that meet stringent fire rating standards without sacrificing flexibility or durability, expanding their application scope into highly regulated commercial building segments. The future technology trajectory is moving towards fully recyclable, high-performance PEX systems that align with circular economy principles while maintaining superior operational lifespan and minimizing environmental impact throughout the product life cycle.

Regional Highlights

- North America (USA and Canada): This region represents a mature and highly regulated market. The widespread adoption of PEX is driven by favorable plumbing codes, especially the International Plumbing Code (IPC) and Uniform Plumbing Code (UPC), which standardize PEX use. The shift away from copper due to cost volatility and concerns over mineral leaching strongly favors PEX, particularly PEX-a for its expansion fitting capabilities. Significant growth drivers include residential remodeling activities and the increasing implementation of high-efficiency hydronic radiant heating systems in cold climate zones.

- Europe (Germany, UK, France, Scandinavia): Europe is a leading market for radiant heating and cooling applications, driven by strong regulatory mandates focused on energy conservation (e.g., the Energy Performance of Buildings Directive). PEX use is deeply ingrained in construction practices, especially in Germany and the Nordic countries, which prioritize durable and thermally efficient floor heating solutions. The focus here is on high-barrier PEX products and advanced composite systems (PEX-AL-PEX) for district heating networks.

- Asia Pacific (China, India, Japan, Southeast Asia): Characterized by the fastest growth rate globally, the APAC market is driven by massive infrastructure investments, rapid urbanization, and a growing middle class demanding higher quality plumbing systems. While initial cost remains a factor, the long-term benefits of corrosion resistance in regions with varying water quality propel PEX adoption, especially in multi-story residential towers and commercial complexes. China is both a major manufacturer and consumer, focusing heavily on PEX-b due to cost advantages.

- Latin America (Brazil, Mexico): Market adoption is accelerating, driven primarily by government-led affordable housing projects requiring economical yet reliable plumbing solutions. Regulatory harmonization across various nations is progressing, slowly removing barriers to adoption. Brazil and Mexico are leading consumers, focusing on replacement of galvanized pipe systems, but market penetration is still dependent on local economic stability and contractor training initiatives.

- Middle East and Africa (MEA): Growth is concentrated in the Gulf Cooperation Council (GCC) states (UAE, Saudi Arabia) where large-scale, climate-controlled commercial and luxury residential developments require reliable systems for chilled water and high-temperature resistance. PEX is valued for its non-corrosive properties in high-mineral content water areas. The harsh climate necessitates specialized UV protection and quality assurance for storage and installation.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the PEX Pipe Market.- Uponor Corporation

- The Lubrizol Corporation

- RWC (Reliance Worldwide Corporation)

- Rehau AG

- Viega GmbH & Co. KG

- Georg Fischer Ltd.

- Roth Industries GmbH & Co. KG

- Zurn Industries, Inc.

- Boway Group

- Aqua-Therm LLC

- Advanced Drainage Systems, Inc. (ADS)

- MrPEX Systems

- Hebei Huiguan Pipe Industry Co., Ltd.

- Maincor AG

- NIBCO Inc.

- Watts Water Technologies, Inc.

- SharkBite Plumbing Solutions

- Vanguard Pipe & Fitting, Inc.

- Polypipe Group PLC

- Borealis AG (Raw Material Supplier)

Frequently Asked Questions

Analyze common user questions about the PEX Pipe market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary differences between PEX-a, PEX-b, and PEX-c pipe types?

The distinction lies in the manufacturing method and resulting properties. PEX-a uses the Peroxide (Engel) method, offering the highest cross-linking degree and 'thermal memory' for expansion fittings. PEX-b uses the Silane method, offering high stability at a lower cost. PEX-c uses the Electron Beam method, known for its clean, chemical-free process.

Is PEX pipe approved for use in all potable water systems globally?

PEX pipe is widely approved for potable water systems across North America and Europe, meeting rigorous standards (e.g., NSF/ANSI 61). However, specific local plumbing codes and material certifications must be verified, as some older regulations or non-standardized regions may still restrict its use in high-rise buildings or certain commercial applications.

How does PEX pipe performance compare to traditional copper piping?

PEX offers significant advantages over copper, including lower material cost, complete resistance to corrosion and scaling, enhanced flexibility for reduced installation time, and greater resistance to freeze damage. While copper is non-permeable and highly UV resistant, PEX is generally preferred for long-term reliability and cost-efficiency in internal building systems.

What is the main driver behind the rising demand for PEX in radiant heating systems?

The principal driver is the increasing focus on energy efficiency in modern construction. Radiant heating systems, which rely heavily on PEX piping for heat distribution, offer superior thermal comfort and lower operating costs compared to forced-air systems, aligning perfectly with green building standards and consumer demand for comfortable living environments.

What are the major technological limitations or challenges facing the PEX Pipe Market?

The primary challenges include the susceptibility of standard PEX to UV degradation, necessitating careful storage and installation, and the long-term resistance to chlorine disinfectants in specific municipal water supplies. Manufacturers continuously address these limitations through UV stabilizers and specialized chlorine-resistant polymer formulations.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- PEX Pipe Crimp Tools Market Statistics 2025 Analysis By Application (Residential, Commercial), By Type (Crimp Ring Removal Tool, PEX Crimp Tool), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- PEX Pipe Connection System Market Statistics 2025 Analysis By Application (Residential, Commercial, Industrial), By Type (Brass Type, Plastic Type), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- PEX Pipe Market Statistics 2025 Analysis By Application (Residential, Commercial), By Type (PEX-A, PEX-B, PEX-C), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager