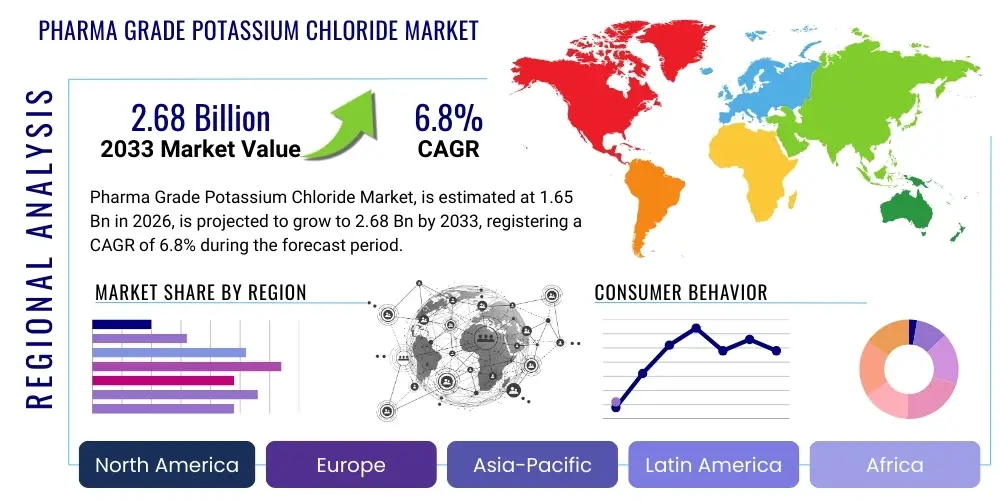

Pharma Grade Potassium Chloride Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 441411 | Date : Feb, 2026 | Pages : 241 | Region : Global | Publisher : MRU

Pharma Grade Potassium Chloride Market Size

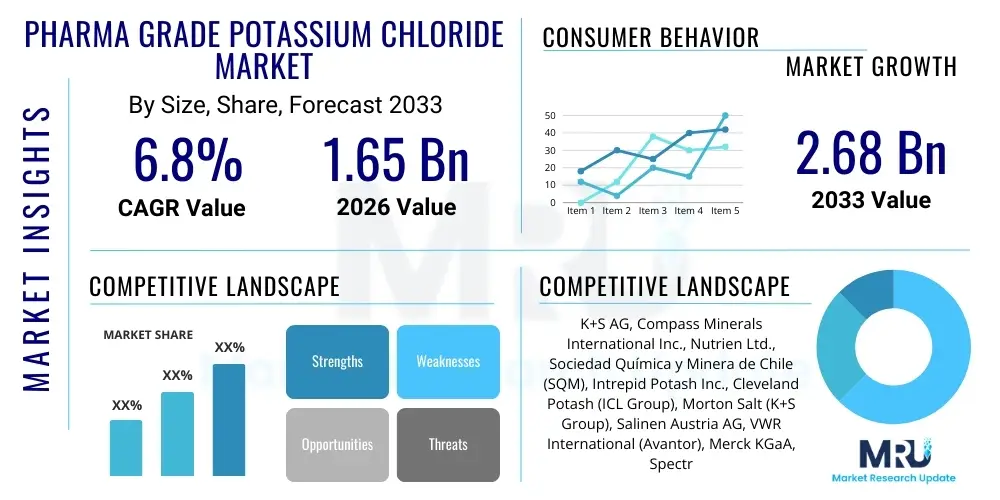

The Pharma Grade Potassium Chloride Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 1.65 Billion in 2026 and is projected to reach USD 2.68 Billion by the end of the forecast period in 2033.

Pharma Grade Potassium Chloride Market introduction

Pharma Grade Potassium Chloride (KCl) is a high-purity mineral salt essential for human health and various medical applications. It is characterized by stringent quality control measures, conforming primarily to pharmacopoeial standards such as USP (United States Pharmacopeia), EP (European Pharmacopoeia), and JP (Japanese Pharmacopoeia). This grade of KCl is mandatory for use in drug formulations, clinical nutrition, and advanced medical treatments where impurity levels must be minimized to ensure patient safety and therapeutic efficacy. Its primary physiological role involves maintaining cellular osmotic pressure, regulating heart function, and facilitating nerve signal transmission, making it indispensable in the pharmaceutical and healthcare sectors. The demand is intrinsically linked to global population growth, the rising incidence of chronic diseases like hypertension and cardiovascular disorders, and the expansion of clinical practices requiring electrolyte supplementation.

The product is widely applied across several crucial medical domains, including the manufacturing of intravenous (IV) solutions, oral electrolyte replacement therapies, and hemodialysis concentrates. In IV solutions, KCl restores potassium balance in patients suffering from hypokalemia, a common complication arising from diuretic use or gastrointestinal fluid loss. Furthermore, it is a critical component in cardiac arrest protocols and is increasingly utilized in the production of specialized nutritional products like total parenteral nutrition (TPN). The necessity for ultra-high purity ensures that the manufacturing processes involve advanced crystallization and purification techniques, separating the pharmaceutical grade from industrial or fertilizer grades, thereby commanding a premium price point in the global market.

Key driving factors accelerating the market’s expansion include the escalating global burden of cardiovascular diseases (CVDs) requiring continuous electrolyte monitoring and management, particularly among the aging demographic. Governments and healthcare providers are also increasingly focusing on preventive health measures, promoting the use of potassium supplements to manage blood pressure, which further stimulates demand. Moreover, the robust growth in the global dialysis sector, fueled by rising rates of chronic kidney disease (CKD) and end-stage renal disease (ESRD), creates a consistent and significant requirement for high-purity potassium chloride used in dialysate solutions. Regulatory adherence to cGMP (current Good Manufacturing Practices) ensures market stability and reinforces trust in established suppliers capable of maintaining rigorous quality standards.

Pharma Grade Potassium Chloride Market Executive Summary

The Pharma Grade Potassium Chloride market is experiencing robust growth driven by sustained demand from the injectable pharmaceuticals and clinical nutrition segments. Business trends indicate a strong push towards vertical integration among major chemical producers and pharmaceutical manufacturers to secure high-purity supply chains, minimizing risks associated with sourcing critical raw materials. Manufacturers are investing heavily in advanced crystallization technologies to meet increasingly stringent pharmacopeial standards, especially concerning heavy metal and microbiological contamination. Furthermore, there is a distinct trend towards the development of specialized delivery formats, such as pre-mixed solutions and precise dose formulations, which enhance ease of use in hospital settings and reduce medication errors. Strategic mergers and acquisitions are common as companies seek to expand their geographic footprint, particularly in emerging markets where healthcare infrastructure development is accelerating.

Regionally, Asia Pacific (APAC) is positioned as the fastest-growing market, largely due to massive investments in healthcare infrastructure, rapid urbanization, and an expanding patient pool suffering from lifestyle-related diseases requiring electrolyte management. China and India are pivotal to this growth, driven by large-scale domestic pharmaceutical production and increasing access to advanced medical treatments, including dialysis and complex surgeries. North America and Europe, while mature, maintain dominant market shares characterized by high per capita healthcare spending and early adoption of novel therapeutic applications. Regulatory landscapes in these regions, such as the FDA and EMA requirements, dictate high-quality standards, favoring established suppliers with proven track records in compliance and quality assurance. Latin America and MEA show promising growth, primarily focusing on importing high-grade materials to meet burgeoning chronic disease management needs.

Segment trends reveal that the injectables and IV solutions application category maintains the largest market share, essential for immediate patient stabilization and critical care. However, the oral supplements segment is projected to exhibit the highest CAGR, propelled by the growing consumer inclination towards dietary supplements for preventive health, particularly for cardiovascular health and electrolyte balance. In terms of product type, powder formulation dominates due to its versatility and ease of incorporation into various drug matrices, though liquid solutions are gaining traction, especially in ready-to-use hospital formats. Purity levels conforming to USP and EP standards remain the core focus, dictating procurement decisions for pharmaceutical end-users who cannot compromise on quality for patient safety. This segmentation landscape underscores the dual market nature: high-volume, critical hospital applications coexisting with high-growth, consumer-driven preventative care applications.

AI Impact Analysis on Pharma Grade Potassium Chloride Market

User queries regarding the impact of Artificial Intelligence (AI) on the Pharma Grade Potassium Chloride market primarily revolve around three core themes: optimization of complex supply chain logistics, enhancement of quality control and purification processes, and the role of AI in new drug discovery utilizing electrolytes. Users are keen to understand how AI can predict demand fluctuations for critical inputs like KCl in global pharmaceutical manufacturing, especially concerning geopolitical risks and raw material volatility. Concerns also focus on whether AI-driven analytical platforms can surpass traditional methods in detecting trace impurities and ensuring compliance with the evolving USP/EP standards for ultra-high purity grade KCl required for sensitive applications like large volume parenterals (LVPs) and dialysis solutions. Furthermore, users explore AI’s potential in accelerating research into novel potassium-based drug delivery systems and personalized medicine protocols that require precise electrolyte management.

The current influence of AI is most pronounced in streamlining the operational efficiency of large-scale chemical manufacturing and pharmaceutical compounding. AI algorithms are deployed to analyze vast datasets concerning raw material sourcing, reactor conditions, crystallization kinetics, and yield optimization. This data-driven approach significantly reduces batch variability, leading to a more consistent output of pharma-grade KCl, which is crucial for maintaining lot-to-lot consistency demanded by regulatory bodies. Predictive maintenance utilizing machine learning models ensures minimal downtime of complex purification equipment, securing a steady supply. This enhanced operational reliability directly impacts the market's stability and price predictability, mitigating the historical instability associated with bulk chemical sourcing.

Furthermore, AI is increasingly integrated into advanced quality assurance (QA) systems. Computer vision and deep learning models analyze spectroscopic and chromatographic data much faster and more accurately than human operators, facilitating real-time contaminant detection in high-speed production lines. This ensures that every batch of Pharma Grade KCl meets or exceeds pharmacopeial specifications for heavy metals, moisture content, and particulate matter. By automating these critical QA steps, manufacturers can achieve superior purity benchmarks necessary for sensitive applications such as injectables and hemodialysis concentrates, thereby fortifying consumer trust and strengthening the competitive advantage of technologically advanced suppliers in this specialized chemical market.

- AI optimizes supply chain management by predicting demand spikes and managing inventory of raw potash sources globally.

- Machine learning algorithms enhance crystallization and purification processes, improving yield and consistency of ultra-high purity KCl.

- Predictive maintenance schedules for manufacturing equipment reduce operational downtime and ensure continuous production capacity.

- Advanced analytical platforms use AI for real-time quality control, rapidly identifying trace impurities beyond traditional detection limits.

- AI assists in optimizing personalized electrolyte dosing regimens within clinical trial settings for novel drug formulations.

- Robotic process automation (RPA) manages documentation and regulatory filing, ensuring faster compliance verification for different pharmacopeias (USP, EP, JP).

- Data analytics identifies potential sourcing risks (geopolitical or logistical) for potassium raw materials, enabling proactive mitigation strategies.

DRO & Impact Forces Of Pharma Grade Potassium Chloride Market

The Pharma Grade Potassium Chloride market is heavily influenced by a confluence of strong drivers and inherent restraints, balanced by emerging opportunities. The primary driver is the pervasive and growing need for electrolyte management necessitated by rising global chronic disease rates, particularly hypertension and renal disorders, which demand continuous potassium supplementation and dialysis. This is supported by increasingly strict regulatory frameworks (like cGMP) that ensure market integrity and push demand toward verified, high-purity suppliers. However, the market is restrained by the reliance on raw material (potash) sourcing, which is highly sensitive to geopolitical factors, mining regulations, and transportation costs. Price volatility of agricultural-grade potash can directly impact the profitability and pricing stability of the pharmaceutical-grade derivative, posing a critical challenge to manufacturers. Furthermore, complex and time-consuming regulatory approval processes for new purification facilities act as a barrier to market entry for new players, concentrating market power among established entities.

Key opportunities in the market center on capitalizing on the rapid growth of the biopharmaceutical sector, which requires specialized, low-endotoxin grades of KCl for cell culture media and fermentation processes. The shift towards preventive healthcare and increased consumer awareness regarding micronutrient deficiencies, particularly in developed economies, opens significant avenues for expansion in the oral supplement segment. Technological advancements in continuous manufacturing and micro-crystallization techniques promise to lower production costs while simultaneously improving purity profiles, offering a dual advantage in cost efficiency and quality assurance. Furthermore, strategic geographic expansion into underserved emerging markets in Southeast Asia and Africa, where healthcare expenditure is rapidly escalating, presents substantial long-term growth prospects for established global suppliers seeking diversified revenue streams.

The impact forces within this market are substantial, manifesting in both upstream and downstream dynamics. Upstream, the consolidation among major potash miners dictates pricing power and supply security, requiring Pharma Grade producers to secure long-term contracts. Downstream, the critical nature of the product—where failure to meet purity standards can lead to catastrophic patient outcomes—imparts immense leverage to pharmaceutical purchasers and regulatory bodies. The high impact of purity and compliance standards forces smaller or less-equipped manufacturers out, ensuring that quality acts as the most significant competitive barrier. The market’s direction will be heavily dictated by the global pace of chronic disease intervention and the successful implementation of advanced purification technologies that can simultaneously address cost pressures and regulatory mandates for ultra-safe, high-purity ingredients.

Segmentation Analysis

The Pharma Grade Potassium Chloride market is segmented based on critical factors including Product Type, Application, Purity Level, and End-User, reflecting the diverse requirements across the healthcare spectrum. Product type segmentation primarily distinguishes between the physical forms of the chemical necessary for different manufacturing processes, while application analysis targets the final therapeutic usage, determining volumetric demand and necessary quality specifications. Purity level segmentation is crucial, as pharmaceutical users strictly adhere to pharmacopeial grades (USP, EP, JP), directly impacting sourcing decisions and pricing. End-user classification helps analyze consumption patterns and regulatory exposure, isolating high-volume hospital needs from specialized compounding requirements. This multi-faceted segmentation provides a comprehensive view of market dynamics and varying purchasing behaviors across the global pharmaceutical industry.

- By Product Type:

- Powder

- Granular

- Liquid Solution/Brine

- Crystalline

- By Application:

- Injectable Solutions (IV Fluids, Large Volume Parenterals)

- Oral Supplements and Pharmaceuticals (Tablets, Capsules)

- Hemodialysis and Peritoneal Dialysis Solutions

- Clinical Nutrition (TPN, Enteral Feeds)

- Biopharmaceutical Manufacturing (Cell Culture Media)

- Compounding Pharmacy

- By Purity Level:

- USP Grade

- EP Grade

- JP Grade

- Custom/Other Pharmacopeial Standards

- By End-User:

- Pharmaceutical and Biopharmaceutical Companies

- Hospitals and Clinics

- Dialysis Centers

- Compounding Pharmacies

- Nutraceutical Manufacturers

- By Region:

- North America (U.S., Canada, Mexico)

- Europe (Germany, U.K., France, Italy, Spain, Rest of Europe)

- Asia Pacific (China, Japan, India, South Korea, Rest of APAC)

- Latin America (Brazil, Argentina, Rest of Latin America)

- Middle East and Africa (UAE, Saudi Arabia, South Africa, Rest of MEA)

Value Chain Analysis For Pharma Grade Potassium Chloride Market

The value chain for Pharma Grade Potassium Chloride begins with the upstream mining and refinement of raw potash (potassium-containing ores), primarily extracted from subsurface deposits through conventional mining or solution mining techniques. This segment is characterized by high capital expenditure, environmental regulatory hurdles, and global commodity price volatility, with key suppliers often being large, multinational commodity companies. The raw potash (KCI) typically goes through preliminary purification stages to remove major impurities, resulting in industrial or fertilizer grades. Upstream factors heavily influence the eventual cost of the pharma-grade derivative, as only high-quality starting material can efficiently proceed to the specialized purification stages. Securing stable, long-term contracts with major potash miners is a crucial strategic consideration for pharmaceutical-grade manufacturers to mitigate supply chain risk and price fluctuations.

The middle segment of the value chain is dedicated to the highly specialized manufacturing of the Pharma Grade product. This involves multi-stage crystallization, advanced filtration, and drying processes designed to achieve purity levels mandated by pharmacopeial standards (e.g., extremely low heavy metal and microbiological content). This stage requires significant investment in cGMP-compliant facilities, specialized analytical laboratories for quality control, and highly trained personnel. Distribution channels for pharma-grade material are stringent and often direct, involving manufacturers selling directly to large pharmaceutical companies or via specialized, audited chemical distributors equipped to handle and store sensitive pharmaceutical raw materials. Direct distribution is favored for critical, high-volume products like IV solutions to maintain traceability and integrity.

Downstream analysis focuses on the end-users: pharmaceutical manufacturers, dialysis centers, and hospitals. Pharmaceutical companies incorporate the Pharma Grade KCl into final dosage forms, such as sterile injectables or oral tablets, after rigorous internal testing. Dialysis centers utilize it in high volumes for dialysate concentrates. The indirect channel involves nutraceutical companies and compounding pharmacies who purchase smaller volumes via certified distributors. The final stage involves the dispensing to the patient. Demand is driven by healthcare expenditure, disease prevalence, and regulatory mandates for quality assurance. The value chain is intrinsically linked to global health trends; for example, an increase in chronic kidney disease directly translates to higher downstream demand for KCl used in dialysis solutions, reinforcing the necessity for reliable upstream and midstream production capabilities.

Pharma Grade Potassium Chloride Market Potential Customers

The primary potential customers and core buyers of Pharma Grade Potassium Chloride are large multinational pharmaceutical companies specializing in injectable drug manufacturing and intravenous therapy. These companies require substantial volumes of ultra-high purity KCl for the formulation of Large Volume Parenterals (LVPs), small volume injectables, and specialized critical care medications. Their purchasing decisions are heavily influenced by supplier compliance with global cGMP standards, documentation quality, consistency of supply, and the ability to provide materials certified to multiple pharmacopeial standards (USP, EP). Due to the life-critical nature of injectables, quality assurance and traceability outweigh marginal price differences, making long-term supplier relationships based on trust and compliance paramount for these major buyers.

Another significant customer segment comprises specialized companies focused on clinical nutrition and dialysis solutions. Dialysis centers, either standalone facilities or those integrated within hospital systems, consume massive quantities of KCl concentrates necessary for preparing dialysate solutions used in hemodialysis and peritoneal dialysis. As the global incidence of Chronic Kidney Disease (CKD) rises, this segment presents a consistently high-volume demand base. Clinical nutrition manufacturers, producing Total Parenteral Nutrition (TPN) and specialized enteral feeding formulas, also require high-purity KCl as an essential electrolyte additive. These buyers prioritize low endotoxin levels and sterility guarantees, often requiring audited facility certifications beyond basic cGMP compliance, reflective of the highly sensitive patient populations they serve.

Furthermore, the growing nutraceutical and compounding pharmacy sectors represent emerging potential customer bases, albeit with smaller individual volume requirements. Nutraceutical companies use Pharma Grade KCl to produce dietary supplements marketed for cardiovascular health and electrolyte balance, catering to the preventive health consumer market. Compounding pharmacies utilize it for preparing customized sterile and non-sterile formulations, often for patients with unique dosage needs or allergies. While their volume is lower, their demand for tailored packaging and rapid availability is higher. Suppliers must adapt their sales strategies to service these diverse clients, ranging from providing bulk containers for major pharmaceutical firms to specialized, smaller batch packaging for compounding pharmacies, ensuring adherence to the specific regulatory and quality needs of each buyer type.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.65 Billion |

| Market Forecast in 2033 | USD 2.68 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | K+S AG, Compass Minerals International Inc., Nutrien Ltd., Sociedad Química y Minera de Chile (SQM), Intrepid Potash Inc., Cleveland Potash (ICL Group), Morton Salt (K+S Group), Salinen Austria AG, VWR International (Avantor), Merck KGaA, Spectrum Chemical Manufacturing Corp., BASF SE, Fisher Scientific (Thermo Fisher Scientific), AkzoNobel NV (Nouryon), Esseco USA, Lonza Group AG, Univar Solutions Inc., Tata Chemicals Ltd., J. T. Baker, Otsuka Chemical Co. Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Pharma Grade Potassium Chloride Market Key Technology Landscape

The manufacturing of Pharma Grade Potassium Chloride relies on advanced chemical engineering and purification technologies, fundamentally centered on achieving ultra-high purity levels necessary for intravenous and critical care applications. The core technological process involves multi-stage crystallization techniques, moving beyond simple evaporative crystallization to incorporate controlled cooling and seeding methods. These advanced techniques ensure precise control over crystal size distribution, morphology, and purity, minimizing the incorporation of impurities within the crystal lattice. Furthermore, specialized leaching and washing steps using high-purity deionized water are critical to removing surface contaminants and reducing the concentration of heavy metals and halides to below pharmacopeial limits. Continuous manufacturing processes, often supported by AI-driven monitoring, are emerging, offering higher throughput, greater consistency, and reduced batch variability compared to traditional batch processing methods.

Crucially, filtration and quality control technologies define the technological edge in the Pharma Grade KCl market. Manufacturers employ sophisticated membrane filtration systems, including ultrafiltration and nanofiltration, to eliminate particulates and residual traces of organic impurities and endotoxins, making the product suitable for injection. Advanced analytical technologies, such as Inductively Coupled Plasma Mass Spectrometry (ICP-MS) and High-Performance Liquid Chromatography (HPLC), are mandatory for detecting trace elements and ensuring compliance with heavy metal specifications stipulated by bodies like the FDA and EMA. Real-time monitoring systems integrated with production lines allow for immediate detection of quality deviations, minimizing waste and ensuring that only highly compliant material progresses to packaging, thus maintaining the integrity of the critical raw material.

The technology landscape also includes significant focus on packaging and material handling to preserve the purity of the final product. High-grade, moisture-barrier packaging materials, often utilized under controlled atmospheric conditions (low humidity, cleanroom environments), are essential to prevent agglomeration and contamination during storage and transport. Furthermore, advanced serialization and track-and-trace technologies, often employing blockchain principles, are being adopted to ensure end-to-end supply chain transparency, particularly vital in the pharmaceutical supply chain where counterfeiting risks must be mitigated. These integrated technologies—from raw material refinement through final packaging—are pivotal differentiators, allowing top-tier producers to consistently meet the demanding quality, safety, and traceability requirements essential for global distribution and critical medical usage.

Regional Highlights

- North America: This region dominates the market share due to its well-established healthcare system, high per capita healthcare expenditure, and the presence of major pharmaceutical companies and biotechnology hubs. The stringent regulatory environment set by the FDA necessitates the use of only the highest purity, USP-certified Pharma Grade KCl, driving premium pricing. High prevalence of cardiovascular diseases and widespread use of dialysis treatments further cement consistent demand.

- Europe: Characterized by sophisticated drug manufacturing capabilities and robust clinical nutrition markets, Europe holds the second-largest market share. Demand is anchored by the adherence to European Pharmacopoeia (EP) standards and strong governmental support for public health programs managing chronic conditions like hypertension. Germany, the UK, and France are key consumers, driven by advanced hospital infrastructure and extensive pharmaceutical production focused on generics and sterile injectables.

- Asia Pacific (APAC): APAC is projected to exhibit the highest Compound Annual Growth Rate (CAGR) globally. This rapid expansion is fueled by explosive growth in pharmaceutical manufacturing, escalating public and private investment in healthcare infrastructure, and the massive patient population base in countries like China and India. Increasing urbanization and improving access to dialysis and critical care services are creating substantial new demand centers for high-purity inputs.

- Latin America: This region shows steady growth, driven primarily by efforts to expand basic healthcare access and increasing foreign direct investment in local pharmaceutical production facilities, particularly in Brazil and Mexico. The market often relies on imports of high-grade raw materials, leading to opportunities for global suppliers focused on establishing regional distribution networks and local compliance support.

- Middle East and Africa (MEA): Growth in MEA is moderate but promising, primarily concentrated in the Gulf Cooperation Council (GCC) countries (UAE, Saudi Arabia) due to advanced healthcare spending and medical tourism initiatives. Demand is currently highest for imported ready-to-use injectable solutions, although local manufacturing is slowly increasing, creating future demand for locally sourced Pharma Grade KCl raw materials.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Pharma Grade Potassium Chloride Market.- K+S AG

- Compass Minerals International Inc.

- Nutrien Ltd.

- Sociedad Química y Minera de Chile (SQM)

- Intrepid Potash Inc.

- Cleveland Potash (ICL Group)

- Morton Salt (K+S Group)

- Salinen Austria AG

- VWR International (Avantor)

- Merck KGaA

- Spectrum Chemical Manufacturing Corp.

- BASF SE

- Fisher Scientific (Thermo Fisher Scientific)

- AkzoNobel NV (Nouryon)

- Esseco USA

- Lonza Group AG

- Univar Solutions Inc.

- Tata Chemicals Ltd.

- J. T. Baker

- Otsuka Chemical Co. Ltd.

Frequently Asked Questions

Analyze common user questions about the Pharma Grade Potassium Chloride market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary difference between Pharma Grade and Industrial Grade Potassium Chloride?

Pharma Grade Potassium Chloride is manufactured under strict cGMP guidelines and must comply with specific pharmacopeial standards (USP, EP) regarding purity, heavy metal limits, endotoxin levels, and particulate matter. Industrial grade, used primarily for fertilizers or general chemicals, does not meet these rigorous safety and purity benchmarks essential for human medical applications, particularly injectables.

Which application segment drives the largest demand for Pharma Grade Potassium Chloride?

The Injectable Solutions and IV Fluids segment drives the largest and most critical demand for Pharma Grade Potassium Chloride globally. This application requires ultra-high purity for critical care, resuscitation, and general electrolyte maintenance in hospital settings, consuming large volumes for LVP manufacturing.

How do raw material price fluctuations impact the Pharma Grade KCl market?

Raw material volatility, particularly the price of mined potash, directly influences the cost of manufacturing Pharma Grade KCl. While purification processes add significant value, price spikes in commodity potash increase operational expenditures for manufacturers, potentially leading to higher end-product pricing, though supply chain stability remains the foremost concern for buyers.

Which geographical region is expected to show the highest growth rate during the forecast period?

The Asia Pacific (APAC) region is projected to register the highest growth rate (CAGR). This acceleration is attributed to massive investments in healthcare infrastructure, the expansion of local pharmaceutical manufacturing capabilities, and the rapidly growing patient pool requiring dialysis and cardiovascular disease management.

What technological advancements are key to maintaining the required purity standards?

Key technological advancements include multi-stage precision crystallization techniques for enhanced impurity exclusion, advanced membrane filtration (ultrafiltration) to reduce particulates and endotoxins, and the deployment of sophisticated analytical instruments like ICP-MS for detecting ultra-trace levels of heavy metals, ensuring compliance with evolving pharmacopeial mandates.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager