Photosensitive Offset Printing Plate Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 441049 | Date : Feb, 2026 | Pages : 257 | Region : Global | Publisher : MRU

Photosensitive Offset Printing Plate Market Size

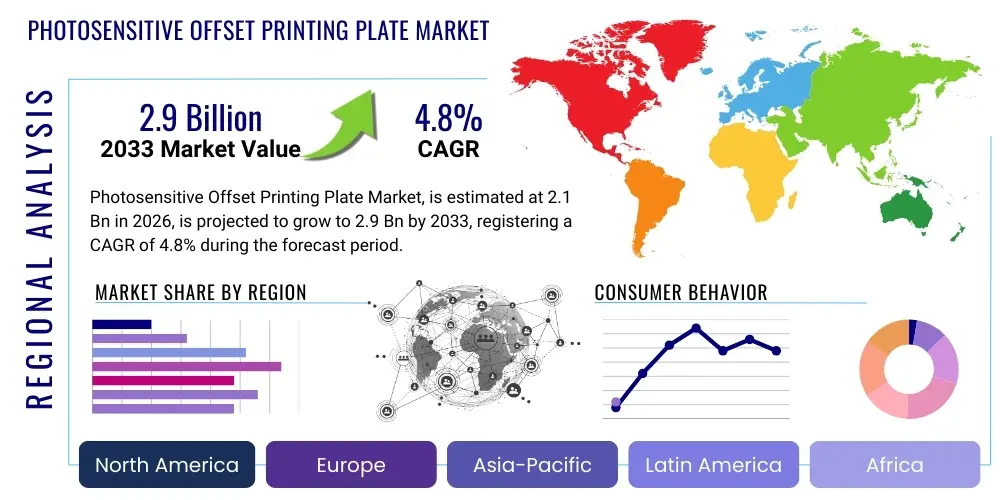

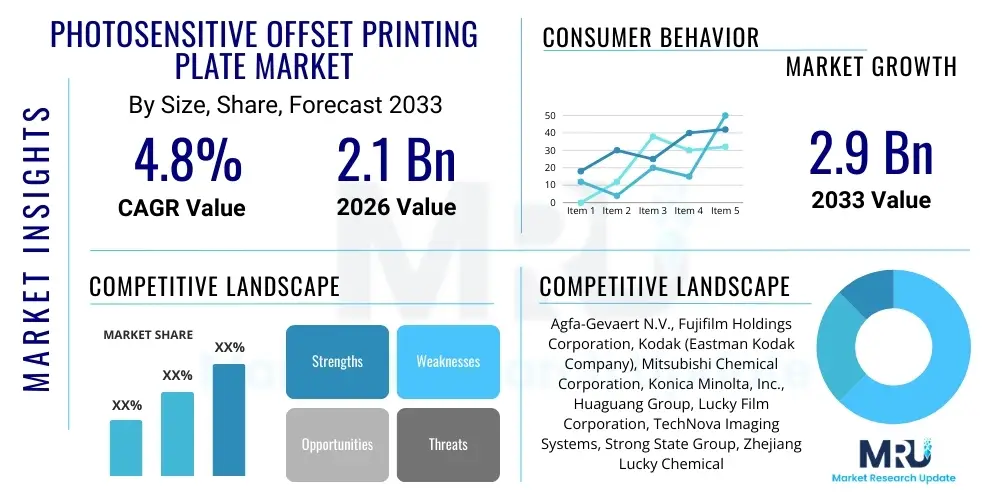

The Photosensitive Offset Printing Plate Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 4.8% between 2026 and 2033. The market is estimated at $2.1 Billion in 2026 and is projected to reach $2.9 Billion by the end of the forecast period in 2033.

Photosensitive Offset Printing Plate Market introduction

The Photosensitive Offset Printing Plate Market encompasses the manufacturing and distribution of specialized plates used in the offset lithography process. These plates, primarily composed of aluminum or polyester substrates coated with a photosensitive emulsion, are fundamental consumables essential for transferring inked images onto rubber blankets and subsequently onto the printing substrate. The market is defined by continuous innovation aimed at enhancing plate durability, reducing processing time, and minimizing environmental impact, particularly through the proliferation of Computer-to-Plate (CTP) technologies which have largely superseded traditional film-based plate making.

Photosensitive offset plates are categorized mainly by their exposure method: thermal, violet photopolymer, and conventional UV/PS plates. Thermal plates, utilizing infrared lasers, offer superior resolution and consistency, dominating the high-end commercial and packaging segments. Violet plates offer speed and lower equipment costs, appealing to newspaper and general commercial printers. Major applications span high-volume commercial printing, sophisticated packaging solutions (flexibility and folding cartons), large-scale newspaper production, and specialized book printing. The plates offer benefits such as cost-effectiveness for long print runs, exceptional image fidelity, and high press speeds, maintaining offset printing’s competitive edge against emerging digital alternatives.

Key driving factors supporting market resilience include the expanding global packaging industry, which heavily relies on offset lithography for quality and scale, particularly for food and beverage packaging. Furthermore, the persistent demand for high-quality, consistent color reproduction in commercial and promotional materials ensures sustained consumption of plates. Technological advancements, such as processless and chemistry-free plates, reduce operating complexities and environmental waste, further supporting adoption even as the overall print volume environment evolves.

Photosensitive Offset Printing Plate Market Executive Summary

The Photosensitive Offset Printing Plate Market is navigating a phase of moderated growth, strategically balancing the mature demand from traditional printing sectors with burgeoning requirements from the robust packaging industry. Business trends indicate a strong focus on sustainability, compelling leading manufacturers to invest heavily in developing processless plates (chemistry-free CTP) that streamline operations, reduce chemical waste, and lower overall operational expenditure (OPEX) for printers. Consolidation among major plate suppliers and strategic partnerships aimed at integrated printing solutions (including software and consumables) are prevalent, optimizing supply chain efficiency and enhancing customer retention amidst increased price competition.

Regionally, Asia Pacific (APAC) stands out as the primary growth engine, fueled by rapid industrialization, burgeoning consumer markets, and resultant massive growth in the packaging and labeling sectors, particularly in China and India. North America and Europe, while representing mature markets, maintain high revenue shares driven by a focus on specialty printing and premium, short-run commercial projects requiring maximum quality assurance. These regions are also the early adopters of advanced automation and highly efficient thermal CTP systems, offsetting volume declines in traditional print media with higher value-per-plate sales. Latin America and MEA show promising trajectories correlated with developing infrastructure and expanding retail sectors, gradually increasing their adoption of advanced offset solutions.

Segment-wise, Thermal CTP plates continue their market leadership due to their precision and stability, essential for high-fidelity color work in packaging and high-end commercial applications. However, the fastest growth trajectory is observed in the chemistry-free and processless plate segments, driven by regulatory pressures and printer demand for ecological and operational simplification. The application segment sees packaging printing rapidly gaining market share against traditional commercial and newspaper printing, which face ongoing secular declines due to digital media substitution. This shift mandates manufacturers adapt plate specifications—such as hardness, durability, and solvent resistance—to meet packaging industry standards.

AI Impact Analysis on Photosensitive Offset Printing Plate Market

Common user questions regarding AI's impact on the Photosensitive Offset Printing Plate Market often revolve around operational efficiency, predictive maintenance of CTP devices, and how AI-driven optimization might affect plate consumption patterns. Users inquire whether AI can reduce plate waste, improve plate setting accuracy, and automate quality control processes to a level that minimizes human error in pre-press. There is significant interest in how AI tools might influence overall print run lengths and the subsequent shift between offset and digital technologies, potentially impacting the long-term demand curve for photosensitive plates. Users also seek clarity on whether AI-powered workflow software can seamlessly integrate processless plate technologies, thus accelerating their adoption and reducing complexity for small-to-midsize printing operations.

The consensus of user concerns centers on the immediate applicability of AI within the traditional pre-press environment, specifically optimizing the laser imaging parameters and developing algorithms that predict plate lifespan based on press conditions (e.g., ink chemistry, dampening solution concentration). Expectations focus on AI enhancing the competitiveness of offset printing by significantly reducing makeready time and materials consumption, thereby lowering the Total Cost of Ownership (TCO). Furthermore, AI is anticipated to play a crucial role in supply chain management, optimizing inventory levels of plates based on forecasted print schedules and fluctuating raw material costs, providing a crucial competitive edge to plate manufacturers and large printing conglomerates.

AI's influence is largely transformative, focusing on efficiency and quality assurance rather than direct substitution of the plate product itself. By optimizing the printing ecosystem around the plate, AI ensures that offset remains economically viable for specific applications, particularly long-run, high-quality jobs. This indirect impact is crucial for stabilizing plate demand against the disruptive forces of advanced digital printing presses. The integration of AI into CTP workflows is expected to solidify the market position of suppliers who offer comprehensive, technologically advanced solutions, creating a distinction based on smart pre-press capabilities.

- AI-driven optimization of CTP rasterization parameters, enhancing image quality and reducing plate defects.

- Predictive maintenance algorithms for CTP equipment, minimizing downtime and ensuring consistent plate quality output.

- Automated quality control systems for plate inspection, identifying microscopic flaws before press mounting.

- Supply chain optimization using AI to forecast demand variability for different plate types (thermal vs. violet).

- Integration of AI with workflow management software (MIS/ERP) to reduce makeready waste and optimize plate sequencing.

- Data analytics utilization to correlate plate performance metrics with specific job types, guiding material selection.

DRO & Impact Forces Of Photosensitive Offset Printing Plate Market

The market dynamics are governed by a complex interplay of internal growth factors and external technological pressures. Primary drivers include the robust, sustained expansion of the global packaging industry—particularly flexible packaging, cartons, and labels—where offset plates provide the necessary high fidelity and low cost for mass production. Concurrently, the increasing emphasis on high-quality, short-to-medium run commercial printing jobs, requiring rapid turnaround and sharp detail, favors the quick setup capabilities offered by modern CTP systems and photosensitive plates. However, the market faces significant restraints, chiefly the rapid advancement and increasing market penetration of industrial digital printing presses, which eliminate the need for plates entirely, particularly for ultra-short runs. Furthermore, volatile prices of key raw materials, primarily aluminum and specific chemicals used in the photosensitive coatings, consistently pressure manufacturer profit margins.

Opportunities for growth lie primarily in the rapid development and commercialization of next-generation, environmentally friendly plates, specifically chemistry-free and processless solutions. These technologies address environmental regulations and printer demand for simpler, cleaner operations, providing a sustainable competitive advantage. Moreover, significant market expansion opportunities exist within emerging economies in Asia Pacific and Latin America, where printing infrastructure is still developing, and the cost-effectiveness of offset printing for large volumes is highly attractive compared to initially expensive digital alternatives. Strategic innovation focusing on plate durability, enabling longer press runs and higher resilience to aggressive UV inks, also represents a key pathway for market differentiation and growth.

Impact forces significantly shaping the market trajectory include the accelerating rate of technological substitution, primarily by inkjet and electrophotographic (toner) digital technologies, which continually expand their economic crossover point against offset printing. Additionally, increasingly stringent environmental regulations governing the disposal and handling of chemicals used in traditional plate processing (developers, fixers) drive demand towards processless alternatives, thereby changing the underlying technological landscape. The market structure is highly sensitive to the economic health of the advertising and media sectors, as commercial printing volumes are highly correlated with corporate marketing expenditures. Manufacturers must adapt to these pressures by focusing on high-efficiency, sustainable, and highly integrated product offerings to maintain market relevance.

Segmentation Analysis

The Photosensitive Offset Printing Plate Market is extensively segmented based on the technology utilized for exposure (dictating speed and quality), the substrate material (influencing cost and durability), and the final application of the printed material (driving volume and specific plate requirements). Understanding these segment dynamics is crucial for manufacturers to tailor their product portfolios effectively. The continuous evolution within the technology segment, particularly the shift from conventional PS plates to high-performance CTP plates, reflects the industry’s drive toward automation and reduced environmental footprint. The application segmentation clearly illustrates the strategic importance of the packaging sector as a crucial counterweight to the maturing commercial and newspaper segments, providing stability and future growth potential.

- Technology

- Thermal CTP Plates

- Violet CTP Plates

- Conventional PS Plates (Pre-Sensitized Plates)

- Substrate Type

- Aluminum Substrate Plates

- Polyester Substrate Plates

- Plate Type (Processing Method)

- Processless/Chemistry-Free Plates

- Process Plates (Requires chemical development)

- Application

- Commercial Printing (Brochures, Magazines, Marketing Collateral)

- Packaging Printing (Labels, Folding Cartons, Flexible Packaging)

- Newspaper Printing

- Book Printing and Publishing

- Regional Analysis (As detailed in Regional Highlights)

Value Chain Analysis For Photosensitive Offset Printing Plate Market

The value chain for the Photosensitive Offset Printing Plate Market begins with the upstream sourcing of raw materials, primarily high-grade aluminum sheets (the most crucial component) and specialized photosensitive coatings (polymers, dyes, and chemical components). Raw material procurement is highly capital-intensive and subject to global commodity price volatility, requiring suppliers to maintain long-term relationships with metal producers and specialty chemical companies. Key suppliers of aluminum must meet stringent quality standards regarding gauge consistency and surface treatment to ensure optimal coating adhesion and printing performance. The manufacturing stage involves complex processes, including cleaning, graining, anodizing the aluminum, and precision coating application in controlled environments, representing significant intellectual property and technological expertise concentrated among a few global players.

Downstream analysis focuses on the distribution channels and the end-users. Distribution relies heavily on specialized printing equipment dealers and consumables suppliers who maintain inventory and provide technical support. Direct distribution models are often used by major manufacturers for large, multi-national printing houses, ensuring just-in-time delivery and integrated technical services. Indirect channels involve regional distributors and smaller resellers catering to local printing businesses. The ultimate downstream segment, the printing houses, utilizes these plates in Computer-to-Plate (CTP) systems for imaging and then mounts them on offset presses. Efficiency in this part of the chain—specifically minimizing plate waste and maximizing run length—directly influences demand patterns and purchasing decisions.

The transition from traditional plate processing requiring chemical developers to processless plates is fundamentally reshaping the downstream segment, reducing the need for chemical supplies and specialized plate processors, thus simplifying the operational structure of printing companies. The most crucial competitive advantage across the value chain stems from integrating plate supply with CTP hardware and software solutions, offering a comprehensive ecosystem to the end-user. Suppliers who can manage the entire lifecycle, from raw material stability to technical support at the press, realize significant control over pricing and market penetration. Furthermore, strong intellectual property related to coating formulas and substrate treatments provides high barriers to entry for new competitors, solidifying the market structure.

Photosensitive Offset Printing Plate Market Potential Customers

Potential customers, or end-users, of photosensitive offset printing plates are diverse, ranging from small, local print shops to large, globally operating commercial printing conglomerates, all united by their reliance on offset lithography for high-volume, quality color reproduction. The largest segment of buyers comprises Commercial Printers who produce items like magazines, brochures, advertising inserts, catalogs, and general marketing materials. These customers prioritize high resolution, fast makeready times, and reliability across various paper stocks, favoring high-performance thermal CTP plates.

The fastest-growing customer segment is the Packaging Industry, including manufacturers of folding cartons, rigid boxes, and some forms of flexible packaging. These buyers require plates offering exceptional durability against aggressive UV and specialized inks, high dimensional stability, and the ability to transfer fine detail onto challenging substrates. Plate suppliers often tailor their products specifically to the demands of food-safe packaging regulations and extended print runs required in this segment. The third major customer group includes Newspaper and Publication Houses, which typically favor high-speed, lower-cost violet CTP plates due to the extremely tight deadlines and high-volume, lower-resolution requirements of newsprint.

Other significant buyers include Book Publishers specializing in color textbooks and high-quality art books, and various large Corporate In-House Print Departments that handle internal documentation and promotional materials requiring professional offset quality. The purchasing decisions of all these groups are heavily influenced by the Total Cost of Ownership (TCO), encompassing not just the plate unit cost, but also the costs associated with chemistry, energy consumption of the processor, and waste disposal. Therefore, processless plates increasingly appeal to all segments seeking operational efficiency and environmental compliance.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $2.1 Billion |

| Market Forecast in 2033 | $2.9 Billion |

| Growth Rate | 4.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Agfa-Gevaert N.V., Fujifilm Holdings Corporation, Kodak (Eastman Kodak Company), Mitsubishi Chemical Corporation, Konica Minolta, Inc., Huaguang Group, Lucky Film Corporation, TechNova Imaging Systems, Strong State Group, Zhejiang Lucky Chemical Co., Ltd., Hanita Coatings RCA Ltd., Folex GmbH, DIC Corporation, Flint Group, Toray Industries, Inc., Sihl Group, A. T. Inks, Screen Holdings Co., Ltd., Trelleborg AB (Printing Solutions), Xante Corporation. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Photosensitive Offset Printing Plate Market Key Technology Landscape

The technological landscape of the Photosensitive Offset Printing Plate Market is dominated by Computer-to-Plate (CTP) systems, which represent the standard for modern plate imaging, rendering traditional film-based processes nearly obsolete. The primary technology battle within CTP is between Thermal and Violet laser systems. Thermal CTP uses infrared lasers to ablate or cross-link the coating, offering exceptionally sharp dots, wide latitude, and high run lengths, making them the preferred choice for high-fidelity color and demanding packaging applications. Violet CTP utilizes violet diodes (405nm), offering faster plate imaging speeds and requiring lower power consumption, appealing significantly to high-volume, time-sensitive applications like newspaper production due to their robust photopolymer chemistry.

A significant disruptive technology is the rise of Processless and Chemistry-Free Plates. These innovations eliminate the need for traditional chemical processing baths, such as developers and fixers, drastically simplifying the pre-press environment, reducing environmental impact, and lowering variable operational costs. Chemistry-free plates often use thermal ablation techniques or require simple water-based rinses post-exposure, integrating sustainability into the core product offering. This shift aligns with global environmental directives and printer demand for lean manufacturing practices, driving rapid technological adoption particularly in Western markets and among large corporate printing groups with mandated environmental, social, and governance (ESG) goals.

Further technological advancements focus on enhancing plate durability and specialized coatings. Manufacturers are constantly developing coatings optimized for challenging printing environments, such as those utilizing highly abrasive UV inks, energy-curing inks, or specialized solvent-based printing for industrial applications. Research is also directed toward improving the hydrophilicity and oleophilicity balance of the plate surface to minimize water consumption on press (reducing environmental burden and improving stability) and maximizing ink transfer efficiency. The ongoing integration of automated CTP loading and plate logistics systems, often utilizing AI for sequencing, further cements the reliance on technologically advanced photosensitive plates capable of flawless integration into these high-speed, automated workflows.

Regional Highlights

- Asia Pacific (APAC): APAC is the largest and fastest-growing regional market, primarily driven by substantial growth in its manufacturing and consumer goods sectors, underpinning the massive demand for packaging materials. Countries like China, India, and Southeast Asian nations are undergoing rapid industrial expansion, leading to increased installation of offset presses and, consequently, high consumption of photosensitive plates. The market here is cost-sensitive, driving significant demand for both high-end thermal plates for export-quality packaging and cost-effective violet plates for domestic publishing and commercial use.

- North America: This region is characterized by high adoption of premium and processless plate technologies. The market is mature, but the focus is heavily skewed towards high-quality, short-to-medium run commercial printing and specialty packaging. Demand is driven by efficiency improvements, environmental compliance mandates, and the continuous upgrade cycle of CTP equipment, favoring sophisticated thermal systems that integrate seamlessly with advanced workflow software.

- Europe: Europe represents a technologically advanced yet slowly expanding market. Regulatory pressure from the European Union regarding chemical waste and environmental protection is a key driver, accelerating the shift towards chemistry-free and low-chemistry plate solutions. Germany, the UK, and France are major consumption hubs, focusing on high-end commercial print and sophisticated pharmaceutical and retail packaging where quality consistency is paramount.

- Latin America (LATAM): The LATAM market, while smaller in volume compared to APAC, is exhibiting promising growth fueled by economic stabilization in key markets such as Brazil and Mexico. The market is primarily focused on serving local commercial printing and growing domestic packaging needs. Price competitiveness remains critical, leading to a balance of conventional PS plates and moderately priced violet CTP solutions.

- Middle East and Africa (MEA): Growth in MEA is concentrated in the Gulf Cooperation Council (GCC) countries and South Africa, linked to infrastructural projects and expanding commercial activities. Demand is intermittent but growing, particularly for high-quality plates used in premium publications and the expanding local packaging sector catering to retail and industrial needs.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Photosensitive Offset Printing Plate Market.- Agfa-Gevaert N.V.

- Fujifilm Holdings Corporation

- Kodak (Eastman Kodak Company)

- Mitsubishi Chemical Corporation

- Konica Minolta, Inc.

- Huaguang Group

- Lucky Film Corporation

- TechNova Imaging Systems

- Strong State Group

- Zhejiang Lucky Chemical Co., Ltd.

- Hanita Coatings RCA Ltd.

- Folex GmbH

- DIC Corporation

- Flint Group

- Toray Industries, Inc.

- Sihl Group

- A. T. Inks

- Screen Holdings Co., Ltd.

- Trelleborg AB (Printing Solutions)

- Xante Corporation

Frequently Asked Questions

Analyze common user questions about the Photosensitive Offset Printing Plate market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary difference between Thermal and Violet CTP plates?

Thermal CTP plates utilize infrared lasers for exposure, offering superior image resolution, consistency, and chemical resistance, favored for high-end commercial and packaging printing. Violet CTP plates use visible light diodes, allowing for faster imaging and lower equipment costs, primarily used in high-volume, time-sensitive newspaper production.

How is the packaging industry driving the demand for offset printing plates?

The packaging sector requires high-quality, high-volume color fidelity, and structural consistency, which offset printing efficiently provides. Growth in consumer goods necessitates high output of folding cartons and labels, increasing the sustained demand for durable, high-resolution thermal offset plates optimized for UV inks.

What are 'processless' or 'chemistry-free' offset plates, and why are they important?

Processless plates eliminate the need for chemical developers and fixers after laser exposure, requiring only a simple water rinse or gumming. They are crucial because they significantly reduce environmental impact, minimize waste disposal costs, simplify pre-press operations, and lower the Total Cost of Ownership (TCO) for printers, aligning with modern sustainability goals.

How does the shift to digital printing impact the photosensitive plate market?

Digital printing decreases demand for plates in ultra-short-run jobs, capturing volumes that were previously done on small offset presses. However, offset plates remain indispensable for long-run jobs due to superior cost-efficiency, speed, and high-quality consistency, especially in large-scale packaging and high-volume commercial sectors, forcing the offset market to focus on higher value applications.

Which geographical region holds the highest growth potential for plate manufacturers?

Asia Pacific (APAC), particularly China and India, offers the highest growth potential. This is driven by large, rapidly expanding consumer markets, burgeoning manufacturing sectors, and ongoing development of printing infrastructure, creating significant volume demand for offset consumables.

The photosensitive offset printing plate market is inherently linked to global economic output and advertising expenditure, showing robust resilience despite technological shifts. The sustained investment by market leaders like Fujifilm, Kodak, and Agfa into chemistry-free technologies underscores the strategic necessity of balancing operational efficiency with environmental stewardship. The segment of processless thermal plates, in particular, is witnessing substantial market penetration, replacing traditional chemically processed plates in regions with strict environmental oversight, such as Western Europe and North America. This transition involves not just the plate material itself but also the optimization of CTP hardware and workflow software, positioning major players as comprehensive solution providers rather than mere plate suppliers. This holistic approach ensures better integration and performance stability for the end-user, further solidifying the position of thermal CTP as the technology of choice for premium applications.

In contrast, the violet photopolymer segment continues to thrive in cost-sensitive, high-speed environments, especially in global newspaper and quick-print commercial sectors. While the volume of newspaper production declines globally, the need for rapid plate output remains paramount, ensuring continued, albeit specialized, demand for violet technology. Furthermore, ongoing research into metal printing plates, aiming to enhance run length capabilities far beyond current standards—sometimes exceeding one million impressions—is critical for sectors like high-volume book publishing and continuous-form industrial printing. These developments ensure offset printing maintains its economic advantage in specific niches against the growing capabilities of high-speed inkjet presses.

The raw material supply chain for photosensitive offset plates presents ongoing challenges, particularly concerning the stability and pricing of aluminum coil stock. As aluminum prices fluctuate based on global trade tariffs and energy costs, manufacturers face continuous pressure to optimize plate thickness (gauge reduction) without compromising mechanical strength or performance stability on high-speed presses. Successful manufacturers are those who have established diversified and resilient supply contracts for both aluminum substrates and specialized coating chemicals, mitigating market volatility risks. Moreover, the environmental cost of aluminum production, although offset by its high recyclability, drives the narrative toward thinner, more durable plate designs that minimize material usage per job, reinforcing the sustainability objective that permeates the entire value chain.

The competitive landscape is characterized by a few global giants who dominate technological innovation and distribution networks, alongside several strong regional players, particularly in Asia, who compete fiercely on price and localized technical support. Strategic acquisitions and joint ventures are common, aimed at consolidating technological advantages, securing key distribution channels, or gaining critical market share in rapidly expanding geographies like Southeast Asia. For example, partnerships between plate manufacturers and press manufacturers are increasingly crucial, ensuring that plate characteristics are perfectly tuned to the latest generation of high-automation offset presses, including those featuring extended color gamut and unitized inking systems. This close collaboration guarantees optimal performance and minimizes troubleshooting for shared customer bases.

Looking ahead, the market is poised for disruption not just from digital printing, but potentially from innovations in plate preparation and on-press imaging techniques. While fully plateless offset (utilizing internal thermal or inkjet processes on the press cylinder) remains largely theoretical or niche, any significant breakthrough in this area could rapidly redefine the traditional photosensitive plate market. Therefore, investment in R&D is heavily focused on making the current photosensitive plates so efficient, reliable, and environmentally benign (zero-waste systems) that they preserve their cost advantage over digital for the majority of medium-to-long run applications. This strategic defensiveness requires ongoing improvement in coating sensitivity, enabling faster exposure times and further reducing energy consumption in the pre-press process, contributing to overall printing profitability.

The application segment dedicated to packaging printing is structurally protected from severe digital displacement because many forms of folding cartons and metal decoration still heavily rely on the unique capabilities of offset lithography, particularly for surface finish and consistency on diverse, often rigid, substrates. Plate manufacturers are thus prioritizing R&D for these heavy-duty applications, focusing on plates that can withstand longer exposure to harsh chemical environments (e.g., specialized inks, varnishes, and coating agents) typical in industrial packaging lines. This differentiation based on application-specific performance is key to future market stability and revenue growth, allowing suppliers to command premium pricing for specialized, high-durability plates compared to the commoditized commercial printing plate segment.

Finally, the long-term outlook for the Photosensitive Offset Printing Plate Market remains tied to the vitality of print media and consumer product growth, particularly in emerging markets. Although North American and European plate consumption may stabilize or slightly contract in volume, the increasing value derived from high-end, sustainable, and specialized plates for packaging applications ensures revenue stability and modest growth. The successful navigation of this market environment requires manufacturers to master sustainable technology transitions, maintain global price competitiveness, and reinforce technical support networks that cater to increasingly complex, automated printing systems globally.

Further analysis of the competitive dynamics reveals that intellectual property surrounding coating chemistry is the primary determinant of long-term market dominance. Companies holding patents on highly sensitive, processless coating formulations possess a distinct competitive edge, allowing them to dictate technological standards and command higher margins. This focus on proprietary chemistry ensures consistent product differentiation, especially in thermal CTP where precise energy absorption and image transfer characteristics are paramount. The cost of entry into the manufacturing of these advanced plates is exceptionally high, involving massive investments in clean room facilities, high-precision coating machinery, and sophisticated quality control systems, effectively limiting the field to established global players who can leverage economies of scale in production and global distribution.

Furthermore, the environmental impact assessment of photosensitive plate manufacturing extends beyond chemical processing to include energy consumption in CTP imaging and the lifecycle of the aluminum substrate. Leading manufacturers are increasingly transparent about their carbon footprint, utilizing renewable energy sources for manufacturing operations and promoting the closed-loop recycling of aluminum printing plates. This commitment to circular economy principles not only satisfies regulatory requirements but also serves as a critical marketing tool, particularly when selling to large corporate clients with stringent vendor sustainability mandates. The ability to provide verified data on reduced energy and water consumption associated with processless plates is becoming a non-negotiable factor in procurement decisions.

The rapid evolution of printing software, often powered by AI algorithms, also indirectly impacts the plate market by optimizing plate usage. Modern workflow systems automatically nest print jobs to maximize the utilization of each plate, minimizing waste and reducing overall plate consumption per unit of printed output. While this optimization slightly lowers the total volume demand for plates, it simultaneously increases the demand for plates with extremely high accuracy and consistent dimensional stability, as imperfections become more critical when utilizing every millimetre of the plate surface. This trend further favors high-end thermal CTP products over conventional PS or less precise violet plates.

Investment trends highlight a strategic shift toward providing integrated solutions rather than standalone products. Key players are bundling plate sales with financing options for CTP equipment, comprehensive service contracts, and proprietary workflow management software. This strategy locks in customers over long periods, creates high switching costs, and allows the manufacturer to capture a larger share of the customer's printing consumables budget. This integration is crucial in mature markets where pure volume growth is stagnant, forcing suppliers to focus on maximizing value capture per customer through sophisticated product ecosystems and performance guarantees. This move from transactional sales to strategic partnerships defines the modern competitive strategy.

Finally, emerging technologies such as micro-LED CTP systems and advancements in liquid crystal display (LCD) exposure units are gradually being explored as lower-cost alternatives to traditional thermal and violet laser systems, particularly for mid-range market applications. While these technologies are still maturing and have not yet significantly disrupted the dominance of thermal systems, they represent a potential future pathway for lowering CTP equipment entry costs. Manufacturers are closely monitoring these developments, ensuring that their plate coatings remain adaptable to new light sources and exposure mechanisms, securing future compatibility and maintaining a flexible product portfolio to address diverse customer requirements globally.

The market for photosensitive offset plates is strategically important for global commerce and industrial production, maintaining its relevance through continuous technological refinement centered on efficiency and sustainability. The shift towards processless plates is irreversible and represents the future standard, driven by both regulatory push and customer demand for streamlined, environmentally friendly pre-press operations. Aluminum remains the dominant substrate, but optimization of gauge and sourcing stability are constant operational challenges. The packaging application segment acts as the primary growth catalyst, providing a high-value anchor against secular declines in traditional print media, ensuring that R&D investments prioritize extreme durability and specialized performance characteristics. Competitive success hinges on vertical integration, proprietary coating chemistry, and the ability to offer comprehensive, smart solutions that maximize the TCO benefits for modern high-speed printing operations, particularly in the thriving Asia Pacific region.

The increasing need for high-security printing, such as specialized currency, financial documents, and highly protected product authentication labels, also provides a niche high-margin application for photosensitive offset plates. These applications demand exceptional registration accuracy, unparalleled detail reproduction, and specialized inks that are often highly abrasive. Only high-quality thermal plates can consistently meet these rigorous specifications, further segmenting the market based on quality and security requirements. Manufacturers capable of certifying their plates for these high-security applications gain a substantial competitive advantage, as the barriers to entry (security clearance, quality assurance protocols) are exceptionally high in this specialized area.

Moreover, the polyester substrate plates, though a smaller segment, retain importance for small-format, low-run printing operations and certain quick-print scenarios where the low cost and flexibility of the substrate are prioritized over the extreme durability of aluminum. These plates are often used in desktop CTP solutions or smaller presses and serve as an entry point for smaller commercial printers who cannot afford the investment in high-end aluminum CTP systems. This segment's stability is tied to the enduring presence of small-to-midsize printing businesses globally, which value the operational simplicity and lower initial investment associated with polyester-based solutions. However, continuous pressure from sophisticated digital presses limits the growth potential of the polyester plate market.

Market analysts project that the rate of innovation in coating chemistry will accelerate significantly over the forecast period, driven by the race to achieve true zero-process plates—those that require absolutely no cleaning or gumming before going on press, minimizing all forms of waste and downtime. Achieving this technological benchmark will likely require entirely new generations of thermal-sensitive polymers or hybrid technologies that react uniquely to imaging energy. The companies that successfully introduce and commercialize these revolutionary products will capture disproportionately large market share, especially in developed economies where labor costs and waste disposal fees are highest, making operational simplicity an enormous economic advantage.

The global regulatory environment, particularly concerning volatile organic compound (VOC) emissions from cleaning and developing chemicals, is a continuous driver of market transformation. Manufacturers must not only comply with existing VOC limits but anticipate future, stricter regulations, mandating preemptive investment in chemistry and process design. This regulatory framework acts as a powerful barrier to entry for smaller, less technologically advanced regional players, consolidating market power among the few global corporations with the resources to invest in sustainable, compliant R&D. This regulatory push reinforces the dominance of environmentally certified, processless CTP solutions as the industry moves towards cleaner manufacturing practices worldwide.

Furthermore, the maintenance of quality consistency across globally dispersed manufacturing sites is a crucial operational challenge for multinational plate suppliers. Photosensitive coatings are highly susceptible to variations in temperature, humidity, and atmospheric particulate contamination during production. Achieving ISO-standard quality and performance consistency across all geographies is essential for retaining the trust of global printing houses that operate standardized equipment worldwide. Investment in advanced manufacturing process control systems, leveraging IoT sensors and sophisticated data analytics, is therefore fundamental to ensuring uniform product quality, which directly impacts the plate's acceptance rate and print performance in the field, reinforcing the competitive position of top-tier suppliers.

In summary, the Photosensitive Offset Printing Plate Market is a technologically mature but strategically evolving sector. Its future is secured by the high-quality demands of packaging and specialty printing, underpinned by the ongoing transition toward sustainable, highly efficient CTP systems. The critical success factors for market participants include innovation in processless technology, resilience in raw material sourcing, and the ability to integrate plate products into comprehensive, intelligent printing workflows designed for maximum operational efficiency and minimal environmental impact.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager