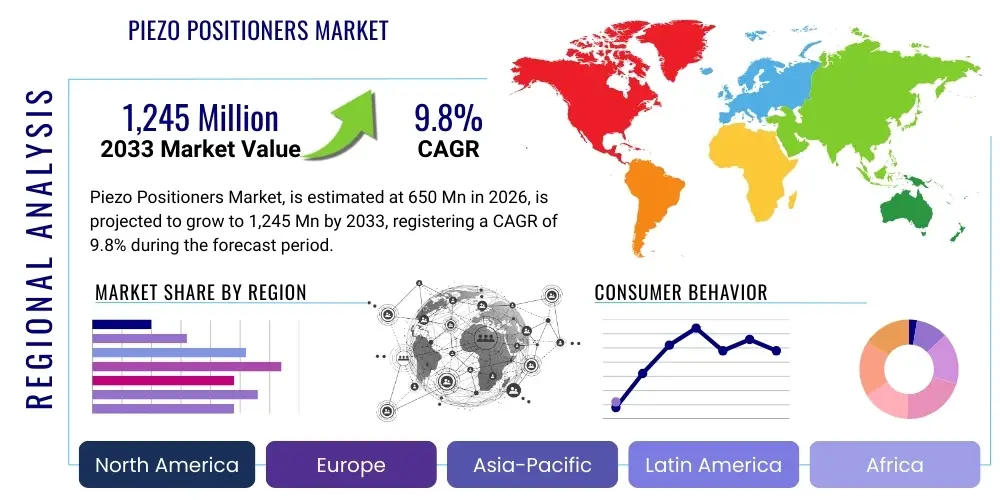

Piezo Positioners Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440957 | Date : Feb, 2026 | Pages : 245 | Region : Global | Publisher : MRU

Piezo Positioners Market Size

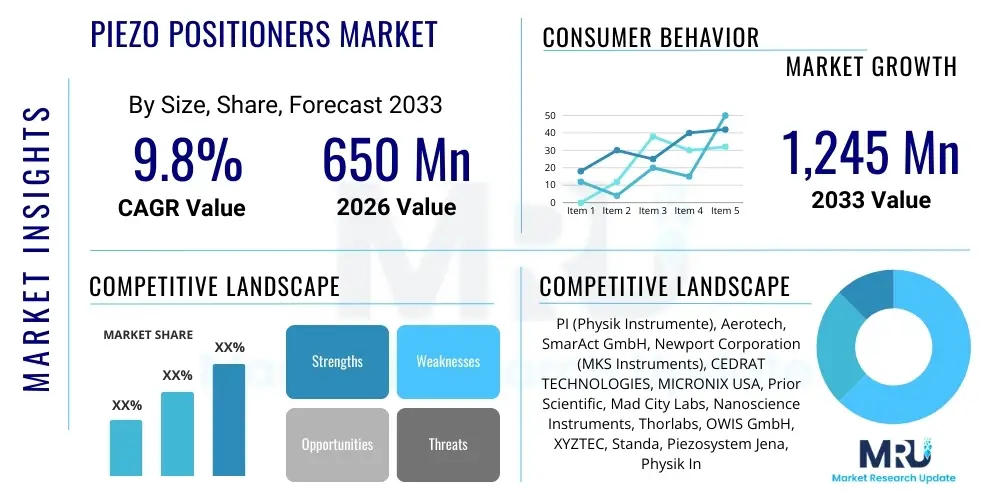

The Piezo Positioners Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 9.8% between 2026 and 2033. The market is estimated at USD 650 Million in 2026 and is projected to reach USD 1,245 Million by the end of the forecast period in 2033.

Piezo Positioners Market introduction

Piezo positioners are highly specialized electromechanical devices designed to achieve extremely fine, high-resolution movement, typically in the nanometer or picometer range. These systems operate based on the piezoelectric effect, where certain materials (piezoelectric ceramics) expand or contract when an electric field is applied. This capability for ultra-precise manipulation makes piezo positioners indispensable across numerous advanced technological fields, driving innovation in areas requiring meticulous alignment and scanning, such as atomic force microscopy, semiconductor lithography, and adaptive optics. The fundamental design allows for high responsiveness, rapid settling times, and the elimination of mechanical backlash commonly associated with conventional positioning stages, cementing their role as critical components in precision engineering.

The product portfolio within the Piezo Positioners Market is diverse, encompassing single-axis linear stages, multi-axis systems (e.g., X-Y or X-Y-Z stages), rotational stages, and complex tip/tilt platforms. Major applications are concentrated in industries that demand stringent accuracy levels, notably in semiconductor fabrication, where precise wafer positioning is crucial for yield; in photonics, for laser alignment and fiber coupling; and in biomedical research, particularly for cell manipulation and microscopic imaging. These positioners offer superior stability and repeatability, often operating in demanding environments such as vacuum chambers or cleanrooms, further expanding their application scope beyond traditional industrial automation into advanced scientific instrumentation.

The primary benefits driving market expansion include their unparalleled resolution, high force generation relative to size, and excellent dynamic performance. Key driving factors involve the accelerating pace of miniaturization in electronics and optics, the global expansion of nanotechnology research, and the escalating investment in advanced manufacturing techniques, such as micro-assembly and precision metrology. Furthermore, the continuous development of novel piezoelectric materials and control electronics, which enhance performance while potentially reducing cost, contributes significantly to sustained market growth and adoption across emerging industrial sectors globally.

Piezo Positioners Market Executive Summary

The Piezo Positioners Market is undergoing robust expansion, fundamentally driven by pervasive technological miniaturization and the growing requirement for nanoscale precision across critical industrial verticals. Business trends indicate a strong focus on developing integrated solutions, where piezo stages are coupled with advanced feedback sensors, such as capacitive sensors or optical encoders, to provide closed-loop control, thereby optimizing accuracy and stability for complex industrial processes. Furthermore, there is a distinct shift toward modular systems that allow users to customize positioning setups for specific experimental or manufacturing needs, enhancing product versatility and market appeal. Competitive dynamics are characterized by intense innovation in materials science and controller design, aimed at increasing speed, load capacity, and operational lifetime while maintaining picometer resolution capabilities.

Regionally, the market exhibits highly uneven growth patterns, with Asia Pacific (APAC) emerging as the most dynamic region due to colossal investments in semiconductor manufacturing (particularly in Taiwan, South Korea, and China) and the rapid expansion of localized R&D activities in photonics and display technologies. North America and Europe, while mature markets, continue to represent significant revenue streams, primarily driven by high-value applications in aerospace, defense, and specialized scientific research institutions. The regional trend is marked by increasing strategic partnerships between hardware manufacturers and system integrators to deliver comprehensive, turnkey solutions tailored to specific regional industrial requirements, notably concerning compliance and quality standards.

Segment trends underscore the dominance of multi-axis positioners, reflecting the increasing complexity of alignment tasks in modern industrial settings, particularly within automated assembly lines and advanced microscopy platforms. The semiconductor manufacturing application segment remains the largest consumer, but significant growth acceleration is observed in the biomedical and life sciences segment, propelled by the demand for high-throughput screening, microfluidics, and precise surgical tools. From a technological perspective, stick-slip and resonant piezo drives are gaining traction due to their enhanced speed and potentially longer travel ranges, complementing the traditional direct-drive stacked actuator designs, thereby broadening the practical utility and adoption rate of piezo positioning technology across diverse end-user landscapes.

AI Impact Analysis on Piezo Positioners Market

User queries regarding AI's influence often center on how artificial intelligence can optimize the performance, calibration, and operational lifetime of ultra-high-precision systems like piezo positioners. Common questions involve the feasibility of predictive maintenance using AI algorithms to anticipate piezo degradation, the potential for AI-driven control loops to achieve sub-nanometer stability beyond traditional PID controllers, and how AI can automate complex alignment and scanning routines currently requiring significant manual intervention or sophisticated algorithmic programming. Users are particularly interested in whether AI can fundamentally reduce the total cost of ownership (TCO) by minimizing downtime and improving process repeatability in highly sensitive applications such as electron beam lithography or adaptive optics systems.

Based on these inquiries, the key themes summarizing user expectations revolve around enhanced operational autonomy and optimized performance stability. Users anticipate AI integration will transition piezo positioners from mere hardware components to intelligent systems capable of self-calibration, real-time environmental compensation, and adaptive control based on continuous operational data streams. The core concerns relate to the complexity of integrating AI models into existing high-speed hardware control architectures and ensuring that the real-time processing demands of nanometer-scale control can be met without introducing latency or computational overhead that compromises precision. Consequently, the market anticipates AI will not only boost performance benchmarks but also democratize the use of highly complex piezo systems by making them easier to deploy and maintain in industrial settings.

The integration of Artificial Intelligence and Machine Learning (ML) is poised to fundamentally revolutionize the utilization and performance envelopes of piezo positioners. AI is enabling the development of truly smart actuation systems that leverage sensor fusion—combining inputs from capacitive sensors, temperature sensors, and strain gauges—to create highly accurate digital twins of the positioning system. This digital model allows AI algorithms to run sophisticated predictive control strategies that compensate for environmental drift, thermal expansion, and inherent hysteresis in real time, surpassing the limitations of traditional closed-loop mechanisms. Furthermore, ML is being utilized for failure analysis and pattern recognition in complex motion profiles, dramatically reducing commissioning time and maintenance requirements, which is crucial for high-uptime, mission-critical applications in semiconductor and optical manufacturing sectors.

- AI-driven Predictive Maintenance: Utilizing sensor data and ML algorithms to forecast component wear and schedule proactive maintenance, maximizing uptime in high-throughput applications.

- Real-time Hysteresis Compensation: Employing neural networks to learn and negate the non-linear behavior (hysteresis and creep) inherent in piezoelectric materials, leading to improved positioning accuracy and repeatability.

- Adaptive Control Systems: Implementation of advanced reinforcement learning techniques to dynamically adjust control parameters based on load variations, vibration, and thermal shifts, maintaining optimal stability.

- Automated High-Precision Alignment: AI algorithms automate complex multi-degree-of-freedom alignment procedures (e.g., fiber coupling), significantly reducing setup time and operator dependence.

- Enhanced Calibration and Metrology: ML models process vast amounts of metrology data to refine and accelerate the calibration process of multi-axis stages, ensuring traceability and precision across varying operational conditions.

DRO & Impact Forces Of Piezo Positioners Market

The dynamics of the Piezo Positioners Market are shaped by a complex interplay of Drivers, Restraints, and Opportunities, which collectively exert significant impact forces on adoption rates and technological trajectory. The principal driver is the relentless pursuit of precision and miniaturization in advanced manufacturing and scientific research, necessitating motion control solutions capable of nanoscale resolution. Opportunities are primarily centered around the exponential growth of emerging fields such as quantum computing, advanced biomedical imaging, and industrial automation where traditional electromagnetic stages are insufficient. Conversely, the market faces significant restraints, chiefly concerning the high initial cost associated with manufacturing high-quality piezoelectric ceramics and sophisticated control electronics, coupled with inherent technical limitations such as limited travel range compared to conventional motors.

The primary impact forces acting upon the market are derived from technological innovation, stringent regulatory requirements in end-user industries (e.g., medical devices, aerospace), and global geopolitical shifts affecting supply chains for specialized materials. Technological advancements in material science, particularly the development of new lead-free or improved high-performance piezo ceramics, constantly push the boundaries of resolution and speed. Furthermore, the increasing integration of high-bandwidth digital controllers and advanced sensing modalities (capacitive and laser interferometers) acts as a powerful enabling force, expanding the operational envelopes of piezo systems into dynamic, high-speed applications previously unattainable. The pressure for greater energy efficiency in manufacturing also favors piezo technology due to its inherent low power consumption during holding periods.

These market forces necessitate continuous investment in research and development to overcome existing limitations. Manufacturers are aggressively pursuing solutions to extend travel ranges through hybrid systems—combining piezo actuation with coarse motorized stages—and focusing on mitigating the effects of thermal drift and inherent hysteresis through advanced control strategies (often AI-enhanced, as noted previously). Successfully addressing the restraint of high capital expenditure through scalable manufacturing processes and improved lifetime performance will unlock opportunities in high-volume industrial automation sectors where cost sensitivity is paramount. Ultimately, the market trajectory is highly dependent on how effectively key players can translate cutting-edge scientific innovations into commercially viable, robust, and cost-effective precision positioning solutions for the rapidly evolving industrial landscape.

- Drivers: High demand for nanometer precision and accuracy; Rapid expansion of the semiconductor and microelectronics industries; Growth in nanotechnology research and development activities; Increasing complexity of optical alignment and metrology tasks.

- Restraints: High manufacturing costs and capital investment requirements; Limited total travel range compared to traditional motion stages; Susceptibility to environmental factors such as temperature drift and humidity; Complexity associated with compensating for inherent material hysteresis and creep.

- Opportunity: Expanding applications in biological and medical fields (e.g., drug discovery, microfluidics); Emergence of advanced manufacturing techniques like additive manufacturing (3D printing) requiring ultra-precise movement; Integration with artificial intelligence for predictive control and performance optimization; Development of hybrid motion systems offering long travel with high resolution.

- Impact Forces: Technological parity in ultra-precision performance; Supply chain volatility for specialized piezoelectric materials; Increasing industry standardization efforts for closed-loop control interfaces; Competition from alternative high-precision technologies (e.g., voice coil motors for specific dynamic applications).

Segmentation Analysis

The Piezo Positioners Market is fundamentally segmented based on factors including the type of positioner architecture, the number of degrees of freedom (axes), the technology used for actuation, and the ultimate end-user application. Understanding these segments is crucial for strategic market penetration and product development, as requirements vary dramatically between, for instance, a university research lab needing a highly customized, low-volume system and a semiconductor fab demanding standardized, high-volume, cleanroom-compatible stages. The differentiation often lies in the balance between travel range, dynamic response, resolution, and load capacity. This granularity ensures that manufacturers can tailor offerings to meet the specific technical demands of nanoscale manipulation in highly divergent environments.

By dissecting the market based on Type, the separation between single-axis and multi-axis positioners is critical, with multi-axis systems, particularly those offering X-Y-Z and tip/tilt capabilities, experiencing faster growth due to the complexity inherent in modern alignment and inspection procedures. Furthermore, segmentation by end-user application reveals the core consumption centers. While semiconductor processing remains the bedrock of demand, the Life Sciences sector is rapidly increasing its market share, driven by breakthroughs in genomic sequencing, single-cell analysis, and neurotechnology, all relying on exacting positional accuracy for successful outcomes. These varied segments highlight the technological versatility of piezo positioning, confirming its status as an enabling technology across the high-tech spectrum.

- By Type:

- Single-axis Positioners (Linear Stages)

- Multi-axis Positioners (X-Y, X-Y-Z, Rotation, Tip/Tilt)

- By Actuation Technology:

- Stacked Piezo Actuators (Direct Drive)

- Piezo Motors (e.g., Stick-slip, Resonant/Ultrasonic)

- Piezo-Inertial Drives

- By Resolution:

- Nanometer Resolution

- Picometer Resolution

- By Application:

- Semiconductor and Microelectronics Manufacturing (Lithography, Wafer Inspection)

- Optical Systems and Photonics (Fiber Coupling, Adaptive Optics, Laser Alignment)

- Biomedical and Life Sciences (Microscopy, Cell Manipulation, Microfluidics)

- Industrial Automation and Metrology (Precision Assembly, CMMs)

- Aerospace and Defense

- By End-User:

- Industrial Manufacturers

- Research and Academic Institutions

- Government Laboratories

Value Chain Analysis For Piezo Positioners Market

The value chain for the Piezo Positioners Market is highly complex and knowledge-intensive, beginning with the upstream supply of specialized raw materials. This initial stage involves sourcing high-purity ceramic powders, primarily lead zirconate titanate (PZT) or increasingly sophisticated lead-free alternatives, alongside specialized metals and polymers for mechanical components and high-speed sensor technology. Upstream processes are characterized by stringent quality control and proprietary material formulations, as the performance of the final positioner is fundamentally dictated by the quality and consistency of the piezoelectric material. Key upstream suppliers include advanced material science companies and specialized electronic component providers who operate in a niche market with significant barriers to entry due to demanding technical specifications.

Moving downstream, the value creation shifts toward sophisticated manufacturing, integration, and distribution. Manufacturers specialize in the precise machining of flexure hinges, the bonding of piezo ceramics, the integration of complex feedback sensors (capacitive or optical), and the development of highly specialized control electronics and software. This manufacturing stage adds immense value through intellectual property related to mechanical design (minimizing thermal effects, maximizing stiffness) and control algorithms (linearization, drift compensation). Distribution channels are critical and typically bifurcated: Direct sales teams handle large industrial OEM customers (like semiconductor equipment manufacturers) where technical consultation and customization are essential. Indirect channels, primarily specialized technical distributors or system integrators, serve smaller research institutions and general industrial users, providing localized support and faster turnaround times.

The efficiency of the distribution network, whether direct or indirect, significantly impacts market reach and customer service responsiveness. Direct channels facilitate deep technical collaboration necessary for custom projects, ensuring the positioners are perfectly optimized for demanding applications like next-generation lithography systems. Indirect channels provide geographical reach and inventory management, catering to the broad academic and smaller industrial sectors. Overall, success in the value chain relies not only on manufacturing excellence but also on the ability to provide comprehensive after-sales support, robust application engineering, and rapid deployment capabilities, maintaining the high precision performance necessary for mission-critical operations.

Piezo Positioners Market Potential Customers

Potential customers for piezo positioners are diverse yet unified by a common requirement: the need for motion control at the absolute limits of precision, typically sub-micron or nanometer resolution. The largest segment of end-users are high-volume industrial manufacturers, particularly those involved in semiconductor fabrication, where piezo stages are integral to photolithography machines, wafer inspection systems, and chip packaging equipment. These industrial manufacturers prioritize reliability, throughput, and compatibility with stringent cleanroom standards, viewing piezo positioners as a core enabling technology essential for achieving high yields of advanced microprocessors and memory chips. The demand here is often for highly standardized, robust, and often customized Original Equipment Manufacturer (OEM) units integrated directly into complex, expensive machinery.

The second major category encompasses scientific and research institutions, including university labs, government research facilities, and specialized R&D centers in the private sector. These end-users utilize piezo positioners for experimental purposes, such as advanced microscopy (e.g., scanning probe microscopy, super-resolution microscopy), particle physics experiments, and fundamental materials science investigations. This segment typically demands extreme flexibility, highly customized configurations, and cutting-edge performance specifications, often purchasing lower volumes of highly specialized or prototype equipment. The purchasing criteria here are often driven by technical specifications and collaboration potential with the manufacturer, rather than cost efficiency in high volume.

A rapidly expanding customer base is found within the biomedical and life sciences sectors, including pharmaceutical companies, medical device manufacturers, and specialized bio-research institutions. Applications include robotic cell injection, high-throughput drug screening systems, precise surgical instrument guidance, and micro-manipulation in microfluidic devices. These customers require high precision coupled with biological compatibility (e.g., non-magnetic or specialized coatings) and stringent quality assurance standards mandated by medical regulations. The commonality across all potential customers is the indispensable need for controlled motion that cannot be achieved using conventional motion control technologies, establishing piezo positioners as essential components in the global technological infrastructure.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 650 Million |

| Market Forecast in 2033 | USD 1,245 Million |

| Growth Rate | CAGR 9.8% |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | PI (Physik Instrumente), Aerotech, SmarAct GmbH, Newport Corporation (MKS Instruments), CEDRAT TECHNOLOGIES, MICRONIX USA, Prior Scientific, Mad City Labs, Nanoscience Instruments, Thorlabs, OWIS GmbH, XYZTEC, Standa, Piezosystem Jena, Physik Instrumente, Dynamic Structures and Materials (DSM), Nano-Terra, Dover Motion, SCANLAB GmbH, FOGALE nanotech. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Piezo Positioners Market Key Technology Landscape

The technological landscape of the Piezo Positioners Market is characterized by continuous innovation aimed at enhancing speed, travel range, and resolution while minimizing environmental sensitivity. The foundational technology remains the utilization of advanced piezoelectric ceramic materials, primarily PZT, but there is significant R&D focused on developing high-performance, lead-free alternatives to meet emerging environmental regulations without sacrificing displacement characteristics. Key technological efforts focus on optimizing the geometry of stacked actuators and leveraging flexure-guided mechanisms. Flexure hinges, typically monolithically machined, provide frictionless, high-stiffness motion that eliminates mechanical play and wear, making them essential for achieving ultra-high resolution and repeatability over long operational cycles.

Beyond the fundamental mechanical design, the market is defined by advancements in actuation principles and control systems. While stacked actuators provide the highest stiffness and dynamic response for short travel ranges (tens of microns), piezo motor technologies—such as stick-slip (inertia) drives and resonant/ultrasonic motors—are critical for applications requiring greater travel (millimeters or centimeters) while retaining fine-positioning capabilities. These motor types often integrate highly sophisticated software compensation and control electronics to manage the switching frequencies and minimize residual vibration. The controller technology itself is rapidly evolving, moving from analog drive circuits to high-bandwidth digital controllers that facilitate advanced feed-forward control, active compensation for thermal drift, and the integration of sophisticated feedback loops using highly accurate capacitive or laser interferometric sensors.

Furthermore, the trend toward miniaturization requires the development of smaller, lighter, and more power-efficient piezo systems capable of integration into portable equipment or complex automated machines where space is severely constrained. This includes advancements in Micro-Electro-Mechanical Systems (MEMS) technology and micro-piezo devices. The increasing demand for multi-axis coordinated motion necessitates sophisticated control software capable of real-time trajectory generation and synchronous actuation across multiple degrees of freedom, often in highly dynamic scenarios. This technological push ensures that piezo positioners remain the preferred choice for boundary-pushing applications in scientific and industrial domains where sub-nanometer stability is paramount for reliable outcomes.

Regional Highlights

Regional dynamics play a crucial role in shaping the Piezo Positioners Market, reflecting localized industrial density, R&D intensity, and varying regulatory environments. The global market can be broadly segmented into North America, Europe, Asia Pacific (APAC), Latin America, and the Middle East & Africa (MEA). Each region presents unique growth opportunities and competitive landscapes, heavily influenced by the presence of key end-user industries such as semiconductor manufacturing, aerospace, and advanced research centers. Understanding the regional market specifics is essential for manufacturers to tailor their supply chains, distribution strategies, and product portfolios effectively.

North America is characterized by robust demand originating from highly advanced R&D initiatives, particularly in fields related to defense, space exploration (e.g., NASA contracts), and pharmaceutical innovation. The United States hosts numerous specialized research institutions and leading technology companies that are early adopters of cutting-edge piezo positioning systems for complex applications like adaptive optics in powerful telescopes and advanced metrology equipment. This region commands a significant share due to high capital expenditure on research infrastructure and a large, established network of specialized system integrators, driving demand for high-performance, customized solutions.

Europe represents a mature but technologically demanding market, particularly concentrated in countries such as Germany, Switzerland, and the Netherlands. Germany, home to several world-leading manufacturers of precision machinery and optics, drives strong internal demand for high-quality, reliable piezo positioners used in precision engineering, machine tools, and automotive manufacturing inspection systems. The European regulatory environment, specifically regarding materials (e.g., REACH regulations affecting PZT usage), further encourages innovation in developing sustainable, lead-free positioning solutions, maintaining Europe's position as a leader in technical quality and standardization.

Asia Pacific (APAC) is projected to be the fastest-growing region, fueled by massive government and private sector investment in semiconductor manufacturing capacity, especially in China, Taiwan (semiconductor foundries), and South Korea. The rapid expansion of electronics assembly, display panel manufacturing (OLED/LED), and localized R&D efforts in emerging technologies makes APAC the epicenter of volume demand. Manufacturers are focusing on establishing local presence and strengthening distribution networks to capitalize on the region's aggressive industrial expansion and the swift transition to advanced fabrication nodes that inherently require nanometer-scale precision.

The MEA and Latin America regions currently hold smaller market shares but offer long-term potential, primarily driven by investments in emerging scientific research facilities, oil and gas exploration requiring specialized inspection equipment, and localized electronics assembly operations. While adoption rates are slower due to higher import costs and less developed supporting infrastructure, increased global investment in infrastructure and technology transfer is expected to gradually stimulate demand for precision motion control systems in specialized industrial niches within these regions over the forecast period.

- Asia Pacific (APAC): Dominates growth due to extensive semiconductor fabrication investment (Taiwan, South Korea, China) and rapid expansion in photonics and display technologies; high volume demand for standardized, high-throughput systems.

- North America: Strong market driven by defense, aerospace, advanced R&D, and established technology companies; focus on high-performance, highly customized, and cutting-edge positioning solutions.

- Europe: Mature market with high demand from precision engineering, automotive, and machine tool industries (Germany, Switzerland); emphasis on quality, reliability, and lead-free technological compliance.

- Latin America & MEA: Emerging markets driven by localized electronics assembly, academic research growth, and specialized industrial sectors (e.g., mining, energy); growth expected to accelerate with infrastructure improvements and technology adoption.

- Key Countries: United States, Germany, China, Taiwan, Japan, South Korea.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Piezo Positioners Market.- PI (Physik Instrumente)

- Aerotech

- SmarAct GmbH

- Newport Corporation (MKS Instruments)

- CEDRAT TECHNOLOGIES

- MICRONIX USA

- Prior Scientific

- Mad City Labs

- Nanoscience Instruments

- Thorlabs

- OWIS GmbH

- XYZTEC

- Standa

- Piezosystem Jena

- Dynamic Structures and Materials (DSM)

- Nano-Terra

- Dover Motion

- SCANLAB GmbH

- PVA TePla AG

- Physik Instrumente GmbH & Co. KG

Frequently Asked Questions

Analyze common user questions about the Piezo Positioners market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the fundamental difference between piezo positioners and traditional motorized stages?

Piezo positioners utilize the piezoelectric effect for movement, offering frictionless, extremely high-resolution motion (nanometer to picometer) with very fast response times. Traditional motorized stages, which rely on mechanical gears or leadscrews driven by DC or stepper motors, offer longer travel ranges but significantly lower resolution, typically limited to the micron level or hundreds of nanometers.

Which industrial application drives the highest demand for Piezo Positioners?

The semiconductor manufacturing industry drives the highest volume and value demand. Piezo positioners are essential for critical processes like photolithography, wafer inspection, and precise alignment in specialized metrology equipment, where positional accuracy directly determines production yield and the viability of manufacturing smaller feature sizes.

How do manufacturers compensate for the inherent material hysteresis and creep in piezoelectric materials?

Manufacturers primarily address hysteresis and creep through advanced control strategies, including closed-loop control utilizing highly accurate sensors (such as capacitive or strain gauge sensors) to provide real-time position feedback. Modern digital controllers employ sophisticated linearization algorithms, sometimes leveraging AI/ML, and feed-forward compensation to minimize non-linear movement errors and maintain stable positioning over time.

Are there environmentally friendly, lead-free alternatives to traditional PZT-based piezo positioners?

Yes, driven by environmental regulations like RoHS and REACH, significant research is underway, and commercial solutions are emerging using lead-free piezoelectric ceramics, such as Barium Titanate (BTO) or other complex bismuth-based compounds. While PZT offers superior performance currently, lead-free alternatives are rapidly closing the performance gap, particularly for high-volume industrial applications in regulated markets like Europe.

What is the typical lifespan and maintenance requirement for a high-precision piezo stage?

The lifespan of a high-precision piezo positioner is generally excellent, as they rely on frictionless flexure mechanisms with no mechanical wear. The lifespan is typically limited by the operational cycles of the piezoelectric ceramic itself (often millions or billions of cycles). Maintenance is minimal, primarily focusing on ensuring the control electronics and external environment (temperature stability, cleanliness) are optimal, especially in systems utilizing high-bandwidth digital controllers and predictive maintenance algorithms.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager