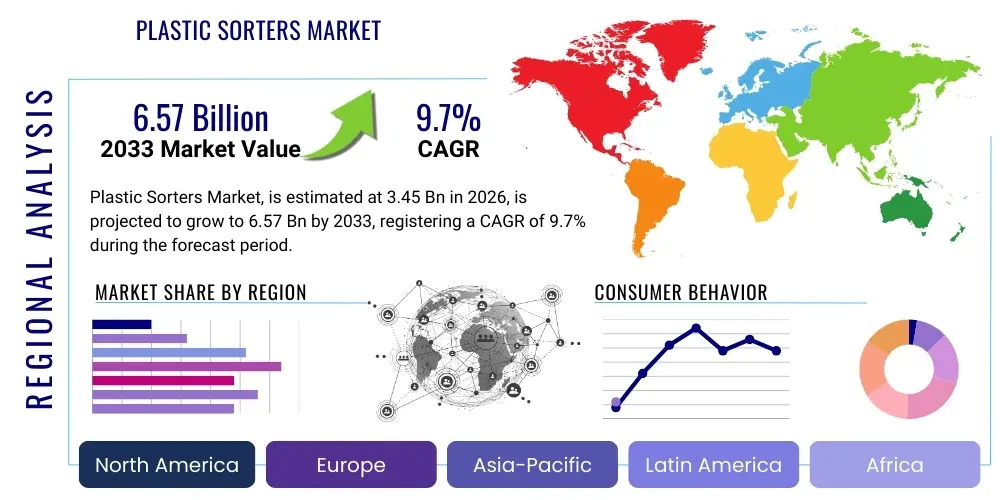

Plastic Sorters Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 441576 | Date : Feb, 2026 | Pages : 248 | Region : Global | Publisher : MRU

Plastic Sorters Market Size

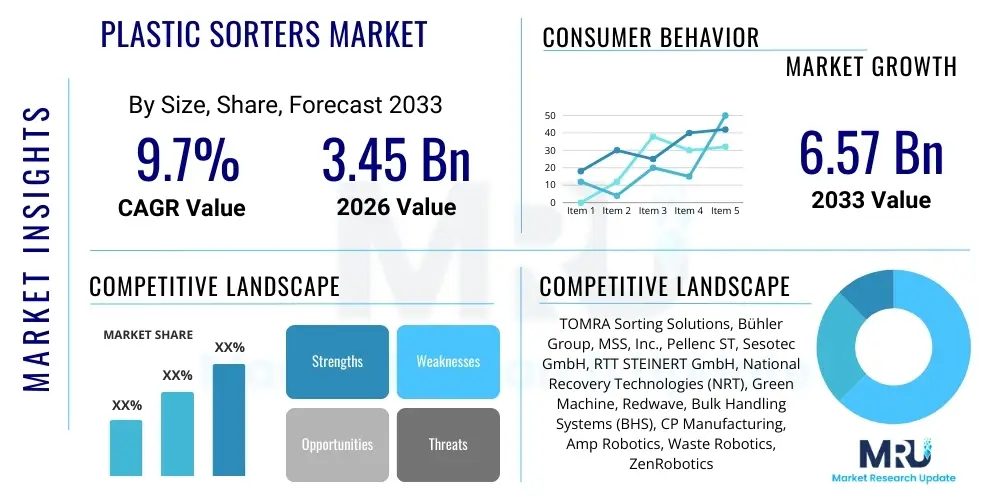

The Plastic Sorters Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 9.7% between 2026 and 2033. The market is estimated at USD 3.45 Billion in 2026 and is projected to reach USD 6.57 Billion by the end of the forecast period in 2033.

Plastic Sorters Market introduction

The Plastic Sorters Market encompasses the ecosystem of advanced mechanical and optical systems designed to separate different types of plastic materials (polymers) from mixed waste streams based on composition, color, size, and shape. These sophisticated sorting technologies are crucial for improving the purity and quality of recycled plastics, which directly impacts the economic viability of recycling operations and the sustainability goals of governmental and industrial entities. Key products include Near-Infrared (NIR) sorters, X-ray Transmission (XRT) sorters, and high-speed robotic sorting arms, often integrated into Material Recovery Facilities (MRFs) and dedicated plastic recycling centers globally. The primary function is to achieve high throughput and high purity output, making the secondary market for plastics competitive with virgin materials.

Major applications of these sorting systems span municipal solid waste (MSW) recycling, commercial and industrial (C&I) waste processing, and specialized sorting of electronic waste (e-waste) and automotive plastics. The increasing global regulatory emphasis on circular economy models, particularly in the EU and North America, mandates higher recovery rates and specific purity standards for various polymers, directly fueling the demand for precision sorting equipment. Benefits include enhanced operational efficiency, reduced labor costs, minimization of landfill waste, and the ability to handle complex, multi-layered plastic waste streams that were previously unrecyclable. Furthermore, these systems contribute significantly to reducing the energy consumption associated with producing virgin plastics.

The market growth is fundamentally driven by the escalating global plastic waste crisis, coupled with stringent environmental regulations such as the European Union’s Packaging and Packaging Waste Regulation (PPWR), which sets mandatory targets for recycled content. Technological advancements, particularly the integration of Artificial Intelligence (AI) and machine learning for enhanced recognition accuracy and material flow optimization, are significantly accelerating market adoption. These combined factors solidify the plastic sorters market as a critical component of the global sustainability infrastructure, moving waste management from linear disposal to a circular resource economy.

Plastic Sorters Market Executive Summary

The Plastic Sorters Market is characterized by rapid technological innovation focused on maximizing purity and throughput efficiency, driven primarily by increasing global legislative pressure to meet ambitious recycling targets. Business trends show a significant shift toward sensor-based sorting technologies, particularly sophisticated NIR and hyperspectral imaging systems that can accurately distinguish between complex polymers like PET, HDPE, PVC, and PP at high speeds. Major manufacturers are focusing on modular system designs and retrofitting capabilities to allow existing MRFs to upgrade their operational efficiency without complete facility overhauls. Consolidation and strategic partnerships between equipment providers and recycling facility operators are increasing to offer comprehensive, integrated solutions, especially those incorporating robotic automation to handle challenging fractions and large throughput volumes efficiently.

Regionally, Europe leads the market adoption due to the bloc's highly mature regulatory framework and aggressive waste reduction policies, fostering an environment where investment in advanced sorting infrastructure is mandatory for compliance. However, the Asia Pacific (APAC) region is projected to exhibit the fastest growth rate, fueled by massive urbanization, increasing domestic waste generation, and substantial governmental investments in modern waste treatment infrastructure, particularly in populous economies like China, India, and Southeast Asia, aiming to address critical pollution issues and develop domestic recycling capacity. North America maintains a steady growth trajectory, influenced by state-level mandates and the increasing operational costs of landfills, making advanced sorting a financially attractive alternative.

Segment trends reveal that the sensor-based sorting segment, specifically utilizing NIR technology, dominates the market due to its proven effectiveness in identifying major polymer types. However, the robotic sorting segment is gaining significant traction, exhibiting the highest growth rate as AI-driven mechanical arms provide the necessary precision for separating smaller, flatter, or complex items that challenge traditional optical systems. Applications for PET (Polyethylene Terephthalate) sorting remain the largest segment, given the material’s prevalence in packaging, but the sorting of mixed plastics and flexible films (often requiring advanced technologies like XRT or deep learning visual systems) is rapidly expanding, reflecting the need to handle the more complex fractions of the waste stream effectively.

AI Impact Analysis on Plastic Sorters Market

Common user questions regarding AI's impact on the Plastic Sorters Market revolve around operational efficiency gains, material purity levels, system integration complexity, and the long-term reliability of machine learning models in dynamic waste environments. Users frequently ask about the cost-benefit analysis of upgrading legacy systems with AI-driven visual sorting capabilities versus traditional NIR sensors, and concerns often center on job displacement versus the creation of new roles focused on system maintenance and data analysis. The key themes summarized from user inquiries indicate high expectation for AI to solve persistent problems such as sorting black plastics (which NIR often fails to detect), identifying multi-layer packaging, and optimizing material flow to maximize throughput. Users expect AI to reduce human error, enhance data reporting for compliance, and provide adaptive learning capabilities to cope with changing municipal waste compositions, thereby fundamentally redefining the required capital expenditure and operational expertise needed in MRFs.

- AI-driven image processing enhances recognition accuracy for complex, soiled, or irregularly shaped plastics.

- Machine learning models optimize sorter performance in real-time by adjusting air jet timing and conveyor speeds based on material density and flow dynamics.

- Deep learning enables the differentiation and accurate sorting of black plastics, which are typically invisible to standard Near-Infrared (NIR) technology.

- Predictive maintenance algorithms use sensor data to anticipate equipment failures, minimizing costly downtime in high-throughput environments.

- Robotic sorting arms, powered by AI vision, can handle small fraction plastics and flexible packaging (films) with greater speed and consistency than human operators.

- Enhanced data collection and analytics provide MRF operators with detailed insights into waste composition and facility efficiency for regulatory compliance and operational planning.

- AI facilitates the identification and separation of complex multi-layered or composite materials, crucial for meeting modern chemical recycling feedstock requirements.

DRO & Impact Forces Of Plastic Sorters Market

The market dynamics are governed by a powerful interplay of regulatory push, technological advancements, and economic pressures arising from the global waste crisis. Drivers include increasingly stringent government regulations globally, particularly in developed economies, mandating high purity levels for post-consumer plastics and establishing aggressive recycled content targets for packaging manufacturers. Furthermore, growing public awareness and corporate sustainability commitments pressure companies to invest in efficient resource recovery solutions. Restraints primarily involve the high initial capital investment required for implementing sophisticated sensor-based and robotic sorting lines, coupled with the variability in quality and composition of municipal solid waste streams, which can sometimes reduce system efficiency and require frequent calibration. Opportunities lie in the synergistic deployment of sorting technologies alongside emerging chemical recycling (pyrolysis, gasification) processes, where high-purity sorted feedstock is essential, creating new high-value end markets for difficult-to-recycle plastics. This combination paves the way for a holistic, circular economy solution.

Impact forces illustrate the market's response to external and internal pressures. High substitution threat from manual labor, though historically present, is rapidly diminishing as automation offers superior consistency, speed, and cost-effectiveness over time, particularly in high-wage economies. The bargaining power of suppliers is moderate, as key component technologies (sensors, optics, air jets) are sourced from a specialized but competitive global market, though proprietary software and machine learning algorithms provide some leverage for leading sorter manufacturers. The bargaining power of buyers (MRFs and large recycling corporations) is increasing due to the availability of modular solutions and intensifying competition among sorter manufacturers offering better service contracts and integration support. Overall, the dominant impact force remains the regulatory environment and evolving Extended Producer Responsibility (EPR) schemes, which necessitate continuous upgrades and investment in sorting infrastructure to achieve mandated recovery rates.

The transition toward a circular economy acts as a major overarching force, shifting the perspective of plastics from 'waste' to 'valuable resource.' This perception change justifies the significant capital expenditure necessary for advanced sorting equipment. While technological integration complexity remains a challenge—requiring specialized maintenance skills and effective integration into existing plant infrastructure—the proven ability of technologies like NIR and XRT to rapidly identify contaminants and separate highly specific polymers makes the investment unavoidable for entities seeking to remain competitive and compliant in the evolving plastics value chain. The market is thus poised for sustained growth, leveraged by regulatory mandates and efficiency gains derived from artificial intelligence and increased automation.

Segmentation Analysis

The Plastic Sorters Market is broadly segmented based on Technology, Type, Application, and End-User. The technological segmentation is crucial as it defines the sophistication and capability of the system, ranging from high-speed sensor-based separation (NIR, XRT) to flexible, precise mechanical handling (Robotic Sorting). Segmentation by type distinguishes between single-stream and multi-stream sorting needs, addressing different operational methodologies prevalent across MRFs globally. Furthermore, the application segmentation highlights the target plastic polymer, such as PET, HDPE, or mixed plastics, which dictates the specific technological calibration required. These structured segments provide market stakeholders with clarity on investment priorities and enable manufacturers to tailor solutions to specific industrial needs, optimizing both cost and sorting performance metrics crucial for profitability in recycling operations.

- By Technology:

- Sensor-Based Sorting (Near-Infrared Spectroscopy (NIR), X-Ray Transmission (XRT), Color Sensors, Hyperspectral Imaging (HSI))

- Robotic Sorting Systems (AI-Driven Grippers and Mechanical Arms)

- Air Separation and Density Sorting

- By Type:

- Single-Stream Sorting Systems

- Multi-Stream Sorting Systems

- By Application (Plastic Type):

- PET (Polyethylene Terephthalate) Sorting

- HDPE (High-Density Polyethylene) Sorting

- PP (Polypropylene) Sorting

- PVC (Polyvinyl Chloride) Sorting

- Mixed Plastics and Films Sorting

- Other Polymers (ABS, PS, etc.)

- By End-User:

- Material Recovery Facilities (MRFs)

- Dedicated Plastic Recycling Plants

- Waste Management and Disposal Companies

- Industrial and Commercial Waste Processors

- E-Waste Recyclers

Value Chain Analysis For Plastic Sorters Market

The value chain for the Plastic Sorters Market begins with the upstream segment, which involves the suppliers of critical high-tech components. This includes manufacturers of highly sensitive optical sensors (NIR, HSI cameras), high-power X-ray sources, sophisticated air jet manifolds, and the industrial robots and gripping mechanisms used in robotic sorting systems. Innovation at this stage, particularly in sensor accuracy and speed, directly dictates the capabilities of the final sorting machine. Key players in the component supply market often specialize in optics, software algorithms, and data processing hardware, ensuring that the manufactured sorting equipment remains at the technological forefront of material recognition and separation efficiency. The quality and availability of these components are crucial for maintaining the competitive edge of sorter manufacturers, who rely heavily on precise, durable technology.

The midstream involves the core activities of research and development, manufacturing, integration, and distribution. Equipment manufacturers design, assemble, and test the complex sorting units, often requiring extensive software integration, calibration, and customization based on the target material stream (e.g., highly contaminated MSW versus cleaner C&I waste). Distribution channels are typically a mix of direct sales teams for large integrated projects and indirect channels utilizing regional distributors or system integrators who specialize in designing and installing entire MRF workflows, ensuring seamless integration of the plastic sorters within a larger processing environment. Service and maintenance—providing ongoing technical support, software updates, and predictive maintenance—form a critical part of the midstream value proposition, generating significant recurring revenue for vendors.

The downstream segment encompasses the end-users—primarily Material Recovery Facilities, dedicated plastic recyclers, and large waste management conglomerates—who utilize the sorters to produce high-purity plastic bales. The efficiency of the sorters directly impacts the value realized by the end-user, as purer output commands higher prices in the secondary market (pelletizers, converters). The value chain concludes with the final recycled products re-entering the manufacturing cycle, often driven by legal requirements for recycled content. Direct distribution is favored for major global contracts due to the specialized nature of the equipment and the need for dedicated installation and training, while indirect channels serve smaller municipal facilities or local niche recyclers, leveraging local expertise in waste management logistics and operational specifics.

Plastic Sorters Market Potential Customers

The primary customers for advanced plastic sorters are entities deeply involved in the management, processing, and recovery of plastic waste streams. Material Recovery Facilities (MRFs) are the largest end-users, serving as the central hub for sorting municipal solid waste. These facilities require high-throughput, versatile sorting systems capable of handling mixed incoming streams and separating various plastics, papers, and metals efficiently to maximize diversion rates and achieve specified commodity purity. As municipalities face stricter environmental regulations and growing waste volumes, MRFs continuously invest in upgrades, making them perpetual customers for advanced NIR, XRT, and robotic sorting technologies to maintain operational viability and competitiveness in the commodity market.

Dedicated Plastic Recycling Plants represent another significant customer segment. Unlike general MRFs, these facilities specialize exclusively in processing pre-sorted or specific plastic waste streams (e.g., rigid plastics or flexible films). Their demand focuses on highly accurate, specialized sorters (such as those optimized for color separation or specific polymer identification) to produce ultra-pure flake or pellet feedstock required for high-grade applications like food-contact packaging. Furthermore, large national and international waste management and environmental service providers, such as Veolia, Republic Services, and Waste Management, frequently purchase sorters in bulk as part of their capital investment strategies to standardize their fleet of recycling infrastructure globally, driving large volume sales and long-term service contracts.

A rapidly growing segment includes industrial and commercial waste processors, particularly those handling packaging waste from large logistics hubs, manufacturing facilities, or e-waste recyclers. E-waste recycling, in particular, requires highly specialized XRT sorters to differentiate between plastics containing flame retardants or specific resins mixed with metal components. Governments and municipalities, through public-private partnerships, are also key buyers, investing in modern infrastructure to meet public goals for resource recovery. These varied end-users share the common requirement for high-efficiency, robust equipment that guarantees a reliable yield of saleable secondary plastic materials, justifying the high initial expenditure on automated sorting technology.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 3.45 Billion |

| Market Forecast in 2033 | USD 6.57 Billion |

| Growth Rate | 9.7% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | TOMRA Sorting Solutions, Bühler Group, MSS, Inc., Pellenc ST, Sesotec GmbH, RTT STEINERT GmbH, National Recovery Technologies (NRT), Green Machine, Redwave, Bulk Handling Systems (BHS), CP Manufacturing, Amp Robotics, Waste Robotics, ZenRobotics (part of Terex), Max-AI (BHS). |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Plastic Sorters Market Key Technology Landscape

The technological landscape of the Plastic Sorters Market is dominated by sensor-based technologies, with Near-Infrared (NIR) spectroscopy being the foundational element. NIR systems utilize reflective light patterns to identify the chemical composition of plastics (polymers) at high speeds, enabling the precise separation of common resins like PET, HDPE, and PP. Recent advancements in NIR involve increasing spectral resolution and incorporating machine learning algorithms to improve accuracy when dealing with pigmented, multi-layered, or highly soiled materials. Furthermore, Hyperspectral Imaging (HSI), a more advanced form of NIR, is gaining prominence by capturing a broader spectrum of light, allowing for even finer differentiation between similar polymers and contaminants, thereby significantly boosting the final purity of the sorted output, which is critical for food-grade recycling applications.

Complementing optical sorting, X-Ray Transmission (XRT) technology is crucial for sorting materials based on density and elemental composition, proving invaluable in segregating plastics containing chlorine (PVC) or brominated flame retardants, which are often mixed into waste electrical and electronic equipment (WEEE). XRT allows processors to efficiently remove problematic plastics that could otherwise contaminate the recycling process or lead to toxic emissions during melting. The combination of NIR and XRT in sequence provides a robust, multi-stage sorting process capable of handling increasingly complex waste mixtures. This duality addresses not only the volume requirements but also the quality control demands necessary for specialized end-markets.

Perhaps the most transformative technological shift involves the integration of Artificial Intelligence (AI) and robotics. AI-driven robotic sorting systems use advanced visual recognition cameras (often leveraging deep learning) to identify items based on shape, size, and brand information, allowing them to sort items that are too small, flat, or obscure for traditional NIR systems, such as flexible packaging, films, and specific food trays. These robotic systems offer unmatched flexibility and resilience against high turnover rates typical of human labor. Furthermore, the increasing adoption of IoT connectivity allows sorters to generate vast amounts of operational data, enabling remote diagnostics, predictive maintenance, and real-time performance optimization, positioning these connected systems as smart assets crucial for future MRF operations.

Regional Highlights

The global plastic sorters market exhibits distinct adoption patterns and growth drivers across major geographic regions, reflecting differing regulatory environments and waste management infrastructure maturity. Europe currently holds the dominant market share, driven primarily by ambitious and binding EU directives, such as the Waste Framework Directive and the Packaging and Packaging Waste Regulation (PPWR), which mandate significant increases in recycling rates and recycled content usage. This regulatory environment necessitates continuous and substantial capital investment in advanced sorting technologies (NIR, XRT, and robotics) to handle complex packaging formats and ensure compliance. Countries like Germany, France, and the Netherlands are technological frontrunners, showcasing highly automated MRFs focused on achieving high purity yields essential for a successful circular economy model.

The Asia Pacific (APAC) region is projected to be the fastest-growing market segment. This explosive growth is attributed to rapid industrialization, massive population density, increasing urbanization leading to soaring municipal waste volumes, and a growing governmental push (especially in China, India, and Southeast Asia) to curb plastic pollution and establish local recycling supply chains following previous export bans. While the initial investment challenge is higher, governments are increasingly funding large-scale infrastructure projects, favoring high-throughput sorting solutions capable of addressing immense waste streams. The adoption of robotic sorting is slower compared to basic sensor-based sorting, but its uptake is accelerating as labor costs rise and the need for high-quality feedstock grows.

North America (NA) is a mature market exhibiting steady growth, largely driven by state-level recycling mandates, the economic necessity to reduce landfill reliance, and the push for greater material recovery quality following interruptions in international commodity markets. The market here focuses heavily on upgrading existing MRFs with modular, high-efficiency equipment, with a particularly strong interest in AI and robotic solutions to offset high labor costs and manage the commingling of waste typical in single-stream recycling systems. Latin America and the Middle East & Africa (MEA) represent emerging markets. Growth in these regions is nascent but significant, spurred by expanding urban centers and increasing awareness regarding environmental sustainability, leading to pilot projects and initial investments in semi-automated and automated sorting facilities, particularly supported by multinational waste management companies.

- Europe: Leading market share due to stringent EU recycling and recycled content mandates (e.g., PPWR). High penetration of NIR and XRT technologies; focus on achieving maximum polymer purity.

- Asia Pacific (APAC): Fastest-growing region; driven by rapid urbanization, massive waste generation, and governmental investment in large-scale infrastructure projects (China, India). Increasing adoption of automation to handle high volumes.

- North America (NA): Steady growth driven by high labor costs and the transition from single-stream to advanced sorting, favoring AI-driven robotics and system upgrades in existing MRFs.

- Latin America (LATAM): Emerging market, focusing on foundational sorting infrastructure establishment, supported by international funding and partnerships to manage burgeoning municipal waste.

- Middle East & Africa (MEA): Growing market segment, primarily linked to large-scale infrastructure development projects in high-income Gulf states and increasing regulatory focus on sustainable waste management in key African nations.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Plastic Sorters Market.- TOMRA Sorting Solutions

- Bühler Group

- MSS, Inc.

- Pellenc ST

- Sesotec GmbH

- RTT STEINERT GmbH

- National Recovery Technologies (NRT)

- Green Machine

- Redwave (a division of BT-Wolfgang Binder)

- Bulk Handling Systems (BHS)

- CP Manufacturing

- Amp Robotics

- Waste Robotics

- ZenRobotics (part of Terex Corporation)

- Max-AI (a brand of BHS)

- Bollegraaf Recycling Solutions

- Machinex Group

- General Kinematics

- TiTech (TOMRA subsidiary)

- Titech Autosort

Frequently Asked Questions

Analyze common user questions about the Plastic Sorters market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary technology used to identify different types of plastics in high-speed sorting?

The primary technology is Near-Infrared (NIR) spectroscopy. NIR systems use light reflection patterns to analyze the chemical composition (polymer type) of plastics on a conveyor belt, enabling rapid and accurate separation via air jets.

How does the integration of AI impact the purity levels of recycled plastic output?

AI, particularly in robotic and visual sorting systems, significantly enhances purity by enabling the accurate identification of complex, multi-layered, or black plastics that traditional NIR systems often miss, leading to higher-quality feedstock for manufacturers.

Which region currently dominates the global plastic sorters market in terms of installed capacity?

Europe dominates the market. This is primarily due to stringent European Union regulations and aggressive recycling targets, necessitating high investment in advanced sorting infrastructure to meet mandatory purity and recovery rates.

What are the main financial restraints affecting the adoption of new plastic sorting technologies?

The main restraints are the high initial capital investment required for purchasing and installing complex sensor-based and robotic sorting lines, coupled with the volatility and uncertainty in pricing for post-consumer recycled plastic commodities.

Are robotic sorters replacing human labor entirely in Material Recovery Facilities (MRFs)?

Robotic sorters are increasingly replacing human labor in repetitive, high-volume tasks and handling hazardous materials. While they increase automation, they often complement human staff, who are then reassigned to focus on maintenance, quality control, and system optimization tasks.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager