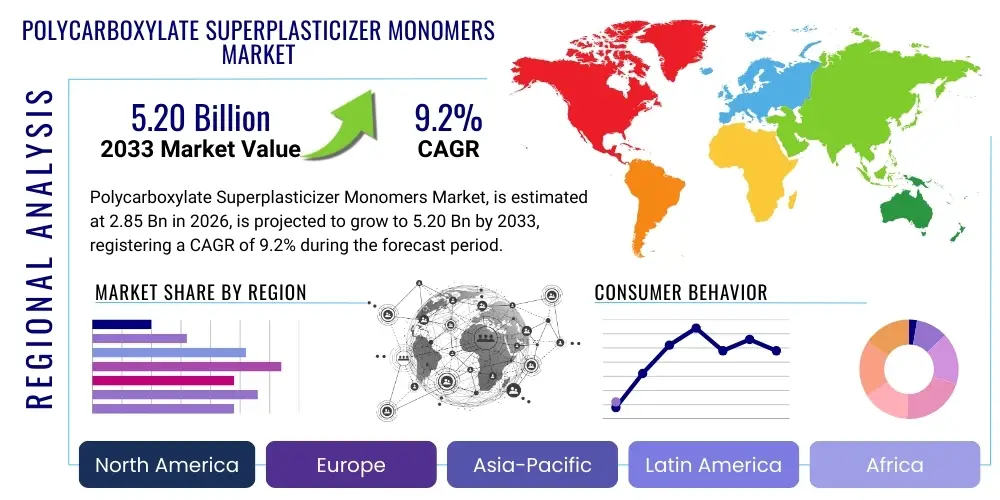

Polycarboxylate Superplasticizer Monomers Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440698 | Date : Feb, 2026 | Pages : 258 | Region : Global | Publisher : MRU

Polycarboxylate Superplasticizer Monomers Market Size

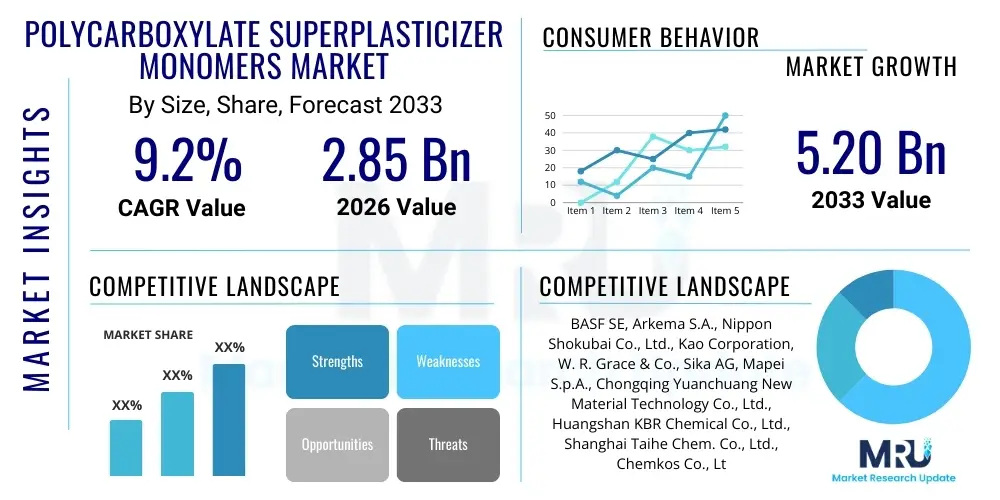

The Polycarboxylate Superplasticizer Monomers Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 9.2% between 2026 and 2033. The market is estimated at USD 2.85 Billion in 2026 and is projected to reach USD 5.20 Billion by the end of the forecast period in 2033.

Polycarboxylate Superplasticizer Monomers Market introduction

The Polycarboxylate Superplasticizer Monomers market serves as a critical upstream component for the construction chemicals industry, specifically in the production of high-performance concrete admixtures. These monomers, primarily polyethylene glycol ethers such as HPEG, APEG, TPEG, and MPEG, are the building blocks for polycarboxylate ether (PCE) superplasticizers, which are renowned for their exceptional water-reducing and slump-retaining capabilities in concrete. The product's fundamental advantage lies in its ability to significantly enhance concrete workability, strength, and durability while allowing for substantial reductions in water content without compromising structural integrity. This leads to more sustainable and efficient construction practices. The market is experiencing robust growth driven by accelerating global urbanization, extensive infrastructure development projects across emerging and developed economies, and an increasing demand for high-performance and specialty concrete in modern construction. The benefits of using PCE-based admixtures, including improved flowability, reduced permeability, and extended setting times, position these monomers as indispensable for advanced construction applications, ensuring their sustained demand.

Polycarboxylate Superplasticizer Monomers Market Executive Summary

The Polycarboxylate Superplasticizer Monomers market is characterized by dynamic business trends reflecting consolidation among key players, significant investments in research and development to create more sustainable and efficient monomer compositions, and a strategic shift towards localized manufacturing to optimize supply chains and reduce logistical costs. Regional trends indicate that the Asia Pacific region continues its dominance due to rapid infrastructure expansion and burgeoning construction sectors in countries like China and India, while North America and Europe demonstrate steady growth driven by renovation, advanced construction techniques, and a focus on high-performance materials. Emerging markets in Latin America, the Middle East, and Africa are showing promising growth trajectories, propelled by increasing urbanization and government-led development initiatives. In terms of segment trends, there is a growing preference for specific monomer types, such as HPEG and APEG, attributed to their superior performance characteristics and versatility in various concrete formulations. Furthermore, the increasing adoption of polycarboxylate superplasticizers in niche applications like self-compacting concrete, ultra-high-performance concrete, and 3D printing concrete is significantly influencing market segmentation, driving innovation towards specialized monomer solutions that can cater to these evolving demands and unlock new market opportunities.

AI Impact Analysis on Polycarboxylate Superplasticizer Monomers Market

The integration of Artificial Intelligence (AI) and machine learning technologies is poised to revolutionize the Polycarboxylate Superplasticizer Monomers market by optimizing various stages of the value chain, from raw material sourcing to end-product application. AI's predictive capabilities can significantly enhance the efficiency of monomer synthesis by optimizing reaction parameters, predicting yields, and minimizing waste, thereby reducing production costs and environmental impact. Furthermore, AI-driven simulations can accelerate the research and development of novel monomer structures with enhanced performance characteristics, allowing manufacturers to tailor products precisely to specific concrete performance requirements, such as improved slump retention under varying environmental conditions or increased early strength development. This technological advancement addresses user questions regarding how to achieve superior and more consistent concrete performance, how to reduce formulation complexity, and how to shorten the development cycle for new admixture products.

Beyond synthesis and R&D, AI algorithms are instrumental in supply chain management, enabling predictive analytics for raw material procurement, demand forecasting, and inventory optimization, which helps mitigate risks associated with price volatility and supply disruptions. In quality control, AI-powered vision systems and data analytics can monitor production processes in real-time, detecting anomalies and ensuring the consistency and purity of monomers, thereby improving overall product quality and reducing defect rates. For end-users, AI tools can assist in admixture formulation guidance, predicting the optimal dosage and combination of superplasticizers for specific concrete mixes based on local aggregate properties, ambient temperatures, and desired performance outcomes, leading to more reliable and efficient construction practices. This addresses concerns about variability in concrete performance and the need for more intelligent, data-driven application strategies in the field.

- AI-driven optimization of monomer synthesis processes for higher yield and purity.

- Accelerated R&D through AI simulations for novel monomer design and performance prediction.

- Enhanced supply chain efficiency via predictive analytics for raw material sourcing and demand forecasting.

- Real-time quality control and anomaly detection in monomer production using AI vision systems.

- Personalized admixture formulation guidance for concrete producers based on AI analytics.

- Predictive maintenance for manufacturing equipment, reducing downtime and operational costs.

- Market trend analysis and competitive intelligence through AI-powered data processing.

- Development of smart, self-optimizing concrete admixtures with AI-embedded capabilities.

DRO & Impact Forces Of Polycarboxylate Superplasticizer Monomers Market

The Polycarboxylate Superplasticizer Monomers market is significantly shaped by a complex interplay of drivers, restraints, and opportunities, alongside various impact forces that influence its trajectory and competitive landscape. The primary drivers include rapid global urbanization and extensive infrastructure development, which necessitate high-performance concrete for modern structures, resilient transportation networks, and sustainable urban living. Additionally, increasing environmental regulations pushing for more sustainable construction practices and a reduction in cement content through highly efficient water reducers further stimulate demand for advanced superplasticizers. However, the market faces notable restraints such as the inherent volatility in raw material prices, particularly for petrochemical derivatives like ethylene oxide and acrylic acid, which can impact profit margins and production stability. Stringent environmental and health regulations concerning chemical manufacturing processes also add compliance costs and operational complexities, posing significant challenges for market players.

Despite these restraints, substantial opportunities exist for market expansion and innovation. The development of bio-based or partially bio-based polycarboxylate monomers offers a promising avenue for sustainable product lines, aligning with global green building initiatives and reducing reliance on fossil-based feedstocks. Furthermore, the untapped potential in emerging economies with their rapidly expanding construction sectors, coupled with the increasing adoption of specialized concrete applications such as 3D printing concrete and ultra-high-performance concrete, presents lucrative growth prospects. The impact forces, often analyzed through frameworks like Porter's Five Forces, reveal a moderately competitive landscape where the bargaining power of buyers (large admixture formulators) can be significant due to product commoditization, while the bargaining power of suppliers is also substantial given the specialized nature of key raw materials. The threat of new entrants is moderate, requiring significant capital investment and technical expertise, whereas the threat of substitutes, though present from older generation superplasticizers, is diminishing due to the superior performance of PCEs. Intense rivalry among existing players drives continuous innovation and competitive pricing strategies, shaping the market dynamics.

Segmentation Analysis

The Polycarboxylate Superplasticizer Monomers market is comprehensively segmented to provide granular insights into its diverse components and applications. This segmentation primarily includes classification by type, which differentiates between various polyether macromonomers based on their chemical structure and performance characteristics, and by application, which categorizes their usage across different concrete types and construction practices. Further segmentation often considers the end-user industry, detailing consumption patterns across residential, commercial, and infrastructure sectors. This structured analysis enables a clearer understanding of demand drivers, growth opportunities, and competitive dynamics within each specific market niche, allowing stakeholders to tailor strategies effectively.

- By Type

- HPEG (Isopentenyl Polyoxyethylene Ether)

- APEG (Allyl Polyoxyethylene Ether)

- TPEG (Methylallyl Polyoxyethylene Ether)

- MPEG (Methoxypolyethylene Glycol)

- Others (e.g., VPEG)

- By Application

- Ready-Mix Concrete

- Precast Concrete

- Self-Compacting Concrete (SCC)

- Ultra-High-Performance Concrete (UHPC)

- Dry Mix Mortars

- Other Specialty Concretes

- By End-User

- Residential Construction

- Commercial Construction

- Infrastructure Development (Roads, Bridges, Tunnels, Dams)

- Industrial Construction

Value Chain Analysis For Polycarboxylate Superplasticizer Monomers Market

The value chain for the Polycarboxylate Superplasticizer Monomers market is a multi-tiered process encompassing several critical stages, beginning with the sourcing of fundamental raw materials and culminating in the application of superplasticized concrete at construction sites. The upstream segment involves the production and supply of key chemical precursors such as ethylene oxide, acrylic acid, methacrylic acid, and alcohol initiators, typically provided by large petrochemical companies. These raw materials are then processed by monomer manufacturers who specialize in polymerizing these precursors into various types of polycarboxylate superplasticizer monomers like HPEG, APEG, TPEG, and MPEG, forming the core manufacturing stage of the value chain. This stage requires significant technical expertise in polymer chemistry and process engineering to ensure product quality and consistency.

Moving downstream, these monomers are supplied to concrete admixture formulators who then synthesize the final polycarboxylate ether (PCE) superplasticizers by further polymerization and blending with other additives. These formulators often develop proprietary formulations tailored for specific performance requirements or regional conditions. The distribution channel for these finished superplasticizers can be direct, where large admixture producers supply directly to major construction companies or ready-mix concrete plants, or indirect, involving a network of distributors, agents, and local dealers who cater to smaller contractors and specialized construction projects. The end-users, primarily the construction industry, including ready-mix concrete producers, precast concrete manufacturers, and on-site contractors, integrate these superplasticizers into their concrete mixes to achieve desired workability, strength, and durability.

The efficiency and effectiveness of this value chain heavily rely on strong collaborations between each stage, ensuring a steady supply of quality raw materials, optimized production of monomers, innovative formulation of admixtures, and efficient distribution to the diverse end-user base. Understanding the intricacies of this value chain is crucial for identifying areas of cost optimization, enhancing supply chain resilience, and fostering innovation, particularly in developing more sustainable and high-performance solutions. Challenges often arise from raw material price fluctuations upstream and the need for strong technical support and precise dosage recommendations downstream to ensure optimal product performance at the construction site, highlighting the importance of integrated value chain management and robust technical services.

Polycarboxylate Superplasticizer Monomers Market Potential Customers

The Polycarboxylate Superplasticizer Monomers market primarily targets entities within the construction chemicals and broader construction industry, serving as crucial suppliers for producers of concrete admixtures. The immediate and most significant potential customers are manufacturers of polycarboxylate ether (PCE) superplasticizers, who purchase these monomers as essential raw materials for their proprietary formulations. These admixture producers, in turn, serve a vast array of end-users in the construction sector. Specifically, ready-mix concrete plants represent a major customer segment, relying on PCE superplasticizers to produce high-flow, high-strength concrete that meets stringent project specifications and delivery timelines. The demand for enhanced workability and extended slump retention in ready-mix concrete makes them consistent and high-volume purchasers of superplasticizer-based admixtures.

Another key customer group includes manufacturers of precast concrete elements, such as beams, columns, pipes, and panels. For these producers, superplasticizers facilitate easier pouring into molds, ensure excellent surface finishes, and enable faster demolding times, thereby improving productivity and aesthetic quality. The self-compacting concrete (SCC) market also represents a vital customer segment, as SCC heavily relies on PCE superplasticizers to achieve its unique properties of high flowability without segregation or external vibration. Beyond these, dry mix mortar manufacturers, who produce tile adhesives, renders, and grouts, are increasingly incorporating PCEs to enhance workability, adhesion, and overall performance of their products, expanding the customer base further.

Furthermore, large construction companies and project developers involved in major infrastructure projects (e.g., bridges, tunnels, highways, dams) and commercial buildings (e.g., high-rise buildings, shopping malls) are indirect but highly influential potential customers. While they directly purchase finished concrete or admixtures, their specifications and demands for high-performance, durable, and sustainable concrete directly drive the requirements for advanced polycarboxylate superplasticizers, and consequently, the underlying monomers. The drive towards sustainable construction and the need for long-lasting, resilient structures in seismic zones or harsh environments continually reinforce the importance of these advanced admixtures, positioning these end-users as perpetual customers for the entire value chain.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 2.85 Billion |

| Market Forecast in 2033 | USD 5.20 Billion |

| Growth Rate | 9.2% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | BASF SE, Arkema S.A., Nippon Shokubai Co., Ltd., Kao Corporation, W. R. Grace & Co., Sika AG, Mapei S.p.A., Chongqing Yuanchuang New Material Technology Co., Ltd., Huangshan KBR Chemical Co., Ltd., Shanghai Taihe Chem. Co., Ltd., Chemkos Co., Ltd., KZJ New Materials, Jiangsu Sobute New Materials Co., Ltd., Denka Company Limited, Fosroc International, Dow Inc., CEMEX S.A.B. de C.V., HeidelbergCement AG, Saint-Gobain S.A., Aditya Birla Chemicals |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Polycarboxylate Superplasticizer Monomers Market Key Technology Landscape

The Polycarboxylate Superplasticizer Monomers market is underpinned by a sophisticated technological landscape, continuously evolving to meet the demands for higher performance, greater efficiency, and enhanced sustainability in concrete admixtures. The core technological processes revolve around the controlled polymerization of various ether-based precursors to synthesize specific macromonomers such as HPEG, APEG, TPEG, and MPEG. Key advancements in this area include precision polymerization techniques, such as living polymerization and controlled radical polymerization methods, which allow for the precise control over molecular weight distribution, polymer architecture, and the placement of side chains. This molecular engineering is critical for tailoring the final superplasticizer's performance characteristics, such as specific water reduction rates, slump retention profiles, and compatibility with diverse cement types and aggregate compositions. Manufacturers are also focusing on optimizing reaction conditions, including temperature, pressure, and catalyst selection, to improve yield, reduce reaction times, and minimize energy consumption.

Further technological innovations involve the development of novel initiator systems and co-monomers to create monomers with unique functionalities. For instance, research into incorporating different functional groups allows for improved dispersion mechanisms or enhanced interaction with cement particles, leading to superior concrete properties. The industry is also exploring solvent-free polymerization processes or using greener solvents to reduce environmental impact and improve occupational safety during monomer production. There is a growing emphasis on process intensification technologies, such as microreactors and continuous flow processes, to achieve higher throughput, better control, and increased safety compared to traditional batch processes. These technological advancements not only drive the performance of the monomers themselves but also significantly impact the efficiency and environmental footprint of the entire polycarboxylate superplasticizer manufacturing ecosystem, enabling formulators to create more advanced and versatile admixtures for the construction sector.

Moreover, the application of computational chemistry and machine learning algorithms is emerging as a critical technological frontier. These tools enable in-silico screening of potential monomer structures, predicting their polymerization behavior and the performance of derived superplasticizers even before laboratory synthesis. This significantly accelerates the research and development cycle, reducing the time and cost associated with new product innovation. Technologies for advanced characterization, such as gel permeation chromatography (GPC) for molecular weight distribution, nuclear magnetic resonance (NMR) for structural elucidation, and rheological studies for performance evaluation, are continuously refined to ensure the consistent quality and performance of the monomers. The convergence of chemical engineering, materials science, and digital technologies is shaping a highly advanced and responsive technological landscape within the polycarboxylate superplasticizer monomers market, pushing the boundaries of what is achievable in concrete technology and sustainable construction practices.

Regional Highlights

- Asia Pacific (APAC): Dominates the market due to massive infrastructure projects, rapid urbanization, and significant growth in the construction sector across countries like China, India, and Southeast Asian nations. High demand for high-performance concrete drives consumption.

- Europe: A mature market characterized by stringent environmental regulations, a strong focus on sustainable construction, and advanced building technologies. Innovation in green chemistry and specialized concrete applications fuels steady growth.

- North America: Exhibits stable growth driven by renovation of aging infrastructure, commercial and residential construction, and a strong emphasis on high-quality and durable concrete solutions. Technological advancements and environmental compliance are key factors.

- Latin America: An emerging market with increasing investment in infrastructure and housing projects, particularly in Brazil, Mexico, and Argentina. Economic development and urbanization are primary growth catalysts, despite some political and economic volatilities.

- Middle East and Africa (MEA): Demonstrates significant growth potential, especially in the Gulf Cooperation Council (GCC) countries due to mega-projects in preparation for global events, diversification efforts, and substantial investments in real estate and infrastructure development across the region.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Polycarboxylate Superplasticizer Monomers Market.- BASF SE

- Arkema S.A.

- Nippon Shokubai Co., Ltd.

- Kao Corporation

- W. R. Grace & Co.

- Sika AG

- Mapei S.p.A.

- Chongqing Yuanchuang New Material Technology Co., Ltd.

- Huangshan KBR Chemical Co., Ltd.

- Shanghai Taihe Chem. Co., Ltd.

- Chemkos Co., Ltd.

- KZJ New Materials

- Jiangsu Sobute New Materials Co., Ltd.

- Denka Company Limited

- Fosroc International

- Dow Inc.

- CEMEX S.A.B. de C.V.

- HeidelbergCement AG

- Saint-Gobain S.A.

- Aditya Birla Chemicals

Frequently Asked Questions

What is a Polycarboxylate Superplasticizer Monomer?

A Polycarboxylate Superplasticizer Monomer is a key chemical building block, typically an ether-based macromonomer like HPEG or APEG, used to synthesize polycarboxylate ether (PCE) superplasticizers, which are high-performance concrete admixtures enhancing workability and strength.

What are the primary applications of Polycarboxylate Superplasticizer Monomers?

These monomers are primarily used in the production of superplasticizers for high-performance concrete, including ready-mix concrete, precast concrete, self-compacting concrete (SCC), ultra-high-performance concrete (UHPC), and dry mix mortars, serving the residential, commercial, and infrastructure construction sectors.

Which factors are driving the growth of the Polycarboxylate Superplasticizer Monomers market?

Market growth is driven by accelerating global urbanization, extensive infrastructure development projects, increasing demand for high-performance and durable concrete, and stringent environmental regulations promoting sustainable construction practices and efficient water reduction in concrete mixes.

What are the key challenges facing the Polycarboxylate Superplasticizer Monomers market?

Key challenges include the volatility of raw material prices (e.g., ethylene oxide, acrylic acid), stringent environmental and health regulations concerning chemical production, and the need for continuous innovation to develop specialized monomers compatible with diverse cement types and demanding application conditions.

How is AI impacting the Polycarboxylate Superplasticizer Monomers market?

AI is impacting the market by optimizing monomer synthesis, accelerating R&D for novel formulations, enhancing supply chain management and quality control, and providing predictive analytics for admixture formulation, ultimately leading to more efficient, consistent, and sustainable production and application.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager