Polyglycidyl Ether Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 441268 | Date : Feb, 2026 | Pages : 249 | Region : Global | Publisher : MRU

Polyglycidyl Ether Market Size

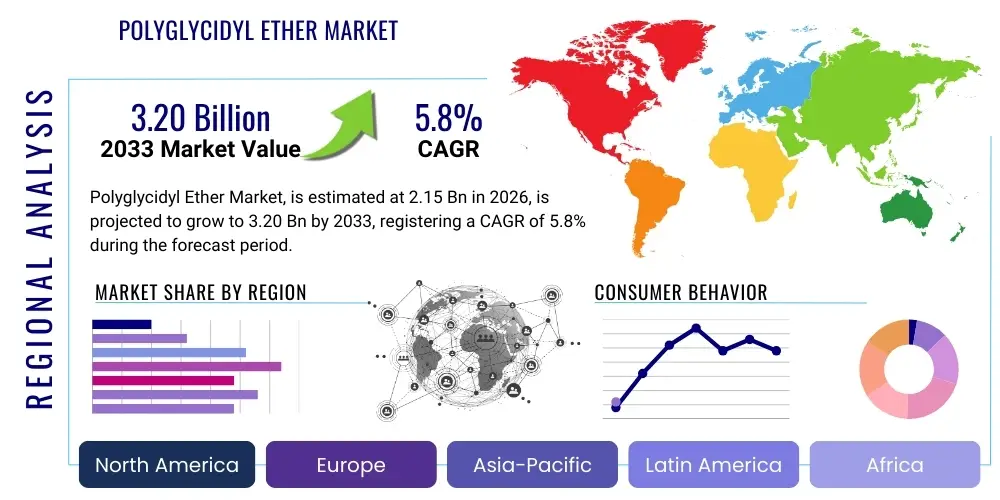

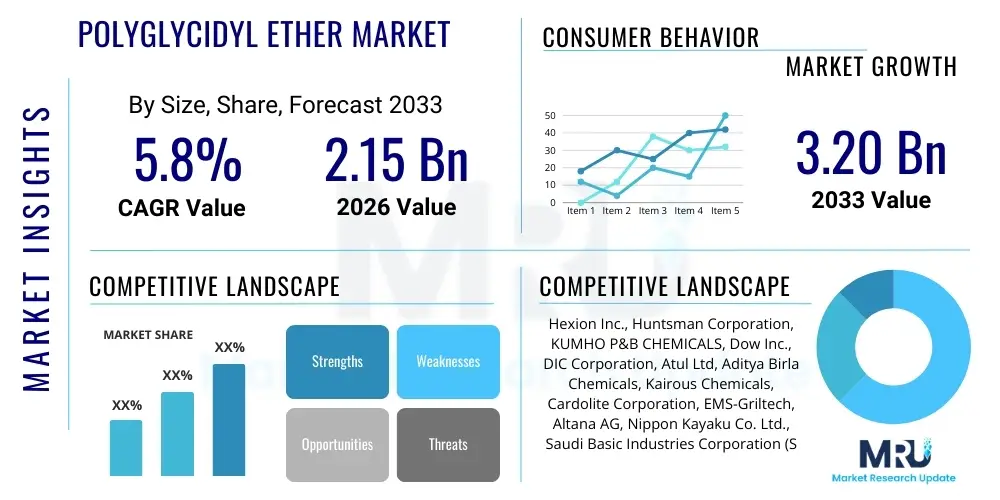

The Polyglycidyl Ether Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 2.15 Billion in 2026 and is projected to reach USD 3.20 Billion by the end of the forecast period in 2033.

Polyglycidyl Ether Market introduction

The Polyglycidyl Ether (PGE) market encompasses various organic compounds characterized by the presence of multiple glycidyl ether groups, which are highly reactive functional moieties. These compounds are predominantly utilized as reactive diluents, viscosity reducers, and performance modifiers in epoxy resin systems. PGEs significantly lower the viscosity of epoxy formulations without compromising the cross-linking density or the final mechanical and chemical resistance properties of the cured product, which is crucial for high-solids and solvent-free coatings, casting, and potting applications. Key product types, such as Butyl Glycidyl Ether (BGE), Cresol Glycidyl Ether (CGE), and Neopentyl Glycol Diglycidyl Ether (NPGDGE), offer specialized characteristics tailored for specific industrial requirements, ranging from thermal stability to flexibility.

Major applications of Polyglycidyl Ethers span industrial protective coatings, where they enhance durability against harsh chemicals and weather, and the electronics sector, used in encapsulation and insulation materials requiring superior dielectric properties and high glass transition temperatures. Furthermore, PGEs find extensive use in composite materials for aerospace and automotive industries, providing lightweight strength and structural integrity. The inherent benefits of PGEs, including their ability to improve wetting characteristics, reduce volatile organic compound (VOC) emissions by minimizing the need for solvent addition, and facilitate easier processing of high-viscosity resins, make them indispensable components in modern high-performance material science. Their adoption is particularly strong in sectors transitioning towards environmentally friendly, solvent-free solutions.

The primary driving factors propelling the growth of this market include the global expansion of the construction industry, particularly in emerging economies, demanding high-quality flooring and protective coatings. Additionally, the increasing focus on advanced manufacturing techniques in the electronics and automotive sectors necessitates materials offering enhanced thermal, electrical, and mechanical resilience. Regulatory pressures encouraging the reduction of VOCs in coatings and adhesives further favor the use of PGEs as effective reactive diluents. The continuous innovation in specialty PGEs designed for demanding applications, such as high-temperature composites, also contributes significantly to market expansion, ensuring sustained demand across diverse industrial landscapes.

Polyglycidyl Ether Market Executive Summary

The Polyglycidyl Ether (PGE) market demonstrates robust business trends characterized by a significant shift toward specialty, low-VOC formulations, driven by stringent environmental regulations in North America and Europe. Manufacturers are focusing on backward integration to secure raw material supply (epichlorohydrin and various alcohols/phenols) and enhance cost efficiency. A critical trend involves the development of bio-based or renewable source PGEs, addressing sustainability concerns and appealing to green material specifications in the construction and consumer goods sectors. Mergers and acquisitions remain a key strategy for market players to expand their technological portfolios and geographic presence, particularly targeting high-growth regions in Asia Pacific, which represent the largest consumer base due to rapid industrialization and infrastructure development.

Regionally, Asia Pacific maintains market dominance, fueled by massive infrastructure investments in China and India, coupled with the rapid growth of the automotive and electronics manufacturing bases in Southeast Asia. Europe and North America exhibit mature markets, with growth primarily concentrated in high-value, high-performance segments such as aerospace and advanced protective coatings, often driven by strict performance standards and regulatory compliance regarding emissions. Segmentation analysis reveals that the coating segment holds the largest market share, directly linked to construction and general industrial maintenance activities. However, the electronics and electrical encapsulation segment is projected to register the fastest growth, underpinned by the global proliferation of electric vehicles (EVs) and 5G communication infrastructure, both requiring high-reliability insulation materials utilizing multi-functional PGEs.

Segment trends indicate a growing preference for multi-functional PGEs, such as those derived from cycloaliphatic structures, over standard mono-functional types like BGE, due to their ability to impart superior thermal stability and higher cross-linking density, crucial for demanding applications. While epoxy-based coatings maintain their leadership, the utilization of PGEs in composite manufacturing is rapidly expanding, particularly in filament winding and pultrusion processes where viscosity reduction without material compromise is paramount. Pricing remains a sensitive factor, influenced significantly by the volatility of raw material costs (e.g., crude oil derivatives); however, the premium pricing achieved by specialty, low-toxicity PGEs ensures healthy profit margins for focused market participants. Strategic partnerships between PGE producers and major end-use compounders are becoming vital for co-developing customized resin systems that meet highly specialized performance criteria.

AI Impact Analysis on Polyglycidyl Ether Market

User queries regarding the impact of Artificial Intelligence (AI) on the Polyglycidyl Ether market often revolve around optimization of synthesis processes, predictive maintenance in manufacturing plants, and AI-driven material discovery for enhanced performance. Key themes highlight concerns about how AI can accelerate the development of novel, low-toxicity PGE structures, potentially replacing incumbent products, and how machine learning algorithms can optimize curing profiles and formulation ratios in complex epoxy systems, thereby improving efficiency and reducing waste in end-use applications like advanced composites and high-specification coatings. Furthermore, users frequently question the ability of AI to analyze vast datasets concerning raw material sourcing and logistics, aiming to mitigate price volatility and supply chain risks inherent in the petrochemical industry, which directly affects PGE production costs. Expectations are centered on AI enabling faster time-to-market for specialized PGE variants and ensuring consistent quality control in large-scale polymerization processes.

- AI optimizes reaction parameters in PGE synthesis, improving yield and purity while reducing energy consumption.

- Machine learning algorithms predict and model the performance characteristics (e.g., viscosity, glass transition temperature) of new PGE formulations before extensive physical testing.

- Predictive maintenance driven by AI minimizes downtime in PGE production facilities, enhancing operational efficiency and asset lifespan.

- AI analyzes global supply chain data to forecast raw material pricing (epichlorohydrin, glycols) and identify potential sourcing bottlenecks, informing procurement strategies.

- Generative design tools, powered by AI, assist in the molecular design of specialty PGEs with tailored properties for niche applications like high-performance thermal interfaces.

- AI-enabled quality control systems utilize image recognition and sensor data to ensure stringent consistency in PGE batches, critical for aerospace and electronics applications.

DRO & Impact Forces Of Polyglycidyl Ether Market

The Polyglycidyl Ether (PGE) market is significantly influenced by a dynamic interplay of Drivers, Restraints, and Opportunities, collectively forming the Impact Forces shaping its trajectory. The primary driver is the accelerating demand for high-performance coatings and adhesives, particularly those requiring low Volatile Organic Compound (VOC) content, a gap that reactive diluents like PGEs efficiently fill by lowering viscosity without requiring excessive solvents. Furthermore, the expansion of the electronics sector, driven by 5G technology and electric vehicle battery encapsulation, necessitates superior dielectric and thermal management properties provided by advanced PGEs, offering strong impetus for market growth. However, growth is restrained by the volatile pricing and supply chain instability of key raw materials, primarily epichlorohydrin, which is derived from petroleum sources, making production costs susceptible to global crude oil market fluctuations. Additionally, regulatory scrutiny regarding the handling and potential toxicity of certain traditional PGE derivatives imposes limitations, pushing R&D towards safer, specialized alternatives.

Opportunities within the market center on the development and commercialization of bio-based Polyglycidyl Ethers, utilizing renewable feedstocks, which addresses both sustainability mandates and consumer preference for green chemistry solutions. Significant potential also lies in the expansion of PGE use in advanced composite manufacturing for industries like wind energy and infrastructure repair, where lightweight, durable materials are essential. The impact forces indicate a competitive environment where innovation in product chemistry, focusing on multi-functional and low-toxicity variants, will be critical for sustained success. Regulatory shifts, such as stricter global REACH standards and similar initiatives, act as a dual impact force, restraining older chemical technologies while simultaneously driving innovation and providing an opportunity for manufacturers with advanced, compliant product lines to capture greater market share.

The market impact forces are highly sensitive to global economic indicators, particularly construction spending and automotive production rates. A downturn in global manufacturing capacity or a slowdown in infrastructure projects can immediately dampen demand for industrial coatings and adhesives, the largest consumer segment. Conversely, technological breakthroughs in curing agents or resin technology that enhance the utility of PGEs can rapidly accelerate adoption. Geopolitical stability and trade policies also significantly impact cross-border supply chains for both raw materials and finished PGE products, requiring manufacturers to maintain diversified production and distribution networks to mitigate operational risks and maintain competitive pricing strategies across key regions.

Segmentation Analysis

The Polyglycidyl Ether market is broadly segmented based on product type, application, and end-use industry, reflecting the diverse requirements and performance demands across various industrial sectors. Segmentation by product type distinguishes between mono-functional, bi-functional, and multi-functional PGEs, with multi-functional types gaining traction due to their ability to impart superior cross-linking density and thermal stability critical for advanced engineering applications. The application segment primarily focuses on the use of PGEs as reactive diluents, plasticizers, and modifiers, with reactive diluents dominating the volumetric consumption. End-use industry segmentation provides insight into the major consumer bases, including coatings, adhesives, electronics, and composite materials, each exhibiting distinct growth characteristics influenced by macro-economic factors and specialized technological advancements within that sector.

- By Product Type:

- Butyl Glycidyl Ether (BGE)

- Cresol Glycidyl Ether (CGE)

- Alkyl Glycidyl Ether

- Neopentyl Glycol Diglycidyl Ether (NPGDGE)

- Other Polyglycidyl Ethers (including specialized multi-functional types)

- By Application:

- Reactive Diluents

- Plasticizers and Stabilizers

- Cross-linking Agents and Modifiers

- By End-Use Industry:

- Coatings (Industrial, Protective, Marine, Automotive)

- Adhesives and Sealants

- Electronics and Electrical Encapsulation

- Composite Materials (Aerospace, Wind Energy, Automotive Composites)

- Paints and Inks

- By Region:

- North America

- Europe

- Asia Pacific (APAC)

- Latin America (LATAM)

- Middle East and Africa (MEA)

Value Chain Analysis For Polyglycidyl Ether Market

The Polyglycidyl Ether value chain commences with the upstream analysis, involving the sourcing and refining of critical petrochemical raw materials. Key precursors include epichlorohydrin (EPI), which is often derived from propylene or glycerol, and various alcohols or phenols (such as butanol, cresol, or neopentyl glycol) that react with EPI. The volatility of crude oil prices and the limited number of large-scale EPI producers significantly dictate the input costs for PGE manufacturers. Efficient process technologies, such as continuous synthesis and solvent recovery systems, are essential at this stage to maintain competitive pricing and high purity levels, as quality variations in precursors directly impact the performance characteristics of the final PGE products used as high-specification reactive diluents.

Moving downstream, the intermediate stage involves the manufacturing and formulation of the PGEs themselves, followed by distribution. Manufacturers invest heavily in specialized production facilities capable of handling the exothermic nature of the glycidylization reaction and ensuring compliance with stringent safety and environmental regulations. The distribution channel is bifurcated into direct sales to large, strategic end-users (e.g., major epoxy resin manufacturers or Tier 1 automotive suppliers) and indirect sales through specialized chemical distributors and regional agents who manage inventory, small batch orders, and provide technical support to SME formulators. The efficiency of the logistics network is paramount, especially for hazardous materials, requiring specialized storage and transportation solutions to minimize lead times and maintain product integrity across diverse geographic regions.

The final stage encompasses the utilization of PGEs by end-users, predominantly compounders, formulators, and finished product manufacturers in key industries such as construction, automotive, and electronics. The demand side is driven by technical specifications; end-users require PGEs to meet specific viscosity targets, curing rates, and final product performance standards (e.g., impact resistance or dielectric strength). Technical service and application support are critical value additions provided by PGE suppliers, assisting customers in optimizing formulations. This segment of the chain is increasingly focused on developing highly customized solutions, where direct interaction between the PGE manufacturer and the formulator facilitates the creation of specialty, high-margin products tailored to unique application challenges, ensuring maximum value capture throughout the chain.

Polyglycidyl Ether Market Potential Customers

The primary potential customers for Polyglycidyl Ethers are major chemical manufacturers and formulators specializing in epoxy resin systems and related products, spanning multiple industrial verticals. These buyers seek PGEs as essential functional additives to manipulate the rheology of their formulations. For instance, large industrial coatings manufacturers require PGEs (like NPGDGE or BGE) to lower the viscosity of high-solids paints, enabling spray application while ensuring compliance with stringent VOC regulations. These customers prioritize bulk supply stability, consistent product quality, and competitive pricing, often entering into long-term supply agreements with PGE producers to secure their continuous production schedules for products used in infrastructure and protective maintenance.

Another significant customer segment includes companies in the electronics and electrical insulation sector, such as those manufacturing printed circuit boards (PCBs), electrical potting compounds, and components for transformers and capacitors. These buyers demand highly specialized, often multi-functional, PGEs that offer superior thermal stability, excellent dielectric properties, and low ionic contamination. The buying decision in this segment is heavily driven by performance specifications and certifications (e.g., UL ratings, high glass transition temperature requirements) rather than solely cost, making this a high-value, high-specification segment for PGE suppliers focusing on purity and advanced chemistry. The proliferation of electric vehicle battery packs, which require robust encapsulation materials, is rapidly expanding this customer base.

Furthermore, aerospace and high-performance composite manufacturers represent crucial, albeit smaller volume, potential customers. These companies utilize PGEs in the formulation of matrices for fiber-reinforced composites (carbon fiber or glass fiber) used in aircraft structures, wind turbine blades, and sporting goods. For these applications, PGEs must provide optimal wetting of the fibers and allow for precise infusion processes, requiring ultra-low viscosity and reliable performance under extreme mechanical and thermal stress. Purchasing criteria in the composites sector emphasize traceability, adherence to strict quality control standards, and the ability to customize PGE formulations to meet exacting curing cycles and structural integrity requirements, demonstrating a strong inclination towards specialty PGE product offerings.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 2.15 Billion |

| Market Forecast in 2033 | USD 3.20 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Hexion Inc., Huntsman Corporation, KUMHO P&B CHEMICALS, Dow Inc., DIC Corporation, Atul Ltd, Aditya Birla Chemicals, Kairous Chemicals, Cardolite Corporation, EMS-Griltech, Altana AG, Nippon Kayaku Co. Ltd., Saudi Basic Industries Corporation (SABIC), Gabriel Performance Products, Olin Corporation, Jiangsu Yangnong Chemical Group Co., Ltd., Shanghai Resin Factory Co., Ltd., Kolon Industries Inc., Mitsui Chemicals, Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Polyglycidyl Ether Market Key Technology Landscape

The technology landscape for the Polyglycidyl Ether market is defined by continuous process optimization and the development of specialized chemistries aimed at enhancing performance and sustainability. Traditional synthesis involves the reaction of alcohols or phenols with epichlorohydrin under alkaline conditions, often resulting in complex purification challenges and wastewater generation. Current technological efforts are heavily focused on refining the glycidylization process, utilizing advanced catalysts and continuous flow reactors to increase reaction selectivity, minimize side product formation, and improve energy efficiency. The implementation of solvent-free processes or those utilizing greener solvents is a critical technological trend, directly aligning with global chemical regulatory trends demanding cleaner manufacturing operations and lower environmental footprints from bulk chemical production.

A significant technological advancement involves the development of bio-based routes for producing key PGE precursors, such as using bio-glycerol instead of petroleum-derived propylene for epichlorohydrin synthesis, leading to bio-EPI and subsequently bio-PGEs. This sustainable chemistry approach allows manufacturers to meet the growing market demand for renewable materials, particularly in the European and North American coatings markets. Furthermore, innovation in multi-functional PGE chemistry is paramount, focusing on incorporating complex molecular architectures, such as dendritic or highly branched structures, to impart unique performance characteristics like ultra-low viscosity combined with high reactivity, critical for filament winding and infusion processes in advanced composite fabrication.

Moreover, digitalization and automation play a crucial role in modern PGE manufacturing technology. Advanced sensor technology, coupled with real-time analytics and Supervisory Control and Data Acquisition (SCADA) systems, enables precise monitoring and control of reaction kinetics, temperature profiles, and purity during the synthesis stage. This enhances batch-to-batch consistency—a non-negotiable requirement for high-reliability end-uses like aerospace and medical device adhesives. Research into novel, non-traditional catalysts is also ongoing, aiming to lower the overall reaction temperature and pressure, thereby reducing operational expenditure and increasing the safety profile of PGE manufacturing facilities worldwide.

Regional Highlights

The global Polyglycidyl Ether market exhibits distinct regional dynamics, primarily driven by varying industrial growth rates, construction activities, and regulatory environments concerning VOC emissions. Asia Pacific (APAC) stands as the dominant and fastest-growing region, accounting for the largest market share due to unparalleled infrastructure development, robust electronics manufacturing bases (especially in South Korea, Taiwan, and China), and thriving automotive and consumer goods sectors. The high demand for industrial protective coatings and electrical encapsulation materials in countries like China and India underpins the sustained double-digit growth projected for this region, making it the focal point for capacity expansion by global PGE producers.

North America and Europe represent mature markets characterized by slower volume growth but significant emphasis on high-specification, specialized PGE variants. Regulatory pressures, notably REACH in Europe and stringent environmental standards in the US, mandate the adoption of low-VOC, high-solids epoxy systems, thus driving the demand for high-performance reactive diluents. The growth in these regions is heavily concentrated in sophisticated applications such as aerospace coatings, wind energy component manufacturing, and specialized industrial maintenance coatings, where end-product performance and compliance with health and safety standards command premium pricing.

Latin America (LATAM) and the Middle East and Africa (MEA) are emerging markets for PGEs. LATAM's growth is spurred by recovering construction sectors and burgeoning automotive production, particularly in Brazil and Mexico. The MEA region, notably the GCC countries, sees steady demand driven by extensive oil and gas infrastructure projects and large-scale residential and commercial construction, requiring high-durability protective and marine coatings that utilize significant quantities of PGEs to withstand harsh environmental conditions. While smaller in scale, these regions present key opportunities for market penetration as their industrial bases mature and regulatory frameworks evolve.

- Asia Pacific (APAC): Dominates the global market share; rapid industrialization, high infrastructure spending, and massive electronics manufacturing capacity in China and India drive exceptional demand for coatings and encapsulants.

- Europe: Focuses on high-value, specialty PGEs; strict environmental regulations necessitate low-VOC formulations, boosting demand in aerospace and wind energy composites.

- North America: Mature market characterized by steady growth in specialized applications, particularly high-performance adhesives for automotive lightweighting and electronics encapsulation.

- Middle East and Africa (MEA): Growth centered on protective coatings for petrochemical facilities, marine applications, and large-scale urban development projects requiring durable materials.

- Latin America (LATAM): Market expansion driven by revitalization in the construction sector and localized growth of the transportation and industrial maintenance coating industries.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Polyglycidyl Ether Market.- Hexion Inc.

- Huntsman Corporation

- KUMHO P&B CHEMICALS

- Dow Inc.

- DIC Corporation

- Atul Ltd

- Aditya Birla Chemicals

- Kairous Chemicals

- Cardolite Corporation

- EMS-Griltech

- Altana AG

- Nippon Kayaku Co. Ltd.

- Saudi Basic Industries Corporation (SABIC)

- Gabriel Performance Products

- Olin Corporation

- Jiangsu Yangnong Chemical Group Co., Ltd.

- Shanghai Resin Factory Co., Ltd.

- Kolon Industries Inc.

- Mitsui Chemicals, Inc.

Frequently Asked Questions

Analyze common user questions about the Polyglycidyl Ether market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are Polyglycidyl Ethers (PGEs) and their primary function in epoxy systems?

Polyglycidyl Ethers are chemical compounds featuring multiple reactive glycidyl groups, primarily used as reactive diluents in epoxy resin formulations. Their main function is to significantly lower the viscosity of highly viscous epoxy resins, facilitating easier processing and application (such as spraying or infusion) without sacrificing the mechanical strength or cross-linking density of the final cured material.

Which application segment drives the highest demand for Polyglycidyl Ethers globally?

The coatings segment is the dominant application driver for PGEs. PGEs are essential in industrial, protective, and marine coatings, enabling the formulation of high-solids, low-VOC systems. Rapid infrastructure expansion and maintenance requirements in regions like Asia Pacific significantly contribute to the sustained high demand from this sector.

How do Polyglycidyl Ethers contribute to achieving low-VOC targets?

PGEs act as reactive diluents, meaning they chemically incorporate into the cured resin matrix rather than evaporating like traditional organic solvents. By effectively lowering viscosity without relying on solvents, PGEs enable formulators to meet strict environmental regulations and high-solids specifications mandated for low Volatile Organic Compound (VOC) compliance in coatings and adhesives.

What is the market outlook for bio-based Polyglycidyl Ethers?

The market outlook for bio-based PGEs is highly positive. Driven by corporate sustainability mandates and favorable regulatory environments, particularly in Europe, there is increasing commercial interest in PGEs derived from renewable feedstocks, such as bio-glycerol-based epichlorohydrin. This niche segment offers high growth opportunities as industries seek to reduce their carbon footprint.

What regulatory challenges influence the Polyglycidyl Ether market?

Regulatory challenges primarily stem from the classification and scrutiny of certain PGE types regarding potential sensitization or toxicity (e.g., specific mono-functional PGEs). Global regulations like REACH necessitate comprehensive testing and registration, compelling manufacturers to innovate by developing safer, non-sensitizing, multi-functional PGE alternatives to ensure market compliance and accessibility across mature economies.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager