Polysiloxane Resin Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440729 | Date : Feb, 2026 | Pages : 257 | Region : Global | Publisher : MRU

Polysiloxane Resin Market Size

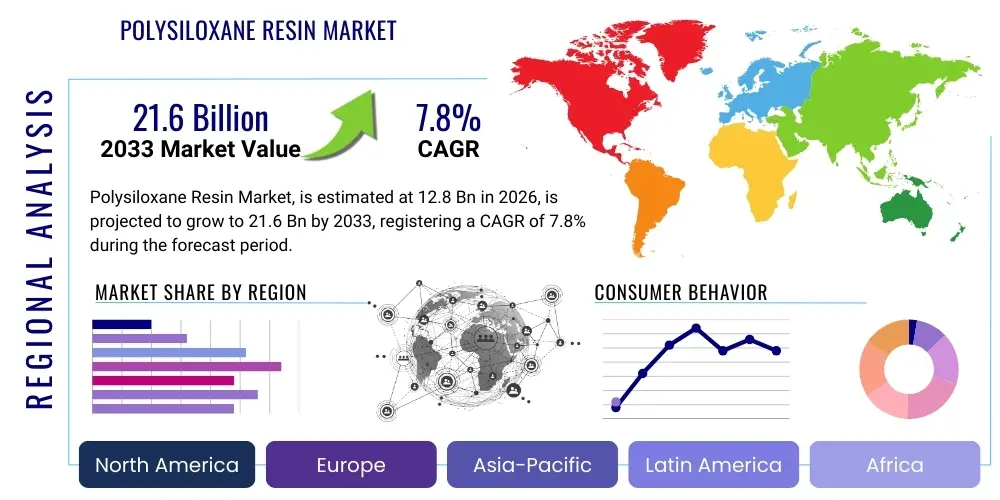

The Polysiloxane Resin Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.8% between 2026 and 2033. The market is estimated at USD 12.8 Billion in 2026 and is projected to reach USD 21.6 Billion by the end of the forecast period in 2033. This robust growth is primarily driven by the increasing demand for high-performance materials across diverse industrial applications, particularly in sectors requiring superior thermal stability, chemical resistance, and electrical insulation properties. The continued expansion of the electronics, automotive, and construction industries globally underpins this positive market trajectory.

Polysiloxane Resin Market introduction

Polysiloxane resins, commonly known as silicone resins, represent a versatile class of thermosetting polymers characterized by their unique inorganic silicon-oxygen (Si-O-Si) backbone combined with organic functional groups attached to the silicon atoms. This distinctive chemical structure bestows polysiloxane resins with an exceptional combination of properties, including outstanding thermal stability, superior oxidative resistance, excellent electrical insulation capabilities, high resistance to UV radiation and weathering, and inherent hydrophobicity. These attributes make them indispensable materials in a wide array of demanding applications where conventional organic polymers fall short.

The primary applications of polysiloxane resins span across numerous high-value industries. They are extensively utilized in high-performance coatings, where they provide enhanced durability, corrosion protection, and aesthetic appeal for industrial, architectural, and marine environments. In the electronics sector, they serve as crucial encapsulants, sealants, and dielectric materials, protecting sensitive components from moisture, vibration, and thermal stress. Furthermore, polysiloxane resins find significant use in adhesives and sealants, offering strong bonding and sealing capabilities under extreme conditions, as well as in the automotive and aerospace industries for lightweighting solutions, thermal management, and robust component protection.

The market for polysiloxane resins is fundamentally driven by several critical factors. The ever-growing demand for durable, high-temperature resistant, and chemically inert materials in advanced manufacturing processes is a primary catalyst. Technological advancements in resin synthesis and formulation, leading to enhanced performance characteristics and application versatility, further stimulate market expansion. Additionally, the increasing focus on energy efficiency and lightweight materials in the automotive and aerospace sectors, coupled with the relentless innovation within the electronics industry, consistently propels the adoption of polysiloxane resins, solidifying their position as a high-performance material of choice.

Polysiloxane Resin Market Executive Summary

The Polysiloxane Resin Market is experiencing dynamic shifts, characterized by evolving business trends, significant regional variations, and distinct segment-specific growth patterns. Key business trends indicate a strong emphasis on product innovation, with manufacturers investing heavily in research and development to create advanced formulations offering improved sustainability, enhanced functionality, and tailored performance for niche applications. There is a growing consolidation trend among major players, alongside strategic partnerships aimed at expanding geographical reach and technological capabilities. Furthermore, the market is witnessing an increased focus on supply chain resilience and raw material sourcing optimization due to global economic fluctuations and geopolitical considerations, pushing companies towards more localized production and diversified supply networks.

From a regional perspective, Asia Pacific remains the dominant and fastest-growing market for polysiloxane resins, propelled by rapid industrialization, burgeoning electronics manufacturing, and extensive infrastructure development in countries like China, India, Japan, and South Korea. North America and Europe, while mature, continue to exhibit stable growth, driven by stringent regulatory frameworks promoting high-performance and environmentally compliant materials, alongside robust demand from the automotive, aerospace, and medical sectors. Latin America and the Middle East & Africa regions are emerging as promising markets, characterized by increasing foreign investments in manufacturing and construction, creating new avenues for market penetration and expansion for polysiloxane resin producers.

Segmentation trends highlight particular areas of robust growth within the polysiloxane resin market. The demand for liquid polysiloxane resins is particularly strong, owing to their ease of processing and versatility in diverse applications such as coatings and electronics encapsulation. Application-wise, high-performance coatings and adhesives & sealants segments are experiencing significant momentum, driven by advancements in automotive lightweighting, protective coatings for industrial infrastructure, and durable sealants for building and construction. The electrical and electronics end-use industry segment also continues to expand rapidly, fueled by the proliferation of consumer electronics, electric vehicles, and advanced semiconductor manufacturing, all of which rely heavily on the insulating and protective properties of polysiloxane resins.

AI Impact Analysis on Polysiloxane Resin Market

The integration of Artificial Intelligence (AI) and Machine Learning (ML) is poised to significantly transform various facets of the polysiloxane resin market, addressing common user questions related to efficiency, innovation, and sustainability. Users frequently inquire about how AI can accelerate new product development, optimize manufacturing processes, enhance quality control, and predict market trends. Concerns also revolve around the potential for AI to mitigate raw material price volatility and improve supply chain transparency and resilience. The overarching expectation is that AI will drive greater operational efficiency, foster innovation in material science, and enable data-driven decision-making across the entire value chain, from synthesis to end-application, ultimately leading to more customized and high-performance polysiloxane resin solutions.

- AI-driven predictive analytics optimizes resin formulation, reducing R&D cycles and material waste.

- Machine learning algorithms enhance quality control by identifying anomalies in production batches, ensuring product consistency.

- AI-powered supply chain management improves raw material procurement, inventory optimization, and logistics efficiency.

- Generative AI tools accelerate the discovery of novel polysiloxane structures with superior properties.

- Predictive maintenance schedules for manufacturing equipment are optimized by AI, minimizing downtime and operational costs.

- AI analyzes market demand and application trends, guiding strategic product development and market entry decisions.

- Computational chemistry and AI simulations facilitate the design of sustainable and environmentally friendly polysiloxane derivatives.

DRO & Impact Forces Of Polysiloxane Resin Market

The Polysiloxane Resin Market is shaped by a confluence of driving factors, restrictive elements, and emerging opportunities, all subjected to various impact forces. The primary drivers include the escalating demand for high-performance materials across sectors such as electronics, automotive, aerospace, and construction, where superior thermal stability, chemical resistance, and electrical insulation are paramount. Rapid industrialization and urbanization in developing economies, coupled with significant technological advancements in material science and increasing investments in renewable energy infrastructure requiring durable protective coatings, further propel market expansion. The continuous evolution of manufacturing processes demanding more resilient and lightweight materials also acts as a strong catalyst for adoption.

However, the market faces notable restraints that could temper its growth trajectory. High production costs associated with the synthesis of polysiloxane resins, coupled with the volatility of raw material prices, particularly silicon metal and methanol, pose significant challenges to manufacturers. Stringent environmental regulations concerning volatile organic compounds (VOCs) and hazardous air pollutants (HAPs) in certain formulations necessitate costly R&D efforts for compliance, which can impede market growth. Furthermore, intense competition from conventional organic polymers in less demanding applications, along with the complexity of processing certain advanced polysiloxane resin formulations, represents additional barriers to widespread adoption.

Despite these challenges, significant opportunities are emerging within the polysiloxane resin market. The increasing focus on sustainable and eco-friendly material solutions drives innovation in bio-based polysiloxanes and solvent-free formulations. The expansion into niche applications such as medical devices, 3D printing, and advanced textile coatings presents untapped growth potential. Moreover, the burgeoning electric vehicle (EV) market and advancements in smart electronics require specialized high-performance encapsulants and protective coatings, creating substantial avenues for market penetration. These opportunities, however, are influenced by impact forces such as global economic stability, geopolitical shifts affecting supply chains, technological breakthroughs, and evolving regulatory landscapes, all of which collectively dictate the market's future direction and growth potential.

Segmentation Analysis

The polysiloxane resin market is comprehensively segmented to provide granular insights into its diverse applications, material compositions, and end-use industries. This segmentation allows for a detailed understanding of market dynamics, growth drivers, and specific opportunities within each category, reflecting the complex and multifaceted nature of polysiloxane resin utilization. Analysis by type, application, and end-use industry helps stakeholders identify key growth areas and tailor their strategies to capitalize on emerging trends across the global market landscape, offering a structured view of market demand and supply dynamics.

- By Type

- Liquid Polysiloxane Resins

- Solid Polysiloxane Resins

- Gel Polysiloxane Resins

- Powder Polysiloxane Resins

- Paste Polysiloxane Resins

- By Application

- Coatings (High-temperature, Protective, Weather-resistant)

- Adhesives & Sealants (Construction, Automotive, Industrial)

- Electronics Encapsulants & Dielectrics

- Composites (Aerospace, Automotive)

- Healthcare & Medical Devices (Implants, Device Coatings)

- Automotive & Aerospace Components

- Construction Materials (Waterproofing, Protective Layers)

- Textile Treatment

- Personal Care Products

- Industrial Molds & Release Agents

- Other Specialty Applications

- By End-Use Industry

- Electrical & Electronics

- Automotive (EVs, Conventional Vehicles)

- Building & Construction

- Aerospace & Defense

- Medical & Healthcare

- Industrial Manufacturing

- Consumer Goods

- Renewable Energy

- Other Industries

Value Chain Analysis For Polysiloxane Resin Market

The value chain for the polysiloxane resin market is a complex network of interconnected stages, beginning with the sourcing of raw materials and extending through various manufacturing processes, distribution channels, and ultimately to the diverse end-use applications. Upstream analysis involves the procurement of fundamental chemical precursors such as silicon metal, methyl chloride, and various catalysts. Key raw material suppliers, often large chemical companies, play a crucial role in providing these basic building blocks, which are then processed through complex chemical reactions to synthesize various intermediates and ultimately, polysiloxane resins. The quality and cost of these raw materials significantly influence the final product’s performance and market competitiveness, necessitating strong supplier relationships and strategic sourcing to mitigate supply chain risks.

Moving downstream, the value chain encompasses the synthesis of polysiloxane resins by specialized chemical manufacturers, who then supply these resins to various formulators and compounders. These formulators often incorporate additional additives, fillers, and pigments to create application-specific products like paints, adhesives, sealants, encapsulants, and coatings. This stage is critical for customizing resins to meet the precise performance requirements of different end-use industries. The integration of advanced research and development capabilities at this stage is essential for developing innovative solutions that cater to evolving market demands, such as high-temperature resistance, flexibility, or specific dielectric properties required for cutting-edge electronics or aerospace applications.

The distribution of polysiloxane resins and their derived products occurs through both direct and indirect channels. Direct sales are common for large-volume industrial customers or highly specialized applications where technical support and custom formulations are required. This approach allows manufacturers to maintain close relationships with key clients and ensure product customization and after-sales service. Indirect distribution channels involve a network of distributors, agents, and resellers who cater to smaller businesses or a wider geographical reach. These intermediaries often provide warehousing, logistics, and localized technical support, bridging the gap between manufacturers and diverse end-users across different regions. Effective management of these distribution networks is vital for ensuring efficient market penetration and timely delivery of products.

Polysiloxane Resin Market Potential Customers

The potential customer base for polysiloxane resins is incredibly broad and diverse, spanning numerous industries that require materials with exceptional performance characteristics under demanding conditions. End-users and buyers of polysiloxane resins are typically large industrial enterprises, specialized manufacturers, and formulators who integrate these resins into their final products or processes. This includes automotive original equipment manufacturers (OEMs) and their suppliers, who utilize polysiloxanes for lightweight components, engine sealants, protective coatings, and increasingly, for electric vehicle battery encapsulation and thermal management solutions. The relentless pursuit of efficiency, durability, and safety in automotive design makes these resins invaluable for next-generation vehicles.

Another significant segment of potential customers includes electronics manufacturers, ranging from semiconductor producers to consumer electronics giants. These companies employ polysiloxane resins as encapsulants, conformal coatings, and dielectric materials to protect sensitive electronic components from moisture, heat, vibration, and environmental contaminants. The miniaturization of devices and the increasing complexity of electronic circuits demand highly reliable and durable protection, a need perfectly addressed by the unique properties of polysiloxane resins. Furthermore, the burgeoning demand for high-performance computing and advanced communication systems continually drives innovation and adoption in this sector.

Beyond automotive and electronics, the building and construction industry represents a substantial customer segment, using polysiloxane resins in high-performance coatings, sealants, and waterproofing membranes for architectural structures, infrastructure projects, and protective barriers. Aerospace and defense companies are also key buyers, leveraging these resins for high-temperature applications, sealants, and lightweight composite structures in aircraft and spacecraft due to their superior thermal stability and resistance to extreme environments. Additionally, the medical and healthcare sector utilizes polysiloxanes for biocompatible coatings on devices, prosthetic components, and in various sterile applications, highlighting the versatility and critical importance of these advanced materials across a wide spectrum of industrial and specialized markets.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 12.8 Billion |

| Market Forecast in 2033 | USD 21.6 Billion |

| Growth Rate | 7.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Dow, Wacker Chemie AG, Shin-Etsu Chemical Co., Ltd., Elkem ASA, Momentive Performance Materials Inc., Evonik Industries AG, KCC Corporation, Zhejiang Xinan Chemical Industrial Group Co., Ltd., Gelest Inc., Guangzhou Tinci Materials Technology Co., Ltd., Wynca Group, China National BlueStar (Group) Co., Ltd., CHT Group, BRB International BV, Iota Silicone Oil (Anhui) Co., Ltd., Jiangsu Hongda New Material Co., Ltd., Shandong Dayi Chemical Co., Ltd., Kaneka Corporation, ACC Silicones, Specialty Silicone Products Inc. (SSP) |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Polysiloxane Resin Market Key Technology Landscape

The technology landscape for the polysiloxane resin market is characterized by continuous innovation aimed at enhancing material performance, improving synthesis efficiency, and developing sustainable solutions. Core manufacturing technologies include various polymerization techniques such as condensation polymerization, which involves the removal of small molecules like water or alcohol, and hydrolysis of chlorosilanes. These traditional methods are continuously being refined to yield resins with precise molecular weights, improved purity, and tailored functionality. Advancements in these foundational processes are crucial for producing the high-quality intermediates necessary for sophisticated polysiloxane resin formulations, enabling better control over the final product's physical and chemical properties, such as viscosity, curing time, and thermal resistance.

Beyond traditional synthesis, the market is witnessing significant technological developments in functionalization and modification of polysiloxane resins. Hydrosilylation, a process involving the addition of Si-H bonds across carbon-carbon double bonds, is gaining prominence for introducing diverse organic groups onto the polysiloxane backbone, thereby imparting specific properties like increased adhesion, improved solvent resistance, or enhanced UV stability. Emulsion polymerization techniques are also evolving to produce polysiloxane dispersions that are environmentally friendly and suitable for water-based coating applications, reducing the reliance on volatile organic solvents. The ongoing research into hybrid organic-inorganic polymers, which combine polysiloxane segments with other polymer chains, represents a frontier in material science, promising novel materials with synergistic properties.

Furthermore, nanotechnology and advanced processing techniques are becoming integral to the polysiloxane resin market. The incorporation of nanoparticles and other inorganic fillers through sol-gel processes or in-situ polymerization is leading to the development of polysiloxane nanocomposites with dramatically improved mechanical strength, barrier properties, and thermal conductivity. Advanced computational modeling and simulation tools are increasingly employed to predict material behavior and optimize resin designs, accelerating the R&D cycle. The focus is also on developing smart polysiloxane materials that can respond to external stimuli, such as temperature or pH, opening up new possibilities in sensors, actuators, and self-healing materials. These technological advancements collectively drive the creation of next-generation polysiloxane resins that meet the increasingly stringent demands of high-tech industries.

Regional Highlights

- North America: This region demonstrates a mature but steadily growing market, driven by robust demand from the aerospace, automotive (especially electric vehicles), and advanced electronics industries. The presence of key manufacturers and strong R&D infrastructure supports innovation in high-performance and specialized polysiloxane resin applications. Strict environmental regulations also encourage the adoption of advanced, eco-friendly formulations.

- Europe: Characterized by a strong emphasis on sustainability and stringent regulatory frameworks, Europe continues to be a significant market. Demand is robust in the automotive, construction, and industrial coatings sectors, with a growing focus on energy efficiency and lightweight materials. Germany, France, and the UK are leading countries, leveraging technological advancements and a well-established manufacturing base.

- Asia Pacific (APAC): The APAC region stands as the largest and fastest-growing market for polysiloxane resins, propelled by rapid industrialization, urbanization, and a booming manufacturing sector. Countries like China, India, Japan, and South Korea are experiencing substantial growth in electronics production, automotive manufacturing, and infrastructure development, driving immense demand for polysiloxane resins across numerous applications.

- Latin America: This region represents an emerging market with significant growth potential, driven by increasing foreign investment in manufacturing and infrastructure projects. While smaller compared to other regions, countries like Brazil and Mexico are witnessing expanding industrial bases, leading to a gradual but consistent increase in the adoption of polysiloxane resins, particularly in construction and automotive sectors.

- Middle East and Africa (MEA): The MEA region is expected to show moderate growth, primarily fueled by ongoing infrastructure development projects, diversification efforts away from oil dependence, and increasing investments in the manufacturing sector. The demand for high-performance coatings and sealants in construction and industrial applications is a key driver in this region.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Polysiloxane Resin Market.- Dow

- Wacker Chemie AG

- Shin-Etsu Chemical Co., Ltd.

- Elkem ASA

- Momentive Performance Materials Inc.

- Evonik Industries AG

- KCC Corporation

- Zhejiang Xinan Chemical Industrial Group Co., Ltd.

- Gelest Inc.

- Guangzhou Tinci Materials Technology Co., Ltd.

- Wynca Group

- China National BlueStar (Group) Co., Ltd.

- CHT Group

- BRB International BV

- Iota Silicone Oil (Anhui) Co., Ltd.

- Jiangsu Hongda New Material Co., Ltd.

- Shandong Dayi Chemical Co., Ltd.

- Kaneka Corporation

- ACC Silicones

- Specialty Silicone Products Inc. (SSP)

Frequently Asked Questions

Analyze common user questions about the Polysiloxane Resin market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the projected growth rate of the Polysiloxane Resin Market?

The Polysiloxane Resin Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.8% between 2026 and 2033, driven by increasing demand for high-performance materials in electronics, automotive, and construction sectors.

Which applications primarily drive the demand for polysiloxane resins?

Demand is primarily driven by high-performance coatings, adhesives & sealants, electronics encapsulants, and applications in automotive (especially EVs) and aerospace, due to their superior thermal stability and chemical resistance.

What are the key challenges faced by the polysiloxane resin market?

Key challenges include high production costs, volatility in raw material prices (silicon metal), and stringent environmental regulations regarding VOCs, which necessitate significant R&D investments for compliance.

Which geographical region holds the largest market share for polysiloxane resins?

Asia Pacific (APAC) currently holds the largest market share and is also the fastest-growing region, fueled by rapid industrialization, burgeoning electronics manufacturing, and extensive infrastructure development across its major economies.

How is AI impacting the Polysiloxane Resin Market?

AI is impacting the market by optimizing resin formulation, enhancing quality control through predictive analytics, streamlining supply chain management, and accelerating the discovery of novel material properties, leading to greater efficiency and innovation.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager