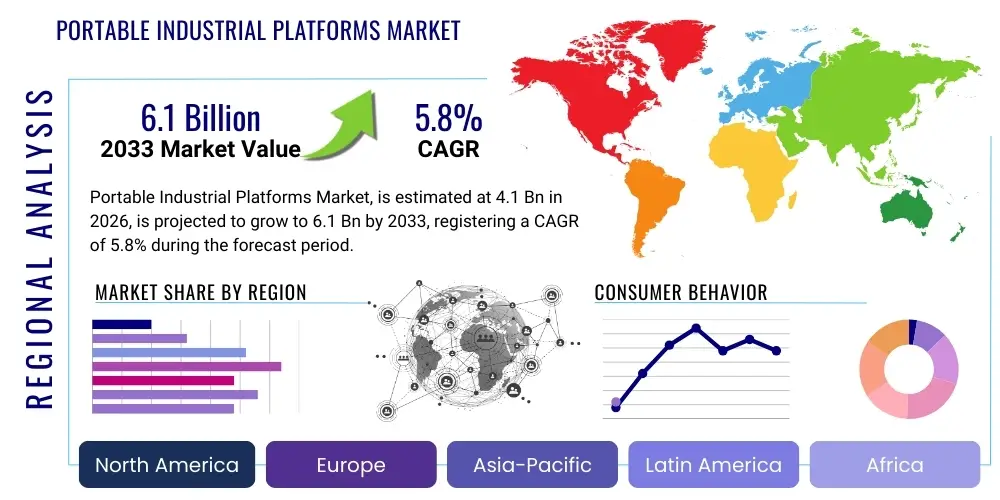

Portable Industrial Platforms Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 443221 | Date : Feb, 2026 | Pages : 257 | Region : Global | Publisher : MRU

Portable Industrial Platforms Market Size

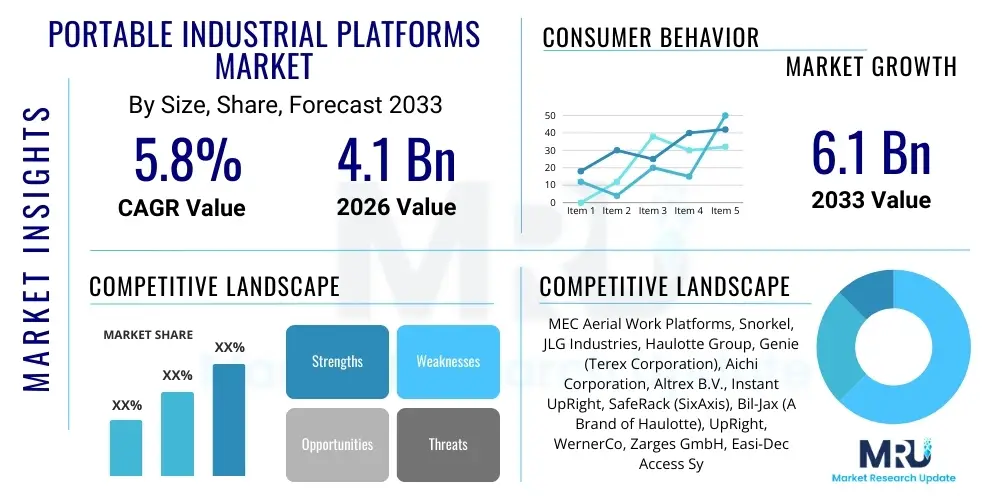

The Portable Industrial Platforms Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 4.1 Billion in 2026 and is projected to reach USD 6.1 Billion by the end of the forecast period in 2033.

Portable Industrial Platforms Market introduction

The Portable Industrial Platforms Market encompasses a diverse range of temporary, modular, and mobile access solutions designed to provide safe, elevated, and stable working surfaces in various industrial, construction, maintenance, and utility environments. These platforms, distinct from fixed scaffolding or permanent structures, offer flexibility, rapid deployment, and enhanced worker safety, making them indispensable for tasks requiring non-permanent access, such as inspections, repairs, assembly, and warehousing operations. The market serves sectors demanding high standards of operational efficiency and stringent adherence to occupational safety regulations, particularly in complex or remote locations where traditional fixed structures are impractical or too time-consuming to install. Key product types include modular staging, mobile access towers, telescoping platforms, and lightweight aluminum work decks, all engineered for load-bearing capacity and portability across different terrains.

Major applications for portable industrial platforms span critical infrastructure maintenance, including aerospace manufacturing and MRO (Maintenance, Repair, and Overhaul), shipbuilding, oil and gas processing facilities, power generation plants, and large-scale commercial construction projects. The core benefit derived from utilizing these systems is the significant improvement in worker productivity coupled with a substantial reduction in fall-related accidents, aligning with global industry shifts toward safety-first operational protocols. Furthermore, the modular nature of these platforms allows for customization to specific geometrical constraints, enhancing their utility in confined spaces or around complex machinery and pipework. This adaptability drives continuous demand, especially in fast-paced industrial settings where downtime minimization is paramount.

Driving factors stimulating market expansion include escalating global investment in infrastructure development and retrofitting older industrial assets, which necessitate temporary high-access solutions. Concurrently, increasingly rigorous international safety standards, mandated by bodies such as OSHA and ISO, pressure industrial operators to adopt certified and ergonomically sound access equipment, favoring sophisticated portable platforms over makeshift solutions. Technological advancements, such as the use of high-strength, lightweight composite materials and integrated sensor technology for platform stability monitoring, are further enhancing product appeal, ensuring higher load capacities with easier mobility. This confluence of regulatory push and technological innovation solidifies the market’s positive trajectory throughout the forecast period.

Portable Industrial Platforms Market Executive Summary

The Portable Industrial Platforms market is characterized by robust business trends centered on the demand for enhanced safety features and operational flexibility. Key market players are increasingly investing in automation features, such as self-leveling mechanisms and remote-controlled deployment systems, to minimize manual handling and reduce setup time. There is a discernible shift towards lightweight materials, particularly high-grade aluminum and engineered composites, to improve platform portability without compromising structural integrity or load-bearing limits. Furthermore, strategic mergers and acquisitions, along with strong emphasis on rental models versus outright purchase, define the competitive landscape, catering to the cyclical nature of industrial projects and capital expenditure constraints faced by end-users. Customization and modularity remain critical differentiators, enabling manufacturers to address highly specific industrial access challenges, ranging from wind turbine maintenance to specialized aviation docking requirements.

Regionally, the market exhibits strong growth momentum across established industrial hubs like North America and Europe, driven by stringent regulatory frameworks and significant expenditure on aging infrastructure modernization. However, the Asia Pacific (APAC) region is emerging as the fastest-growing market segment, fueled by rapid industrialization, large-scale infrastructure projects (e.g., factory expansions, new airport construction), and increasing adoption of Western safety standards in manufacturing and construction sectors. Latin America and the Middle East & Africa (MEA) present substantial opportunities, primarily driven by investments in the oil and gas sector and burgeoning utility development, though market growth here is often dependent on stabilizing geopolitical and economic conditions, influencing capital deployment for industrial equipment acquisition.

Segmentation trends highlight the dominance of the self-propelled and mobile access platform segment, offering unparalleled flexibility and vertical reach, particularly in warehousing and logistics where vertical stacking optimization is crucial. Based on material, the aluminum segment continues to command a significant market share due to its lightweight properties and corrosion resistance, essential for outdoor and maritime applications. The construction and infrastructure sector remains the primary end-user segment, although specialized sectors such as aerospace and defense are exhibiting above-average growth rates, demanding platforms integrated with specific features for precision maintenance and assembly tasks. Overall, the market's evolution is heavily influenced by the interplay between regulatory compliance, technological material science advancements, and the global push for operational safety improvements across heavy industries.

AI Impact Analysis on Portable Industrial Platforms Market

User inquiries regarding the impact of Artificial Intelligence (AI) on the Portable Industrial Platforms Market predominantly focus on how AI enhances safety protocols, optimizes operational logistics, and facilitates predictive maintenance of the equipment itself. Common questions revolve around the integration of AI-powered sensor data for real-time stability monitoring, autonomous navigation capabilities for self-propelled platforms, and the use of machine learning algorithms to schedule platform usage and maintenance based on project demand and wear analysis. Users are keenly interested in understanding if AI can virtually eliminate human error during platform setup and operation, and how AI-driven simulation tools can optimize platform design for complex access scenarios. This focus indicates that the primary expectation for AI in this domain is centered on leveraging data analytics and automation to elevate safety standards and drastically improve asset utilization rates, moving beyond mere mechanical operation toward intelligent industrial access solutions.

The immediate impact of AI is visible in augmenting existing platform capabilities through advanced IoT integration. Machine learning models analyze vast datasets generated by sensors monitoring wind speed, tilt angles, load distribution, and ground stability conditions, providing operators with actionable insights or triggering immediate safety shutdowns autonomously. This capability transforms the platform from a static piece of equipment into an intelligent, responsive system, drastically mitigating the risk of structural failure or operator error in hazardous conditions. Furthermore, AI algorithms are being applied to fleet management systems, optimizing the deployment and relocation of platforms across large industrial sites, ensuring the right type of platform is available at the precise time and location needed, thus maximizing resource efficiency and minimizing project delays associated with equipment availability.

Looking ahead, Generative AI and advanced computer vision are poised to revolutionize the design phase. AI can rapidly prototype specialized platform configurations based on 3D scans of the worksite, significantly cutting down on engineering time for custom solutions. For training and certification, AI-powered virtual reality (VR) simulations offer immersive, risk-free environments for operators to practice emergency procedures and standard operational tasks, ensuring a higher level of proficiency before accessing real-world platforms. This technological convergence promises not only safer industrial access but also a substantial reduction in operational expenditures through predictive maintenance scheduling, identifying component fatigue long before it leads to catastrophic failure or unplanned downtime.

- AI-Enhanced Predictive Maintenance: Machine learning models analyze vibration and strain data to forecast component wear, optimizing maintenance cycles and reducing unexpected equipment failures.

- Real-Time Stability Monitoring: Integrated AI processes sensor inputs (e.g., gyroscopes, load cells) to continuously assess platform stability and instantaneously alert operators or initiate corrective actions in high-risk scenarios.

- Autonomous Fleet Management: AI algorithms optimize the logistical allocation, tracking, and scheduling of rental and owned platforms across complex industrial landscapes to maximize utilization.

- Computer Vision for Safety Compliance: Cameras integrated with AI detect worker compliance with safety harnesses and required Personal Protective Equipment (PPE) on the platform, triggering alarms for non-compliance.

- Optimized Platform Design: Generative AI tools assist engineers in rapidly designing customized, complex platform geometries for specific industrial environments, improving ergonomic efficiency and fit.

- Augmented Operator Guidance: AI provides real-time, data-driven operational feedback to platform users, improving operational efficiency and reducing human error during setup and use.

DRO & Impact Forces Of Portable Industrial Platforms Market

The Portable Industrial Platforms Market is strongly influenced by a robust set of Drivers, counterbalanced by inherent Restraints, while significant Opportunities shape its long-term growth trajectory, all encapsulated by distinct Impact Forces. A primary driver is the accelerating stringency of global occupational safety regulations, compelling industries to phase out outdated or non-compliant access methods in favor of certified, modern portable platforms. Concurrently, increasing infrastructure investment, particularly in maintenance and refurbishment activities across power, chemical, and transportation sectors, fuels consistent demand for flexible and safe temporary access solutions. Technological advancements in material science (lighter, stronger alloys) and mechatronics (automated leveling and safety features) further enhance platform utility and appeal, making complex tasks more accessible and efficient for workers.

However, the market faces significant restraints, including the high initial capital expenditure associated with purchasing sophisticated, certified portable platforms, which can be prohibitive for smaller contractors or businesses in developing economies. Furthermore, the variability and cyclical nature of industrial construction and maintenance projects often lead to unpredictable demand, favoring rental models over outright sales, which can impact manufacturers' revenue stability. Supply chain volatility, particularly concerning specialized raw materials and electronic components necessary for advanced platforms, poses logistical challenges and can contribute to inflationary pricing pressures, potentially slowing adoption rates in sensitive sectors.

Opportunities for market expansion are vast, primarily centered on untapped potential in emerging economies where rapid industrialization is currently outpacing the establishment of comprehensive safety standards, presenting a massive future market for compliant equipment. The increasing demand for specialized platforms tailored for niche applications, such as high-altitude wind turbine blade maintenance or cleanroom environments in pharmaceuticals, offers premium market segments. Moreover, the integration of advanced telematics, IoT, and AI into platforms not only enhances safety but also enables manufacturers to offer value-added services like predictive maintenance contracts and operational analytics, diversifying revenue streams beyond hardware sales. These forces collectively dictate market dynamics, pushing innovation toward safer, lighter, and more intelligently operated access solutions.

Segmentation Analysis

The Portable Industrial Platforms Market is segmented based on critical attributes including platform type, material composition, load capacity, and diverse end-user applications, providing a granular view of market demands and technological preferences across various industrial sectors. This detailed segmentation allows manufacturers to tailor product development and marketing strategies to meet specific operational requirements, ranging from the need for ultra-lightweight, quickly assembled units in telecommunications to heavy-duty, high-reach platforms required in shipbuilding. The differentiation based on material, particularly between robust steel and corrosion-resistant aluminum, often determines suitability for specific environments, such as offshore oil rigs versus controlled indoor manufacturing settings. Analysis of these segments is crucial for understanding current market shares and forecasting future growth trajectories driven by evolving regulatory and industry-specific needs globally.

The segmentation by platform type—encompassing categories such as modular access systems, mobile scissor lifts, and telescopic booms—reflects the variety of vertical and horizontal reach capabilities demanded by different tasks. Modular systems are favored for adaptability in complex geometries, while mobile lifts provide verticality and ease of relocation. Load capacity segmentation is essential for safety compliance, ensuring that platforms can safely support specified weights, including personnel, tools, and materials, which is a major regulatory concern in heavy engineering and construction. The end-user analysis provides insights into sectoral demand, highlighting the varying requirements of industrial maintenance, logistics, utilities, and construction, each requiring platforms with distinct performance characteristics, durability, and safety certifications tailored to their unique operational hazards and environments.

- By Platform Type:

- Modular Access Systems (Staging, Scaffolding Alternatives)

- Mobile Scissor Lifts (Self-Propelled, Push-Around)

- Telescopic Boom Platforms

- Articulated Boom Platforms

- Vehicle-Mounted Platforms

- Specialized Industrial Work Platforms (e.g., Aviation Docking)

- By Material:

- Aluminum Platforms

- Steel Platforms

- Fiberglass/Composite Platforms

- By Load Capacity:

- Light Duty (< 500 lbs)

- Medium Duty (500 lbs – 1500 lbs)

- Heavy Duty (> 1500 lbs)

- By End-User Industry:

- Construction and Infrastructure

- Industrial Maintenance and Repair (MRO)

- Aerospace and Defense

- Oil and Gas (Upstream, Midstream, Downstream)

- Utility and Power Generation

- Logistics and Warehousing

- Chemical and Pharmaceuticals

Value Chain Analysis For Portable Industrial Platforms Market

The value chain for the Portable Industrial Platforms Market begins with the Upstream activities centered on the procurement and processing of fundamental raw materials, primarily high-grade steel, aluminum alloys, and specialized composite materials, along with sophisticated electronic components for control systems, sensors, and hydraulic mechanisms. Key upstream suppliers include metallurgical processing plants and electronics manufacturers, whose pricing stability and technological advancements directly influence the final product cost and performance specifications. Rigorous quality control and adherence to material strength standards are crucial at this initial stage to ensure the safety and longevity of the final platform product. Relationships between platform manufacturers and raw material providers are often long-term, focusing on securing specialized, certified materials that meet stringent industrial safety criteria.

The subsequent phase involves Core Manufacturing and Assembly, where platform components are fabricated, welded, and assembled, followed by the integration of mechanical, hydraulic, and electrical systems. This stage includes intensive R&D to incorporate new features like automated stabilization, self-leveling technologies, and advanced safety interlocks, which represent significant value addition. Certification and compliance testing (e.g., ANSI, CE, OSHA standards) are mandatory steps here, ensuring the marketability and legal use of the equipment globally. Downstream activities encompass the distribution, rental, sales, and comprehensive post-sale service network. Given the high cost and specialized nature of these platforms, the rental sector plays a disproportionately large role in the downstream value chain, providing necessary equipment accessibility without demanding high capital outlay from end-users.

Distribution channels are multifaceted, utilizing both Direct and Indirect routes. Direct sales are often preferred for highly customized or large-scale purchases, involving manufacturer representatives who provide detailed technical consultations and training to large industrial clients like energy companies or aviation MRO facilities. Indirect channels rely heavily on specialized industrial equipment dealers and extensive rental companies (e.g., United Rentals, H&E Equipment Services) that possess broad regional reach, maintenance capabilities, and established relationships with various construction and industrial contractors. The aftermarket segment, including parts supply, repairs, and mandatory annual inspections and certifications, constitutes a significant and high-margin component of the overall value chain, ensuring the sustained operational safety and compliance of the installed base of platforms.

Portable Industrial Platforms Market Potential Customers

The primary end-users, or potential customers, of the Portable Industrial Platforms Market are organizations engaged in activities requiring temporary, safe, and elevated access to structures, machinery, or infrastructure assets. These buyers prioritize safety compliance, operational efficiency, and the total cost of ownership (TCO) over the lifespan of the equipment. Major customers include large General Contractors (GCs) involved in commercial, residential, and industrial construction projects who require flexible access solutions for erecting structures and finishing work. Similarly, maintenance, repair, and overhaul (MRO) divisions within various heavy industries—such as petrochemical plants, power generation facilities, and specialized manufacturing (e.g., automotive assembly lines)—represent consistent demand, needing platforms for routine inspection and unexpected repairs without long-term commitment.

A significant customer base exists within the utility and infrastructure sectors, including companies managing telecommunications towers, electrical transmission grids, water treatment facilities, and bridge maintenance operations. These buyers often require specialized platforms capable of navigating rough terrain or operating safely near high-voltage environments, demanding non-conductive materials like fiberglass. The aerospace and defense sector represents a high-value, niche customer segment, purchasing bespoke docking systems and highly engineered platforms for precise assembly and detailed maintenance of aircraft and military vehicles, prioritizing zero-tolerance safety standards and custom dimensions. These customers frequently employ rigorous procurement processes, emphasizing certified safety ratings, structural durability, and extensive manufacturer support and training programs.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 4.1 Billion |

| Market Forecast in 2033 | USD 6.1 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | MEC Aerial Work Platforms, Snorkel, JLG Industries, Haulotte Group, Genie (Terex Corporation), Aichi Corporation, Altrex B.V., Instant UpRight, SafeRack (SixAxis), Bil-Jax (A Brand of Haulotte), UpRight, WernerCo, Zarges GmbH, Easi-Dec Access Systems, Sky High Access Platforms, Hydro Mobile, Faraone Industrie S.p.A., Waco Scaffolding & Equipment, Little Giant Ladder Systems, Guardian Fall Protection. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Portable Industrial Platforms Market Key Technology Landscape

The Portable Industrial Platforms market is defined by several converging technological advancements aimed at maximizing safety, increasing operational efficiency, and enhancing portability. Central to the current landscape is the widespread adoption of advanced materials, moving towards lighter, yet structurally superior, materials such as high-tensile steel alloys and sophisticated aluminum blends. This material engineering focus is crucial for reducing the platform’s overall weight, thereby simplifying transportation, deployment, and conforming to reduced ground pressure limits often required on specific job sites. Furthermore, the use of corrosion-resistant coatings and treatments is essential, extending the service life of platforms used in harsh environments like coastal areas, chemical processing plants, and offshore marine operations. Innovations in modular design, utilizing quick-lock connections and standardized component sizes, significantly reduce assembly time and complexity, promoting rapid deployment across varying industrial settings.

The integration of sensor technology, categorized broadly under the Internet of Things (IoT), represents a transformative shift in platform intelligence and safety management. Modern platforms are equipped with sophisticated load sensing technology, tilt sensors, wind speed monitors, and proximity sensors that feed real-time data back to the control unit. These systems are designed to enforce operational limits autonomously, preventing catastrophic failures caused by overloading, uneven terrain, or high winds. Advanced hydraulic and electronic controls enable self-leveling capabilities, ensuring the platform remains horizontal even when deployed on gradients, greatly improving worker safety and comfort. Telematics systems are becoming standard, enabling fleet managers to remotely track platform location, usage hours, fuel consumption, and operational status, which is vital for optimizing utilization rates and scheduling proactive maintenance interventions.

Looking forward, the technology landscape is being shaped by digitalization and augmented reality (AR) applications. AR is being deployed to assist assembly workers and inspectors, overlaying digital instructions or safety checklists onto the physical platform, reducing the likelihood of human error during setup and inspection phases. Additionally, battery technology improvements (e.g., high-density lithium-ion batteries) are extending the operational range and duty cycles of electric-powered mobile platforms, making them increasingly viable alternatives to combustion engine models, particularly for indoor or emission-controlled environments. These technological imperatives underscore the industry’s commitment to providing access solutions that are not only compliant with regulations but are also intelligently managed and seamlessly integrated into broader industrial operational frameworks, ensuring maximum safety and return on investment for end-users.

Regional Highlights

- North America: North America represents a mature and highly regulated market, dominated by stringent occupational safety standards enforced by organizations like OSHA and ANSI. Market growth is primarily driven by replacement demand for aging equipment, substantial infrastructure modernization projects (roads, bridges, utilities), and continuous investment in the aerospace and automotive sectors. The high adoption rate of advanced, technologically integrated platforms (IoT-enabled, self-leveling) reflects the region's strong focus on minimizing liability and maximizing operational efficiency. The rental market is particularly robust here, offering a high degree of flexibility to contractors and maintenance firms, favoring manufacturers who maintain extensive service and parts networks.

- Europe: Europe is characterized by equally demanding safety and environmental regulations (e.g., CE marking and Euro Stage V emission standards for mobile machinery). Western European nations exhibit stable, innovation-driven demand, focusing heavily on ergonomically superior and electrically powered platforms to meet sustainability goals and reduce noise pollution in urban construction sites. Eastern Europe, conversely, is experiencing faster growth driven by ongoing industrial expansion and significant investments into modernizing aging Soviet-era infrastructure. Germany, the UK, and France remain key regional markets, prioritizing advanced manufacturing and industrial maintenance sectors that demand specialized access solutions.

- Asia Pacific (APAC): APAC is the fastest-growing region globally, fueled by rapid urbanization, massive infrastructure development, and exponential growth in manufacturing capacity across countries like China, India, and Southeast Asian nations. Although regulatory compliance historically lagged behind Western standards, increasing global integration and the presence of multinational corporations are rapidly elevating safety expectations, driving demand for certified portable platforms. Price sensitivity remains a factor; however, the sheer volume of construction and industrial projects, combined with the need for high-reach access in high-rise construction, ensures robust market expansion. Investment in local manufacturing and assembly capabilities is increasing across the region.

- Latin America (LATAM): The LATAM market growth is closely tied to commodity prices, particularly in resource-rich countries like Brazil, Mexico, and Chile. Demand is predominantly driven by the energy sector (oil and gas exploration and refining) and mining operations, requiring heavy-duty, rugged platforms capable of operating in challenging, remote environments. Economic instability and currency fluctuations often restrict outright purchasing, leading to a strong reliance on equipment rental services. Improving safety legislation across key nations is providing a fundamental floor for market demand, gradually pushing out non-compliant equipment.

- Middle East and Africa (MEA): The MEA region is experiencing significant market growth, largely concentrated around the Gulf Cooperation Council (GCC) states due to ambitious mega-projects in infrastructure, tourism, and renewable energy (solar and wind farms). Demand is high for platforms that can withstand extreme heat and sand ingress, necessitating specialized sealed components and robust cooling systems. The oil and gas industry remains a dominant end-user. The African market, while smaller, is focused primarily on utility development and mining, exhibiting high growth potential as industrialization efforts gain traction, albeit hampered by logistical challenges and varying regulatory environments.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Portable Industrial Platforms Market.- MEC Aerial Work Platforms

- Snorkel

- JLG Industries

- Haulotte Group

- Genie (Terex Corporation)

- Aichi Corporation

- Altrex B.V.

- Instant UpRight

- SafeRack (SixAxis)

- Bil-Jax (A Brand of Haulotte)

- UpRight

- WernerCo

- Zarges GmbH

- Easi-Dec Access Systems

- Sky High Access Platforms

- Hydro Mobile

- Faraone Industrie S.p.A.

- Waco Scaffolding & Equipment

- Little Giant Ladder Systems

- Guardian Fall Protection

- Manitou Group

- Teupen Maschinenbau GmbH

- Niftylift Ltd.

- LGMG (Lingong Group Jinan Heavy Industry Co., Ltd.)

Frequently Asked Questions

Analyze common user questions about the Portable Industrial Platforms market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the projected CAGR for the Portable Industrial Platforms Market between 2026 and 2033?

The Portable Industrial Platforms Market is projected to exhibit a Compound Annual Growth Rate (CAGR) of 5.8% during the forecast period from 2026 to 2033, driven by increasing safety mandates and infrastructure spending globally.

Which factors are primarily driving the demand for advanced portable industrial platforms?

Primary drivers include increasingly stringent occupational safety regulations (e.g., OSHA, CE), significant global investment in infrastructure maintenance and construction, and technological advancements focusing on lightweight materials and integrated IoT safety features.

How is AI impacting the operational safety of portable industrial platforms?

AI integration is enhancing operational safety through real-time stability monitoring, predictive maintenance forecasting of crucial components, and autonomous safety shutdowns triggered by sensor data detecting hazardous operating conditions, significantly reducing human error.

What is the leading end-user segment for portable industrial platforms?

The leading end-user segment is the Construction and Infrastructure sector, driven by the persistent need for temporary, flexible, and safe elevated access solutions required for erecting and maintaining commercial, industrial, and civil structures.

Why is the Asia Pacific (APAC) region anticipated to be the fastest-growing market?

APAC's rapid growth is attributed to aggressive industrialization, large-scale urbanization projects, and increasing acceptance and implementation of international safety standards across major economies like China and India, stimulating high volume demand.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager