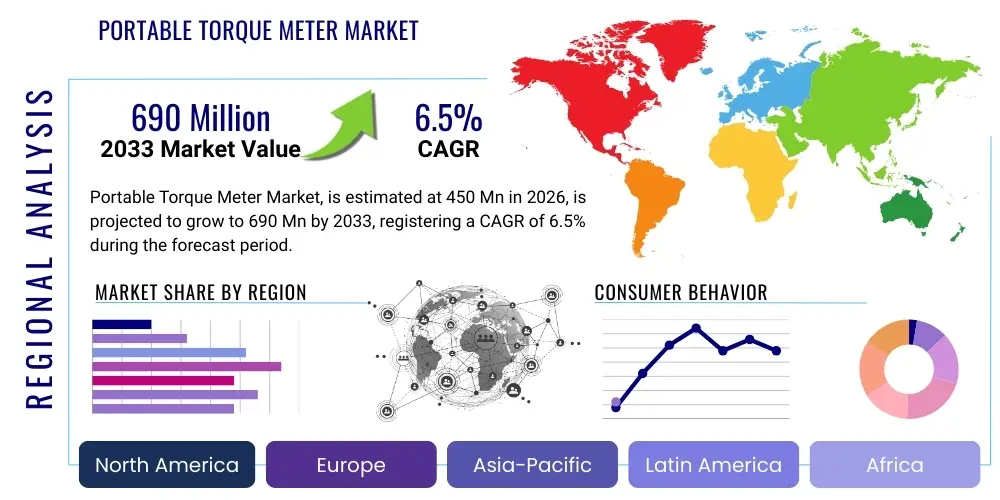

Portable Torque Meter Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 442025 | Date : Feb, 2026 | Pages : 246 | Region : Global | Publisher : MRU

Portable Torque Meter Market Size

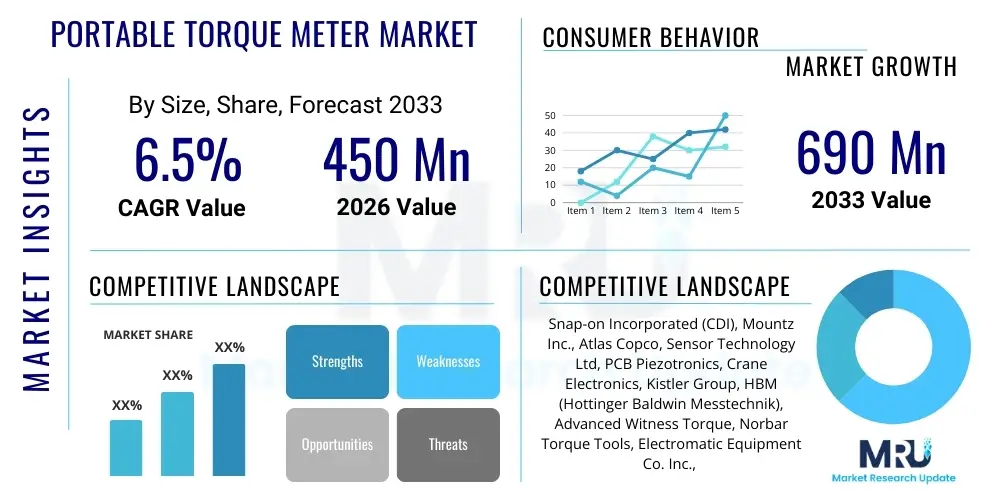

The Portable Torque Meter Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5% between 2026 and 2033. The market is estimated at USD 450 Million in 2026 and is projected to reach USD 690 Million by the end of the forecast period in 2033. This consistent expansion is driven primarily by the increasing necessity for stringent quality control and precision assembly across critical manufacturing sectors, particularly aerospace, automotive, and general heavy machinery. The drive towards zero-defect manufacturing mandates highly accurate, easily deployable torque measurement devices.

Portable Torque Meter Market introduction

The Portable Torque Meter Market encompasses devices designed for precise measurement of torque in various applications, offering critical data for quality assurance, calibration, and product testing. These devices are characterized by their compact size, handheld design, and capability to provide real-time, highly accurate readings in dynamic field environments or on the production floor where fixed, inline systems are impractical. Portable torque meters typically utilize advanced strain gauge technology or non-contact sensing methods to measure rotational forces, converting mechanical strain into electrical signals that quantify the applied torque, essential for ensuring the structural integrity and functional safety of fastened components.

Major applications of portable torque meters span a diverse range of industries. In the automotive sector, they are indispensable for testing and calibrating assembly tools, verifying bolted joint integrity, and performing maintenance checks on engines and transmissions. The aerospace industry relies heavily on these meters to ensure compliance with stringent safety standards for critical fasteners on airframes and propulsion systems. Furthermore, applications in medical device manufacturing, specialized tool calibration, and general heavy engineering contribute significantly to market demand, as manufacturers seek reliable tools to minimize risk, enhance operational efficiency, and adhere to global quality standards such as ISO 9001.

The core benefits driving market adoption include enhanced measurement flexibility, superior accuracy compared to traditional methods, and integrated data logging capabilities. Driving factors include the continuous proliferation of complex automation systems (Industry 4.0), stricter regulatory scrutiny on product quality, and the global trend toward lightweighting materials which necessitate precise control over tightening sequences. The ongoing technological evolution, particularly the integration of wireless data transfer and sophisticated user interfaces, further positions portable torque meters as essential tools for modern industrial maintenance and quality control professionals.

Portable Torque Meter Market Executive Summary

The Portable Torque Meter Market is characterized by robust technological innovation, primarily focusing on enhancing measurement accuracy, miniaturization, and seamless integration with existing manufacturing execution systems (MES). Key business trends include the shift toward non-contact measurement technologies, such as magnetic sensing and optical methods, which offer improved durability and reduced maintenance compared to traditional rotary transformers. Moreover, strategic alliances between sensor manufacturers and software developers are accelerating the development of meters that offer advanced data analytics, predictive maintenance alerts, and cloud connectivity, transforming the role of torque measurement from a simple quality check to a proactive operational optimization tool.

Regional trends indicate that the Asia Pacific (APAC) region is the fastest-growing market, propelled by massive investments in automotive manufacturing, electronics assembly, and rapidly expanding infrastructure projects, particularly in China and India. North America and Europe maintain dominance in terms of technological adoption and market value, driven by high labor costs necessitating automated quality assurance processes and strict adherence to established safety regulations in aerospace and defense sectors. The demand in these mature markets is concentrated on high-precision, specialized torque meters with advanced features suitable for highly regulated environments.

Segmentation trends highlight a strong preference for digital portable torque meters over mechanical variants due to their superior data logging capacity and integration ease. By application, quality control and auditing services account for the largest market share, reflecting the widespread industry effort to validate tool accuracy and bolted joint reliability post-assembly. Furthermore, the increasing complexity of fastening techniques, particularly in electric vehicle (EV) manufacturing requiring multi-stage tightening protocols, ensures sustained growth for portable meters capable of complex measurement routines and immediate data visualization, thereby validating the market's positive long-term outlook.

AI Impact Analysis on Portable Torque Meter Market

User queries regarding AI's influence on the Portable Torque Meter Market frequently center on themes of predictive calibration needs, automated anomaly detection in fastening data, and the potential for smart, closed-loop tool control systems. Users are concerned about how AI algorithms can interpret vast datasets generated by wireless torque meters to move beyond simple pass/fail metrics, enabling predictive insights into tool wear or structural weakness in joints before catastrophic failure occurs. The expectation is that AI will minimize reliance on manual, periodic calibration schedules by predicting drift based on environmental factors and usage patterns, thus maximizing tool uptime and measurement reliability. This transition promises to elevate quality assurance from reactive checking to proactive, data-driven management across complex assembly lines.

The most immediate impact of AI is observed in advanced data interpretation and optimization of measurement protocols. Integrated AI models are beginning to process real-time torque profiles, comparing actual tightening curves against ideal theoretical models derived from material science and engineering specifications. This allows the portable meters, or their associated cloud platforms, to instantly identify subtle deviations indicative of fastener quality issues, improper tool setup, or operator error, significantly surpassing the diagnostic capabilities of traditional statistical process control (SPC) methods. This capability reduces the window for error and improves the effectiveness of non-destructive testing procedures executed in the field.

Furthermore, AI is crucial for optimizing the inventory and maintenance lifecycle of the meters themselves. By analyzing usage frequency, environmental conditions (temperature, humidity), and historical calibration records, AI-powered software can schedule preventative maintenance and calibration cycles precisely when they are most needed, rather than following rigid, time-based schedules. This optimization not only reduces operational costs but also ensures that the instruments maintain peak performance, a requirement for industries like aerospace and medical device manufacturing where measurement uncertainty must be minimized, thereby solidifying the critical link between AI and operational excellence in torque measurement.

- AI enables predictive maintenance scheduling for torque meter calibration, minimizing downtime.

- Machine learning algorithms enhance anomaly detection in tightening cycles for superior quality control.

- AI facilitates real-time comparison of measured torque curves against theoretical models, improving diagnostic accuracy.

- Integration into smart manufacturing ecosystems allows AI to optimize fastening sequences based on material inputs.

- Advanced data analysis via AI converts raw torque readings into actionable insights for process improvement and operator training.

- AI supports closed-loop control systems where the portable meter feeds data back to automated tools for immediate adjustment.

DRO & Impact Forces Of Portable Torque Meter Market

The Portable Torque Meter Market is significantly influenced by a confluence of driving factors, pervasive restraints, and emergent opportunities, collectively shaping its trajectory and competitive landscape. A primary driver is the accelerating demand for precision and traceability across high-stakes industries, fueled by the globalization of supply chains and increasingly stringent international quality standards (e.g., ISO 17025 compliance). This necessity compels manufacturers to invest in highly accurate, frequently calibrated portable meters to validate the performance of automated tooling and to audit finished product quality. The proliferation of complex, multi-material assemblies, especially in electric vehicle (EV) chassis and advanced aircraft structures, requires torque control far beyond basic tolerance checking, thus bolstering the demand for feature-rich, dynamic portable measurement solutions.

However, the market faces notable restraints. The high initial capital expenditure associated with advanced, high-accuracy digital torque meters, particularly those incorporating non-contact sensors and wireless communication capabilities, can deter small and medium-sized enterprises (SMEs) from immediate adoption. Furthermore, the intrinsic complexity of maintaining calibration traceability and ensuring proper handling in rugged industrial environments presents an operational challenge. The requirement for specialized, routine calibration services by accredited laboratories adds to the total cost of ownership (TCO) and logistical overhead, acting as a frictional force against broader market penetration, especially in developing regions where local calibration infrastructure may be underdeveloped.

Opportunities for growth are significant, centered around technological convergence and geographical expansion. The integration of IoT (Internet of Things) functionality allows portable meters to seamlessly transmit data to centralized cloud databases, facilitating enterprise-wide quality monitoring and remote diagnostics, opening lucrative software and service opportunities. Moreover, the robust growth in emerging economies, driven by rapid industrialization and escalating domestic manufacturing standards, offers vast, untapped markets. Manufacturers focusing on developing ruggedized, user-friendly interfaces combined with subscription-based calibration services are well-positioned to capitalize on these opportunities. The competitive impact is high, forcing innovation towards better battery life, enhanced wireless range, and modular designs that accommodate diverse transducer types, ensuring that only agile and technologically advanced providers can secure market leadership.

Segmentation Analysis

The Portable Torque Meter Market is segmented based on several key operational and technical parameters, including the Type of Torque Meter, the Measurement Technology employed, the specific End-User Industry, and the Application area. This segmentation provides a nuanced understanding of market dynamics, revealing specific demand pockets driven by regulatory compliance and technological needs. Digital portable torque meters, which offer superior data handling and analytical features, dominate the market share compared to traditional mechanical versions. The structure of demand is heavily influenced by end-user requirements for portability, accuracy ranges (low, medium, high torque), and specific interface requirements for data integration into Enterprise Resource Planning (ERP) systems.

Further breakdown by technology shows a clear trend toward non-contact sensors (e.g., utilizing magnetic induction or optical encoders) in high-end applications, favored for their enhanced longevity and ability to maintain accuracy under continuous usage without frictional wear. Conversely, in maintenance and basic calibration tasks, traditional strain gauge technology remains widely utilized due to its cost-effectiveness and proven reliability. Understanding these segmentation nuances is crucial for strategic planning, allowing vendors to tailor product development—for instance, developing high-torque meters specifically for heavy equipment maintenance or ultra-low torque meters for medical device assembly—to address precise industrial demands effectively and efficiently.

- By Type:

- Digital Portable Torque Meters

- Mechanical Portable Torque Meters

- By Transducer Type:

- Reaction Torque Transducers

- Rotary Torque Transducers

- By Measurement Technology:

- Strain Gauge-Based

- Non-Contact (Magnetic, Optical)

- By Application:

- Quality Control & Audit

- Tool Calibration & Verification

- R&D and Product Testing

- Maintenance, Repair, and Overhaul (MRO)

- By End-User Industry:

- Automotive (Including EV Manufacturing)

- Aerospace & Defense

- Industrial Machinery & Equipment

- Oil & Gas

- Electronics & Semiconductor

- Medical Devices

Value Chain Analysis For Portable Torque Meter Market

The value chain for the Portable Torque Meter Market is complex, beginning with upstream raw material sourcing and highly specialized component manufacturing, progressing through assembly and calibration, and culminating in downstream distribution and after-sales service. Upstream activities are dominated by specialized suppliers providing high-precision components, most notably the sensing elements such as strain gauges, magnetic sensors, and high-quality electronics necessary for signal conditioning and digitization. The quality and performance of the final torque meter are intrinsically linked to the reliability of these proprietary sensor technologies, often leading to deep integration or strategic partnerships between meter manufacturers and sensor suppliers. Manufacturers must maintain high internal capabilities for precise machining and environmental sealing to protect these sensitive components.

Midstream activities involve the crucial steps of meter assembly, testing, and initial calibration, which represent the primary value addition. Calibration is a non-negotiable process, requiring certified laboratories and highly controlled environments to ensure metrological traceability, a key factor differentiating premium products. Once assembled and certified, the product moves into the distribution stage. Direct distribution is common for high-value, customized, or proprietary torque measurement solutions, particularly when serving large OEM clients in the automotive or aerospace sectors, allowing for direct technical support and immediate feedback loops. This channel ensures specialized consulting services can be bundled with the product offering.

The downstream distribution channels heavily rely on a mix of specialized industrial distributors, third-party sales representatives, and increasingly, e-commerce platforms for standardized, lower-cost models. Indirect channels, through specialized distributors, are particularly important for reaching SMEs and geographically dispersed MRO markets, as these distributors often provide regional warehousing, localized technical support, and critical integration services. Post-sale, the ongoing requirement for periodic calibration, repair, and certification services generates a significant recurring revenue stream for manufacturers and certified service providers, demonstrating that the service component of the value chain is equally as critical as the hardware itself for long-term customer retention and market presence.

Portable Torque Meter Market Potential Customers

The end-user base for portable torque meters is exceptionally broad, spanning nearly all industries where mechanical fastening is critical and regulatory compliance is paramount. The primary customer segment includes manufacturing enterprises in the automotive industry, encompassing both traditional internal combustion engine (ICE) assembly lines and the rapidly growing electric vehicle (EV) sector. EV manufacturing demands extremely tight tolerances for battery pack assembly and structural components, making portable meters essential for verifying automated tool outputs and auditing critical joints. Similarly, Tier 1 and Tier 2 suppliers in the automotive ecosystem are major buyers, utilizing these meters for incoming material quality checks and process control validation.

A second major cohort consists of the aerospace and defense sectors, including Original Equipment Manufacturers (OEMs) and Maintenance, Repair, and Overhaul (MRO) facilities. For these customers, the consequences of joint failure are catastrophic, mandating the use of the highest precision, traceable torque meters. They require instruments capable of measuring a wide range of torque values, often accompanied by extensive documentation and digital records for full operational life traceability. The stringent AS9100 quality standards applied in this industry ensure sustained demand for premium, certified portable torque meters.

Furthermore, general heavy industrial machinery, construction equipment manufacturing, and the energy sector (oil & gas and renewable energy infrastructure) represent substantial potential customers. These industries utilize high-torque fastening applications that require robust, ruggedized meters suitable for harsh operating environments. Calibration laboratories and third-party quality testing service providers also constitute a significant buying segment, as they need versatile, highly accurate meters to provide certified testing and calibration services to smaller organizations unable to maintain their own accredited equipment fleets, solidifying their role as intermediaries in the market demand structure.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450 Million |

| Market Forecast in 2033 | USD 690 Million |

| Growth Rate | 6.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Snap-on Incorporated (CDI), Mountz Inc., Atlas Copco, Sensor Technology Ltd, PCB Piezotronics, Crane Electronics, Kistler Group, HBM (Hottinger Baldwin Messtechnik), Advanced Witness Torque, Norbar Torque Tools, Electromatic Equipment Co. Inc., Teledyne Technologies, PCE Instruments, S. Himmelstein and Co., Torque Control Specialists Inc., Transducer Techniques, A&D Company, Rad Torque Systems, Tohnichi Mfg. Co., and Aimco. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Portable Torque Meter Market Key Technology Landscape

The technological landscape of the Portable Torque Meter Market is rapidly evolving, moving beyond simple strain gauge mechanisms toward highly sophisticated, interconnected systems. A major technological advancement is the widespread integration of wireless connectivity, primarily Bluetooth Low Energy (BLE) and Wi-Fi, which allows meters to instantly transmit measured data to central databases, cloud platforms, or handheld smart devices. This eliminates manual data logging errors and significantly improves data traceability, a fundamental requirement for regulatory compliance in safety-critical industries. Furthermore, the development of specialized algorithms embedded in the meter firmware is enhancing measurement stability, compensating for environmental factors like temperature variation and minor alignment inconsistencies, thereby ensuring superior accuracy in dynamic field conditions.

Another crucial innovation involves the increasing deployment of non-contact torque measurement technologies. Traditional rotary torque meters rely on slip rings or rotary transformers, which are prone to wear, noise, and maintenance issues. In contrast, non-contact solutions, utilizing magnetic inductance or proprietary optical sensors, eliminate physical connection points, resulting in higher rotational speed limits, vastly improved durability, and reduced signal noise, particularly critical for high-speed motor testing and continuous auditing applications. This shift enables the creation of smaller, lighter, and more robust meters that can withstand severe industrial usage without compromising measurement integrity, driving preference among advanced manufacturing users.

Software and interface improvements also define the contemporary technology landscape. Modern portable torque meters are equipped with high-resolution digital displays and intuitive graphical user interfaces (GUIs) that guide operators through complex fastening or auditing procedures, often incorporating multilingual support and touch-screen functionality. Crucially, the accompanying data management software offers features such as automated reporting, statistical analysis, trend charting, and integration APIs (Application Programming Interfaces) to interface with SCADA (Supervisory Control and Data Acquisition) and Quality Management Systems (QMS). This comprehensive digital ecosystem transforms the portable meter from a standalone tool into an integral part of the broader industrial internet of things (IIoT) framework, ensuring maximum utility and data exploitability.

Regional Highlights

Regional dynamics play a crucial role in shaping the Portable Torque Meter Market, with significant variances in demand drivers, technological adoption rates, and regulatory mandates across different geographies. North America, particularly the United States, commands a substantial market share, driven by a robust aerospace and defense sector, demanding ultra-high precision tools, and a strong presence of advanced automotive manufacturing and R&D facilities. High labor costs and stringent safety regulations necessitate investments in automated quality verification tools, ensuring that portable meters with advanced connectivity and high levels of certification are favored in this market. Furthermore, heavy investment in sophisticated calibration services sustains market growth.

The Asia Pacific (APAC) region is projected to exhibit the highest Compound Annual Growth Rate (CAGR) during the forecast period. This acceleration is attributed to the rapid expansion of manufacturing capabilities across China, India, South Korea, and Southeast Asian nations. Substantial government initiatives supporting domestic manufacturing, combined with escalating quality standards imposed by global supply chain partners, fuel the demand for affordable yet reliable portable torque meters for mass production quality checks and tool calibration. The increasing adoption of EVs and the growth of the regional electronics manufacturing industry further bolster APAC’s dominance in volume, though often favoring cost-effective digital solutions over the highest-end specialized meters prevalent in Western markets.

Europe represents a mature and technologically advanced market, driven by strict regulatory environments concerning machinery safety (e.g., EU Directives) and the strong presence of the German automotive industry (Industry 4.0 initiatives). Demand here focuses on integration capabilities, traceability features, and compliance with EU-wide metrological standards. The shift towards sustainable manufacturing and precision engineering in aerospace and wind energy sectors ensures sustained demand for non-contact and smart torque measurement devices. Conversely, regions like Latin America and Middle East & Africa (MEA) are emerging markets, primarily driven by investments in oil & gas infrastructure and localized infrastructure development projects, leading to demand spikes for robust, high-torque meters designed for heavy maintenance and auditing tasks.

- North America: Focus on aerospace, defense, and high-precision R&D; leading market for technological adoption and high-accuracy, certified meters.

- Asia Pacific (APAC): Highest growth rate fueled by automotive and electronics manufacturing expansion, driven by China and India.

- Europe: Mature market characterized by stringent quality regulations (Industry 4.0); high demand for seamlessly integrated and traceable measurement solutions.

- Latin America & MEA: Emerging markets with demand concentrated in energy, infrastructure, and heavy machinery MRO applications.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Portable Torque Meter Market.- Snap-on Incorporated (CDI)

- Mountz Inc.

- Atlas Copco

- Sensor Technology Ltd

- PCB Piezotronics

- Crane Electronics

- Kistler Group

- HBM (Hottinger Baldwin Messtechnik)

- Advanced Witness Torque

- Norbar Torque Tools

- Electromatic Equipment Co. Inc.

- Teledyne Technologies

- PCE Instruments

- S. Himmelstein and Co.

- Torque Control Specialists Inc.

- Transducer Techniques

- A&D Company

- Rad Torque Systems

- Tohnichi Mfg. Co.

- Aimco

Frequently Asked Questions

Analyze common user questions about the Portable Torque Meter market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary factor driving the adoption of digital portable torque meters over mechanical ones?

The primary driver is the superior data logging, traceability, and integration capabilities of digital meters, essential for meeting modern Industry 4.0 quality assurance standards and detailed regulatory compliance requirements across critical sectors like aerospace and automotive manufacturing.

How does the integration of IoT and wireless connectivity enhance the utility of portable torque meters?

IoT integration enables real-time data transfer from the meter to centralized QMS platforms, eliminating manual data entry, facilitating remote monitoring of assembly quality, and enabling immediate statistical process control (SPC) analysis across multiple production lines simultaneously.

Which end-user industry accounts for the largest market share for high-precision portable torque meters?

The Aerospace and Defense industry, followed closely by high-end Automotive manufacturing (including Electric Vehicles), represents the largest share for high-precision meters due to extremely tight quality tolerances and stringent safety regulations demanding traceable and highly accurate measurement devices.

What are the key technical advantages of non-contact torque measurement technology?

Non-contact technology, utilizing methods like magnetic sensing, offers enhanced durability, reduced maintenance requirements, the ability to operate at higher rotational speeds without wear, and superior accuracy stability compared to traditional slip-ring or rotary transformer designs.

What is the expected CAGR for the Portable Torque Meter Market between 2026 and 2033?

The Portable Torque Meter Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5% during the forecast period, reflecting sustained demand driven by global industrial modernization and increasing regulatory pressure for quality control.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager