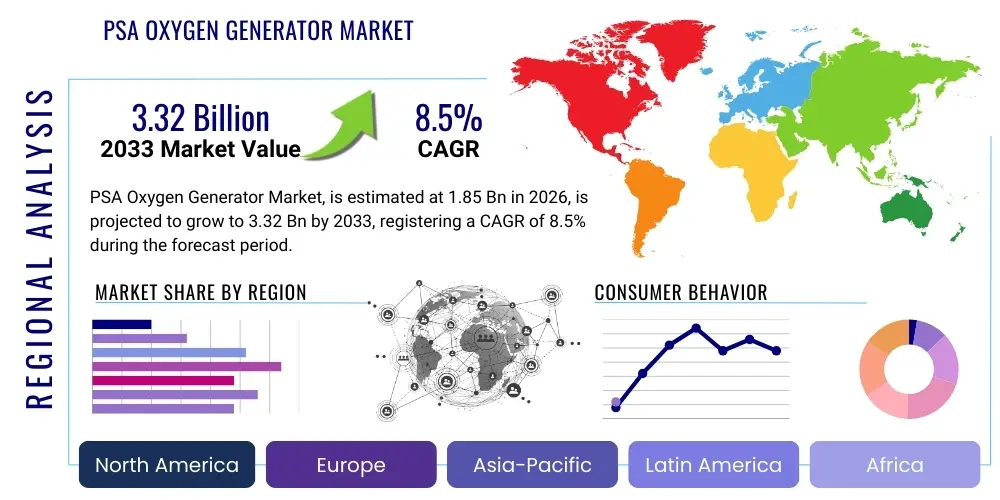

PSA Oxygen Generator Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 442704 | Date : Feb, 2026 | Pages : 246 | Region : Global | Publisher : MRU

PSA Oxygen Generator Market Size

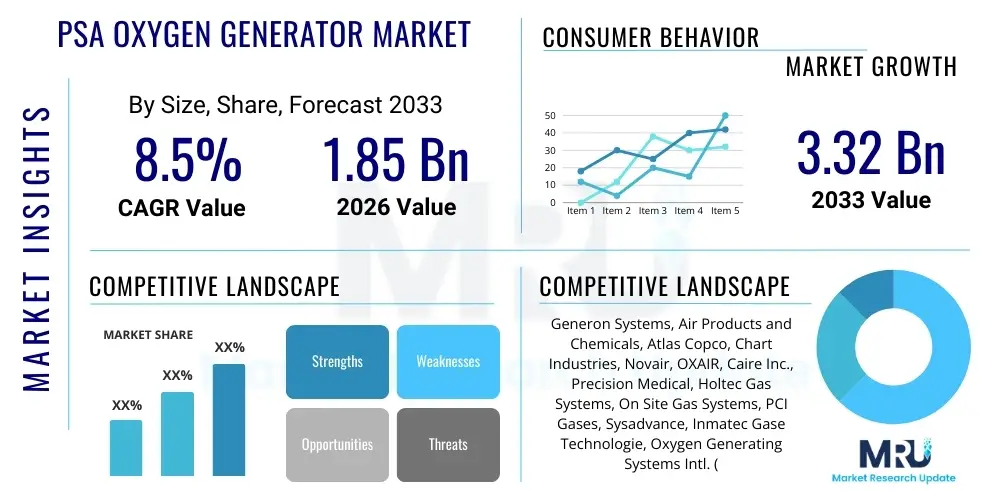

The PSA Oxygen Generator Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.5% between 2026 and 2033. The market is estimated at USD 1.85 billion in 2026 and is projected to reach USD 3.32 billion by the end of the forecast period in 2033. This robust expansion is primarily driven by the escalating demand for reliable, on-site oxygen generation solutions across critical sectors, including healthcare, metallurgy, and water treatment. The inherent cost-efficiency and environmental benefits of PSA technology over traditional cryogenic separation or transported oxygen cylinders contribute significantly to this sustained growth trajectory, particularly in regions prioritizing self-sufficiency in medical oxygen supply.

The market valuation reflects a fundamental shift toward localized production, mitigating supply chain vulnerabilities exposed during global health crises. Investments in modular and compact PSA systems are surging, catering specifically to remote hospitals, military installations, and decentralized industrial operations that require consistent high-purity oxygen without dependence on external logistics. Furthermore, technological advancements focusing on optimizing sieve material performance and reducing power consumption are enhancing the economic feasibility of PSA generators, making them competitive even for medium-scale industrial processes.

Geographically, growth is anticipated to be led by emerging economies in the Asia Pacific and Latin America, where rapid urbanization, coupled with expanding healthcare infrastructure and increasing industrial activity, fuels the need for resilient oxygen supply infrastructure. Regulatory support promoting environmental sustainability and energy efficiency also acts as a catalyst, favoring PSA systems that offer lower long-term operational costs and reduced carbon footprints compared to energy-intensive liquid oxygen production methods.

PSA Oxygen Generator Market introduction

The Pressure Swing Adsorption (PSA) Oxygen Generator Market encompasses the design, manufacture, distribution, and maintenance of systems utilizing PSA technology to separate oxygen from compressed ambient air. These generators operate by selectively adsorbing nitrogen and other trace gases onto adsorbent materials, typically zeolites (molecular sieves), under high pressure, leaving high-purity oxygen (typically 90% to 95%) as the product gas. The market is fundamentally driven by the versatility of PSA technology, offering an economical, safe, and continuous supply of oxygen critical for sustaining life and enabling various industrial processes.

Major applications span diverse sectors. In healthcare, PSA generators are vital for providing medical-grade oxygen to hospitals, clinics, and increasingly, home-care settings, serving as a reliable alternative to bulk liquid oxygen storage or high-pressure cylinders. Industrially, applications are concentrated in processes like steel manufacturing, brazing, welding, wastewater treatment (aeration), and glass blowing, where oxygen enrichment significantly enhances combustion efficiency and process speed. The core benefits include on-demand generation, elimination of logistical costs associated with transporting oxygen, enhanced safety due to lower operating pressures compared to cylinders, and a relatively small physical footprint, especially for modern, containerized solutions.

Driving factors propelling market expansion include global efforts to improve healthcare infrastructure, particularly in underserved rural areas, where reliable oxygen is essential for critical care. The rising global prevalence of respiratory diseases, necessitating long-term oxygen therapy, further fuels the demand for residential and portable PSA units. Additionally, stringent environmental regulations encouraging efficient industrial processes favor the adoption of oxygen enrichment technologies powered by PSA, leading to lower energy consumption and reduced NOx emissions in combustion applications. Continuous innovation in molecular sieve material science is enhancing purity levels and system durability, solidifying PSA technology's position as a preferred method for medium-to-low volume oxygen production.

PSA Oxygen Generator Market Executive Summary

The PSA Oxygen Generator Market is experiencing dynamic expansion, underpinned by strong business trends focusing on modularity, digitalization, and healthcare resilience. Business trends indicate a movement towards decentralized oxygen supply models, reducing reliance on centralized cryogenic facilities, thereby boosting the demand for containerized and mobile PSA units suitable for rapid deployment. Key companies are investing heavily in IoT-enabled generators, allowing for real-time remote monitoring, predictive maintenance, and operational optimization, significantly improving uptime and reducing total cost of ownership for end-users. Furthermore, mergers and acquisitions targeting niche technology providers, particularly those specializing in high-efficiency zeolites or advanced control systems, are shaping the competitive landscape and driving technological differentiation among leading manufacturers.

Regional trends highlight the Asia Pacific (APAC) as the fastest-growing market, driven by massive public and private investment in hospital capacity expansion, coupled with booming industrialization, particularly in chemical processing and metal fabrication sectors across China and India. North America and Europe, characterized by high adoption rates of home healthcare solutions and stringent medical oxygen standards, remain mature but stable markets, focused primarily on replacement cycles and the integration of smaller, quieter residential units. Latin America and the Middle East and Africa (MEA) are emerging as high-potential regions, necessitated by governmental initiatives aimed at improving healthcare access and modernizing existing industrial infrastructure.

Segmentation trends reveal robust growth in the medical application segment due to sustained demand following recent public health crises and the continued global increase in Chronic Obstructive Pulmonary Disease (COPD) cases. By product type, the market sees heightened demand for small-to-mid size generators (up to 500 Nm³/h), favoring localized hospital use and various small industrial operations. The shift towards higher purity requirements (95%+) in certain industrial applications, such as specialized electronics manufacturing, is driving innovation in multi-bed PSA systems and vacuum pressure swing adsorption (VPSA) hybridization, ensuring market stability across different end-user demands.

AI Impact Analysis on PSA Oxygen Generator Market

User inquiries regarding the impact of Artificial Intelligence (AI) on the PSA Oxygen Generator Market primarily revolve around operational efficiency, predictive failure, and optimization of energy consumption. Users are keen to understand how AI algorithms can interpret vast datasets generated by modern PSA systems—such as pressure swings, adsorption cycle times, and temperature fluctuations—to achieve higher oxygen purity and reduced energy costs. Key themes include the implementation feasibility of machine learning models for forecasting molecular sieve degradation and optimizing the complex valve switching sequences inherent in the PSA process. There is a strong expectation that AI will transition PSA systems from reactive maintenance models to highly proactive, self-optimizing platforms, ensuring maximum uptime, a critical factor, especially in life-support medical applications. Concerns sometimes center on data security and the necessity of robust edge computing capabilities to manage real-time optimization without relying solely on cloud connectivity, essential for remote or critical infrastructure deployments.

AI's primary influence is channeled through advanced control systems and predictive analytics platforms integrated into new generation PSA units. Machine learning models analyze historical operational data, environmental variables (temperature, humidity), and output purity metrics to dynamically adjust adsorption and desorption cycles. This dynamic tuning, replacing static, pre-programmed cycles, minimizes the time required to reach optimal purity and significantly reduces compressed air consumption, which is the largest operational expense. The ability of AI to detect subtle anomalies in pressure drops or valve timing allows for the early identification of potential equipment failure, thereby scheduling maintenance before catastrophic breakdown occurs, which is invaluable in maintaining a consistent supply of medical oxygen.

Furthermore, AI-driven demand forecasting is revolutionizing inventory management for consumables and spares, ensuring that replacement parts for crucial components like valves or molecular sieve dust filters are available precisely when needed. This level of optimization extends the lifespan of the adsorbent material itself by ensuring optimal operating conditions and preventing thermal or mechanical stress associated with suboptimal cycling. As systems become more interconnected through the Industrial Internet of Things (IIoT), AI acts as the central intelligence layer, harmonizing performance across distributed networks of generators, especially relevant for large healthcare networks or industrial parks relying on multiple PSA units.

- AI optimizes adsorption cycle timing for maximum efficiency and purity yield.

- Predictive maintenance algorithms forecast molecular sieve and valve degradation, minimizing unplanned downtime.

- Machine learning models dynamically adjust compressed air input based on real-time ambient conditions, reducing energy consumption.

- AI-driven remote monitoring enhances diagnostics and troubleshooting, reducing service response times.

- Automated performance benchmarking across multiple units ensures standardized operational excellence.

DRO & Impact Forces Of PSA Oxygen Generator Market

The market is governed by a complex interplay of Drivers, Restraints, and Opportunities (DRO), significantly influencing its growth trajectory and competitive dynamics. A key driver is the increasing necessity for healthcare facilities, particularly in developing nations, to secure independent, reliable oxygen sources, catalyzed by heightened awareness of oxygen supply chain vulnerabilities globally. This is complemented by the cost advantages and long-term economic viability of on-site generation versus the recurring expenditure of cylinder logistics. However, market growth faces restraints, primarily high initial capital expenditure (CAPEX) required for purchasing and installing large-scale PSA systems, which can be prohibitive for small and medium enterprises (SMEs) or smaller healthcare providers. Furthermore, the inherent limitation of PSA technology in achieving ultra-high purities (above 99%), which are essential for certain high-tech industrial applications like semiconductor manufacturing, restricts its penetration in those niche areas, favoring cryogenic separation instead.

Opportunities abound in technological innovation and geographical expansion. Significant opportunities lie in developing next-generation adsorbents (e.g., lithium-based zeolites) that offer higher selectivity and greater capacity, potentially increasing oxygen purity and reducing system size, thus making them more attractive for portable and residential markets. The growing adoption of Vacuum Pressure Swing Adsorption (VPSA) and Vacuum Swing Adsorption (VSA) variations represents a crucial opportunity to improve energy efficiency for medium-scale applications. Additionally, the increasing global focus on decentralized infrastructure, coupled with government subsidies aimed at bolstering domestic oxygen production capacity, particularly in regions like Southeast Asia and Africa, creates vast greenfield opportunities for deployment.

The collective impact of these forces is substantial. The strong imperative for reliable healthcare oxygen acts as a powerful accelerating force, sustaining high growth in the medical segment regardless of economic cyclicality. Restraints related to CAPEX are gradually being mitigated by favorable financing options, leasing models offered by manufacturers, and the demonstrated rapid return on investment (ROI) achieved through eliminating recurring procurement and transportation costs. The primary challenge remains educating potential users in industrial sectors about the technical nuances of PSA versus alternative supply methods, ensuring correct system sizing and implementation to maximize performance and longevity, thereby translating technical opportunities into tangible market gains.

Segmentation Analysis

The PSA Oxygen Generator Market is comprehensively segmented based on product type, technology, application, and capacity, providing a granular view of demand patterns and targeted investment areas. This segmentation is crucial for stakeholders to tailor their product offerings and strategic focus. Product type differentiation separates portable and stationary units, reflecting the diverse needs spanning mobile emergency services to fixed hospital infrastructure. Technology segmentation includes traditional PSA, VPSA, and hybridized systems, each optimized for different purity levels and flow rates. The application spectrum is broadly divided into medical (hospitals, home care) and industrial (metallurgy, water treatment, chemical), highlighting the primary end-user sectors driving volume and value growth. Capacity segmentation further divides the market into small, medium, and large-scale generators, directly correlating with the scale of the facility or operation they serve, ranging from individual patient care to large-scale industrial complexes demanding hundreds of cubic meters per hour.

Detailed analysis of these segments reveals that stationary generators dominate the market share by revenue, driven by long-term investments in large hospital networks and heavy industrial facilities. However, portable and residential units are exhibiting the fastest growth rate, fueled by the global trend toward home healthcare and aging populations requiring continuous respiratory support. Within the industrial sector, the wastewater treatment segment is increasingly adopting PSA generators for aeration purposes, capitalizing on the operational savings and reliability offered over traditional compressed air systems, positioning it as a significant emerging application area. The capacity analysis indicates that the medium capacity range (50 Nm³/h to 500 Nm³/h) is highly competitive, catering to mid-sized hospitals and numerous factory floor applications, representing the sweet spot for many regional manufacturers.

The strategic importance of segmentation lies in understanding the shift in end-user requirements. For instance, the medical segment demands high regulatory compliance and strict purity verification, driving manufacturers to invest in advanced monitoring and filtration systems. Conversely, the industrial segment prioritizes throughput, ruggedness, and energy efficiency, necessitating robust designs and integration with broader plant control systems. The continued refinement of VPSA technology specifically targets high-volume industrial users seeking a more energy-efficient alternative to traditional PSA for large-scale aeration or high-throughput processes, showcasing how technological segmentation addresses specific market needs for both volume and efficiency.

- By Type:

- Stationary Generators

- Portable/Mobile Generators

- By Technology:

- Pressure Swing Adsorption (PSA)

- Vacuum Pressure Swing Adsorption (VPSA)

- Vacuum Swing Adsorption (VSA)

- By Capacity:

- Small (Up to 50 Nm³/h)

- Medium (50 Nm³/h to 500 Nm³/h)

- Large (Above 500 Nm³/h)

- By Application:

- Medical & Healthcare (Hospitals, Clinics, Home Care)

- Industrial (Welding, Brazing, Metallurgy)

- Chemical & Pharmaceutical

- Wastewater Treatment & Ozone Generation

- Pulp & Paper

- Aerospace & Military

Value Chain Analysis For PSA Oxygen Generator Market

The value chain for the PSA Oxygen Generator Market spans from the sourcing of specialized raw materials to the final installation, service, and decommissioning phases, with several critical nodes influencing overall cost and competitive positioning. Upstream analysis focuses predominantly on the suppliers of core components: air compressors, control valves, filtration systems, and most critically, molecular sieve materials (zeolites). The quality and consistency of these specialized zeolites, often sourced from a limited number of global suppliers, directly impact the generator’s efficiency, purity, and lifespan. Compressor technology, dictating the system's power consumption, is another high-leverage point upstream. Manufacturers must maintain strong, strategic relationships with these component suppliers to ensure stable pricing, reliable quality, and access to the latest material science innovations.

The midstream involves the core manufacturing and integration process, where the generator assembly, system design (including skid mounting and containerization), testing, and quality assurance take place. Differentiation at this stage is achieved through proprietary design patents that optimize air flow dynamics, heat management, and programmable logic controller (PLC) sequencing, leading to superior energy efficiency and minimal maintenance requirements. Direct channels for distribution typically involve manufacturers selling large, custom-engineered systems directly to major industrial customers or large hospital networks, often including commissioning and long-term service contracts. Indirect channels involve authorized distributors, local engineering firms, and medical equipment resellers who handle smaller, standardized, or portable units, providing localized installation support and acting as the frontline for regional sales and maintenance.

Downstream analysis centers on end-user adoption and post-sale services. The service component, including routine maintenance, sieve replacement, remote monitoring, and emergency repair, constitutes a significant revenue stream and competitive differentiator. For medical applications, compliance verification and validation services are essential downstream requirements. The selection of distribution channels heavily depends on the segment: specialized medical dealers are crucial for hospital penetration due to regulatory knowledge, while industrial distributors focus on technical support and integration into existing plant infrastructure. The effectiveness of the downstream network, particularly in providing rapid response maintenance, directly correlates with perceived system reliability and customer retention, given the critical nature of continuous oxygen supply.

PSA Oxygen Generator Market Potential Customers

The potential customer base for PSA Oxygen Generators is highly diversified, spanning governmental bodies, large private corporations, and individual end-users, broadly categorized into the medical and industrial sectors. In the medical sector, primary customers include large multi-specialty hospitals, regional medical centers, military field hospitals, and specialized clinics requiring guaranteed, continuous oxygen supply for anesthesia, intensive care units (ICUs), and trauma support. A rapidly expanding segment comprises home healthcare providers and individual patients suffering from chronic respiratory illnesses, purchasing smaller, quieter, and portable generators for long-term oxygen therapy (LTOT), often facilitated through insurance or government healthcare programs. Governmental and non-governmental organizations (NGOs) focused on disaster relief and rural health infrastructure development also represent significant buyers for mobile and containerized units.

On the industrial side, the customer spectrum is vast, reflecting diverse needs for oxygen enrichment. Key potential customers include large steel mills and metal fabrication facilities where oxygen is used to enhance combustion and reduce heating times, improving overall furnace efficiency. Chemical processing plants, especially those involved in oxidation reactions or petrochemical manufacturing, rely on large-scale PSA units. The environmental sector, specifically municipal and industrial wastewater treatment plants, utilizes PSA-generated oxygen for highly effective aeration and ozone production to purify water. Furthermore, industries like glass manufacturing, specialized electronics (soldering, inert environments), and the rapidly growing aquaculture sector (for enhancing fish growth) constitute robust secondary markets, each demanding varying levels of purity and flow rate tailored to their specific operational requirements.

Identifying and targeting these customer segments requires a nuanced approach, recognizing that medical customers prioritize reliability, regulatory compliance, and service contracts, while industrial customers focus heavily on energy efficiency, throughput capacity, and seamless integration with existing plant utilities. The trend towards modularity has also opened doors to smaller enterprises and remote mining/construction camps, which previously relied on expensive cylinder deliveries, now opting for containerized PSA solutions to achieve self-sufficiency and reduce operational logistics costs associated with remote deployment.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.85 Billion |

| Market Forecast in 2033 | USD 3.32 Billion |

| Growth Rate | CAGR 8.5% |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Generon Systems, Air Products and Chemicals, Atlas Copco, Chart Industries, Novair, OXAIR, Caire Inc., Precision Medical, Holtec Gas Systems, On Site Gas Systems, PCI Gases, Sysadvance, Inmatec Gase Technologie, Oxygen Generating Systems Intl. (OGSI), Techgen Systems, Peak Scientific, Parker Hannifin, UTAS, VSA Systems, ZAO S-AZS |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

PSA Oxygen Generator Market Key Technology Landscape

The technology landscape of the PSA Oxygen Generator Market is dominated by incremental improvements in the core Pressure Swing Adsorption process, alongside significant advancements in complementary technologies like Vacuum Pressure Swing Adsorption (VPSA) and Vacuum Swing Adsorption (VSA). The fundamental PSA process relies on molecular sieve beds (typically lithium or calcium-based zeolites) that preferentially adsorb nitrogen under pressure. Recent technological breakthroughs focus on developing highly selective adsorbent materials that increase the nitrogen adsorption capacity, thereby reducing the size and energy required for the air compression stage while improving oxygen purity levels closer to the 95% threshold. This material science focus is critical for maintaining competitiveness against cryogenic methods, particularly for high-end applications where purity is non-negotiable.

VPSA and VSA represent crucial evolutionary paths, particularly for large-scale industrial consumers seeking higher energy efficiency. Unlike traditional PSA, which uses atmospheric pressure for desorption, VPSA utilizes a vacuum pump to actively strip the nitrogen from the sieve material during the regeneration phase. This results in significantly lower consumption of compressed air per unit of oxygen produced, yielding energy savings of up to 40% for large-capacity systems, making VPSA highly attractive for continuous, high-volume industrial uses like steel production and wastewater aeration. The adoption of advanced, high-speed control valves and sophisticated Programmable Logic Controllers (PLCs) further refines the swing cycle timing, minimizing transition losses and maximizing the output purity and stability across varying load demands.

Digital integration and monitoring systems now form an indispensable part of the technology landscape. Modern PSA generators are increasingly equipped with IIoT sensors and cloud-connectivity features, enabling real-time performance tracking of critical parameters such as dew point, purity, flow rate, and pressure stability. This digitalization facilitates predictive maintenance driven by AI, allowing operators to preemptively address component wear (e.g., compressor maintenance, valve leakage) and optimize the nitrogen stripping process based on real-time environmental data. Furthermore, the development of compact, silent, oil-free compressors tailored for small, portable medical units is a significant technological trend, crucial for penetrating the rapidly growing home care market where noise reduction and ease of use are paramount features.

Regional Highlights

The global PSA Oxygen Generator Market exhibits distinct growth patterns and maturity levels across major geographical regions, influenced by localized healthcare policies, industrial growth rates, and regulatory frameworks governing oxygen supply.

- North America: This region is characterized by high market maturity, driven by sophisticated healthcare infrastructure and substantial demand for home-care oxygen devices. The focus is increasingly on replacing older units with energy-efficient, digitally integrated models. Strict regulatory standards set by the FDA ensure that medical-grade generators maintain high purity and reliability, favoring established global players. The industrial segment sees steady demand from metallurgy and wastewater treatment, emphasizing the adoption of VPSA technology for operational cost reduction.

- Europe: Europe represents a technologically advanced market with strong regulatory emphasis on energy efficiency and environmental standards. Western Europe maintains high demand for high-quality, continuous medical oxygen supply, while Eastern European nations show increasing investment in modernizing hospital infrastructure, driving sales of medium-scale stationary units. Government initiatives promoting decentralized energy and utility solutions also favor the integration of on-site generation, particularly in pharmaceuticals and chemical processing industries.

- Asia Pacific (APAC): APAC stands as the dominant and fastest-growing region globally, fueled by rapid industrialization, massive population growth, and expansive infrastructure development, particularly in India, China, and Southeast Asian countries. The urgent need to augment oxygen capacity, especially post-pandemic, has led to significant government procurement and private investment in both large-scale hospital generators and decentralized systems for remote regions. Industrial demand is immense, spanning across steel, glass, and electronics manufacturing, creating vast opportunities for high-capacity PSA and VPSA systems.

- Latin America (LATAM): Growth in LATAM is spurred by improving economic conditions and increased government focus on public health reform. Brazil and Mexico are key markets showing rising adoption of PSA technology to secure stable oxygen supplies in hospitals, reducing reliance on cross-border logistics. Market expansion here often involves overcoming distribution challenges and adapting technology to meet localized power supply stability issues, favoring rugged, easy-to-maintain designs.

- Middle East and Africa (MEA): MEA is an emerging, high-potential market. The Middle East benefits from significant infrastructure spending, particularly in oil and gas (using oxygen for enhanced recovery) and healthcare expansion. Africa presents critical humanitarian and development opportunities, where mobile and containerized PSA units are essential for providing medical oxygen in remote areas lacking basic utility infrastructure. Investment is often tied to foreign aid and governmental initiatives aimed at building resilient national health systems.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the PSA Oxygen Generator Market.- Generon Systems

- Air Products and Chemicals

- Atlas Copco

- Chart Industries

- Novair

- OXAIR

- Caire Inc.

- Precision Medical

- Holtec Gas Systems

- On Site Gas Systems

- PCI Gases

- Sysadvance

- Inmatec Gase Technologie

- Oxygen Generating Systems Intl. (OGSI)

- Techgen Systems

- Peak Scientific

- Parker Hannifin

- UTAS

- VSA Systems

- ZAO S-AZS

- Advanced Gas Technologies Inc.

- Beijing Orient Institute of Measurement and Control (BOIMC)

- Nippon Sanso Holdings Corporation

- Wenzhou Blue Sky Energy Technology Co., Ltd.

- MVS Engineering Pvt. Ltd.

- Oxus America, Inc.

- Energy Products, LLC

- Shenzhen Gastech Equipment Co., Ltd.

Frequently Asked Questions

Analyze common user questions about the PSA Oxygen Generator market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the typical lifespan and required maintenance for a PSA Oxygen Generator?

The general operational lifespan of a high-quality PSA generator is 15 to 20 years, provided the core components are maintained. Molecular sieves typically last 5 to 10 years, depending on usage and environmental factors. Required maintenance primarily involves annual checks, filter replacements, and scheduled servicing of the air compressor to ensure efficiency and oxygen purity are consistently met.

How does the purity of PSA oxygen compare to cryogenic liquid oxygen (LOX)?

PSA oxygen typically achieves purity levels between 90% and 95%, which is sufficient for most medical applications (including many hospital requirements) and general industrial uses. Cryogenic Liquid Oxygen (LOX) offers ultra-high purity, often exceeding 99.5%, making it necessary for highly sensitive applications like semiconductor manufacturing or aerospace, where PSA purity may be insufficient.

What are the primary factors driving the high initial capital expenditure (CAPEX) for PSA systems?

The high CAPEX is primarily attributed to the sophisticated, heavy-duty air compressor, which is the most energy-intensive and critical component. Additionally, the cost of specialized, high-performance molecular sieve material (zeolite), the automated control systems (PLCs), and the precision, high-cycle valves significantly contribute to the upfront investment cost.

Can PSA Oxygen Generators be used for home healthcare and portability?

Yes, PSA technology is fundamental to portable and stationary home healthcare oxygen concentrators. Advancements in miniaturization, coupled with highly efficient, quiet compressors, have made portable PSA units lightweight and viable for long-term oxygen therapy (LTOT) patients, offering continuous, reliable oxygen supply outside of clinical settings.

How does VPSA technology differ from traditional PSA in terms of energy efficiency?

VPSA (Vacuum Pressure Swing Adsorption) achieves significantly higher energy efficiency, particularly for large capacity systems, by utilizing a vacuum pump in the regeneration phase to pull nitrogen off the sieves at sub-atmospheric pressure. This reduces the energy required for the air compressor, leading to substantial operating cost savings compared to traditional PSA, which regenerates at atmospheric pressure.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager