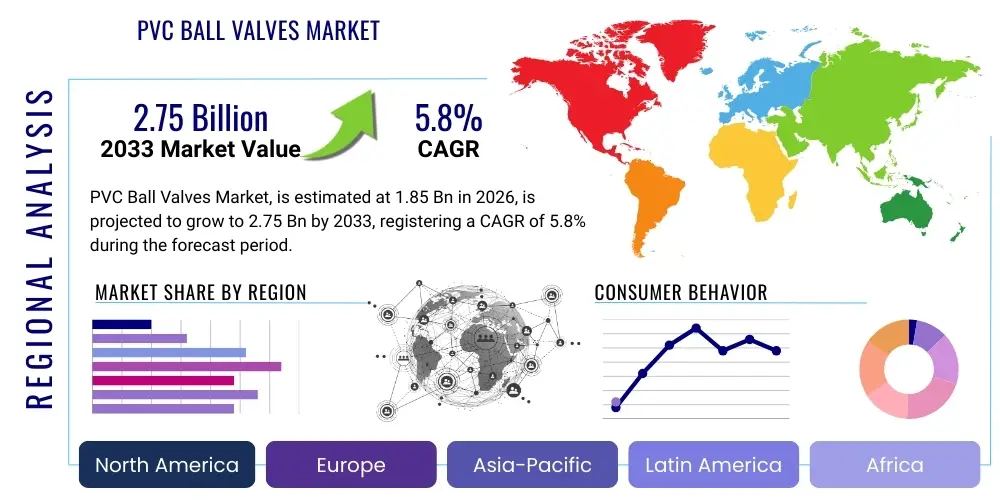

PVC Ball Valves Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 443199 | Date : Feb, 2026 | Pages : 255 | Region : Global | Publisher : MRU

PVC Ball Valves Market Size

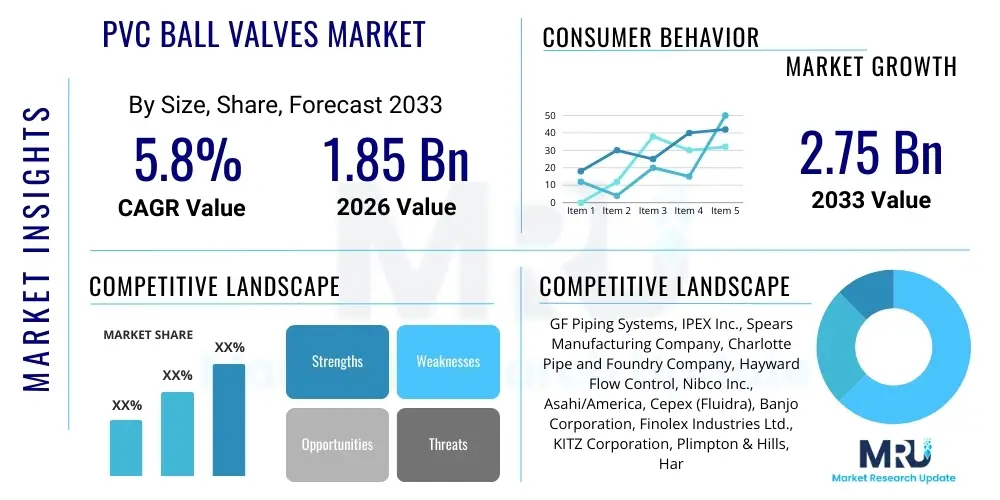

The PVC Ball Valves Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 1.85 Billion in 2026 and is projected to reach USD 2.75 Billion by the end of the forecast period in 2033. This consistent growth trajectory is primarily fueled by the accelerating infrastructural development across emerging economies, coupled with the inherent advantages of PVC materials, such as cost-effectiveness, corrosion resistance, and ease of installation, making them highly suitable alternatives to traditional metallic valves in various fluid handling systems. The increasing focus on water management and irrigation efficiency further solidifies the market expansion, particularly in agricultural and residential sectors where reliable and maintenance-light piping solutions are paramount for long-term operational success.

The market expansion is significantly influenced by regulatory shifts favoring non-toxic and lead-free plumbing components, particularly in developed regions like North America and Europe. PVC ball valves meet these stringent requirements, enabling their widespread adoption in potable water systems and food processing industries. Furthermore, the global shift towards sustainable infrastructure and energy-efficient building standards promotes the use of materials with lower embodied energy and longevity, reinforcing the demand for durable PVC alternatives over conventional materials.

While industrial applications, including chemical processing and wastewater treatment, remain crucial demand drivers, the largest volume growth is observed in municipal and residential construction projects. The affordability and operational simplicity of PVC ball valves allow for cost optimization in large-scale piping networks. This financial advantage, combined with superior chemical resistance against various acids and alkalis commonly encountered in industrial effluents, ensures the PVC ball valve market maintains a stable and upward growth trajectory throughout the forecast period.

PVC Ball Valves Market introduction

The PVC Ball Valves Market encompasses the global trade and utilization of flow control devices manufactured primarily from Polyvinyl Chloride (PVC) plastic. These valves utilize a spherical ball with a bore through the center to control the flow of media, offering quick shut-off capabilities via a 90-degree turn of the handle. PVC is valued for its exceptional resistance to corrosion, low cost, lightweight properties, and ease of solvent welding or threading installation, making these valves ideal for applications handling non-abrasive fluids, including water, weak acids, and bases. Major applications span municipal water treatment and distribution, residential plumbing and irrigation systems, chemical handling in manufacturing facilities, and swimming pool maintenance infrastructure, driven by the need for reliable, maintenance-free, and chemically inert flow control solutions.

Key market drivers include rapid urbanization leading to substantial investment in new water infrastructure and wastewater treatment plants globally, particularly in Asia Pacific. The low material cost and simplified installation processes associated with PVC ball valves provide a significant competitive edge over metallic counterparts, especially in large-scale residential and agricultural projects where budget constraints are tight. Additionally, the inherent benefits of PVC—such as thermal insulation properties and resistance to scaling—contribute to longer service life and reduced operational downtime across diverse operating environments.

Despite competition from alternative polymers like CPVC and PP, PVC ball valves maintain a dominant position due to their optimal balance of mechanical strength, chemical resistance, and economic viability. The market is characterized by ongoing innovation focused on enhancing valve durability, improving pressure ratings, and introducing features like true union designs for easier maintenance. Furthermore, the growing trend of smart farming and automated irrigation systems utilizes PVC components extensively, ensuring precise water delivery and resource efficiency, thereby stimulating demand in the agricultural sector.

PVC Ball Valves Market Executive Summary

The PVC Ball Valves Market is poised for robust expansion, projected to exceed USD 2.7 Billion by 2033, driven primarily by favorable business trends in infrastructure spending and the continuing material conversion from metallic to plastic valves in non-critical applications. Key business trends highlight manufacturers investing in fully automated production processes to enhance product consistency and scalability, meeting the high volume demand from construction and agricultural sectors. Strategic collaborations between PVC resin producers and valve manufacturers are focusing on developing high-impact resistant and UV-stabilized PVC compounds, broadening the scope of application for these valves in harsh outdoor environments. Furthermore, a rising emphasis on sustainable manufacturing practices, including recycling PVC scrap back into non-pressure components, influences consumer preference and aligns with global environmental stewardship goals, accelerating market acceptance.

Regionally, the Asia Pacific (APAC) market is expected to demonstrate the highest growth rate, fueled by massive governmental investments in smart city projects, rural water accessibility initiatives, and rapid industrialization in countries like China, India, and Southeast Asian nations. North America and Europe, while being mature markets, exhibit stable demand sustained by replacement cycles in aging municipal water systems and stringent environmental regulations favoring corrosion-resistant materials. The Middle East and Africa (MEA) region shows accelerating uptake, particularly in irrigation and non-potable water transportation projects essential for agricultural self-sufficiency and mitigating water scarcity challenges, often preferring the low-maintenance attributes of PVC valves in challenging climatic conditions.

Segment trends reveal that the True Union ball valve design is gaining prominence over single union or compact designs due to its superior ease of maintenance and repair without disturbing the adjacent piping network. By end-use, the Irrigation and Agriculture segment holds a significant market share, reflecting the widespread adoption of micro-irrigation and drip systems globally, which rely heavily on cost-effective PVC flow control components. Conversely, in the material sub-segment, virgin PVC remains dominant, but the integration of specialized stabilizers and fillers to enhance chemical and thermal tolerance is a growing trend, catering to more demanding industrial processes while retaining the core benefits of the PVC structure.

AI Impact Analysis on PVC Ball Valves Market

Analysis of common user questions regarding the impact of Artificial Intelligence (AI) on the PVC Ball Valves Market reveals core themes centered on predictive maintenance, supply chain optimization, and automated quality control during manufacturing. Users frequently inquire about how AI can predict valve failure before catastrophic leaks occur, reduce inventory holding costs by optimizing demand forecasting based on dynamic construction schedules, and integrate AI vision systems for defect detection in high-volume production lines. The overarching concern is how a relatively low-tech component like a PVC ball valve can benefit from sophisticated AI integration, leading to expectations that AI will primarily revolutionize the manufacturing efficiency and the aftermarket servicing infrastructure rather than the physical product itself. Users anticipate significant improvements in material usage efficiency and streamlined logistics, lowering overall product costs and improving reliability indices across large-scale installations.

- AI-driven predictive maintenance algorithms analyze sensor data (flow rate, pressure fluctuations) in piping systems to anticipate valve wear or potential jamming, scheduling preemptive replacement of PVC ball valves.

- Generative Design capabilities powered by AI can optimize the internal geometry of PVC valves, minimizing material usage while maximizing flow efficiency and structural integrity under stress.

- AI-based demand forecasting models improve supply chain resilience, accurately predicting regional PVC ball valve requirements based on seasonal construction trends and climate data, reducing stockouts and excess inventory.

- Automated optical inspection (AOI) systems using machine learning identify microscopic defects, inconsistencies in molding, and dimensional errors in PVC valve bodies and internal components, ensuring higher quality assurance than manual inspection.

- AI optimizes the injection molding process parameters (temperature, pressure, cycle time) for PVC compounds, minimizing scrap rates and enhancing the material crystalline structure for improved valve durability.

- Natural Language Processing (NLP) tools enhance customer service by rapidly processing technical inquiries and providing optimized recommendations for specific PVC valve configurations tailored to application parameters (e.g., chemical compatibility and maximum operating pressure).

- AI integration into smart building management systems allows PVC valves, when equipped with smart actuators, to be controlled autonomously, optimizing water usage in commercial and residential settings.

- AI monitors energy consumption patterns in valve manufacturing plants, identifying inefficiencies and suggesting optimal operational schedules, contributing to reduced production costs for PVC components.

- Robot guidance systems utilizing AI vision assist in the rapid assembly of complex multi-part PVC True Union valves, boosting throughput and maintaining strict component alignment tolerances.

- Machine learning models analyze historical performance data across different application environments (e.g., extreme UV exposure, chemical baths) to inform future material modifications and product design iterations for specialized PVC ball valves.

DRO & Impact Forces Of PVC Ball Valves Market

The PVC Ball Valves Market is profoundly influenced by a complex interplay of Drivers, Restraints, and Opportunities (DRO), which collectively determine its growth trajectory and competitive landscape. Key drivers include the overwhelming cost advantage and corrosion resistance of PVC over traditional metals, coupled with surging global infrastructure investment, particularly in water and sewage systems mandated by rapid urbanization. Restraints primarily involve the inherent limitations of PVC, such as lower pressure and temperature thresholds compared to metal valves, restricting their use in high-performance industrial applications, along with significant market consolidation and intense price competition which squeeze profit margins for smaller players. However, substantial opportunities exist in developing highly customized, specialized PVC compounds (e.g., UV-stabilized or fire-retardant grades) and expanding penetration in emerging agricultural automation markets where durability and low cost are critical determinants of adoption. These forces necessitate continuous product innovation and diversification of geographical sales channels to mitigate risks and capitalize on long-term growth trends.

Impact forces acting upon this market include political stability influencing large-scale public infrastructure projects, fluctuating prices of PVC resin derived from petrochemical feedstock, and changing trade tariffs affecting the global movement of manufactured valves. Environmental regulations concerning the disposal and recyclability of plastic components exert pressure on manufacturers to adopt more sustainable PVC formulations and end-of-life management strategies. Technological advancements in competing materials, such as fiberglass-reinforced plastics or high-density polyethylene, also pose an indirect threat, demanding continuous improvement in the structural integrity and application range of PVC offerings to maintain market share dominance across high-volume utility applications.

Specifically, the escalating global water crisis acts as a potent driver, pushing governments worldwide to invest in leak prevention and efficient distribution networks, creating sustained demand for reliable shut-off devices like PVC ball valves. Conversely, negative public perception regarding plastics use, particularly in food and beverage handling, requires manufacturers to maintain rigorous certifications (like NSF approval for potable water) and transparently communicate the safety and non-toxic nature of the specific PVC grades utilized. The net impact of these forces remains positive, favoring market growth, provided manufacturers strategically address material limitations and adhere to evolving regulatory standards.

Segmentation Analysis

The PVC Ball Valves Market segmentation provides a detailed structural view of demand distribution based on design, size, material grade, and application, allowing stakeholders to identify high-growth niches and tailor their product strategies effectively. The market is primarily segmented by Type (Compact, True Union, Single Union), Size (Small, Medium, Large Diameter), End-Use Application (Irrigation, Chemical Processing, Residential/Commercial Plumbing, HVAC, Wastewater Treatment), and Distribution Channel (Direct Sales, Distributors/Wholesalers). This granular analysis underscores the functional preferences of various buyer groups, from contractors seeking cost-effective compact valves for residential systems to industrial procurement teams requiring robust true union designs for ease of maintenance in chemical plants. The dominance of the True Union segment highlights the increasing value placed on operational longevity and reduced downtime in institutional and industrial settings, signaling a preference for long-term total cost of ownership over initial purchasing price.

Geographically, market segmentation reflects significant variances in demand patterns; for instance, large-diameter valves see greater usage in municipal water systems prevalent in rapidly expanding urban centers in Asia Pacific, whereas small-to-medium sized valves dominate the highly regulated replacement and maintenance markets of North America and Europe. Understanding these segment-specific requirements is critical for manufacturers specializing in particular product lines, such as those focused solely on high-pressure rated compact valves for pool and spa installations, a segment highly sensitive to seasonal demand fluctuations and regulatory changes regarding water safety and circulation efficiency. Furthermore, the segmentation by material grade, although often implicit within the PVC category, is becoming increasingly relevant, differentiating standard PVC from enhanced versions like CPVC or specialized UV-resistant PVC for specific outdoor or high-temperature applications.

The proliferation of standardized product offerings means competitive advantage is often gained through segment focus, offering customization, or delivering superior logistical support tailored to specific end-user segments. For example, focusing on the agriculture segment requires deep logistical capabilities to serve remote farms and offering durable valves resistant to common agricultural chemicals and physical impact. Conversely, targeting the residential segment necessitates adherence to broad consumer safety standards and attractive aesthetic designs suitable for exposed plumbing. Detailed segmentation analysis thus guides resource allocation towards the most profitable and strategically aligned product development initiatives within the broader PVC valve market landscape.

- By Type:

- Compact Ball Valves

- True Union Ball Valves

- Single Union Ball Valves

- By Size:

- Small Diameter (0.5 inch to 1.5 inch)

- Medium Diameter (2 inch to 4 inch)

- Large Diameter (Above 4 inch)

- By End-Use Application:

- Irrigation and Agriculture

- Water Treatment and Distribution (Municipal)

- Chemical and Process Industry

- Residential and Commercial Plumbing

- Swimming Pools and Aquaculture

- HVAC and Cooling Towers

- Wastewater Management

- By Operating Mechanism:

- Manual

- Actuated (Electric, Pneumatic)

- By Distribution Channel:

- Direct Sales

- Distributors and Wholesalers

- Retail and E-commerce

Value Chain Analysis For PVC Ball Valves Market

The value chain for the PVC Ball Valves Market begins with the upstream raw material suppliers, primarily PVC resin manufacturers and additive producers (stabilizers, plasticizers, colorants). The profitability and stability of valve manufacturers are heavily reliant on the consistent supply and fluctuating price of virgin PVC resin, which is derived from petrochemical processes. Upstream analysis highlights that competitive dynamics in the resin market often dictate the cost structure of the final valve product. Manufacturers frequently employ long-term contracts or vertical integration strategies to mitigate volatility in raw material costs and ensure material quality adheres to strict industry standards required for pressure applications.

The midstream segment involves the core manufacturing process, including injection molding of the valve body, ball, and stem components, followed by precise machining, assembly, and rigorous pressure testing. Efficiency at this stage, achieved through advanced automation and strict quality control protocols, is crucial for maintaining competitive pricing and product reliability. Key differentiating factors among manufacturers at this stage include proprietary molding techniques that enhance durability, and certifications (e.g., NSF, ISO) validating performance for specific applications like potable water. Consolidation among molders and assemblers is a notable trend, aiming for economies of scale and centralized R&D efforts to optimize designs.

Downstream distribution channels are diverse, ranging from direct sales for large municipal or industrial projects to extensive networks of authorized distributors, wholesalers, and increasingly, specialized e-commerce platforms serving contractors and maintenance professionals. The complexity of the distribution structure often involves multiple layers, where master distributors stock high volumes, and regional dealers provide technical support and localized inventory. The most successful indirect channels are those that offer high levels of technical expertise and immediate product availability, crucial for construction and repair projects where time sensitivity is paramount. Furthermore, the growth of online sales has expanded geographical reach, allowing smaller manufacturers to compete globally by bypassing traditional distribution hierarchies.

PVC Ball Valves Market Potential Customers

The potential customers and end-users of PVC Ball Valves are highly diverse, spanning essential public utilities, large-scale industrial operations, and decentralized residential and commercial property development. Primary buyers include municipal water authorities and utility districts responsible for managing water distribution networks, sewage systems, and treatment plants, where the corrosion resistance and longevity of PVC are highly valued. These institutional buyers typically purchase large volumes of medium to large-diameter valves through competitive public tenders, emphasizing product certifications and long-term warranties to ensure system reliability and minimize future maintenance costs, making them the cornerstone of market demand.

The second major group comprises professional contractors and installers specializing in irrigation, landscaping, and residential/commercial plumbing. This segment includes agricultural enterprises deploying drip and pivot irrigation systems, where thousands of small-diameter PVC ball valves are required for zone control and precise water flow management. These users prioritize ease of installation, availability via local distributors, and competitive pricing, often opting for compact or single-union designs that facilitate quick field repairs and system modifications necessary for agricultural operations.

Additionally, specialized industrial sectors such as chemical processing, aquaculture, and swimming pool construction form critical niche markets. Chemical plants utilize PVC valves for handling non-corrosive chemicals and low-temperature acids, favoring True Union designs for frequent maintenance requirements. Swimming pool builders rely extensively on PVC due to its resistance to chlorine and other pool chemicals, focusing on UV-stabilized models for outdoor durability. These diverse end-user applications highlight the PVC ball valve's position as a versatile, entry-level flow control device suited for applications where pressure and temperature constraints are moderate, but resistance to chemical attack and environmental degradation is essential.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.85 Billion |

| Market Forecast in 2033 | USD 2.75 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | GF Piping Systems, IPEX Inc., Spears Manufacturing Company, Charlotte Pipe and Foundry Company, Hayward Flow Control, Nibco Inc., Asahi/America, Cepex (Fluidra), Banjo Corporation, Finolex Industries Ltd., KITZ Corporation, Plimpton & Hills, Harvel Plastics, Lesso Group Holdings Ltd., Astral Pipes, Vinidex Pty Ltd., American Granby Inc., FIP S.p.A., Polypipe Group plc, Emuge-Frank GmbH |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

PVC Ball Valves Market Key Technology Landscape

The technology landscape in the PVC Ball Valves Market is less focused on radical product reinvention and more centered on optimizing manufacturing precision, enhancing material properties, and integrating connectivity for smarter flow management. A key technological trend is the advancement in injection molding techniques, specifically the use of computer-aided design (CAD) and simulation software to ensure uniform wall thickness and minimize internal stresses during the molding process. This precision engineering reduces the risk of thermal deformation and micro-cracking, significantly increasing the pressure rating and overall longevity of standard PVC components. Manufacturers are increasingly utilizing multi-cavity molds and highly automated robotic extraction systems to boost throughput and maintain competitive unit costs essential for high-volume consumer and utility applications.

Material science innovation constitutes another critical area, with focus placed on developing specialized PVC compounds tailored for extreme conditions. This includes the formulation of enhanced UV-resistant PVC (for prolonged outdoor exposure in agricultural settings), and impact-modified PVC designed to withstand physical shocks during installation or operation. Furthermore, there is growing interest in integrating anti-microbial additives into PVC formulations destined for potable water and food processing applications, ensuring compliance with strict public health standards by inhibiting biofilm growth on the valve's interior surfaces. These chemical enhancements broaden the applicability of PVC valves into areas traditionally reserved for higher-end polymers or metals.

In terms of operational technology, the integration of smart actuation and monitoring systems represents the future of high-value PVC valve applications. While the valve body remains passive PVC, the mechanism is becoming increasingly sophisticated, featuring electric or pneumatic actuators equipped with IoT sensors. These sensors facilitate remote operation, flow measurement, and data logging, enabling integration into larger SCADA systems for centralized water or chemical management. Although currently representing a smaller segment, this transition towards digitally enabled flow control solutions leverages AI-driven analytics for real-time performance optimization and predictive maintenance, adding significant value beyond the basic mechanical shut-off function of the traditional PVC ball valve.

Regional Highlights

- Asia Pacific (APAC): APAC is the undisputed growth engine of the PVC Ball Valves Market, characterized by massive investments in public infrastructure and rapid urbanization. Countries like China, India, and Indonesia are prioritizing centralized water treatment, sewage infrastructure expansion, and agricultural modernization, driving overwhelming demand for cost-effective PVC piping components. The region benefits from lower manufacturing costs and a large consumer base, fueling high volume production of compact and single-union valves for residential and construction projects. Governmental initiatives aimed at improving rural sanitation and access to clean water create continuous opportunities, often preferring PVC due to its affordability and durability in diverse climatic zones. This region’s growth is sustained by both new project construction and extensive replacement cycles in rapidly aging existing utility networks.

- North America: The North American market is highly mature but maintains stable growth primarily driven by stringent quality standards and infrastructure replacement. Demand is concentrated in specialized segments, particularly high-quality True Union valves for industrial applications, and certified NSF-rated valves for residential and commercial potable water systems. The region shows a strong preference for domestically manufactured or highly certified imported products, reflecting a focus on reliability and regulatory compliance. Replacement of aging metallic infrastructure, especially in municipal water distribution, constitutes a significant market activity, favoring PVC for its excellent resistance to corrosion caused by aggressive water chemistries prevalent in parts of the U.S. and Canada. The pool and spa industry also remains a consistent, high-value consumer of specialized PVC ball valves optimized for chemical resistance and UV exposure.

- Europe: The European market is characterized by slow but steady growth, heavily influenced by environmental regulations and a focus on water efficiency. Demand is highly segmented, with strong emphasis on product sustainability and compliance with REACH regulations regarding chemical additives. Western Europe drives demand for high-end, specialized PVC valves used in chemical processing and pharmaceutical facilities, where precise dosing and minimal contamination risk are paramount. Eastern and Central Europe demonstrate higher growth rates, mirroring infrastructural catch-up dynamics seen in APAC, particularly in upgrading older Soviet-era water and heating infrastructure. The market penetration of actuated (automated) PVC ball valves is notably higher in Europe compared to other regions, reflecting advanced industrial automation standards.

- Latin America (LATAM): LATAM presents a market characterized by high potential but economic volatility. Brazil and Mexico are the dominant markets, driven by necessary public investments in sanitation and water management systems struggling to keep pace with population growth. The agricultural sector, crucial to the LATAM economy, is a major consumer, utilizing PVC ball valves for large-scale irrigation projects and fluid fertilizer applications where cost-efficiency is a primary purchasing criterion. Challenges include reliance on imported raw materials and localized manufacturing limitations, but the fundamental need for robust and affordable infrastructure components ensures continued demand for PVC solutions over higher-cost alternatives.

- Middle East and Africa (MEA): MEA is experiencing significant demand acceleration, particularly in Gulf Cooperation Council (GCC) countries focusing on massive desalination and water transportation projects. The region's hot climate necessitates materials that are highly resilient to thermal stress and UV degradation, driving preference for specialized PVC compounds. In Africa, initiatives backed by international aid focusing on community water access and irrigation development in countries like South Africa and Nigeria are boosting the use of basic, low-cost PVC compact valves. The necessity for reliable fluid control in areas facing extreme water scarcity makes PVC ball valves an essential component in managing scarce resources and ensuring the viability of arid-land agriculture, positioning MEA as a rapidly emerging, high-potential market.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the PVC Ball Valves Market.- GF Piping Systems

- IPEX Inc.

- Spears Manufacturing Company

- Charlotte Pipe and Foundry Company

- Hayward Flow Control

- Nibco Inc.

- Asahi/America

- Cepex (Fluidra)

- Banjo Corporation

- Finolex Industries Ltd.

- KITZ Corporation

- Plimpton & Hills

- Harvel Plastics

- Lesso Group Holdings Ltd.

- Astral Pipes

- Vinidex Pty Ltd.

- American Granby Inc.

- FIP S.p.A.

- Polypipe Group plc

- Emuge-Frank GmbH

Frequently Asked Questions

Analyze common user questions about the PVC Ball Valves market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary advantage of PVC Ball Valves over metallic alternatives?

The primary advantages are superior corrosion resistance against water, acids, and alkalis, coupled with significantly lower material and installation costs. PVC valves are lightweight and require minimal maintenance, making them ideal for non-critical, high-volume fluid handling applications.

What are the temperature and pressure limitations of standard PVC Ball Valves?

Standard PVC ball valves typically operate optimally at temperatures below 140°F (60°C). They are generally limited to lower pressure ratings compared to metal valves, typically suitable for up to 150 PSI, depending on the valve size and specific compound formulation used.

Are PVC Ball Valves safe for potable (drinking) water systems?

Yes, many PVC ball valves are certified safe for potable water. Buyers should ensure the specific product carries recognized certifications, such as NSF/ANSI Standard 61, verifying that the PVC material and assembly process do not leach harmful substances into the drinking water supply.

Which end-use application drives the highest demand in the market?

The Irrigation and Agriculture sector, along with Municipal Water Treatment and Distribution, collectively drive the highest volume demand, leveraging PVC's cost-effectiveness for extensive network installations and routine flow control in large-scale farming and public utility projects.

What is a True Union PVC Ball Valve and why is it preferred in industrial settings?

A True Union PVC Ball Valve features two solvent or threaded ends that allow the valve body to be disconnected from the piping system without requiring the pipes themselves to be cut. This design is highly preferred in industrial settings because it facilitates swift inspection, cleaning, or replacement, significantly reducing maintenance downtime.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager