Quantitative Respirator Fit Testing Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 441812 | Date : Feb, 2026 | Pages : 253 | Region : Global | Publisher : MRU

Quantitative Respirator Fit Testing Market Size

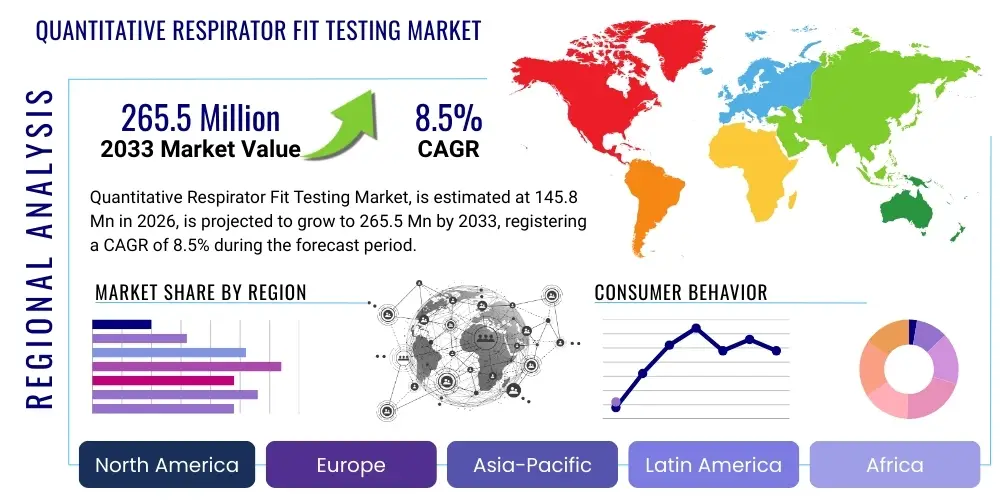

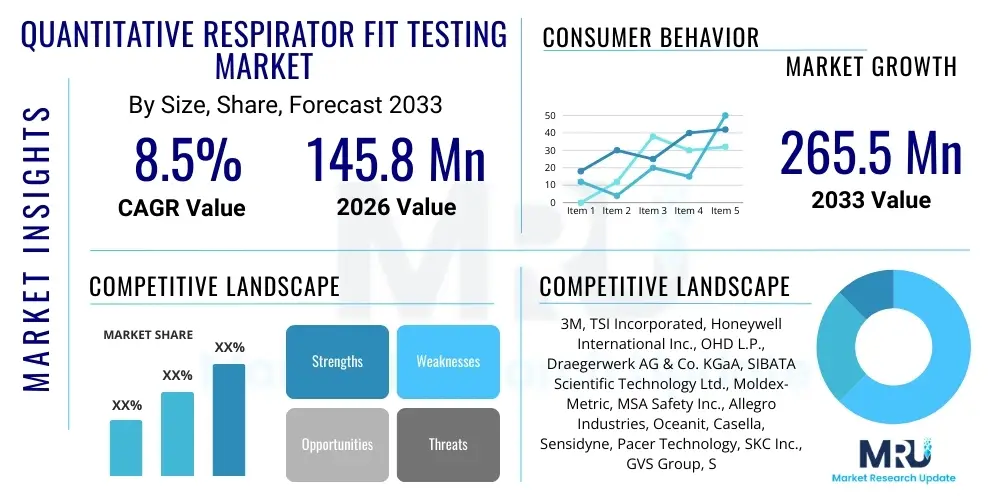

The Quantitative Respirator Fit Testing Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.5% between 2026 and 2033. This robust growth trajectory is driven by stringent occupational health and safety regulations globally, particularly concerning airborne hazards in healthcare and industrial settings. The increasing emphasis on workplace safety mandates that workers exposed to hazardous particulates, gases, or vapors must wear properly fitted respirators, a requirement that only quantitative testing can definitively satisfy.

The market is estimated at $145.8 Million in 2026 and is projected to reach $265.5 Million by the end of the forecast period in 2033. This substantial expansion is fueled by technological advancements, such as the miniaturization of Condensation Nuclei Counting (CNC) technology, making quantitative fit testing more accessible and portable for on-site assessments across diverse industries, including oil and gas, pharmaceuticals, and general manufacturing. Furthermore, major global health crises have significantly heightened awareness regarding respiratory protection, establishing quantitative fit testing as an indispensable standard of practice.

Quantitative Respirator Fit Testing Market introduction

The Quantitative Respirator Fit Testing Market encompasses devices and services used to measure the adequacy of a respirator’s seal on an individual’s face. This critical process involves the use of specialized instruments—primarily relying on Condensation Nuclei Counting (CNC) technology or particle counting—to generate a numerical measure called the ‘fit factor,’ ensuring the respirator provides the intended level of protection against workplace contaminants. Major applications span high-risk environments in healthcare, where protection against biological aerosols is paramount, and industrial sectors like mining, construction, and manufacturing, which require defense against dust, fumes, and chemicals. The primary benefits include enhanced worker safety, compliance with regulatory standards (such as OSHA and HSE), and reduced liability for employers. Key driving factors include escalating global regulatory pressure, heightened awareness of occupational lung diseases, and the continuous innovation leading to more portable and user-friendly testing equipment that can deliver accurate, objective results rapidly.

Quantitative Respirator Fit Testing Market Executive Summary

The Quantitative Respirator Fit Testing Market is characterized by robust growth anchored in global compliance mandates and persistent demand from high-hazard industries. Current business trends indicate a shift towards subscription-based service models and cloud-integrated systems that facilitate data management and reporting for large organizations. Regional trends show North America maintaining market dominance due to early adoption and strict enforcement of occupational safety laws, while the Asia Pacific region is experiencing the highest growth rate, driven by rapid industrialization and improving regulatory frameworks in countries like China and India. Segmentation trends highlight the CNC technology segment as the fastest-growing technology due to its ability to accurately test all types of respirators, including filtering facepieces (N95s), and the healthcare sector retaining its position as the largest end-user segment following global health events that necessitated widespread respirator use and subsequent testing protocols. Furthermore, the market is becoming increasingly competitive, focusing on the development of more automated and less intrusive testing protocols to minimize downtime for workers.

AI Impact Analysis on Quantitative Respirator Fit Testing Market

User queries regarding the intersection of Artificial Intelligence (AI) and quantitative fit testing predominantly center on three themes: predictive modeling for respirator leakage, automation of the testing protocol, and enhanced data analytics for compliance reporting. Users are highly interested in how AI can move beyond simple numerical measurements to analyze facial geometry data and historical fit factors, predicting potential poor fit scenarios before testing even occurs, thereby optimizing resource allocation. Another significant concern is the expectation that AI integration will streamline the currently time-intensive testing procedures, automating calibration, sequence execution, and final documentation, ensuring absolute consistency regardless of the technician's experience level, directly addressing the variability associated with manual protocol adherence.

The application of AI is expected to revolutionize compliance management. By deploying machine learning algorithms on aggregated fit testing data across thousands of employees and different respirator models, safety managers can identify critical risk patterns, such as shifts requiring higher failure rates or specific equipment batches performing poorly. This capability allows for predictive maintenance of testing equipment, proactive employee training adjustments, and targeted procurement decisions. Ultimately, AI transforms fit testing from a mandatory periodic requirement into a continuous, data-driven safety optimization process, significantly enhancing the overall effectiveness of respiratory protection programs in complex organizational structures.

- AI enables predictive modeling of respirator fit based on facial scanning data and historical test results, minimizing failed tests.

- Machine learning optimizes testing sequences and calibration checks, drastically reducing the required testing time per employee.

- Automated reporting and data integrity checks, utilizing AI for anomaly detection in compliance logs.

- Improved quality control through AI analysis of aerosol generation and flow stability within the testing equipment.

- Development of personalized fit protocols based on individual historical physiological responses to different respirator models.

DRO & Impact Forces Of Quantitative Respirator Fit Testing Market

The Quantitative Respirator Fit Testing Market is primarily driven by stringent regulatory frameworks enforced by bodies like OSHA, NIOSH, and the EU's HSE, which mandate objective fit testing for reusable and disposable respirators utilized in hazardous environments, making compliance a non-negotiable business cost. Additionally, the increasing incidence of occupational respiratory diseases, coupled with growing public and corporate emphasis on Environmental, Social, and Governance (ESG) standards related to worker welfare, compels industries to invest proactively in superior protection measures. However, restraints include the high initial capital expenditure associated with purchasing sophisticated CNC fit testing equipment and the perceived complexity of conducting the standardized protocols, which necessitates specialized training for operators. Opportunities lie in expanding adoption in emerging economies where industrialization is rapidly outpacing the establishment of comprehensive safety standards, and through the integration of testing solutions with existing IoT and safety management platforms, enhancing data connectivity and operational efficiency.

The market faces significant impact forces originating from both the supply and demand sides. On the demand side, the recurring threat of global pandemics or widespread environmental crises (e.g., wildfires, pollution spikes) exerts a powerful positive force, skyrocketing the immediate need for reliable respirator testing. Conversely, technological advancements, specifically in high-throughput screening methods and automated testing procedures, act as a key driver on the supply side, continuously improving the value proposition of quantitative testing over qualitative alternatives. The threat of substitutes, mainly from perceived simpler and cheaper qualitative fit testing, remains a mitigating factor, especially for small businesses, although quantitative testing’s superior accuracy and legal defensibility increasingly marginalize qualitative methods in high-liability sectors.

Furthermore, innovation in portable and non-traditional testing technologies is creating new avenues for market penetration. The development of fit testers that are less dependent on ambient aerosol concentrations and offer enhanced diagnostic capabilities regarding the source of leaks provides a significant competitive advantage. Successful market players are focusing on developing comprehensive software suites that integrate testing protocols, scheduling, training records, and maintenance logs into one cohesive platform, aligning with the industry trend toward holistic safety management systems. This integration minimizes administrative burdens and maximizes the strategic utility of the testing data, further solidifying the market's trajectory towards digitalization and automation.

Segmentation Analysis

The Quantitative Respirator Fit Testing market is broadly segmented based on product type, technology, and end-user, reflecting the diverse requirements across industries and compliance needs. The product segmentation details the differentiation between highly mobile, battery-operated portable units favored for fieldwork or multiple site testing, and larger, more robust desktop or console systems typically utilized in centralized testing centers or hospital environments. Technological segmentation is crucial, differentiating the market dominance of Condensation Nuclei Counting (CNC) from other particle counting methods due to CNC’s reliability across various environments and its acceptance by major regulatory bodies globally. This structural segmentation allows market participants to tailor their offerings precisely to the operational scale, budget, and regulatory mandates of their target clientele, ensuring optimal resource allocation and compliance adherence across sectors ranging from heavy industry to specialized pharmaceutical manufacturing.

- By Product Type:

- Portable Fit Testers

- Desktop/Console Fit Testers

- Accessories & Consumables (Probes, Adapters, Alcohol/Isopropanol)

- By Technology:

- Condensation Nuclei Counting (CNC)

- Particle Counting/Photometric

- Pressure Differential/Controlled Negative Pressure (CNP)

- By End-User:

- Healthcare (Hospitals, Clinics, Emergency Services)

- Industrial Sector (Manufacturing, Automotive, Construction)

- Oil & Gas and Mining

- Pharmaceutical and Biotechnology

- Government & Military (Defense, Public Health Agencies)

Value Chain Analysis For Quantitative Respirator Fit Testing Market

The value chain for the Quantitative Respirator Fit Testing market begins with upstream component manufacturers specializing in highly precise optical sensors, aerosol generators, and fluid dynamics control systems, which are foundational to CNC technology. These components are sourced by Original Equipment Manufacturers (OEMs), who focus heavily on R&D to enhance portability, accuracy, and user interface design, investing substantial resources into meeting international standards like ISO and OSHA protocols. Downstream distribution is critical, often involving specialized safety equipment distributors and third-party testing service providers who bridge the gap between complex technology and end-users. Direct sales channels are frequently employed for large institutional clients (e.g., government agencies or large hospital networks), while indirect channels rely on regional distributors who manage inventory, calibration services, and localized technical support.

The downstream segment also includes the provision of recurring services, such as annual calibration and maintenance agreements, which form a significant revenue stream and enhance customer loyalty. Certification and training services—ensuring end-users are competent in administering the test protocols—are often integrated into the value proposition, either delivered directly by the OEM or through certified training partners. This reliance on expert training and post-sale technical support underscores the high-value nature of the offering, differentiating it significantly from simpler safety product markets.

The shift towards cloud-based data management and reporting platforms has added a significant layer to the value chain, where software providers and IT integrators now play a role in ensuring compliance data is securely stored, easily auditable, and accessible across multiple organizational sites. This digital integration maximizes the efficiency of the testing process, making the entire solution more attractive to large multinational corporations requiring standardized global safety protocols. Effective channel management, therefore, requires manufacturers to maintain strong relationships with specialized software developers and technical service organizations alongside traditional equipment distributors.

Quantitative Respirator Fit Testing Market Potential Customers

Potential customers for quantitative respirator fit testing equipment are predominantly organizations operating in environments where regulatory exposure limits dictate the mandatory use of tight-fitting facepiece respirators, ensuring employee health protection against airborne hazards. The largest segment remains the Healthcare sector, including hospitals, clinics, and emergency medical services (EMS), driven by the recurrent need to fit test N95 and equivalent respirators for protection against biological agents, airborne infections, and chemotherapy drugs. Following this are the vast Industrial sectors, encompassing heavy manufacturing, automotive production, and construction, where workers face exposure to silica dust, welding fumes, asbestos, and various chemical aerosols, demanding rigorous fit testing compliance to mitigate long-term occupational illnesses.

The Oil & Gas and Mining industries represent another high-value customer base, utilizing fit testing services and equipment to protect personnel from toxic gases like H2S, dusts, and complex chemical mixtures encountered during extraction and processing activities. These industries often require highly portable testing solutions due to remote operational sites. Furthermore, the Pharmaceutical and Biotechnology industries are critical consumers, requiring precise respiratory protection during sterile compounding, handling of potent active pharmaceutical ingredients (APIs), and maintenance activities in cleanroom environments, where adherence to stringent Good Manufacturing Practices (GMP) and worker protection standards is non-negotiable.

Finally, Government bodies, including national defense forces, public health departments, and first responders (fire and police), are consistent buyers, maintaining large inventories of specialized respirators that require regular, mandated quantitative testing to ensure operational readiness and compliance. These agencies often purchase large-scale contracts for equipment and maintenance, emphasizing durability, accuracy, and the capability for high-throughput testing during emergency scenarios, solidifying their role as essential long-term customers in the market landscape.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $145.8 Million |

| Market Forecast in 2033 | $265.5 Million |

| Growth Rate | 8.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | 3M, TSI Incorporated, Honeywell International Inc., OHD L.P., Draegerwerk AG & Co. KGaA, SIBATA Scientific Technology Ltd., Moldex-Metric, MSA Safety Inc., Allegro Industries, Oceanit, Casella, Sensidyne, Pacer Technology, SKC Inc., GVS Group, Sundstrom Safety AB, ILC Dover, RAE Systems (by Honeywell), Sperian Protection (now Honeywell). |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Quantitative Respirator Fit Testing Market Key Technology Landscape

The technological landscape of the Quantitative Respirator Fit Testing market is overwhelmingly dominated by the Condensation Nuclei Counting (CNC) method. CNC technology is preferred because it can measure sub-micron particles, mimicking real-world aerosols, and is the only technique recognized by major regulatory bodies (like OSHA) for testing all types of tight-fitting respirators, including filtering facepieces (N95s). Recent technological advancements in CNC have focused primarily on miniaturization, transitioning historically bulky laboratory-grade equipment into highly portable, hand-held devices. This portability significantly enhances flexibility, allowing corporations to conduct efficient on-site testing for large decentralized workforces, reducing logistical costs and minimizing worker downtime associated with travel to centralized testing centers.

A second major technological trend involves the integration of smart features and connectivity into testing units. Newer models are equipped with Wi-Fi or Bluetooth capabilities, enabling seamless data transfer directly to cloud-based health and safety management systems. This integration supports automated record-keeping, ensures immediate audit readiness, and allows for centralized monitoring of compliance across global operations. Furthermore, sophisticated software interfaces guide technicians through the complex testing protocols, reducing human error and improving the consistency and reliability of the fit factor measurements, critical for legal defensibility.

While CNC leads, complementary technologies like Controlled Negative Pressure (CNP) testing persist in certain specialized segments, particularly where minimizing exposure to ambient challenge aerosols is paramount. However, the overarching technological trajectory is towards enhanced automation and diagnostic capability—systems that not only provide a pass/fail result but also offer specific feedback on where the seal failed (e.g., cheekbone, chin area), assisting in personalized mask selection and adjustment. This diagnostic focus, coupled with enhanced durability and reduced calibration complexity, defines the cutting edge of quantitative fit testing equipment development.

Regional Highlights

The global market for Quantitative Respirator Fit Testing exhibits distinct regional performance profiles driven by varying regulatory stringency, industrial concentration, and safety awareness levels. North America currently holds the largest market share, predominantly due to the strict enforcement of occupational health and safety standards by organizations such as OSHA in the United States and similar agencies in Canada. The high concentration of critical end-user segments, including large hospital networks, advanced manufacturing facilities, and extensive oil and gas operations, necessitates widespread adoption of quantitative methods, establishing this region as the benchmark for compliance rigor and technological deployment. The mature nature of this market means growth is steady, driven by replacement cycles, continuous compliance audits, and adoption of newer, IoT-enabled testing solutions.

Europe represents the second-largest market, characterized by comprehensive regulatory oversight from the European Agency for Safety and Health at Work (EU-OSHA). Western European nations, particularly Germany, the UK, and France, exhibit high maturity and consistent demand, focusing heavily on worker protection against industrial pollutants and stringent standards within the pharmaceutical industry. The emphasis in Europe is often placed on the longevity and precision of equipment, coupled with robust training certification schemes. Expansion in this region is increasingly focused on Eastern Europe, where industrial expansion is accelerating and regulatory compliance is tightening, opening new avenues for both equipment sales and third-party testing services.

The Asia Pacific (APAC) region is projected to register the highest Compound Annual Growth Rate (CAGR) during the forecast period. This rapid expansion is primarily fueled by accelerated industrialization in countries like China, India, and Southeast Asian nations, leading to increased factory output and subsequent rise in occupational hazards. While regulatory frameworks in some areas are less mature than in the West, there is a growing governmental and corporate mandate to improve worker safety standards, often catalyzed by international investment requirements. The immense population size and massive industrial base in APAC create a vast, underdeveloped market for respiratory protection, making it the most significant growth opportunity for quantitative fit testing equipment manufacturers.

- North America: Market leader driven by strict OSHA enforcement, mature healthcare systems, and high industrial safety expenditure. Focus on replacing qualitative methods with superior CNC technology and integrating testing data into existing safety software.

- Europe: Strong market supported by EU-wide occupational health directives and high demand from pharmaceutical and advanced manufacturing sectors. Emphasis on certified training and sophisticated equipment for complex respirator types.

- Asia Pacific (APAC): Fastest-growing market due to rapid industrial and infrastructure development. Growth is propelled by increasing adoption of international safety standards and large-scale manufacturing operations in countries like China and India.

- Latin America (LATAM): Developing market characterized by growing mining and oil and gas activity. Adoption is often localized and project-dependent, but government pressure for safety compliance is slowly increasing, offering foundational growth potential.

- Middle East and Africa (MEA): Growth concentrated in the Gulf Cooperation Council (GCC) countries due to massive petrochemical, construction, and infrastructure projects, requiring stringent protection against heat and hazardous materials. African market growth is nascent, focused primarily on large-scale mining operations.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Quantitative Respirator Fit Testing Market, emphasizing their product portfolio, technological specialization (especially in CNC), strategic acquisitions, and global distribution networks. These companies are instrumental in setting industry standards and driving technological innovation, particularly in areas like portability and data integration.- 3M

- TSI Incorporated

- Honeywell International Inc.

- OHD L.P.

- Draegerwerk AG & Co. KGaA

- SIBATA Scientific Technology Ltd.

- Moldex-Metric

- MSA Safety Inc.

- Allegro Industries

- Oceanit

- Casella

- Sensidyne

- Pacer Technology

- SKC Inc.

- GVS Group

- Sundstrom Safety AB

- ILC Dover

- RAE Systems (by Honeywell)

- Sperian Protection (now Honeywell)

Frequently Asked Questions

Analyze common user questions about the Quantitative Respirator Fit Testing market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary difference between quantitative and qualitative respirator fit testing?

Quantitative fit testing (QNFT) provides an objective, numerical measurement (fit factor) of the respirator's seal adequacy, typically using CNC technology. Qualitative fit testing (QLFT) relies on the wearer's subjective sense of taste or smell using challenge agents, which provides only a pass/fail result without a specific numerical fit factor, making QNFT the legally preferred method for half-mask and full-face respirators in high-hazard environments.

Which regulatory bodies mandate the use of Quantitative Respirator Fit Testing?

The primary regulatory body mandating QNFT, particularly for tight-fitting respirators like N95s and full-face elastomeric masks, is the U.S. Occupational Safety and Health Administration (OSHA). Similar requirements are enforced by the Health and Safety Executive (HSE) in the UK and analogous occupational safety agencies throughout the European Union and Asia Pacific, driving global market demand for these objective methods.

What is Condensation Nuclei Counting (CNC) technology and why is it dominant?

CNC technology measures the concentration of microscopic particles (nuclei) both inside and outside the respirator, calculating the objective fit factor. It dominates the market because it is highly accurate, approved for use with disposable filtering facepiece respirators (like N95s), and offers immediate, verifiable results essential for rigorous compliance and worker safety documentation.

How frequently must employees undergo quantitative respirator fit testing?

Regulations typically require fit testing to be conducted at least annually for all employees required to wear a tight-fitting respirator. Furthermore, testing must be repeated whenever a different make, model, or size of respirator is used, or if there are significant facial changes in the wearer (e.g., weight change, dental work) that could compromise the seal.

What are the major technological trends driving the market growth?

Market growth is significantly driven by enhanced portability of CNC devices, allowing for efficient on-site testing, and the integration of testing units with cloud-based safety management software. These trends streamline compliance reporting, automate data record-keeping, and reduce the overall administrative burden associated with large-scale respirator programs.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager