Quartz Tubing Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 442861 | Date : Feb, 2026 | Pages : 249 | Region : Global | Publisher : MRU

Quartz Tubing Market Size

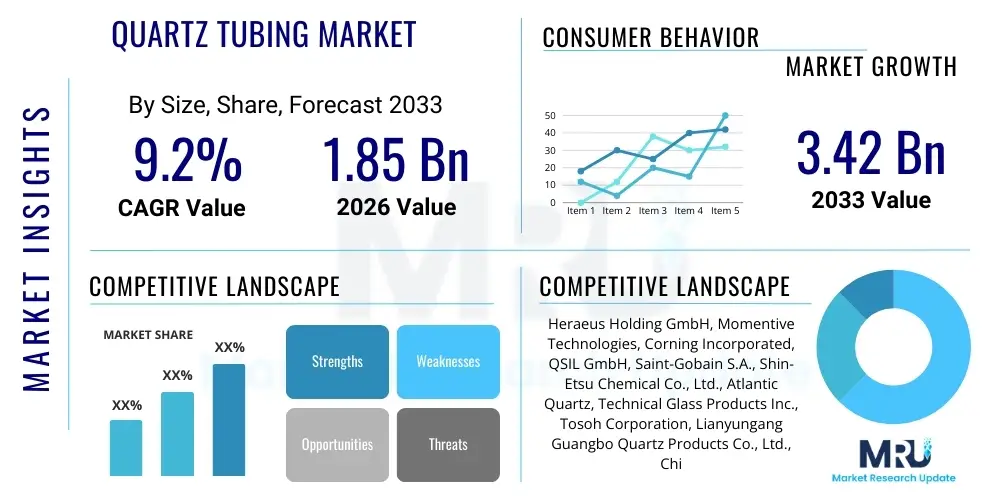

The Quartz Tubing Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.8% between 2026 and 2033. The market is estimated at USD 1.85 Billion in 2026 and is projected to reach USD 3.12 Billion by the end of the forecast period in 2033. This growth is primarily driven by escalating demand in the semiconductor manufacturing sector, where high-purity quartz components are essential for wafer processing and thermal treatment, coupled with rising adoption in UV disinfection applications globally.

Quartz Tubing Market introduction

The Quartz Tubing Market encompasses the manufacturing and distribution of tubing made from high-purity fused silica (amorphous silicon dioxide). This material is characterized by exceptional thermal resistance, low thermal expansion coefficient, high chemical inertness, and excellent optical transmission across a broad spectrum, including the ultraviolet range. Quartz tubing is manufactured using processes such as continuous fusion or modified flame hydrolysis, ensuring minimal contaminants and high structural integrity necessary for sensitive technological applications. The tubing comes in various forms, including clear, opaque, and doped variations, tailored for specific physical and optical requirements.

Major applications of quartz tubing span several critical high-tech industries. In semiconductor manufacturing, quartz tubes are indispensable for diffusion, oxidation, annealing, and chemical vapor deposition (CVD) processes, acting as reactor tubes and furnace components that must withstand extreme temperatures and corrosive environments. Furthermore, the high UV transparency of fused quartz makes it crucial for UV lamps used in water purification, air sterilization, and photolithography. Other significant uses include high-intensity lighting, fiber optics, laboratory equipment (especially crucibles and beakers for high-temperature chemistry), and specialized components in aerospace and defense systems requiring robust material performance under challenging conditions.

The core benefits driving market demand include its unparalleled thermal stability, allowing operation up to 1200°C without deformation; superior electrical insulation properties; and resistance to almost all acids, except hydrofluoric acid. Key driving factors accelerating market expansion are the massive global investment in semiconductor fabrication plants (fabs), particularly in Asia Pacific, the increasing adoption of UV-C technology for germicidal disinfection spurred by health concerns, and continuous advancements in optical communication networks requiring high-precision quartz components for optical fiber drawing and handling equipment.

Quartz Tubing Market Executive Summary

The Quartz Tubing Market is experiencing robust growth driven by high-capital investment cycles in advanced technological sectors. Business trends indicate a shift towards ultra-high-purity quartz (UHPQ) materials to meet stringent purity requirements in next-generation semiconductor nodes (7nm and below). Companies are focusing on enhancing manufacturing efficiency through automated processes and developing specialized doped quartz tubing to improve UV transmission efficiency and longevity in disinfection systems. Consolidation among major players and strategic long-term supply agreements with tier-one semiconductor equipment manufacturers are prevalent strategies to secure market position and mitigate supply chain vulnerabilities, particularly those related to raw material sourcing, namely high-grade quartz sand.

Regionally, Asia Pacific maintains its dominance, primarily fueled by massive expansion in the Chinese, Taiwanese, South Korean, and Japanese semiconductor and display manufacturing industries. China’s push for self-sufficiency in high-tech materials and continuous investment in new fabrication facilities is a central growth catalyst. North America and Europe, while representing mature markets, exhibit steady demand driven by research and development activities, niche specialized applications, and the modernization of water infrastructure necessitating advanced UV treatment systems. The rapid urbanization and increasing focus on public health standards across developing economies further bolster regional demand for UV system components.

Segment trends highlight the Semiconductor segment as the largest consumer, valuing precision and material stability above all. However, the UV Sterilization segment is projected to register the fastest CAGR due to widespread integration of germicidal lamps in HVAC systems, municipal water treatment, and consumer appliances. By Type, the Clear Quartz Tubing segment commands the majority share owing to its use in high-transmission optical applications and thermal processing where visual monitoring is essential. The demand for large diameter quartz tubing is also increasing as wafer sizes continue to grow from 300mm to future anticipated sizes, requiring larger and more robust furnace tubes capable of handling increased batch sizes.

AI Impact Analysis on Quartz Tubing Market

User queries regarding the intersection of AI and the Quartz Tubing Market primarily center on how artificial intelligence can enhance manufacturing precision, optimize supply chain logistics, and improve material quality control. Users frequently question AI’s role in detecting microscopic defects in UHPQ tubing, automating complex drawing processes to maintain tight tolerances, and predicting equipment failure in high-temperature processing environments. Key themes emerging from these analyses include expectations for higher yields, reduced waste, predictive maintenance protocols for furnace systems, and the potential for AI-driven material discovery to develop new quartz variants with even higher thermal stability or specialized optical properties. Concerns often revolve around the high initial investment required for AI integration and the need for specialized data scientists to implement and manage these advanced manufacturing systems.

AI is transforming the quartz tubing manufacturing landscape by enabling advanced process control and quality assurance, thereby directly impacting market efficiency and end-product reliability. Machine learning algorithms are being deployed to analyze real-time data from temperature sensors, flow meters, and optical inspection systems during the fusion and drawing processes. This allows for immediate micro-adjustments to parameters, maintaining wall thickness uniformity and overall dimensional accuracy, which is critical for semiconductor applications. Furthermore, generative AI tools are assisting in optimizing furnace designs and simulation models, predicting stress points and extending the lifespan of the quartz components themselves.

- AI optimizes quartz drawing processes, enhancing dimensional precision and material homogeneity.

- Machine vision systems powered by AI detect minute surface or internal defects invisible to human inspectors, increasing quality yield.

- Predictive maintenance schedules for quartz processing furnaces are generated by AI, minimizing unexpected downtime and maximizing asset utilization.

- AI models analyze raw quartz sand quality, assisting sourcing teams in identifying the optimal purity grades quickly.

- Generative design tools utilize AI to simulate and optimize complex quartz component geometries for enhanced thermal and chemical performance in reactors.

DRO & Impact Forces Of Quartz Tubing Market

The Quartz Tubing Market is propelled by several potent market drivers, counterbalanced by inherent constraints, while emerging opportunities offer significant growth pathways. The primary driver is the relentless growth and expansion of the global semiconductor industry, particularly the transition to smaller node sizes requiring extremely high-purity processing materials. Coupled with this is the accelerating global adoption of UV disinfection systems in municipal water treatment plants and commercial HVAC installations, directly increasing demand for high-transparency quartz sleeves and tubes. The stringent quality standards in optics, telecommunications, and high-intensity discharge (HID) lighting also contribute significantly, demanding quartz’s unique combination of properties.

However, the market faces significant restraints. The exceptionally high cost associated with manufacturing ultra-high-purity quartz tubing, stemming from expensive raw material sourcing (high-purity quartz sand) and energy-intensive fusion processes, limits accessibility and increases final product cost. Another constraint is the reliance on a limited number of specialized raw material suppliers, creating potential bottlenecks and supply chain volatility. Furthermore, the inherent fragility of fused quartz material presents handling and logistics challenges, leading to considerable waste rates during transportation and assembly, which impacts overall profitability.

Opportunities for market growth lie in the development of synthetic fused quartz, offering a controllable and potentially purer alternative to naturally derived materials, thereby addressing sourcing constraints. Moreover, the integration of advanced coating technologies to improve the chemical resistance and mechanical strength of quartz tubing, particularly for aggressive etch processes in semiconductor fabs, presents a compelling opportunity for product differentiation. The rapid evolution of the LED industry and specialty optical fiber sectors also creates specialized demand for tailored quartz products with enhanced characteristics like tailored refractive indices or improved thermal shock resilience, allowing manufacturers to penetrate lucrative niche markets requiring highly engineered solutions.

Segmentation Analysis

The Quartz Tubing Market is comprehensively segmented based on Type, Application, and Diameter, reflecting the diverse requirements across end-use industries. Segmentation by Type differentiates between clear, opaque (milky), and doped quartz, catering to specific optical transmission and thermal uniformity needs. Clear quartz tubing, utilized in optical fibers and UV lamps, dominates due to its superior UV transmission capabilities. Segmentation by Application highlights the Semiconductor industry as the major revenue driver, while the UV Sterilization segment demonstrates the highest growth momentum. Analyzing the market by Diameter addresses the operational scale, differentiating between small, medium, and large diameter tubing, which directly correlates to the size of process equipment and the type of manufacturing operation undertaken.

- By Type:

- Clear Quartz Tubing (Fused Silica)

- Opaque/Milky Quartz Tubing

- Doped Quartz Tubing (e.g., Titanium-doped)

- By Application:

- Semiconductor Manufacturing (Diffusion, Oxidation, CVD, Etching)

- UV Sterilization & Disinfection (Water Treatment, Air Purification)

- Lighting (High-Intensity Discharge Lamps, Halogen Lamps)

- Photovoltaics (Solar Cell Manufacturing)

- Fiber Optics Manufacturing (Preform Production)

- Laboratory & Chemical Processing

- By Diameter:

- Small Diameter (< 25 mm)

- Medium Diameter (25 mm – 100 mm)

- Large Diameter (> 100 mm)

Value Chain Analysis For Quartz Tubing Market

The value chain for the Quartz Tubing Market begins fundamentally with the Upstream Analysis, which focuses primarily on the sourcing and processing of raw materials. The highest quality quartz tubing requires ultra-high-purity quartz sand, often mined from select locations globally. Key upstream activities involve meticulous extraction, purification (acid washing and high-temperature treatments), and refining of this raw material to achieve silicon dioxide purity levels exceeding 99.998%. Suppliers specializing in UHPQ sand hold substantial leverage in the value chain, as raw material cost and purity dictate the final quality and applicability, especially in sensitive semiconductor environments. Securing stable, high-quality sourcing agreements is paramount for manufacturers.

The core manufacturing stage involves converting the refined quartz sand into tubing via high-temperature fusion processes, such as continuous flame hydrolysis or electrical melting, followed by precision drawing and shaping. Manufacturers must invest heavily in specialized, non-contaminating equipment and advanced quality control systems to maintain tight dimensional tolerances and eliminate internal stress or defects. This stage adds the most significant value, transforming raw material into a highly engineered component. Following manufacturing, the distribution channel plays a crucial role. Direct distribution is common for large-volume OEM clients, particularly semiconductor equipment manufacturers, facilitating close technical collaboration and customized product specifications.

Indirect distribution often involves specialized distributors or agents who manage smaller orders, provide local technical support, and handle inventory for diverse end-users like smaller laboratories or regional water treatment system integrators. Downstream analysis focuses on the end-use integration, where the quartz tubing is incorporated into final capital equipment—such as diffusion furnaces, UV reactor vessels, or high-intensity lamps. Successful downstream integration requires technical support and sometimes customization (e.g., cutting, grinding, and sealing) by the tubing manufacturers or specialized secondary processors, ensuring compatibility with the demanding operating environments of end-user industries like microelectronics and environmental technology.

Quartz Tubing Market Potential Customers

Potential customers for quartz tubing are predominantly found in industries requiring materials with exceptional thermal, chemical, and optical performance under harsh conditions. The largest segment of end-users are Semiconductor Fabrication Plants (Fabs) and Original Equipment Manufacturers (OEMs) specializing in semiconductor processing equipment. These customers utilize quartz tubing for furnace tubes, process vessels, carriers, and liners essential for high-temperature operations like thermal oxidation and LPCVD (Low-Pressure Chemical Vapor Deposition). Their buying decisions are primarily driven by material purity, thermal stability, longevity, and supplier reliability, as component failure can result in massive financial losses due to batch contamination or equipment downtime.

A rapidly growing customer base includes Municipal Water Treatment Authorities and Commercial/Industrial Disinfection System Integrators. These entities purchase quartz sleeves and jackets for housing UV-C lamps used in water purification and air handling units. Key buying criteria here involve UV transmission efficiency, resistance to scaling or fouling, and cost-effectiveness over the operational lifespan. The increasing global regulatory focus on water quality and sanitation standards directly drives procurement in this segment, emphasizing durability and germicidal effectiveness.

Additional significant end-users include manufacturers of high-intensity lighting (HID lamps, halogen lamps), where quartz maintains integrity under high heat and pressure, and the Fiber Optics industry, which uses quartz components in the drawing towers for manufacturing optical fibers. Research institutions, universities, and specialized chemical laboratories also constitute a steady customer stream, requiring customized, chemically resistant quartz glassware and reactors for high-purity experimental procedures and corrosive testing environments.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.85 Billion |

| Market Forecast in 2033 | USD 3.12 Billion |

| Growth Rate | 7.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Heraeus Holding, Momentive Technologies, TOSOH Corporation, Shin-Etsu Chemical Co., Ltd., Corning Incorporated, QSIL, Atlantic Ultraviolet Corporation, Technical Glass Products (TGP), Saint-Gobain Quartz, Jiangsu Pacific Quartz Co., Ltd., Lianyungang Guangwei Quartz Products Co., Ltd., Raesch Quarz (Germany) GmbH, Fushu Quartz Products, Zhejiang Fenghua Quartz Glass Co., Ltd., Beijing Lideng Quartz Product Co., Ltd., Guolun Quartz, Opticorp Inc., JELENKO Glass, Randa Industrial, The Thermal Source. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Quartz Tubing Market Key Technology Landscape

The technological landscape of the Quartz Tubing Market is dominated by sophisticated fusion and drawing techniques designed to achieve ultra-high purity and precise dimensional control. The primary manufacturing technologies involve either the electric melting method or the flame fusion method. Electric melting utilizes high-temperature resistance heating to fuse natural quartz sand, producing tubing often characterized by extremely low hydroxyl (OH) content, crucial for high-temperature and deep UV applications where OH groups can absorb energy and degrade performance. The flame fusion technique, conversely, uses a high-temperature flame (oxyhydrogen) to fuse either natural or synthetic silica powder, offering excellent control over wall thickness and diameter uniformity, which is critical for demanding semiconductor furnace environments.

A crucial ongoing technological focus is the development and refinement of doping techniques. Doped quartz tubing, often infused with elements like Titanium (TiO2) or Cerium (Ce), serves specialized purposes. For instance, Titanium-doped quartz can block undesirable visible light while allowing UV transmission, protecting sensitive components in purification systems. Advancements in synthetic fused silica production, often leveraging methods like Chemical Vapor Deposition (CVD) or soot deposition, are also paramount. Synthetic quartz offers superior homogeneity and ultra-low metallic impurity levels compared to natural quartz, making it essential for the most advanced photolithography and semiconductor applications where even parts-per-billion contamination is intolerable.

Furthermore, technology related to surface treatment and post-processing is highly valued. Advanced grinding, polishing, and annealing techniques are employed to remove surface defects, reduce internal stress, and improve the mechanical strength of the tubing. Techniques such as plasma polishing and acid etching enhance the surface finish, minimizing particle generation within semiconductor processing reactors. The integration of high-precision metrology systems, including laser scanning and ultrasonic measurement, ensures every piece of manufactured tubing adheres to the extremely tight geometric tolerances demanded by modern microelectronics fabrication, thereby directly correlating technology adoption with market competitiveness and product value proposition.

Regional Highlights

- Asia Pacific (APAC) Market Dominance and Growth Drivers

The Asia Pacific region commands the largest market share and is expected to exhibit the highest Compound Annual Growth Rate (CAGR) throughout the forecast period. This dominance is intrinsically linked to the geographical concentration of global semiconductor manufacturing capabilities, particularly in Taiwan, South Korea, China, and Japan. Massive governmental and private investments, such as China’s commitment to growing its domestic semiconductor supply chain and the establishment of new gigafabs in South Korea and Taiwan, necessitate enormous volumes of high-purity quartz tubing for process equipment like diffusion furnaces and vertical furnaces. The region benefits from lower manufacturing costs and a robust supply chain ecosystem catering to high-volume production needs.

Beyond semiconductors, APAC’s rapid urbanization and increasing focus on environmental safety and public health contribute significantly to demand in the UV sterilization segment. Countries like India and China are heavily investing in large-scale municipal water treatment facilities utilizing UV-C disinfection technology to meet growing population demands for clean water, driving the need for quartz sleeves and associated components. Furthermore, the region is a global hub for consumer electronics and display manufacturing, both of which require specialized quartz glass components for various thermal processes and sputtering applications, cementing its position as the engine of market growth.

The strategic expansion of key quartz manufacturers within APAC, often through joint ventures or establishment of new production facilities closer to major end-users, minimizes logistical complexities and response times. The region is also at the forefront of adopting advanced quartz materials, including large-diameter tubing for 300mm wafer processing and advanced synthetic fused silica for extreme ultraviolet (EUV) lithography systems, ensuring sustained technological leadership and market maturity across diverse application areas.

- North America Market Dynamics and Technological Leadership

North America holds a substantial share of the global quartz tubing market, characterized by demand centered around highly specialized, high-value applications and strong R&D activities. The market here is less driven by sheer volume compared to APAC, but rather by the technological complexity required for advanced aerospace, defense, and niche high-performance optics sectors. Government initiatives aimed at bringing semiconductor manufacturing back to the U.S. (e.g., the CHIPS Act) are expected to significantly boost local demand for UHPQ products, mitigating dependency on overseas supply chains and stimulating domestic production capabilities.

The regional market places a high premium on innovative products, particularly specialized doped quartz and custom fabrication services for scientific research and advanced optical instruments. Furthermore, North America is a pioneer in water and wastewater management technologies, leading the charge in implementing state-of-the-art UV systems in both municipal and industrial settings. This robust regulatory environment and focus on infrastructure modernization provide a stable, growing foundation for the UV sterilization application segment, demanding extremely reliable and long-lasting quartz components.

Key players in North America often focus on premium, synthetic fused silica production, catering to the demanding specifications of cutting-edge technologies. The emphasis is on maintaining superior quality control and providing deep technical expertise, serving high-end customers who require stringent material certifications and traceable supply lines. The presence of major semiconductor equipment OEMs also ensures continuous demand for sophisticated quartz components designed to work flawlessly in the latest processing tools.

- Europe Market Overview and Regulatory Influence

Europe represents a mature and technologically sophisticated market for quartz tubing, with demand concentrated in industrial processes, specialized lighting, and environmental applications. Germany and France are key contributors, hosting major chemical processing industries and advanced manufacturing sectors. The European Union’s strong emphasis on environmental protection and stringent water quality directives provides a solid market driver for UV disinfection systems, particularly in large industrial effluent treatment and public water supply networks, driving the need for high-quality quartz sleeves.

The European market is also distinguished by its strong base in high-performance lighting and automotive sectors, where quartz tubing is used for robust, high-intensity discharge (HID) lamps and specific thermal applications. Strict regulatory frameworks regarding material safety and environmental impact necessitate high-quality, durable materials, favoring established manufacturers capable of providing comprehensive compliance documentation and sustainable manufacturing practices.

While semiconductor manufacturing is smaller in scale compared to APAC, niche capabilities in specialized equipment manufacturing and high-precision optics sustain steady demand. European manufacturers often specialize in custom, small-batch, high-value components, leveraging expertise in material science and glass fabrication techniques to serve unique research and industrial requirements where extreme thermal shock resistance or tailored optical properties are essential.

- Latin America and MEA Emerging Market Trends

Latin America and the Middle East & Africa (MEA) currently hold smaller market shares but are projected to see accelerated growth, predominantly fueled by infrastructure development and increasing environmental awareness. In Latin America, investment in industrial expansion and modernization of aging water infrastructure, particularly in Brazil and Mexico, is driving demand for UV sterilization systems and, consequently, quartz tubing components. Economic stability and governmental focus on public health standards are key market accelerators.

The MEA region, particularly the Gulf Cooperation Council (GCC) countries, is investing heavily in water management technologies due to acute water scarcity, making UV disinfection a crucial technology for tertiary treatment and water reuse initiatives. Large-scale construction projects and rapid urbanization also increase the need for high-intensity lighting and specialized industrial components. Market growth in these regions, however, is often dependent on technology import, with local distribution networks playing a critical role in service delivery and technical support.

Growth in both regions is highly susceptible to commodity prices and geopolitical stability, influencing investment cycles in infrastructure and high-tech manufacturing. However, the long-term trend indicates a strong pipeline of opportunities as these regions continue to integrate modern industrial standards and adopt globally recognized health and safety practices, demanding reliable quartz products for essential infrastructure.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Quartz Tubing Market.- Heraeus Holding GmbH

- Momentive Technologies

- TOSOH Corporation

- Shin-Etsu Chemical Co., Ltd.

- Corning Incorporated

- QSIL (Quarzschmelze Ilmenau)

- Saint-Gobain Quartz

- Jiangsu Pacific Quartz Co., Ltd.

- Lianyungang Guangwei Quartz Products Co., Ltd.

- Raesch Quarz (Germany) GmbH

- Fushu Quartz Products

- Zhejiang Fenghua Quartz Glass Co., Ltd.

- Beijing Lideng Quartz Product Co., Ltd.

- Guolun Quartz

- Atlantic Ultraviolet Corporation (Component focus)

- Technical Glass Products (TGP)

- Opticorp Inc.

- JELENKO Glass

- Randa Industrial

- The Thermal Source

Frequently Asked Questions

Analyze common user questions about the Quartz Tubing market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary factor driving demand for ultra-high-purity quartz tubing?

The primary driver is the ongoing miniaturization and expansion of the global semiconductor industry, particularly the demand for sub-10nm fabrication nodes. UHPQ tubing is essential for diffusion, oxidation, and CVD processes, where material purity must exceed 99.998% to prevent contamination of silicon wafers and ensure high device yield.

How do clear quartz and opaque quartz tubing differ in their application?

Clear quartz tubing (fused silica) offers superior optical transparency across UV and visible spectra, making it ideal for UV lamps, optical fibers, and viewing ports. Opaque or milky quartz, due to its bubble structure, provides enhanced thermal insulation and scattering properties, making it preferred for use as heat-retaining outer jackets in high-temperature furnaces where thermal uniformity is critical.

Which geographical region exhibits the fastest growth potential for quartz tubing?

Asia Pacific (APAC), particularly driven by China, Taiwan, and South Korea, is projected to demonstrate the fastest growth. This is due to massive government and private sector investment in new semiconductor fabrication facilities (giga-fabs) and significant infrastructure spending on municipal UV water treatment projects across the region.

What constraints are impacting the profitability and growth of the quartz tubing market?

Key constraints include the high manufacturing cost associated with ultra-high-purity quartz sand sourcing and energy-intensive fusion processes. Additionally, the market faces supply chain risks due to reliance on a limited number of specialized raw material suppliers and the inherent fragility of quartz, leading to handling waste.

What role does synthetic fused silica play compared to natural quartz tubing?

Synthetic fused silica is chemically manufactured, resulting in superior purity (lower metallic impurities) and better homogeneity compared to tubing made from natural quartz sand. It is exclusively used in the most technologically demanding applications, such as advanced photolithography and high-power laser optics, where even trace contaminants are unacceptable.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Quartz Tubing Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033

- Quartz Tubing Market Size Report By Type (Transparent quartz tube, Opaque and translucent tubes), By Application (The segment applications including, Lighting, Semiconductor, Industrial Applications, Photovoltaic), By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Share, Trends, Outlook and Forecast 2025-2032

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager