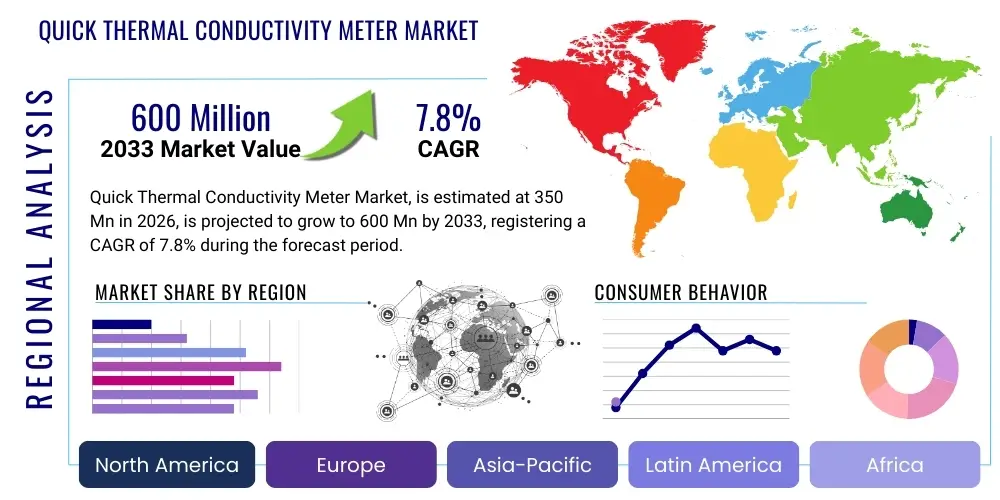

Quick Thermal Conductivity Meter Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 442800 | Date : Feb, 2026 | Pages : 243 | Region : Global | Publisher : MRU

Quick Thermal Conductivity Meter Market Size

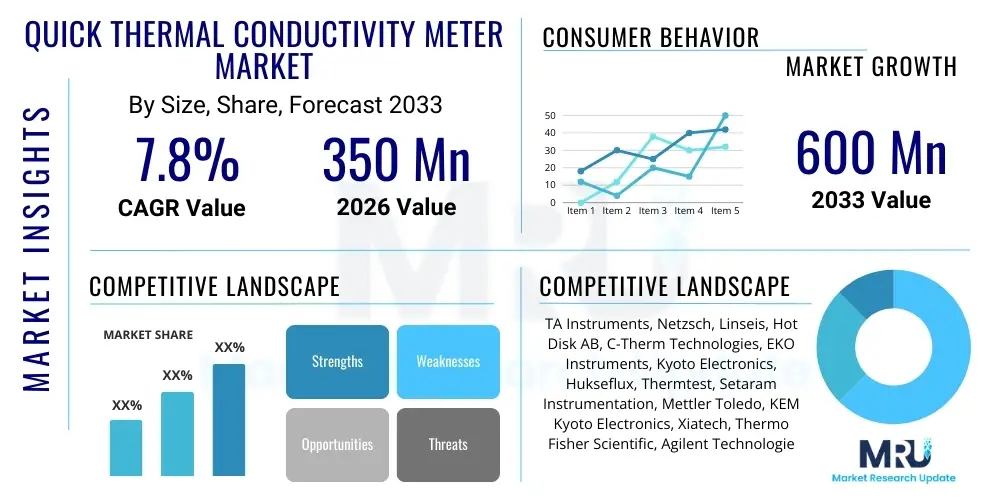

The Quick Thermal Conductivity Meter Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.8% between 2026 and 2033. The market is estimated at USD 350 Million in 2026 and is projected to reach USD 600 Million by the end of the forecast period in 2033.

Quick Thermal Conductivity Meter Market introduction

The Quick Thermal Conductivity Meter Market encompasses advanced instrumentation designed for the rapid and accurate measurement of a material's capacity to conduct heat. These meters are critical tools across diverse industries where thermal management and material characterization are paramount, including electronics, building materials, aerospace composites, and energy storage systems. The core product provides significant advantages over traditional steady-state methods by drastically reducing measurement time, often yielding results in seconds or minutes, thereby accelerating research and development cycles and improving quality control processes in manufacturing environments. The operational principle often relies on transient methods, such as the Transient Hot Wire or Transient Plane Source techniques, which minimize measurement errors associated with moisture migration or convection effects in porous samples.

Major applications of these quick-response devices span quality assurance for insulation materials in construction, precise characterization of thermal interface materials (TIMs) crucial for high-performance computing and electric vehicles (EVs), and material development in polymer and ceramic industries. Benefits derived from adopting quick thermal conductivity meters include improved operational efficiency due to rapid throughput, enhanced accuracy in temperature-sensitive applications, and the ability to test materials across a wide range of temperatures and pressures. These meters are essential for validating thermal models and ensuring compliance with strict industry standards regarding energy efficiency and safety in consumer and industrial products.

The primary driving factor for market expansion is the escalating demand for energy-efficient materials coupled with rapid technological advancements in sectors like 5G infrastructure, advanced battery technology (lithium-ion and solid-state), and sophisticated aerospace engineering. As electronic components become smaller and generate more heat, the need for materials with precisely characterized and often ultra-low or ultra-high thermal conductivity becomes a non-negotiable requirement. Furthermore, increasing regulatory scrutiny on the energy performance of building envelopes globally further compels manufacturers and research institutions to invest in state-of-the-art thermal testing equipment.

Quick Thermal Conductivity Meter Market Executive Summary

The Quick Thermal Conductivity Meter Market is experiencing robust growth driven by accelerating digitalization in R&D and manufacturing sectors, demanding faster material analysis turnaround times. Business trends indicate a shift towards modular and portable instrumentation capable of on-site measurements, addressing the needs of construction and field inspection services. Key market participants are focusing on integrating sophisticated data processing algorithms and standardized software interfaces to enhance usability and comparability of results globally. Furthermore, strategic collaborations between equipment manufacturers and material science research institutions are accelerating the development of application-specific meters optimized for next-generation materials like aerogels, phase change materials (PCMs), and advanced thermal composites, thereby capturing niche high-value segments.

Regionally, the Asia Pacific (APAC) stands out as the fastest-growing market, primarily fueled by massive investments in electronics manufacturing, automotive electrification, and large-scale infrastructure projects, particularly in China, South Korea, and Japan. North America and Europe maintain leading positions in terms of technological adoption and market value, driven by stringent energy efficiency regulations and significant government and private funding directed toward advanced materials research in aerospace and defense sectors. Segments trends show Transient Plane Source (TPS) methods gaining traction due to their high versatility across solid, liquid, powder, and porous samples, while the electronics and automotive industries represent the dominant application segments, demanding meters capable of highly repeatable measurements under variable operational conditions.

Overall, the market structure is characterized by intense competition among specialized metrology firms and larger diversified analytical instrument manufacturers. The core market challenge revolves around balancing measurement speed with absolute accuracy, especially for highly anisotropic or non-homogeneous materials. Future growth will be highly dependent on the successful integration of automation capabilities, enabling high-throughput screening in industrial settings, making the Quick Thermal Conductivity Meter an indispensable tool for material innovation and quality control across global supply chains. Investment is increasingly flowing into developing non-contact and remote measurement techniques to further enhance the speed and adaptability of these instruments in complex industrial environments.

AI Impact Analysis on Quick Thermal Conductivity Meter Market

User queries regarding AI's role in the Quick Thermal Conductivity Meter Market frequently revolve around automation, predictive modeling, and data interpretation challenges. Users are keen to understand how AI can reduce the variability inherent in transient thermal measurements, accelerate calibration processes, and facilitate the automatic identification of measurement anomalies caused by sample preparation errors or environmental drift. A significant concern is whether AI-driven data processing can reliably handle novel or complex materials whose thermal behavior deviates significantly from established models. Key expectations focus on the implementation of machine learning for optimizing testing parameters in real-time and for creating vast, accurate material databases that can predict thermal properties based on compositional data, thus reducing the reliance on purely physical testing for initial material screening.

The integration of Artificial Intelligence (AI) and Machine Learning (ML) algorithms is poised to revolutionize the operation and utility of quick thermal conductivity meters. AI can analyze massive datasets generated during high-throughput testing, identifying subtle correlations between material structure, temperature, density, and thermal response that might be missed by traditional linear regression analysis. This capability significantly enhances the predictive accuracy of thermal models, allowing researchers to screen thousands of potential material compositions virtually before committing resources to physical synthesis and testing. Furthermore, AI-driven quality control systems can monitor meter performance, predicting component failure or the need for recalibration, thereby minimizing downtime and ensuring the highest data integrity throughout continuous operation cycles.

Specifically, ML models are being employed to optimize the transient heating pulse duration and power levels based on the preliminary thermal response of an unknown sample, drastically improving the speed of convergence and minimizing measurement uncertainty. This optimization is crucial for samples that are sensitive to excessive heating, such as certain biological or polymer materials. AI also plays a vital role in automating the thermal mapping of complex components, such as multi-layer PCBs or battery packs, where automated pattern recognition and anomaly detection algorithms quickly flag areas of potential thermal hotspot generation. This not only accelerates product development but also elevates the reliability and safety standards of end-user applications.

- Accelerated data processing and interpretation of complex transient thermal data.

- Predictive modeling of material thermal properties based on compositional input, minimizing physical testing.

- Real-time optimization of measurement parameters (e.g., heating power, duration) for unknown samples.

- Automated quality control and anomaly detection in high-throughput material screening.

- Enhanced calibration accuracy and predictive maintenance scheduling for instrumentation.

DRO & Impact Forces Of Quick Thermal Conductivity Meter Market

The market dynamics are defined by a strong confluence of drivers rooted in technological progression and regulatory pressures, moderated by certain technical and economic restraints, while vast opportunities emerge from developing sectors. The primary drivers include the global push for energy efficiency in construction and the exponential growth of thermal management requirements in consumer electronics and electric vehicle battery systems. Restraints predominantly involve the high initial cost of advanced transient measurement equipment, the need for specialized training to operate and interpret results accurately, and the inherent complexity associated with standardizing measurements across highly diverse material types, such as anisotropic composites or highly porous insulations. Opportunities are centered around the proliferation of additive manufacturing (3D printing), which necessitates rapid thermal characterization of newly developed materials, and the increasing global focus on sustainable and green building standards demanding continuous thermal monitoring.

Impact forces acting on this market can be categorized into supply chain fluctuations, standardization efforts, and competitive intensity. Regulatory mandates, particularly those related to automotive safety (thermal runaway prevention in batteries) and building energy codes (U-values), exert a high-positive influence, compelling widespread adoption. The scarcity of specialized high-performance sensor materials or dedicated electronic components can occasionally restrain growth, forcing reliance on long lead times. Conversely, rapid advancements in micro-sensor technology and wireless data transmission capabilities significantly boost the market's trajectory by enabling smaller, more adaptable, and field-deployable meters. The continuous need for better thermal management solutions, outpacing the current capabilities of many traditional testing methodologies, ensures a sustained demand curve for quick, accurate instruments.

Specific market pressures also arise from competitive pricing strategies among Asian manufacturers versus the premium technology offerings from North American and European specialized firms. The intellectual property landscape is heavily guarded, particularly concerning proprietary algorithms used in transient analysis methods, which act as a barrier to entry for new players. The sustained governmental and corporate focus on R&D investment, particularly in areas like superconductivity and high-temperature materials, creates persistent opportunities for high-specification instruments. Ultimately, the market is poised for expansion, provided manufacturers can navigate the complexities of material diversity and deliver robust instruments that maintain exceptional accuracy under high-speed operational requirements, effectively mitigating the restraining forces related to cost and technical expertise.

Segmentation Analysis

The Quick Thermal Conductivity Meter Market is segmented based on the core measurement technique employed, the type of application, and the primary end-user industry. This segmentation is crucial for understanding the varied demand profiles across the global landscape, as different industries prioritize either speed, accuracy, or sample compatibility. Technical segmentation often differentiates between transient methods that offer quick results and are suitable for a wider range of materials (solids, liquids, powders) and specific techniques like Laser Flash Analysis (LFA) which are reserved for highly specialized applications, typically high-temperature solids. The choice of segmentation method directly impacts the instrument's design, cost, and overall market potential within targeted industrial niches.

The application-based segmentation reveals that general R&D and quality control in manufacturing hold the largest market shares, reflecting the universal need for thermal characterization during both product inception and mass production. However, specialized applications, such as thermal interface material testing in electronics or battery thermal management, are the fastest-growing segments due to the acute thermal challenges faced in these areas. End-user segmentation highlights the dominance of industrial companies, which require rugged, high-throughput systems, contrasted with academic and governmental research institutions, which prioritize versatility and high precision for novel material discovery and fundamental science projects. This distinct segmentation profile dictates specialized product development and targeted marketing efforts within the industry.

- By Measurement Technique:

- Transient Hot Wire (THW) Method

- Transient Plane Source (TPS) Method (Hot Disk Method)

- Laser Flash Analysis (LFA)

- Heat Flow Meter (HFM) (Quick Test Versions)

- Guarded Heat Flow (GHF) (Quick Test Versions)

- By Application:

- R&D and Laboratory Testing

- Quality Control in Manufacturing

- Thermal Interface Material (TIM) Testing

- Building Materials and Insulation Characterization

- Aerospace and Defense Material Testing

- Electronics and Semiconductors

- Automotive (Battery Thermal Management)

- By End-User Industry:

- Industrial Companies (Plastics, Chemicals, Metals)

- Academic and Research Institutions

- Government and Standards Laboratories

- Construction and Building Sector

- By Region:

- North America

- Europe

- Asia Pacific (APAC)

- Latin America (LATAM)

- Middle East and Africa (MEA)

Value Chain Analysis For Quick Thermal Conductivity Meter Market

The value chain for the Quick Thermal Conductivity Meter Market begins with upstream activities involving the sourcing of highly specialized components, including precision temperature sensors (thermocouples, thermistors), sophisticated data acquisition systems (ADCs), and high-reliability heating elements. Raw material suppliers must meet stringent purity and dimensional tolerance requirements, especially for sensor fabrication, which dictates the fundamental accuracy of the final instrument. Research and development activities form a critical link in the upstream chain, focused on developing proprietary transient measurement algorithms and improving sensor-sample coupling techniques to minimize thermal contact resistance—a major source of error in quick measurements. The intellectual property generated at this stage provides manufacturers with significant competitive advantage and justifies premium pricing.

Midstream operations involve the core manufacturing, assembly, software integration, and rigorous calibration processes. Instruments are complex, requiring expert assembly and highly detailed quality assurance to ensure they meet international standards (e.g., ASTM, ISO). Distribution channels are multifaceted, utilizing both direct sales models for large industrial clients requiring extensive technical support and specialized indirect distributors or channel partners who possess deep regional market knowledge and calibration service capabilities. The effectiveness of the distribution network is crucial, especially in emerging markets where direct technical support may be geographically challenging. The sales process often includes substantial pre-sale consultation to ensure the selected meter aligns precisely with the customer's specific material testing needs.

Downstream activities center on post-sale services, including installation, extensive technical training for specialized personnel, and long-term maintenance and recalibration services. Due to the high precision and complexity of the technology, repeat business often relies heavily on the quality and responsiveness of these downstream support services. End-users (potential customers) primarily consist of engineering and R&D departments in manufacturing firms, where the measured thermal data directly feeds into product design decisions and material selection processes. The market structure necessitates a high degree of integration between instrument design and application-specific needs, linking the initial R&D directly to the final user application support.

Quick Thermal Conductivity Meter Market Potential Customers

Potential customers for Quick Thermal Conductivity Meters are broadly defined as organizations or individuals who require fast, accurate, and non-destructive thermal property analysis for materials across various phases of matter. The primary demand originates from industrial sectors driven by compliance requirements and competitive pressure to optimize thermal performance. These customers include R&D departments in polymer and plastics manufacturing, essential for developing new compounds with specific thermal insulation or dissipation characteristics. Furthermore, companies involved in automotive manufacturing, particularly those focused on electric vehicle battery packs, are crucial buyers, as the thermal stability and efficiency of battery components are paramount for safety and range performance.

Beyond traditional manufacturing, significant end-user demand comes from the electronics and semiconductor industry, where rapid testing of thermal interface materials (TIMs), heat sinks, and PCB substrates is vital for preventing component overheating and ensuring device longevity. Architectural and construction material manufacturers represent another major customer group, utilizing these meters to quickly assess the insulating properties (lambda values) of concrete, foam insulation, and composites, thereby ensuring compliance with increasingly strict global energy efficiency building codes. These end-users prioritize high throughput and robust systems capable of handling large sample volumes in routine quality control environments.

Finally, the academic, governmental, and specialized testing laboratory sectors constitute a stable customer base, although often demanding instruments with higher flexibility and precision for fundamental research on novel materials, such as meta-materials, nanomaterials, and high-temperature ceramics. These institutional buyers focus less on raw speed and more on the ability to customize testing protocols and handle specialized, often irregular, samples. Therefore, instrument manufacturers must tailor their product lines, offering both rugged industrial models and highly versatile research-grade instruments to capture the full spectrum of potential customers.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 350 Million |

| Market Forecast in 2033 | USD 600 Million |

| Growth Rate | CAGR 7.8% |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | TA Instruments, Netzsch, Linseis, Hot Disk AB, C-Therm Technologies, EKO Instruments, Kyoto Electronics, Hukseflux, Thermtest, Setaram Instrumentation, Mettler Toledo, KEM Kyoto Electronics, Xiatech, Thermo Fisher Scientific, Agilent Technologies, Ametek (Atlas Material Testing Technology), Eltra GmbH, ZwickRoell GmbH & Co. KG, Qualitest International Inc., ULVAC-PHI. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Quick Thermal Conductivity Meter Market Key Technology Landscape

The technological landscape of the Quick Thermal Conductivity Meter Market is dominated by sophisticated transient methods, primarily Transient Hot Wire (THW) and Transient Plane Source (TPS), which offer significant speed advantages over traditional steady-state techniques. THW involves inserting a thin electrical heating element into the sample, while TPS uses a planar sensor placed between two sample halves, both measuring the temperature rise over time to deduce thermal diffusivity and conductivity. The continuous innovation in sensor design, particularly the development of robust, flexible sensors capable of handling high pressures and temperatures, is a major focus. Furthermore, advancements in data acquisition hardware, allowing for sub-millisecond data logging, ensure highly accurate capture of the rapid temperature transients crucial for these quick methods. Manufacturers are also heavily investing in automation interfaces and robotic sample handling systems to facilitate high-throughput screening in industrial environments, moving thermal testing from a laboratory task to an integrated manufacturing quality control step.

A critical technological evolution involves the refinement of software algorithms used for post-processing the transient data. Modern meters employ advanced numerical modeling and inverse analysis techniques to deconvolute complex heat transfer phenomena, such as internal convection or radiation, from the pure conduction measurement, especially relevant when testing porous or semi-transparent materials. The push towards non-contact measurement is gaining traction, exemplified by specialized Laser Flash Analysis (LFA) systems designed for thin films and high-temperature ceramics, offering speed and eliminating the contact resistance issues inherent in probe methods. However, LFA often measures thermal diffusivity, requiring separate density and specific heat measurements to derive thermal conductivity, maintaining the relevance of direct conductivity transient methods for many applications.

Furthermore, the market is seeing increased adoption of IoT connectivity and cloud computing capabilities. Integrating meters into industrial internet of things (IIoT) frameworks allows for remote monitoring, centralized data management, and the application of AI/ML algorithms to constantly improve measurement protocols and data integrity across multiple testing facilities globally. Portability and miniaturization, driven by the need for quick field measurements, are also key technological trends. This involves developing robust, battery-powered systems with integrated processors, reducing reliance on external laboratory equipment while maintaining high precision. These advancements underscore the market's trajectory towards smarter, faster, and more integrated thermal metrology solutions essential for cutting-edge material science.

Regional Highlights

- Asia Pacific (APAC): APAC represents the highest growth potential and market velocity, primarily driven by massive investments in the electronics supply chain, particularly in China, Taiwan, and South Korea, which require rapid thermal characterization for semiconductors and consumer devices. The region’s burgeoning electric vehicle manufacturing base, notably in China and India, mandates stringent thermal testing of battery components and insulation materials. Government initiatives supporting energy-efficient building construction in densely populated urban centers further accelerate the demand for high-throughput thermal meters for building materials quality control.

- North America: North America holds a leading position in terms of technology adoption and high-value research applications. Demand is strongly anchored in the aerospace and defense sectors, where rigorous testing of advanced composite materials is mandatory. Significant investment in domestic semiconductor production (driven by national security concerns) and extensive R&D spending by academic institutions and national laboratories solidify the need for premium, high-precision thermal metrology equipment, often incorporating advanced LFA and specialized TPS techniques.

- Europe: Europe is characterized by stringent environmental and energy efficiency regulations, particularly in Germany and Scandinavian countries, fueling demand for meters used in insulating material assessment and passive house standards compliance. The automotive industry, specifically major German and French manufacturers transitioning rapidly to EV platforms, is a major end-user, prioritizing quick, repeatable thermal measurements for battery cooling systems and lightweight composite chassis components. The region is also a hub for specialized metrology manufacturers, sustaining innovation and local supply.

- Latin America (LATAM): This region is an emerging market, driven by expanding construction sectors and modernization of industrial infrastructure, particularly in Brazil and Mexico. While initial adoption rates are slower due to economic factors, the increasing foreign investment in manufacturing and localized efforts to meet international product quality standards are expected to drive steady, sustained growth in demand for cost-effective, quick-response thermal conductivity meters.

- Middle East and Africa (MEA): Growth in MEA is largely concentrated in the Gulf Cooperation Council (GCC) countries, focusing on large-scale infrastructure projects and diversification away from oil economies. The extreme climate conditions necessitate robust testing of high-performance insulation materials, driving localized demand. South Africa also shows notable demand, particularly in mining and industrial processing, requiring durable instruments suitable for harsh environments and diverse material characterization.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Quick Thermal Conductivity Meter Market.- TA Instruments (A business unit of Waters Corporation)

- Netzsch Group

- Linseis Thermal Analysis

- Hot Disk AB

- C-Therm Technologies Ltd.

- EKO Instruments Co., Ltd.

- Kyoto Electronics Manufacturing Co., Ltd. (KEM)

- Hukseflux Thermal Sensors B.V.

- Thermtest Inc.

- Setaram Instrumentation (A unit of KEP Technologies)

- Mettler Toledo

- Xiatech Co., Ltd.

- Thermo Fisher Scientific Inc.

- Agilent Technologies, Inc.

- Ametek (Atlas Material Testing Technology)

- Eltra GmbH

- ZwickRoell GmbH & Co. KG

- Qualitest International Inc.

- ULVAC-PHI, Inc.

- Vaisala Oyj

Frequently Asked Questions

Analyze common user questions about the Quick Thermal Conductivity Meter market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary advantages of Quick Thermal Conductivity Meters over steady-state methods?

Quick thermal conductivity meters utilize transient methods (like TPS or THW) to drastically reduce measurement time, often yielding results in minutes or seconds, significantly improving throughput for R&D and quality control compared to hours required for steady-state techniques. They also minimize the effects of moisture migration and convection within the sample.

Which transient method is most versatile for testing different material types?

The Transient Plane Source (TPS) method, often known as the Hot Disk method, is widely regarded as highly versatile. It can accurately measure thermal properties across solids, liquids, powders, pastes, and foams, and requires minimal sample preparation compared to techniques relying on specific geometric shapes.

How is the growth of the electric vehicle (EV) sector influencing the thermal meter market?

The EV sector is a major driver, demanding rapid and accurate testing of battery cell components, thermal interface materials (TIMs), and housing insulation to ensure safety, prevent thermal runaway, and optimize battery performance and lifespan. This necessity fuels high demand for high-speed, repeatable testing equipment.

What role does AI or Machine Learning play in modern Quick Thermal Conductivity Meters?

AI/ML algorithms are increasingly used for optimizing measurement parameters in real-time, automatically processing large datasets, compensating for measurement drift, and creating predictive thermal models. This integration enhances accuracy, speed, and automation in material characterization.

Which geographical region is projected to exhibit the fastest growth in this market?

The Asia Pacific (APAC) region is projected to show the fastest growth due to extensive investments in electronics manufacturing, rapid expansion of the automotive electrification industry, and large-scale infrastructure projects necessitating stringent quality control for building materials.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager