Radiation Shielding Textile Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 442608 | Date : Feb, 2026 | Pages : 258 | Region : Global | Publisher : MRU

Radiation Shielding Textile Market Size

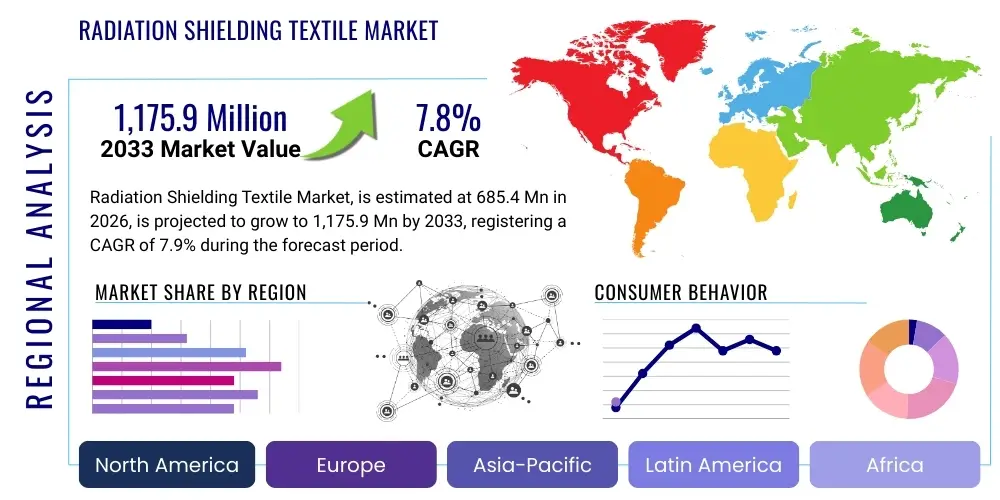

The Radiation Shielding Textile Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.85% between 2026 and 2033. The market is estimated at USD 685.4 Million in 2026 and is projected to reach USD 1,175.9 Million by the end of the forecast period in 2033. This substantial expansion is fundamentally driven by the escalating demand for advanced personal protective equipment (PPE) in high-radiation environments, particularly within the healthcare, nuclear, and defense sectors. Regulatory mandates for occupational safety, coupled with technological advancements in integrating conductive and attenuating materials into wearable fabrics, are propelling market valuation across major global economies.

Radiation Shielding Textile Market introduction

The Radiation Shielding Textile Market encompasses high-performance fabrics engineered to mitigate the penetration of electromagnetic radiation (EMR), radiofrequency (RF) waves, and, in specialized applications, ionizing radiation such as X-rays and gamma rays. These textiles integrate materials like conductive polymers, metallic fibers (e.g., copper, nickel, silver), and dense composite fillers to achieve high attenuation efficiency. They find critical application in creating protective clothing, medical drapery, infrastructural shielding, and flexible electronic enclosures. The inherent benefits include lightweight protection, flexibility, breathability, and durability, making them superior to traditional rigid shielding solutions in many scenarios.

Major applications of these textiles span the medical field, where they are essential for surgical staff protection during interventional radiology procedures; the aerospace and defense industries for protecting sensitive electronics and personnel from high-intensity electromagnetic pulses (EMP) and space radiation; and consumer electronics for minimizing electromagnetic interference (EMI). The core driving factor for market growth is the ubiquitous proliferation of wireless communication technologies (5G, IoT), which necessitates effective EMI shielding, alongside the rising number of radiological diagnostic and therapeutic procedures globally, heightening the need for robust medical radiation protection.

The development of next-generation shielding textiles focuses on multi-functional integration, offering not only radiation protection but also thermal regulation, antimicrobial properties, and enhanced mechanical strength. Key innovations involve nanocoatings and precise material layering to optimize shielding effectiveness across broad frequency ranges without sacrificing comfort or washability. The stringent international safety standards governing occupational exposure and electronic compatibility further solidify the market's trajectory towards innovative, high-specification products.

Radiation Shielding Textile Market Executive Summary

The Radiation Shielding Textile Market exhibits robust growth, primarily fueled by stringent health and safety regulations, rapid advancements in 5G and wireless infrastructure requiring sophisticated EMI mitigation, and increasing geopolitical focus on defense applications involving electromagnetic warfare. Key business trends indicate a shift towards sustainable and lighter-weight shielding solutions, utilizing techniques like electrospinning and advanced chemical vapor deposition (CVD) to integrate shielding properties at the fiber level. Strategic alliances between textile manufacturers and material science companies are common, aimed at developing composite fabrics that offer broad-spectrum protection while maintaining textile characteristics such as drape and comfort. Investment in automated manufacturing processes is accelerating to meet the high volume demand from the consumer electronics and healthcare sectors.

Regionally, North America and Europe currently dominate the market due to mature healthcare infrastructure, significant R&D spending in defense and aerospace, and early adoption of stringent regulatory standards regarding EMR exposure. However, the Asia Pacific (APAC) region is projected to register the highest CAGR, driven by rapid industrialization, expansion of telecommunications infrastructure, and massive investment in nuclear energy and medical facilities in countries like China, India, and South Korea. Emerging markets are increasingly prioritizing workplace safety and implementing international radiation safety protocols, thereby creating substantial new opportunities for specialized shielding textile suppliers.

In terms of segment trends, the Non-Ionizing Radiation Shielding segment holds the largest market share, predominantly due to the pervasive nature of RF/EMI protection requirements across commercial sectors. Conversely, the Ionizing Radiation Shielding segment, while smaller in volume, commands a higher average selling price and is characterized by specialized, high-performance polymers and metal composite materials mandated by strict nuclear and medical regulations. Within application types, the Personal Protective Equipment (PPE) category remains the most dynamic, constantly evolving to integrate better ergonomics and aesthetic qualities alongside superior attenuation capabilities for clinical, military, and industrial workers.

AI Impact Analysis on Radiation Shielding Textile Market

Analysis of common user questions reveals strong interest in how Artificial Intelligence (AI) can optimize material selection, predict shielding effectiveness, and automate quality control in the Radiation Shielding Textile Market. Users frequently inquire about AI’s role in simulating complex electromagnetic environments to design targeted shielding solutions and whether machine learning (ML) can accelerate the development of novel conductive polymers or nanocomposites. Key themes revolve around the potential for AI to dramatically reduce R&D cycle times, enhance the personalization of protective gear based on specific radiation exposure profiles, and integrate predictive maintenance capabilities into smart shielding textiles. Concerns often focus on the required computational infrastructure and the necessity for massive, high-quality material performance datasets to effectively train ML models for radiation attenuation predictions.

- AI-driven Material Informatics: Accelerating the discovery and selection of optimal composite materials for superior radiation attenuation through rapid simulation and predictive modeling.

- Optimized Manufacturing Parameters: Using machine learning to fine-tune coating thicknesses, fiber density, and material integration techniques to maximize shielding efficacy while minimizing material usage.

- Predictive Performance Modeling: AI algorithms simulating electromagnetic field propagation and radiation interaction with textile structures, reducing the need for extensive physical prototyping and testing.

- Quality Control Automation: Implementing computer vision and ML for real-time defect detection (e.g., uneven coating, material discontinuities) during the manufacturing process to ensure consistent shielding quality.

- Smart Textile Integration: Utilizing AI to manage data collected by embedded sensors in protective clothing, providing real-time exposure monitoring and determining textile degradation levels.

- Customized Shielding Design: AI generating tailored protective garment designs based on individual anatomical data and specific exposure risks, optimizing fit and minimizing radiation gaps.

DRO & Impact Forces Of Radiation Shielding Textile Market

The Radiation Shielding Textile Market is primarily driven by the escalating demand from the healthcare sector, particularly for interventional cardiology and oncology procedures, necessitating advanced protection for medical personnel. Simultaneously, the proliferation of 5G, IoT devices, and complex electronic systems mandates high-performance electromagnetic shielding to ensure system integrity and prevent cross-device interference. Regulatory mandates set by agencies like the International Atomic Energy Agency (IAEA) and various national occupational safety bodies enforce strict compliance regarding personnel exposure, directly bolstering the demand for certified protective textiles. However, market expansion is constrained by the relatively high cost of advanced raw materials (e.g., silver, specialized polymers, and metallic composites) and complex manufacturing processes, which limits widespread adoption, particularly in price-sensitive markets.

Significant opportunities arise from the convergence of textile technology with nano-engineering, allowing for the creation of ultra-lightweight, highly flexible, and multi-functional textiles. The emergence of the Electric Vehicle (EV) market presents a new vertical requiring sophisticated EMI shielding for battery management systems and onboard electronics. Furthermore, the rising awareness among consumers regarding potential health hazards associated with prolonged exposure to EMR is driving demand for consumer-grade protective items like apparel and home textiles. The primary impact forces include technological advancements, which consistently push the boundaries of attenuation efficiency, and evolving regulatory environments that continuously heighten safety standards, thereby obsolescing older, less effective shielding materials and driving innovation.

Restraints include the challenge of achieving effective shielding against high-frequency radiation while maintaining textile comfort, washability, and durability. Additionally, the lack of standardized testing protocols across all regions for newly developed shielding materials sometimes creates barriers to rapid market entry and consumer trust. The interaction between these dynamic drivers, persistent restraints, and untapped opportunities defines the strategic landscape, compelling manufacturers to invest heavily in R&D to deliver cost-effective and compliant next-generation shielding solutions.

Segmentation Analysis

The Radiation Shielding Textile Market is comprehensively segmented based on the type of radiation being protected against, the material composition of the textile, the application sector, and the end-use product format. This granular segmentation allows for precise market sizing and strategic targeting, highlighting the unique requirements of the medical field versus the military sector. The complexity of radiation types—ranging from low-frequency EMR to high-energy ionizing radiation—necessitates distinct material science approaches, resulting in specialized product offerings that cater to specific performance benchmarks and regulatory compliance needs across different verticals.

Segmentation by material is crucial, separating metallic materials (like copper and stainless steel fiber blends) which offer robust broad-spectrum EMR shielding, from composite materials (such as lead-loaded or tungsten-infused polymers) essential for high-density ionizing radiation protection. Application segmentation reveals the dominance of the healthcare sector, followed closely by telecommunications and defense, illustrating the diverse utility of these high-tech textiles. Understanding these segments is vital for stakeholders seeking to align product development with areas of maximal growth and technological need, particularly as regulatory landscapes become increasingly specialized.

- By Radiation Type:

- Ionizing Radiation (e.g., X-rays, Gamma rays)

- Non-Ionizing Radiation (e.g., RF, Microwave, EMI/EMR)

- By Material Type:

- Metallic Fabrics (Copper, Silver, Stainless Steel, Nickel)

- Metallized Fabrics (Coated or Plated Textiles)

- Non-Metallic/Composite Fabrics (Polymer Composites, Nanomaterials, Lead-Free Fillers)

- By Application:

- Healthcare/Medical (Diagnostic Imaging, Interventional Procedures)

- Defense and Military

- Telecommunications and IT

- Aerospace and Space

- Industrial and Manufacturing (Nuclear Plants)

- Consumer Electronics and Appliances

- By Product Type:

- Apparel (Aprons, Gloves, Thyroid Shields, Vests)

- Drapery and Barrier Fabrics (Medical Curtains, Tents, Covers)

- Infrastructure and Architectural Shielding

- By End-Use Industry:

- Hospitals and Clinics

- Research Institutions

- Defense Forces

- Commercial Industries

Value Chain Analysis For Radiation Shielding Textile Market

The value chain for the Radiation Shielding Textile Market is complex and highly specialized, beginning with the upstream sourcing of advanced raw materials such as high-purity metal powders, conductive fibers, and specialized polymer resins. These materials are then processed through sophisticated techniques like electroplating, weaving, knitting, or non-woven formation to imbue standard textile substrates with shielding properties. The critical upstream activities involve precision material science and formulation, ensuring the attenuation efficiency meets stringent industry standards and regulatory thresholds, which often requires collaboration between chemical suppliers and textile processors.

The midstream phase focuses on textile manufacturing and functional integration, where core competencies lie in achieving uniformity in metal coating or composite dispersion, optimizing fabric breathability, and maintaining mechanical properties. This phase often includes rigorous testing and certification processes to validate shielding effectiveness (measured in dB). The distribution channel, which constitutes the downstream element, involves specialized distributors who understand the technical specifications required by end-users, such as medical procurement agencies, defense contractors, and specialized industrial suppliers. Direct sales channels are common for highly customized or proprietary solutions offered directly to major defense organizations or large hospital networks, emphasizing technical support and post-sales service.

Indirect channels involve partnerships with large Personal Protective Equipment (PPE) providers or electronic enclosure manufacturers who integrate the shielding textiles into final products. Profit margins tend to be highest in the specialized upstream material formulation and the high-value, bespoke product manufacturing segments, particularly those dealing with ionizing radiation protection. Optimization of the value chain is increasingly focused on reducing material waste, enhancing supply chain transparency, and accelerating the time-to-market for novel, regulatory-compliant shielding textile innovations.

Radiation Shielding Textile Market Potential Customers

Potential customers for Radiation Shielding Textiles span a wide array of high-stakes industries where protection against electromagnetic or ionizing radiation is mission-critical for human safety, equipment reliability, and regulatory compliance. The largest segment of buyers comprises healthcare institutions, specifically hospitals, diagnostic centers, and interventional cardiology labs, who purchase textiles for lead-free aprons, mobile barriers, and patient drapes used during fluoroscopy and angiography. Defense and aerospace contractors represent another high-value customer base, utilizing these textiles for protective apparel for military personnel, stealth technology applications, and shielding compartments within aircraft and spacecraft against EMP and natural space radiation.

The second major group includes telecommunication companies, data center operators, and electronics manufacturers who purchase large quantities of EMI shielding fabrics for infrastructure protection, server room enclosure lining, and integration into consumer electronics to meet FCC and CE standards. Research institutions, particularly those involved in nuclear physics, high-energy particle research, and materials science, are consistent buyers for specialized high-attenuation barrier materials. Industrial facilities, such as nuclear power generation plants and decommissioning sites, require durable, long-lasting protective clothing for workers exposed to low-level but cumulative doses of ionizing radiation, creating a steady demand stream for specialized industrial PPE.

Furthermore, the growing consumer market, driven by health awareness and concern over RF exposure from mobile devices and smart meters, constitutes an emerging customer segment for residential shielding fabrics, apparel, and personal electronic accessories. These diverse customer bases require varying levels of technical performance, durability, and customization, necessitating a flexible and technically competent supplier network capable of meeting strict quality assurance and regulatory requirements for specialized end-use applications.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 685.4 Million |

| Market Forecast in 2033 | USD 1,175.9 Million |

| Growth Rate | CAGR 7.85% |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered |

|

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Radiation Shielding Textile Market Key Technology Landscape

The technology landscape for Radiation Shielding Textiles is highly sophisticated, driven by the need to balance high attenuation efficiency with the physical characteristics of conventional textiles, such as flexibility, low weight, and breathability. A primary technological focus involves advanced metallization techniques, including chemical vapor deposition (CVD) and physical vapor deposition (PVD), to uniformly coat polymer fibers or synthetic fabrics with conductive metals like silver, copper, or nickel. These methods achieve superior electromagnetic shielding effectiveness (SE) compared to traditional blending methods, ensuring high performance against EMR without compromising the textile’s wearability. Furthermore, electrospinning is emerging as a critical process for creating nanofiber meshes with exceptionally high surface area to volume ratios, allowing for ultra-lightweight and highly efficient EMI shielding fabrics, which are crucial for sensitive electronic component protection and advanced military uniforms.

For ionizing radiation protection, the technological innovation centers around replacing traditional, heavy, and toxic lead-based materials with lightweight, non-toxic alternatives. This shift has accelerated the adoption of composite materials incorporating elements with high atomic numbers, such as bismuth, tungsten, and barium sulfate, dispersed homogeneously within polymer matrices (e.g., rubber or specialized plastics) that are then integrated into textile structures. Advanced compounding techniques are essential here to ensure the fillers are evenly distributed to prevent radiation leakage points. The goal is to achieve equivalent lead protection levels (e.g., 0.5 mm Pb equivalent) in garments that are significantly lighter and more ergonomic for clinical staff, addressing the widespread issue of orthopedic injuries associated with prolonged use of traditional lead aprons.

Another crucial technological development is the implementation of smart textiles, integrating micro-sensors and embedded electronics into the shielding fabric. This allows for real-time monitoring of radiation exposure levels, tracking accumulated dose, and assessing the physical integrity and wear life of the protective garment. The fabrics often employ complex weave structures, such as rip-stop patterns utilizing conductive yarns, not only for shielding but also for durability and signal integrity, especially in military and aerospace applications where mechanical robustness is critical. Ongoing research focuses on developing self-healing or adaptive shielding textiles that can dynamically adjust their shielding properties based on the ambient electromagnetic environment or cumulative damage.

Regional Highlights

- North America: This region maintains a dominant position, characterized by high defense spending, a mature and technologically advanced healthcare system, and stringent regulatory compliance related to both occupational safety and electronic emissions (FCC regulations). The market is driven by significant adoption in interventional radiology, robust demand from aerospace manufacturers (Boeing, Lockheed Martin), and pioneering research in space radiation protection for NASA missions. The rapid deployment of 5G infrastructure also generates massive demand for specialized EMI/RF shielding materials for base stations, data centers, and consumer electronics. The presence of major textile and material science innovators further solidifies North America’s leading role in high-value, specialized segments.

- Europe: Europe represents a strong market segment, heavily influenced by strict EU directives regarding health and safety (e.g., Euratom standards for radiation protection) and electromagnetic compatibility (EMC). Countries like Germany, Switzerland, and the UK are centers for advanced textile manufacturing and medical device production, leading to high uptake of non-lead radiation protective apparel. Growth is also significantly bolstered by the automotive sector, particularly the rapid expansion of the Electric Vehicle (EV) market, which requires high-performance shielding solutions for onboard electronics and battery shielding. Strategic partnerships between research institutions and industry bodies (e.g., EURATEX) ensure a steady pipeline of innovative, certified products.

- Asia Pacific (APAC): APAC is forecast to be the fastest-growing region, propelled by rapid industrialization, massive investments in digital infrastructure (telecom and IT), and substantial expansion of healthcare facilities, especially in emerging economies such as China and India. The regional market benefits from the establishment of new nuclear power generation facilities and increased defense modernization programs, fueling demand for high-specification shielding solutions. While the market initially lagged in adopting premium protective equipment, increasing public awareness and stricter governmental safety enforcement are accelerating the transition from basic shielding to advanced, certified textile solutions.

- Latin America (LATAM): The LATAM market is growing steadily, primarily driven by the modernization of healthcare infrastructure and increasing foreign direct investment in telecommunications and defense capabilities. Brazil and Mexico are the largest contributors, where demand for basic and intermediate radiation protective apparel in clinical settings is rising. Market expansion is somewhat challenged by import dependency and economic volatility, yet the underlying need for regulatory compliance provides a foundational demand for cost-effective shielding textiles.

- Middle East and Africa (MEA): Growth in the MEA region is segmented, with high demand concentrated in the GCC (Gulf Cooperation Council) countries due to substantial investments in mega-projects, sophisticated medical centers, and burgeoning defense expenditures. The implementation of advanced medical technology, particularly in diagnostics and oncology, is a key driver. Africa's market remains nascent, focused mainly on essential medical shielding equipment, but shows long-term potential fueled by urbanization and improvements in public health infrastructure.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Radiation Shielding Textile Market, analyzing their product portfolios, strategic initiatives, technological competencies, and global market presence.- Shieldex Trading GmbH (Statex)

- KnitWarm Industrial Ltd.

- Schoeller Textil AG

- Lomartire Industria Tessile

- W. L. Gore & Associates, Inc.

- Soliani EMC s.r.l.

- Swiss Shield AG

- Sint-Maarten-P&E NV

- Holland Shielding Systems B.V.

- E-Textiles.co.uk

- Mars-Tech

- Atex Technologies

- Arcam AB (GE Additive)

- Texray AB

- RadiaShield Technologies

- Radium Protection India

- Pure-Life

- Zhengzhou Boda Anti-Radiation Material Co., Ltd.

- Trevira GmbH

- 3M Company

- VestGuard UK Ltd.

- Parker Chomerics

- Kemper Medical, Inc.

- Microwave Textiles

Frequently Asked Questions

Analyze common user questions about the Radiation Shielding Textile market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary difference between Ionizing and Non-Ionizing Radiation Shielding Textiles?

Ionizing shielding textiles protect against high-energy radiation (X-rays, gamma rays) and typically use dense, high-atomic-number materials like tungsten or bismuth composites. Non-ionizing shielding textiles focus on lower-energy electromagnetic fields (RF, EMI) and primarily rely on conductive metallic fibers or coatings (silver, copper) to reflect or absorb the waves.

Are lead-free radiation shielding textiles as effective as traditional lead aprons in medical settings?

Modern lead-free textiles, which utilize advanced composite materials such as tungsten and bismuth compounds, are designed to offer equivalent protection levels (e.g., 0.5 mm Pb equivalent) while significantly reducing the weight and increasing the flexibility of the garment, improving wearer comfort and mobility during lengthy procedures.

Which application segment drives the highest demand for radiation shielding textiles?

The Healthcare/Medical segment currently accounts for the largest demand, primarily driven by the mandatory use of protective apparel (aprons, shields) during interventional radiology, fluoroscopy, and computed tomography (CT) procedures to safeguard clinical personnel from scatter radiation.

How does 5G technology impact the growth of the Non-Ionizing Radiation Shielding Textile market?

The widespread deployment of 5G infrastructure operates at higher frequencies, increasing ambient electromagnetic noise and requiring stricter Electromagnetic Interference (EMI) mitigation. This necessitates greater use of high-performance metallized and conductive textiles for shielding server rooms, sensitive electronics, and large-scale data transmission equipment.

What are the key technological advancements making radiation shielding textiles lighter and more comfortable?

Key advancements include the use of nanotechnology (nanofibers and nanopowders) for homogeneous material dispersion, advanced electroplating and sputtering techniques for uniform metal coatings, and incorporating high-density, non-toxic elements like bismuth and tungsten in polymer matrices rather than relying solely on bulk materials.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager