Rechargeable Cordless Hot Melt Glue Gun Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 443200 | Date : Feb, 2026 | Pages : 258 | Region : Global | Publisher : MRU

Rechargeable Cordless Hot Melt Glue Gun Market Size

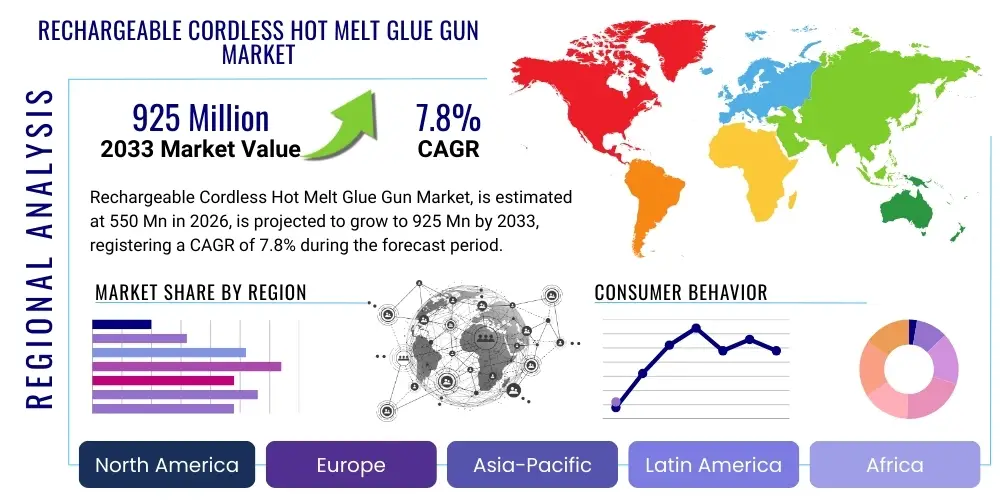

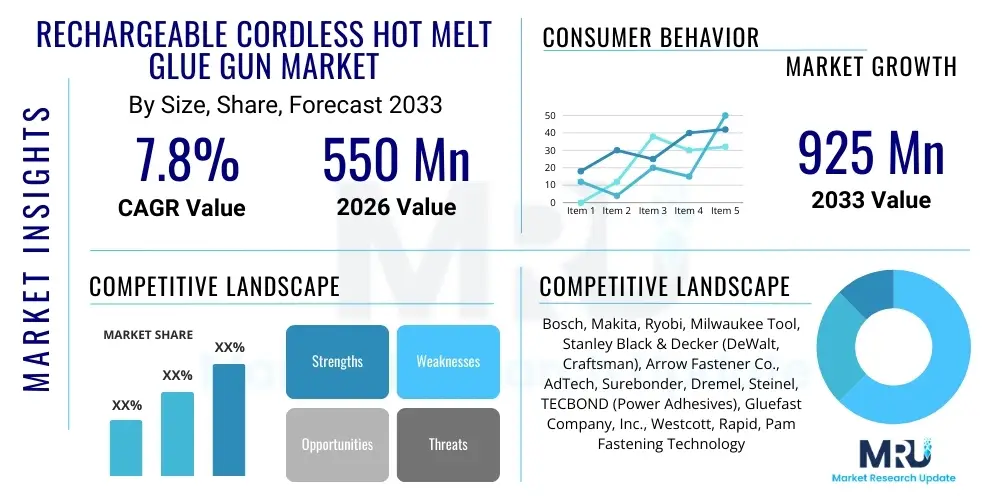

The Rechargeable Cordless Hot Melt Glue Gun Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.8% between 2026 and 2033. The market is estimated at $550 Million in 2026 and is projected to reach $925 Million by the end of the forecast period in 2033.

Rechargeable Cordless Hot Melt Glue Gun Market introduction

The Rechargeable Cordless Hot Melt Glue Gun Market encompasses devices utilizing thermoplastic adhesives, powered by integrated rechargeable battery packs, predominantly Lithium-ion technology, to facilitate highly effective bonding across diverse materials without reliance on a fixed power outlet. These tools represent a significant evolution from traditional corded versions, offering superior portability, operational freedom, and enhanced safety, particularly in environments where unrestricted movement is paramount, such as construction sites, large workshops, or outdoor applications. The product is defined by its core functionality: rapidly heating and melting solid thermoplastic glue sticks, enabling quick and durable adhesion for a wide range of materials including wood, plastic, fabric, ceramics, and light metals. This versatility positions the cordless glue gun as an indispensable tool across numerous sectors, including professional trades, manufacturing, arts and crafts, and home repair.

Major applications of these devices span professional industrial use, large-scale packaging, automotive repair, complex electrical wiring installations, and comprehensive home improvement projects. For professionals, the convenience of a rapid heat-up time and sustained battery performance drastically reduces operational downtime. For consumers, the ergonomic design, combined with integrated safety features like drip-control nozzles and insulated casings, makes complex tasks accessible and minimizes the risk of accidents. The convergence of high-capacity battery technology and efficient heating elements has solidified the market's growth trajectory, offering tools that match or exceed the performance specifications of their corded predecessors, thereby encouraging mass adoption.

Key benefits driving market adoption include unparalleled mobility, crucial for intricate or remote work, and improved user safety due to the elimination of trip hazards associated with extension cords. Furthermore, advancements in smart battery management systems ensure consistent temperature control, leading to superior bond strength and material integrity. These factors are directly contributing to the increasing penetration rate across developing and developed economies, spurred further by the global expansion of DIY culture and the rising necessity for reliable, quick-fix repair solutions in commercial and residential settings. The market dynamics are highly responsive to technological advancements in battery energy density and rapid charging capabilities, influencing consumer purchasing decisions toward higher-specification, longer-lasting models.

Rechargeable Cordless Hot Melt Glue Gun Market Executive Summary

The global Rechargeable Cordless Hot Melt Glue Gun Market is characterized by robust growth, propelled primarily by enduring business trends such as increasing industrial automation requiring quick, flexible adhesive solutions, and the strong consumer inclination toward efficient, portable tools for DIY activities. Major manufacturers are intensely focused on developing higher voltage platforms (e.g., 18V and 20V systems) to integrate these glue guns into existing professional tool ecosystems, thereby maximizing user convenience and cross-platform battery interchangeability. This focus on system integration, coupled with continuous improvements in thermal efficiency and ergonomic design, underscores the competitive landscape, where brand loyalty often hinges on battery longevity and tool reliability under strenuous working conditions. Business strategies are centered on penetrating emerging markets through competitive pricing strategies and broadening application suitability through specialized adhesive offerings.

Regional trends indicate that North America and Europe currently dominate the market share, driven by a high prevalence of home improvement projects, established professional construction sectors, and strong disposable income allocated toward high-quality power tools. However, the Asia Pacific (APAC) region is poised for the most rapid expansion throughout the forecast period, fueled by burgeoning manufacturing industries, rapid urbanization necessitating localized construction and repair, and the escalating affordability of advanced cordless technology for both professional and consumer segments. Strategic investments in APAC are focusing on establishing localized production facilities to mitigate supply chain volatilities and tailor product specifications to regional requirements, such as enhanced dust and humidity resistance, which are critical in certain high-growth economies.

Segment trends highlight the dominance of the high-temperature segment due to its superior bonding strength, favored by industrial and professional users, though the dual-temperature and low-temperature segments maintain steady growth in the crafting and delicate materials sectors. By voltage, the 12V and above categories are demonstrating faster adoption rates than the lower voltage segments, directly correlating with the increasing demand for industrial-grade performance and extended run times. The key competitive edge is shifting from mere portability to integrated smart features, including battery life indicators, pre-set temperature controls, and optimized heat-up algorithms, enabling precise application control, a significant factor influencing procurement decisions within highly specialized end-user industries.

AI Impact Analysis on Rechargeable Cordless Hot Melt Glue Gun Market

User inquiries regarding the impact of Artificial Intelligence (AI) on the Rechargeable Cordless Hot Melt Glue Gun Market primarily focus on themes related to manufacturing optimization, smart tool integration, and enhanced safety diagnostics. Common questions revolve around how AI can optimize the internal heating cycles for energy efficiency, predict maintenance needs based on usage patterns, and integrate glue application into automated or semi-automated robotics lines. Users are particularly keen on understanding whether AI-driven diagnostics could monitor internal component stress (e.g., heating element degradation or battery cell health) in real-time to prevent failure or overheating, thus improving the tool’s lifespan and user safety. The overarching expectation is that AI will transform the glue gun from a simple heating tool into an intelligent, data-generating peripheral within a larger smart workshop ecosystem, enabling precision adhesive deployment in controlled industrial environments.

The direct impact of AI at the tool level is currently nascent but progressing rapidly, focusing largely on integrated machine learning algorithms within the tool's microcontroller unit (MCU). These algorithms analyze the thermal inertia of the specific glue stick material used, the ambient temperature, and the required dispensing rate to dynamically adjust the Pulse Width Modulation (PWM) cycling of the heating element. This ensures the adhesive remains at the optimum viscosity for the duration of the application, thereby maximizing bond strength and minimizing waste or inconsistent flow. This predictive thermal management represents a crucial step toward "smart gluing," where the tool optimizes performance autonomously, abstracting complexity away from the operator and ensuring consistent industrial quality outcomes.

Furthermore, in large-scale manufacturing and packaging sectors, AI and vision systems are already influencing the usage parameters of automated glue dispensing stations, which often employ advanced hot melt techniques. While the tool itself is not strictly a handheld device, the underlying hot melt technology benefits from AI-driven quality control. Predictive maintenance models, trained on sensor data from numerous tools across a production line, can forecast potential malfunctions (like nozzle clogging or motor failure) before they occur. This transition toward prescriptive maintenance, enabled by AI data processing, ensures maximal operational uptime for high-volume users, significantly lowering the total cost of ownership for professional-grade cordless systems and enhancing the overall reliability of adhesive applications.

- AI optimizes heating element cycling for material-specific viscosity control and energy efficiency.

- Predictive maintenance algorithms analyze battery and heating element health, minimizing unexpected failures.

- Integration with industrial IoT platforms allows for tracking usage metrics and compliance in professional settings.

- Vision systems driven by AI enhance quality control in automated hot melt dispensing lines.

- AI-driven usage pattern analysis informs ergonomic design improvements and optimal battery sizing.

DRO & Impact Forces Of Rechargeable Cordless Hot Melt Glue Gun Market

The dynamics of the Rechargeable Cordless Hot Melt Glue Gun Market are governed by a complex interplay of Drivers, Restraints, and Opportunities (DRO), which collectively constitute the critical Impact Forces shaping its evolution. A primary driver is the pervasive demand for operational flexibility, particularly within repair, installation, and construction trades, where mobility is non-negotiable, rendering corded tools obsolete for many modern applications. This is powerfully augmented by continuous technological improvements in Lithium-ion batteries, which now offer dramatically extended run times and faster charging cycles, effectively eliminating the primary historical barrier to cordless adoption: insufficient power longevity. Furthermore, the global proliferation of the Do-It-Yourself (DIY) culture, especially post-pandemic, has created a massive consumer segment actively seeking user-friendly, safe, and portable adhesion tools for residential projects and hobbies.

Conversely, significant restraints hinder growth potential. The most critical restraint is the relatively high initial capital expenditure associated with high-quality rechargeable systems compared to inexpensive corded alternatives, particularly in price-sensitive emerging markets where budget constraints dictate purchasing behavior. Additionally, battery degradation over time, a fundamental characteristic of rechargeable chemistry, represents a lifecycle cost and performance limitation that budget-conscious users must factor in. Competition from advanced alternative adhesive technologies, such as industrial-grade chemical epoxies or fast-curing UV adhesives, also poses a constraint, especially in specialized manufacturing where superior tensile strength or specific material compatibility is required beyond the capabilities of standard EVA hot melt formulations.

Despite these challenges, substantial opportunities exist, predominantly centered on innovation and market expansion. The development of specialized glue guns that dispense application-specific materials (e.g., high-performance polyamide or reactive polyurethane hot melts) opens doors to high-margin industrial niches like electronics assembly and demanding outdoor applications. Moreover, strategic market penetration into untapped commercial sectors, such as professional floristry, large-scale event decoration, and specialized packaging logistics, offers significant growth potential. The industry is also poised to capitalize on sustainability trends by developing eco-friendly adhesive sticks and designing tools with modular, easily replaceable components, appealing to environmentally conscious consumers and corporations committed to minimizing electronic waste.

The impact forces are substantial, pushing the market toward higher performance and greater integration. Drivers such as portability and battery innovation exert a strong upward force on adoption rates, especially in professional segments. Restraints, notably initial cost and battery lifecycle issues, maintain downward pressure, requiring manufacturers to continuously improve cost-to-performance ratios. Opportunities focusing on niche material compatibility and sustainability act as accelerants, prompting diversification and premium product development. Collectively, these forces mandate a market trajectory defined by technological convergence, where high-efficiency heating elements, advanced battery management systems, and ergonomic excellence become the standard benchmark for competitiveness.

Segmentation Analysis

The Rechargeable Cordless Hot Melt Glue Gun Market is comprehensively segmented based on several key dimensions, including the tool's operating temperature, its voltage platform, the primary end-user profile, and the specific type of glue stick utilized. This granular segmentation allows manufacturers and market analysts to accurately gauge demand trends and tailor product development to specific industrial and consumer needs. Understanding these segment dynamics is critical, as the requirements for a hobbyist using a low-temperature, 4V craft gun are fundamentally different from those of a construction professional relying on a high-temperature, 18V industrial-grade system for securing cable runs or performing rapid structural repairs.

The segmentation by temperature is vital, distinguishing between low-temperature models (suitable for heat-sensitive materials like fabrics and foam), high-temperature models (providing superior adhesive strength for wood, metal, and heavy plastics), and dual-temperature models that offer versatility. Voltage segmentation, correlating directly with power output and sustained heat capacity, dictates the market penetration across professional and consumer markets; lower voltage systems (e.g., 4V, 7.2V) dominate the consumer segment, while high voltage systems (12V, 18V, 20V) are integral to professional trade and industrial applications, often leveraging interchangeable battery packs shared across extensive tool platforms.

End-user analysis further refines the market view, clearly differentiating between Industrial/Commercial users (including manufacturing, packaging, and construction) who require durability and high throughput, and DIY/Hobbyist users who prioritize ease of use, safety, and compact design. The analysis of glue stick type segmentation, ranging from standard EVA (Ethylene-Vinyl Acetate) to advanced polyolefin or specialized polyamide formulations, highlights the diversification toward specialized bonding requirements in niche markets. This detailed breakdown ensures targeted marketing and product positioning, optimizing the value proposition for each distinct market cohort and maximizing revenue potential across the diverse application landscape.

- By Temperature Type:

- Low Temperature

- High Temperature

- Dual Temperature

- By Voltage Platform:

- Below 7.2V (Consumer/Crafting)

- 7.2V to 12V (Prosumer/Light Duty Professional)

- 12V to 20V (Industrial/Heavy Duty Professional)

- Above 20V (Specialized High-Volume Applications)

- By End-User:

- Professional (Construction, Automotive, HVAC, Electrical)

- Consumer (DIY, Crafting, Home Repair)

- By Glue Stick Type:

- EVA (Ethylene-Vinyl Acetate)

- Polyamide (PA)

- Polyolefin (PO)

- Others (Including PUR and specialized formulations)

Value Chain Analysis For Rechargeable Cordless Hot Melt Glue Gun Market

The value chain for the Rechargeable Cordless Hot Melt Glue Gun Market begins with upstream activities focused on the procurement and processing of fundamental components, including advanced semiconductor microcontrollers, high-density Lithium-ion battery cells, specialized Positive Temperature Coefficient (PTC) heating elements or ceramic heaters, and engineered plastics for the tool casing. Key upstream suppliers specialize in battery technology and electronic components, where competitive advantage is often derived from achieving high energy density, fast charging capabilities, and sophisticated battery management system integration. Manufacturers must maintain robust relationships with these critical suppliers to secure stable component pipelines, especially given the global volatility in semiconductor and battery material markets, directly impacting production costs and time-to-market for new models.

The midstream stage involves the design, assembly, and manufacturing processes, where tool manufacturers focus heavily on research and development to improve thermal efficiency, ergonomics, and system integration (e.g., compatibility with existing battery platforms). Manufacturing often incorporates high levels of automation to ensure precision assembly and consistency in critical performance metrics such as heat-up time and temperature stability. Direct distribution channels, such as branded company stores and dedicated e-commerce platforms, offer manufacturers higher margins and direct control over pricing and customer feedback. Conversely, indirect distribution, relying on global distributors, large-scale hardware retailers (e.g., Home Depot, Lowe's), and regional specialty tool suppliers, offers the necessary broad market reach and inventory management crucial for high-volume sales and consumer accessibility across diverse geographical regions.

Downstream analysis focuses on logistics, marketing, sales, and crucially, post-sale service, including warranty provisions and the availability of consumable glue sticks and replacement parts. End-users, who function as the terminal point of the value chain, exert significant pull on product development through demands for reliability, portability, and safety features. The increasing prominence of professional trade associations and online user reviews acts as a powerful downstream influence, shaping brand reputation and purchase decisions. Effective downstream management, particularly ensuring widespread availability of proprietary glue stick formulations and fast, reliable customer support, is essential for maintaining market share and fostering long-term brand loyalty in both the professional and consumer segments.

Rechargeable Cordless Hot Melt Glue Gun Market Potential Customers

The potential customer base for Rechargeable Cordless Hot Melt Glue Guns is exceptionally broad, spanning multiple economic sectors from heavy industry to individual hobbyists, categorized primarily into professional commercial buyers and individual consumer/DIY buyers. Professional end-users represent the high-volume, high-value segment, encompassing construction companies, automotive repair facilities, telecommunications and data cabling installers, and HVAC technicians. These buyers prioritize tools integrated into established battery ecosystems (e.g., 18V/20V systems), demanding exceptional durability, rapid heat recovery, and extended battery run times for continuous, demanding fieldwork. For these commercial customers, the cost of ownership, including the lifespan of the tool and compatibility with existing power tool fleets, is a primary procurement consideration, driving demand for heavy-duty, performance-focused models.

In contrast, the consumer and prosumer segments constitute a high-frequency, fragmented customer base driven largely by aesthetics, ease of use, and competitive pricing. This group includes home renovation enthusiasts, crafters, artists, and individuals focused on minor household repairs. These customers often opt for lower voltage, lighter-weight models that feature enhanced safety elements, such as anti-drip nozzles and ergonomic handles designed for intermittent use. Marketing strategies aimed at this segment emphasize convenience, versatility for multiple materials, and accessible instructional content, often utilizing social media platforms to showcase creative project applications and DIY success stories. Educational institutions, including vocational schools and art departments, also represent a stable, institutional end-user category seeking safe, reliable low-temperature units for student use.

Additionally, specialized industrial buyers, such as electronics manufacturers and packaging logistics firms, serve as critical, albeit niche, potential customers. While often utilizing automated systems, manual or semi-manual hot melt application is essential for prototyping, complex cable bundling, securing components, and specialized packaging closure where corded tools are impractical. These buyers require tools capable of dispensing specialized, high-performance adhesives like PUR or polyamide hot melts, necessitating highly precise temperature control and robust component longevity under continuous operational stress. Expanding product lines to meet the stringent technical requirements of these specialized industrial applications represents a significant opportunity for premium market growth and technological differentiation.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $550 Million |

| Market Forecast in 2033 | $925 Million |

| Growth Rate | 7.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Bosch, Makita, Ryobi, Milwaukee Tool, Stanley Black & Decker (DeWalt, Craftsman), Arrow Fastener Co., AdTech, Surebonder, Dremel, Steinel, TECBOND (Power Adhesives), Gluefast Company, Inc., Westcott, Rapid, Pam Fastening Technology |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Rechargeable Cordless Hot Melt Glue Gun Market Key Technology Landscape

The technological landscape of the Rechargeable Cordless Hot Melt Glue Gun Market is dominated by advancements in three core areas: battery energy storage, heating element efficiency, and microprocessor control systems. The shift from older Nickel-Metal Hydride (NiMH) batteries to high-capacity Lithium-ion (Li-ion) cells is foundational, providing the necessary energy density to support extended run times and maintain high operating temperatures consistently. Modern tools leverage 18V or 20V Li-ion platforms, ensuring compatibility with extensive professional tool ecosystems, a major commercial advantage. Furthermore, the integration of sophisticated Battery Management Systems (BMS) is crucial, protecting the battery from over-discharge, optimizing charging cycles for longevity, and communicating real-time remaining charge status to the user, enhancing operational planning and reliability in demanding environments.

In terms of heating technology, manufacturers are increasingly moving toward high-efficiency Positive Temperature Coefficient (PTC) ceramic heating elements, often replacing traditional resistance wires. PTC heaters offer rapid heat-up times, drastically reducing the waiting period for operation (often under 90 seconds for professional models), and exhibit superior temperature self-regulation capabilities. This self-regulating property is key to maintaining a consistent adhesive viscosity, minimizing dripping, and preventing thermal damage to sensitive components. High-end models also integrate dedicated microprocessors to manage PID (Proportional-Integral-Derivative) control loops, ensuring the temperature remains within a precise, narrow band, which is essential when working with specialized, temperature-sensitive industrial adhesives like Polyurethane Reactive (PUR) hot melts that require stringent thermal profiles.

Ergonomic and material science innovations are also vital. Tools are now designed with advanced material composites for heat dissipation, ensuring the exterior remains cool during prolonged use, significantly enhancing user safety and comfort. Nozzle technology has advanced rapidly, incorporating anti-drip mechanisms, interchangeable tips for precision application, and optimized flow geometry to handle various glue viscosities and dispensing speeds required by different end-user applications, from intricate crafting to fast-paced construction work. The convergence of superior power delivery, intelligent thermal management, and improved material handling represents the key technological battleground for competitive advantage in this rapidly evolving cordless tool segment.

Regional Highlights

- North America: This region maintains a significant market presence, characterized by high consumer expenditure on DIY home improvement and a robust professional construction and automotive aftermarket sector. Demand is overwhelmingly focused on high-voltage (18V/20V) professional-grade systems integrated into established brand platforms (e.g., Milwaukee, DeWalt). Marketing is heavily focused on performance metrics, such as heat-up time, battery run capacity, and structural durability. The competitive environment is mature, necessitating continuous product differentiation through features like advanced digital temperature control and connectivity options for tool tracking. The rapid adoption of specialized adhesives in localized manufacturing is also contributing to sustained premium segment growth.

- Europe: Europe represents a technologically advanced market driven by stringent regulatory standards concerning tool safety and environmental impact. Germany, the UK, and France are key contributors, emphasizing quality craftsmanship and energy efficiency. European professionals prioritize modularity and ease of maintenance, leading to strong sales of systems with replaceable battery packs and standardized charging interfaces. The robust European crafting and hobby market also drives consistent demand for compact, safe, low-temperature models. Future growth is expected to be fueled by renovations focused on sustainability, requiring flexible, cordless sealing and bonding solutions.

- Asia Pacific (APAC): APAC is projected to be the fastest-growing region, driven by rapid industrialization, burgeoning manufacturing sectors in countries like China, India, and Vietnam, and increasing urbanization leading to significant construction and infrastructure development. While price sensitivity remains high, the increasing disposable income is accelerating the transition from corded to affordable, reliable cordless tools. The market is split between high-volume, cost-effective consumer models and rapidly increasing demand for mid-to-high voltage professional tools required for large-scale assembly and installation tasks across the region's expansive supply chains. Localized manufacturing competition is intense, focusing on optimizing local supply chains for battery components.

- Latin America: The market in Latin America is characterized by emerging adoption rates, primarily in Brazil and Mexico, driven by growing informal construction sectors and small-scale manufacturing. Demand is characterized by a need for durable, multi-functional tools that offer excellent value for money. Challenges include infrastructure limitations and reliance on indirect distribution channels, making brand visibility and post-sale support crucial for market penetration. The adoption of cordless technology is accelerating as professional users recognize the time savings and safety improvements associated with high-mobility tools.

- Middle East and Africa (MEA): Growth in MEA is driven by large-scale infrastructure and energy projects, particularly in the Gulf Cooperation Council (GCC) countries. The demand is heavily skewed towards high-temperature, robust tools capable of operating reliably in harsh environmental conditions (high heat, dust). The adoption rate is slower in many African nations due to economic constraints, but government-backed construction initiatives are creating new pockets of demand for durable professional power tools. International brand reputation and long-term durability are critical purchasing criteria in this region.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Rechargeable Cordless Hot Melt Glue Gun Market.- Robert Bosch GmbH

- Makita Corporation

- Milwaukee Tool (Techtronic Industries Co. Ltd.)

- Stanley Black & Decker (DeWalt, Craftsman)

- Ryobi (Techtronic Industries Co. Ltd.)

- Arrow Fastener Co. LLC

- AdTech (Adhesive Technologies, Inc.)

- Surebonder (FPC Corporation)

- Dremel (Robert Bosch Tool Corporation)

- Steinel GmbH

- TECBOND (Power Adhesives Ltd.)

- Gluefast Company, Inc.

- Westcott (Acme United Corporation)

- Rapid (Isaberg Rapid AB)

- Pam Fastening Technology Inc.

- Pneumatic Tool Company (PTC)

- WORX (Positec Tool Corporation)

- Hilti Corporation

Frequently Asked Questions

Analyze common user questions about the Rechargeable Cordless Hot Melt Glue Gun market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary advantage of a rechargeable cordless hot melt glue gun over a traditional corded model?

The primary advantage is superior mobility and operational freedom, enabling users to work without being tethered to a power outlet, drastically improving efficiency in fieldwork, construction sites, and large workspaces, while also eliminating the trip hazard associated with cords.

Which voltage platform is most suitable for professional or industrial use?

For professional and industrial applications, voltage platforms of 12V to 20V are generally recommended. These higher voltages deliver the necessary power to maintain consistent high temperatures and provide extended run times crucial for continuous, heavy-duty bonding applications, often integrating seamlessly with existing power tool battery ecosystems.

How do advancements in battery technology influence the performance of cordless glue guns?

Advanced Lithium-ion (Li-ion) batteries significantly influence performance by offering higher energy density for longer operational periods, faster charging cycles, and the ability to consistently supply high current to the heating element, ensuring rapid heat-up times and stable adhesive viscosity for superior bond strength.

What are the key differences between low-temperature and high-temperature cordless glue guns?

Low-temperature guns operate around 120°C and are ideal for delicate, heat-sensitive materials like fabric, foam, and certain plastics, prioritizing safety. High-temperature guns operate near 200°C, providing significantly stronger, more durable bonds suitable for demanding materials like wood, metal, and heavy plastics for professional and industrial repairs.

What role does the Positive Temperature Coefficient (PTC) heating element play in modern glue guns?

PTC heating elements utilize self-regulating ceramic technology to ensure rapid, highly efficient heat-up and maintain a remarkably stable operating temperature. This consistency minimizes dripping, optimizes adhesive flow, and protects the tool from overheating, directly contributing to both performance quality and tool longevity.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager