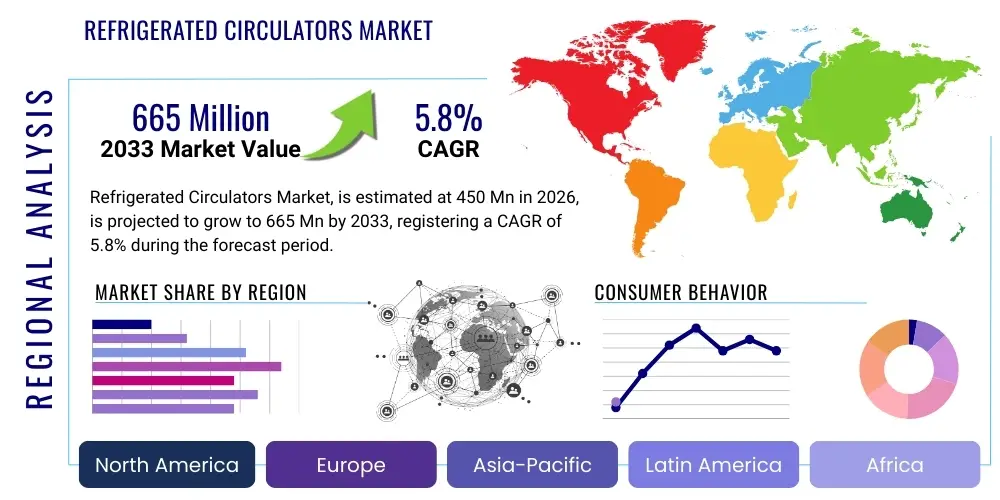

Refrigerated Circulators Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440885 | Date : Feb, 2026 | Pages : 248 | Region : Global | Publisher : MRU

Refrigerated Circulators Market Size

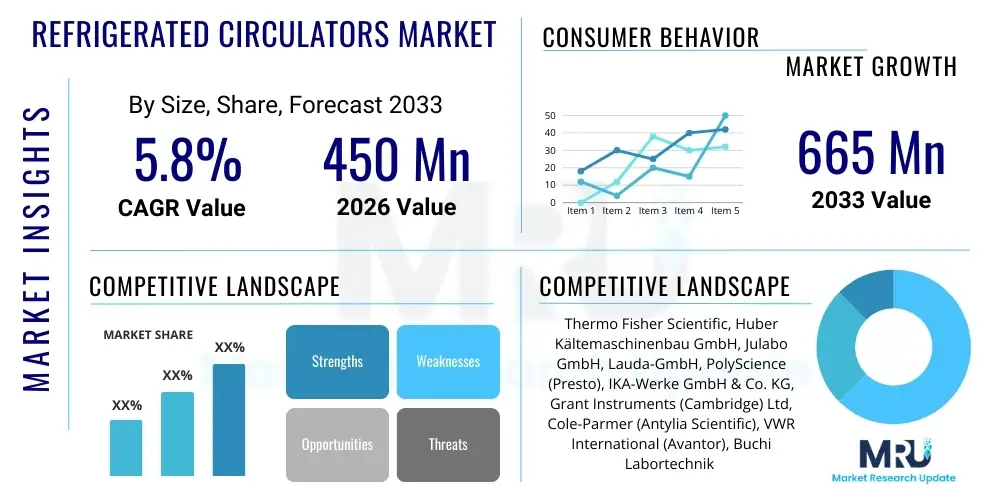

The Refrigerated Circulators Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 450 Million in 2026 and is projected to reach USD 665 Million by the end of the forecast period in 2033. This consistent expansion is primarily fueled by a burgeoning global emphasis on advanced research and development across critical scientific disciplines, alongside increasingly stringent quality control and assurance requirements within various industrial processes. The indispensable role of precise temperature control in modern laboratories and manufacturing environments positions refrigerated circulators as fundamental tools, with their capabilities becoming even more vital for handling sensitive materials and complex reactions. The market’s trajectory is also positively influenced by continuous innovations aimed at enhancing energy efficiency, user-friendliness, and integration into automated laboratory workflows.

Refrigerated Circulators Market introduction

Refrigerated circulators represent a cornerstone technology in contemporary scientific and industrial environments, providing exceptionally accurate and stable temperature control for external applications. These sophisticated instruments are engineered to manage thermal conditions with unparalleled precision, typically operating through a closed-loop system that circulates a temperature-controlled fluid—such as water, ethylene glycol, or silicone oil—to an external apparatus. Core components include an advanced refrigeration unit, a robust pump, and a highly responsive digital controller, all meticulously integrated to ensure consistent performance. Their fundamental purpose is to maintain a constant, user-defined temperature within connected devices like jacketed reaction vessels, viscometers, refractometers, electrophoresis chambers, and various material testing systems, especially crucial when temperatures below ambient are required. The capacity to achieve and sustain precise sub-ambient temperatures, coupled with minimal temperature fluctuation, underscores their critical importance in experiments and processes where thermal integrity is non-negotiable.

The application landscape for refrigerated circulators is remarkably broad and diverse, permeating sectors such as pharmaceuticals, biotechnology, academic research, chemical manufacturing, and the food and beverage industry, along with specialized material science applications. Within pharmaceutical research, these circulators are indispensable for accelerating drug discovery processes, conducting rigorous stability testing, and optimizing complex synthesis reactions, thereby ensuring that new compounds are developed under precisely controlled thermal parameters. Biotechnology leverages these devices extensively for sensitive procedures like DNA amplification, protein crystallization, cell culture maintenance, and bioreactor temperature regulation, where even minute temperature shifts can profoundly impact experimental outcomes. Industrial applications span from precise calibration procedures and stringent quality control in manufacturing facilities to highly specialized cooling requirements for advanced electronics, automotive components, and environmental simulation chambers, highlighting their versatility and critical role in diverse production pipelines.

The adoption of refrigerated circulators offers substantial benefits, including significantly enhanced experimental reproducibility, marked improvements in product quality, and considerable gains in operational efficiency. Their ability to deliver temperature stability, often within an impressive ±0.01 °C, is a defining feature that makes them indispensable for sensitive assays, analytical measurements, and fine-tuned manufacturing processes. Key driving forces propelling the market forward include a sustained global increase in research and development investments, particularly evident in the rapidly evolving biopharmaceutical and personalized medicine sectors. Furthermore, the escalating global demand for stringent quality assurance across manufacturing industries, coupled with a consistent push for innovation leading to more energy-efficient, compact, and intuitively designed circulators, are collectively contributing to their widespread and growing acceptance across a multitude of high-value applications. This convergence of scientific advancement, industrial demand, and technological evolution ensures a dynamic and expanding market for these critical thermal management tools.

Refrigerated Circulators Market Executive Summary

The global refrigerated circulators market is currently undergoing a period of robust expansion, underpinned by several key business trends and strategic developments aimed at optimizing performance, sustainability, and user convenience. A predominant trend involves manufacturers investing heavily in research and development to introduce highly energy-efficient models. These newer circulators often incorporate advanced inverter technology, variable-speed compressors, and eco-friendly refrigerants, aligning with global environmental regulations and reducing operational costs for end-users. There is also a strong emphasis on developing smart circulators equipped with advanced digital interfaces, touchscreen controls, and robust connectivity options, enabling seamless integration with laboratory automation systems (LIMS) and offering capabilities for remote monitoring and control. This shift towards smart, connected devices enhances workflow efficiency and data integrity, meeting the evolving demands of modern, automated laboratories. Furthermore, strategic alliances, mergers, and acquisitions among market leaders are becoming more frequent, as companies seek to expand their product portfolios, enhance technological capabilities, and strengthen their global distribution networks, particularly in high-growth potential regions.

Regional dynamics play a pivotal role in shaping the market landscape, with North America and Europe consistently retaining dominant market shares. This supremacy is largely attributed to their mature and well-established pharmaceutical and biotechnology industries, which are characterized by significant R&D spending, a robust presence of leading academic research institutions, and advanced healthcare infrastructure. These regions are typically early adopters of cutting-edge laboratory technologies, driven by stringent regulatory environments that mandate precise and verifiable experimental conditions. However, the Asia Pacific (APAC) region is rapidly emerging as the fastest-growing market, presenting substantial opportunities for market players. This accelerated growth in APAC is fueled by rapid industrialization, increasing government and private sector investments in scientific research and development, the expansion of healthcare facilities, and the proliferation of contract research organizations (CROs) and manufacturing hubs in countries like China, India, and South Korea. These nations are actively enhancing their scientific capabilities and infrastructure, creating a fertile ground for the adoption of advanced laboratory equipment, including refrigerated circulators.

Segmentation analysis reveals distinct growth patterns within the market. The closed-loop refrigerated circulators segment is witnessing significant traction due to its superior temperature stability, enhanced energy efficiency, and reduced risk of fluid contamination, making them ideal for highly sensitive and critical applications. In terms of temperature range, the low-temperature circulators (operating below -20°C) are projected to experience substantial growth, driven by specialized requirements in cryopreservation, advanced material science, and complex chemical synthesis processes. From an end-user perspective, the pharmaceutical and biotechnology sectors remain the primary revenue generators, owing to their continuous need for precise thermal management in drug discovery, development, and manufacturing. Academic and research institutions also contribute substantially, along with the chemical industry, food and beverage processing, and various industrial sectors that increasingly rely on accurate temperature control for process optimization, quality assurance, and product innovation. The market also observes an increasing demand for larger capacity units to support industrial-scale operations and high-throughput screening prevalent in contemporary research settings.

AI Impact Analysis on Refrigerated Circulators Market

The integration of Artificial Intelligence (AI) into the refrigerated circulators market is poised to usher in a new era of operational intelligence, predictive capabilities, and enhanced user experience, directly addressing long-standing user questions concerning reliability, precision, and efficiency. Common inquiries from users frequently explore how AI can elevate the intrinsic accuracy and stability of temperature control, automate the execution of complex experimental protocols with minimal human intervention, and provide sophisticated early warning systems for potential mechanical failures. A significant area of interest lies in AI's capacity to facilitate more intelligent data logging, advanced analytical insights, and seamless integration of circulators within broader laboratory automation ecosystems. The prevailing expectation among the scientific and industrial community is that AI will transform these instruments from largely passive, standalone devices into proactive, intelligent components of fully integrated scientific workflows. This evolution promises to not only mitigate human error and optimize research timelines but also to unlock unprecedented levels of precision and operational foresight, making laboratory processes more efficient and reproducible than ever before.

The application of AI algorithms can dramatically improve the operational lifecycle and precision of refrigerated circulators. For instance, AI-driven predictive maintenance models analyze real-time operational parameters such as pump motor current, compressor run times, and subtle temperature deviations. By identifying patterns indicative of impending component wear or malfunction, these systems can alert users to potential issues before they escalate, thereby preventing costly downtime and extending the instrument's operational lifespan. Furthermore, AI can optimize energy consumption by intelligently adjusting cooling cycles and pump speeds based on the actual thermal load and historical usage patterns, leading to significant energy savings and reduced environmental impact. This proactive approach to maintenance and efficiency directly responds to user demands for more reliable and cost-effective equipment, transforming reactive repairs into managed, predictive interventions.

Beyond maintenance and efficiency, AI profoundly impacts the control and data management aspects of refrigerated circulators. AI-powered control systems can learn the thermal characteristics of specific external applications and environmental conditions, dynamically fine-tuning PID parameters to achieve and maintain temperature set points with even greater precision and responsiveness. This capability is particularly valuable for highly sensitive reactions where even marginal temperature fluctuations are detrimental. In terms of data, AI algorithms can process vast datasets generated by circulators—including temperature logs, error codes, and power consumption—to extract meaningful insights. These insights can help researchers identify unexpected experimental variables, optimize protocols, and ensure data integrity. Moreover, AI facilitates seamless integration with Laboratory Information Management Systems (LIMS) and other laboratory automation platforms, enabling automated reporting, remote control, and the creation of intelligent, self-correcting workflows. This comprehensive impact underscores AI's transformative potential across the entire spectrum of refrigerated circulator applications, from basic research to industrial production.

- Enhanced Predictive Maintenance: AI algorithms continuously analyze operational data (e.g., fluid pressure, compressor cycles, power consumption) to detect subtle anomalies and predict potential component failures, enabling proactive servicing and maximizing uptime.

- Optimized Performance and Energy Efficiency: AI-driven control systems learn the thermal dynamics of specific applications and environmental conditions, dynamically adjusting cooling and pumping parameters to achieve superior temperature stability while minimizing energy consumption.

- Automated Workflow Integration: AI facilitates seamless communication with other laboratory instruments and automation platforms, allowing for the autonomous execution of complex, multi-step experimental protocols with pre-programmed thermal profiles.

- Advanced Data Analytics and Anomaly Detection: AI processes extensive temperature and operational data, identifying subtle trends, outlier events, and potential experimental inconsistencies that might go unnoticed by human observation, providing deeper insights.

- Intelligent Remote Monitoring and Control: AI powers sophisticated remote access functionalities, enabling users to monitor circulator status, adjust settings, and receive critical alerts on mobile devices or through web interfaces, enhancing operational flexibility.

- Self-Calibration and Adaptive Control: Future AI integration may include features for autonomous self-calibration and adaptive control, where the circulator learns from its environment and adjusts its internal parameters to maintain optimal performance without manual intervention.

- Improved User Experience: AI can lead to more intuitive and adaptive user interfaces that learn user preferences and simplify complex programming tasks, reducing the learning curve and making advanced functionalities more accessible.

- Enhanced Safety Protocols: AI systems can monitor for unsafe operating conditions (e.g., overheating, fluid leaks) and trigger automated shutdown procedures or alarms, enhancing laboratory safety beyond conventional measures.

DRO & Impact Forces Of Refrigerated Circulators Market

The refrigerated circulators market is fundamentally propelled by a confluence of robust drivers, with the escalating global expenditure on research and development standing as the primary catalyst. As pharmaceutical companies, biotechnology firms, and academic institutions worldwide intensify their efforts in drug discovery, vaccine development, advanced material science, and fundamental scientific inquiry, the demand for precise and reliable temperature control equipment becomes increasingly critical. The rapid expansion and innovation within the biopharmaceutical industry, particularly in the production of complex biologics, gene therapies, and mRNA vaccines, mandates extraordinarily stringent temperature management at every stage—from upstream cell culture and fermentation to downstream purification, formulation, and cryogenic storage. This precision requirement renders refrigerated circulators indispensable, driving their continuous adoption. Furthermore, the burgeoning trend of laboratory automation and high-throughput screening methodologies across various research fields necessitates integrated and highly accurate thermal control solutions that can operate seamlessly within complex automated workflows, thereby consistently fueling market growth.

Despite the strong growth drivers, the refrigerated circulators market faces several notable restraints that temper its expansion. A significant barrier to entry and adoption is the substantial initial capital investment required for high-performance, advanced refrigerated circulators. This cost, coupled with ongoing expenses related to installation, specialized heat transfer fluids, routine maintenance, and calibration, can be prohibitive for smaller research laboratories, start-up biotechnology firms, or academic institutions operating with constrained budgets. The operational complexity of certain high-end models, which often feature intricate programming capabilities and advanced control parameters, necessitates skilled personnel for optimal setup, operation, and troubleshooting. This requirement for specialized expertise can add to operational overheads. Moreover, the market remains susceptible to broader economic downturns, geopolitical instabilities, and fluctuations in government funding for scientific research, which can directly impact procurement cycles and investment decisions in laboratory infrastructure. Additionally, evolving environmental regulations regarding the use of specific refrigerants (e.g., F-gases) impose continuous pressure on manufacturers to innovate and comply, adding to R&D and production costs.

Opportunities within the refrigerated circulators market are abundant and geographically diverse, particularly in emerging economies where scientific research and industrial production infrastructure are experiencing rapid growth. Countries across Asia Pacific (e.g., China, India, Southeast Asian nations), Latin America, and the Middle East are significantly increasing investments in R&D, establishing new academic centers, and expanding manufacturing capabilities, thereby creating vast untapped markets for advanced laboratory equipment. Furthermore, the growing demand for highly customized solutions, precisely tailored to meet specific application requirements—such as ultra-low temperature capabilities for specialized material testing, integration with specific reactor designs, or enhanced remote control features for smart laboratories—presents lucrative niche segments for innovation. The increasing global focus on sustainability and energy efficiency in laboratory operations also opens avenues for manufacturers to develop and market eco-friendlier and more cost-effective circulators, leveraging renewable energy sources or advanced insulation technologies. These collective opportunities and the interplay of drivers and restraints compel market players to engage in continuous technological advancement, strategic market diversification, and proactive customer-centric product development to maintain a competitive edge and capture emerging growth segments in this dynamic market.

Segmentation Analysis

The global refrigerated circulators market is meticulously segmented to offer a granular understanding of its intricate dynamics and diverse demand landscape, facilitating the development of highly targeted market strategies and specialized product offerings. This comprehensive segmentation permits a detailed examination of market trends, competitive forces, and growth opportunities across various critical dimensions, including distinct product types, specific temperature ranges, varying capacities, and a broad array of end-user applications. Each defined segment exhibits unique characteristics, growth trajectories, and demand patterns, which are profoundly influenced by ongoing technological advancements, evolving regulatory frameworks, and the precise operational needs of different scientific research, industrial processing, and quality control applications. A thorough understanding of these distinct market segments is absolutely essential for identifying the most promising growth areas, tailoring innovative solutions to meet highly specialized demands, and optimizing market penetration strategies for laboratories, manufacturing facilities, and research institutions globally, thereby ensuring sustained market relevance and expansion.

- By Type:

- Open-Bath Refrigerated Circulators: These units typically feature an open reservoir where samples or smaller external devices can be directly immersed. While often more economical and offering direct access to the circulating fluid, they generally provide slightly less thermal stability compared to closed-loop systems due to exposure to ambient conditions. They are commonly used for general laboratory tasks, sample conditioning, and applications where moderate precision is acceptable.

- Closed-Loop Refrigerated Circulators: Representing the more advanced and dominant segment, these systems are designed for continuous, precise circulation of fluid to external, sealed applications, minimizing thermal exchange with the environment. They offer superior temperature stability, enhanced energy efficiency, reduced fluid evaporation, and are ideal for highly sensitive reactions, analytical instrumentation, and critical industrial processes where unwavering thermal control is paramount. The increasing demand for automation and high-precision results is driving growth in this segment.

- By Temperature Range:

- Low Temperature Circulators (below -20°C): This segment is crucial for specialized applications requiring extreme cold. Demand stems from cryopreservation, freeze-drying (lyophilization), material testing at sub-ambient temperatures, advanced chemical synthesis, and research into superconductors. Technological advancements are focused on achieving lower temperatures with improved energy efficiency and reliability.

- Medium Temperature Circulators (-20°C to +100°C): This is the most versatile and widely adopted segment, catering to a vast array of laboratory and industrial processes that require precise control around or below ambient temperatures, as well as moderate heating capabilities. Applications include reaction vessel cooling, viscometry, refractometry, and general sample conditioning.

- High Temperature Circulators (above +100°C): While the "refrigerated" aspect typically implies cooling, some advanced circulators offer the ability to reach elevated temperatures in addition to sub-ambient ranges, providing broader application flexibility for processes requiring both heating and cooling cycles. Their market share within the refrigerated segment is niche but growing as integrated thermal solutions gain popularity.

- By Capacity:

- Small Capacity (up to 5 Liters): These compact units are ideal for individual experiments, benchtop setups, personal workstations, and smaller-scale research applications where space is limited and fluid volume requirements are low. Their portability and ease of use make them popular in academic and analytical labs.

- Medium Capacity (5 to 20 Liters): This segment serves as the workhorse for general laboratory use, pilot plant operations, and multiple small-scale applications or larger single reactors. They offer a balance of cooling power, capacity, and footprint, making them suitable for a wide range of research and development activities.

- Large Capacity (above 20 Liters): Designed for industrial-scale processes, larger reaction vessels, high-volume sample conditioning, and substantial cooling power requirements. These units are critical in chemical manufacturing, bioprocessing, and environmental simulation chambers, supporting heavy-duty and continuous operations.

- By End-User:

- Pharmaceutical and Biotechnology Companies: The dominant and fastest-growing segment, driven by intensive R&D in drug discovery, process development, manufacturing of biologics, vaccines, and advanced therapies, as well as stringent quality control procedures. Precision temperature control is non-negotiable in this sector.

- Academic and Research Institutions: Encompasses universities, government laboratories, and non-profit research organizations. These entities utilize circulators for fundamental scientific inquiry, applied research, educational experiments, and diverse analytical tasks across chemistry, biology, and physics.

- Chemical Industry: Crucial for fine chemical synthesis, polymer research, petrochemical processing, and material characterization. Circulators ensure precise reaction temperature control, product quality, and safety in various chemical processes.

- Food and Beverage Industry: Used for quality control testing, product development, shelf-life studies, viscosity measurements of liquids, and maintaining optimal temperatures for sensitive ingredients or processes to ensure product integrity and safety.

- Industrial and Manufacturing: Applications include calibration of sensors and instruments, material stress testing, cooling for electronics manufacturing, automotive component testing, and diverse industrial processes requiring stable temperature environments.

- Clinical and Healthcare Laboratories: Utilized in diagnostic testing, sample preparation, pathology, and specialized medical research where controlled thermal conditions are essential for assay performance and sample preservation.

- By Region:

- North America

- Europe

- Asia Pacific (APAC)

- Latin America

- Middle East and Africa (MEA)

Value Chain Analysis For Refrigerated Circulators Market

The value chain for the refrigerated circulators market commences with upstream activities, which are critical for the foundational quality and performance of the final product. This initial phase involves the meticulous sourcing and procurement of essential raw materials and specialized components. Key upstream suppliers provide highly engineered parts such as compressors (often hermetic or scroll types), robust refrigeration units, efficient heat exchangers, precision pumps (magnetic drive or impeller types), sophisticated temperature sensors (e.g., Pt100), advanced microcontrollers, power electronics, and various other electronic circuit boards. The emphasis at this stage is on acquiring components that are not only reliable and energy-efficient but also meet stringent quality and safety standards, adhering to international certifications. Manufacturers often engage in strategic partnerships and long-term supply agreements with these component providers, fostering collaboration to ensure a consistent supply chain, optimize cost efficiencies through economies of scale, and co-develop custom components that offer proprietary performance advantages in the highly competitive market.

Moving downstream, the value chain progresses through the core manufacturing, precision assembly, and rigorous testing phases of the refrigerated circulator units. This stage is characterized by advanced engineering, skilled craftsmanship, and the implementation of comprehensive quality assurance protocols to produce instruments renowned for their accuracy, durability, and operational longevity. Manufacturing processes typically involve the fabrication of robust stainless steel or plastic bath tanks, the integration of complex refrigeration circuits, precise mounting of pumps and heating elements, and the sophisticated wiring of control electronics. A critical aspect of this phase is the development and integration of intuitive user interfaces, advanced control software, and robust safety features (e.g., over-temperature protection, low-liquid-level alarms). Post-production, each unit undergoes extensive calibration and performance testing to verify its temperature stability, cooling capacity, and overall reliability before market release. Subsequently, the products enter the distribution channel, which serves as a pivotal link connecting manufacturers to a diverse global base of end-users. This distribution network is typically a hybrid model, combining direct sales efforts for major institutional clients or through a manufacturer's own regional sales offices, with indirect sales facilitated by a broad network of authorized distributors, specialized laboratory equipment dealers, and online scientific supply platforms. These indirect channels are crucial for achieving widespread market penetration, offering localized technical support, and providing essential after-sales services across geographically fragmented markets, enhancing customer accessibility and responsiveness.

The final, yet equally vital, stage of the value chain encompasses comprehensive after-sales support, maintenance, and ongoing customer service, which are instrumental in cultivating long-term customer loyalty and ensuring the sustained operational efficiency of these critical instruments. This includes offering prompt technical assistance, managing warranty claims, providing readily available repair facilities, and ensuring the efficient supply of spare parts and essential consumables (like heat transfer fluids). Robust after-sales support not only maximizes instrument uptime but also significantly contributes to customer satisfaction and repeat business, which are crucial for market reputation in the specialized scientific equipment sector. Both direct sales teams and indirect distribution partners play an integral role in delivering these services, with distributors often acting as the first point of contact for local support and routine maintenance. The entire value chain operates within a dynamic feedback loop, where invaluable insights gathered from end-user experiences, performance data, and emerging market needs are continuously fed back to the product development and upstream component sourcing stages. This iterative process drives ongoing innovation, facilitates incremental product improvements, and ensures that refrigerated circulators evolve to meet the ever-changing and increasingly sophisticated demands of modern scientific research and industrial applications.

Refrigerated Circulators Market Potential Customers

The prospective customer base for refrigerated circulators is remarkably extensive and highly diverse, spanning numerous scientific, industrial, and commercial entities that critically depend on precise and stable temperature regulation for their core operations. The most substantial segment of end-users is firmly anchored within the pharmaceutical and biotechnology industries. Here, these instruments are absolutely indispensable across virtually every stage of drug discovery, development, and manufacturing processes. This includes, but is not limited to, advanced research laboratories engaged in molecular biology, cell culture, bioreactor fermentation, protein purification, and rigorous analytical testing, where maintaining specific and unwavering temperatures is paramount for achieving optimal reaction kinetics, preserving enzyme activity, and ensuring the absolute integrity of sensitive biological samples. Furthermore, specialized Contract Research Organizations (CROs) and Contract Development and Manufacturing Organizations (CDMOs), which are heavily involved in outsourced R&D and production activities, represent a significant and expanding customer segment due to their pervasive need for stringent and verifiable thermal management solutions in their high-stakes work.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450 Million |

| Market Forecast in 2033 | USD 665 Million |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Thermo Fisher Scientific, Huber Kältemaschinenbau GmbH, Julabo GmbH, Lauda-GmbH, PolyScience (Presto), IKA-Werke GmbH & Co. KG, Grant Instruments (Cambridge) Ltd, Cole-Parmer (Antylia Scientific), VWR International (Avantor), Buchi Labortechnik AG, Heidolph Instruments GmbH & CO. KG, Corning Inc., Yamato Scientific Co., Ltd., Lab Companion (Jeio Tech), Memmert GmbH + Co. KG, Techne (Bibby Scientific), BINDER GmbH, Eppendorf AG, Hitachi High-Tech Corporation, Bio-Rad Laboratories Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Refrigerated Circulators Market Key Technology Landscape

Moreover, breakthroughs in materials science are playing a crucial role in shaping the technological evolution, leading to the development of more durable, chemically resistant components for bath tanks and all wetted parts, which significantly extends the lifespan and expands the application versatility of refrigerated circulators. There is a strong industry-wide push towards highly modular designs, which not only simplify routine maintenance and facilitate easy upgrades but also enable manufacturers to offer highly customized solutions precisely tailored to very specific application requirements, such as ultra-low temperature ranges, unique reactor coupling mechanisms, or specialized fluid handling. Energy efficiency remains a paramount design objective, manifested through continuous improvements in advanced insulation materials, optimized heat exchanger designs, and intelligent power management systems that dynamically adapt to varying operational demands. This relentless pursuit of efficiency directly translates into reduced operational costs and a lower environmental impact. Collectively, the modern technological landscape is characterized by a synergistic blend of robust mechanical engineering, cutting-edge electronics, and intelligent software, all converging to deliver highly reliable, exceptionally precise, and seamlessly connected thermal control solutions that are indispensable for the scientific and industrial challenges of the 21st century. This holistic approach ensures that refrigerated circulators continue to evolve as critical enablers of innovation and progress.

Regional Highlights

- North America: This region consistently commands a substantial market share, primarily propelled by unparalleled investments in pharmaceutical and biotechnology research and development, particularly concentrated within the United States and Canada. The robust presence of numerous globally leading research universities, extensively funded private and public research institutions, and a highly advanced healthcare infrastructure collectively fuels a continuous and growing demand for sophisticated refrigerated circulators. Furthermore, the existence of stringent regulatory standards for drug manufacturing, quality assurance, and laboratory practices necessitates the widespread adoption of highly precise and verifiable temperature control equipment. Pioneering innovation in areas such as laboratory automation, personalized medicine, and advanced materials research also contributes significantly to this region's enduring market dominance and high adoption rates of cutting-edge thermal management solutions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Refrigerated Circulators Market.- Thermo Fisher Scientific

- Huber Kältemaschinenbau GmbH

- Julabo GmbH

- Lauda-GmbH

- PolyScience (Presto)

- IKA-Werke GmbH & Co. KG

- Grant Instruments (Cambridge) Ltd

- Cole-Parmer (Antylia Scientific)

- VWR International (Avantor)

- Buchi Labortechnik AG

- Heidolph Instruments GmbH & CO. KG

- Corning Inc.

- Yamato Scientific Co., Ltd.

- Lab Companion (Jeio Tech)

- Memmert GmbH + Co. KG

- Techne (Bibby Scientific)

- BINDER GmbH

- Eppendorf AG

- Hitachi High-Tech Corporation

- Bio-Rad Laboratories Inc.

Frequently Asked Questions

What is a refrigerated circulator and what is its primary function in a laboratory setting?

A refrigerated circulator is a highly specialized laboratory and industrial instrument engineered to provide exceptionally precise and stable temperature control for external applications. Its primary function in a laboratory is to circulate a thermally regulated fluid, such as water or silicone oil, through an external system like a jacketed reactor vessel, viscometer, or electrophoresis unit. This meticulous control allows scientists to maintain specific temperatures, often significantly below ambient, which is critical for sensitive chemical reactions, biological assays, material testing, and analytical procedures, ensuring experimental accuracy, reproducibility, and optimal conditions for research and development.

How do refrigerated circulators achieve and maintain such high temperature stability?

Refrigerated circulators achieve and maintain their renowned high temperature stability through a sophisticated combination of advanced components. A powerful compressor-based cooling system precisely lowers the temperature of a fluid reservoir. This fluid is then circulated by a robust pump through an external loop connected to the application, facilitating efficient heat exchange. An integrated, highly responsive PID (Proportional-Integral-Derivative) controller continuously monitors the fluid temperature with sensitive sensors (e.g., Pt100). This controller rapidly analyzes any deviation from the set point and dynamically adjusts the cooling power, heating elements (if present), and pump speed to counteract fluctuations, ensuring unwavering thermal consistency, often within fractions of a degree Celsius, even under varying external loads.

What are the key industries and main applications where refrigerated circulators are indispensable?

Refrigerated circulators are indispensable across a broad spectrum of industries and applications. In the pharmaceutical and biotechnology sectors, they are crucial for drug discovery, stability testing of compounds, cell culture, fermentation processes, and precise temperature regulation in bioreactors. The chemical industry relies on them for controlled chemical synthesis, reaction temperature management, and material characterization. Academic and governmental research institutions widely utilize them for fundamental scientific experiments across chemistry, biology, and physics. Furthermore, the food and beverage industry uses them for quality control and product development, while industrial and manufacturing sectors employ them for instrument calibration, material testing, and specialized cooling tasks in electronics and automotive production, highlighting their pervasive utility.

What critical factors should be considered when selecting a refrigerated circulator for a specific application?

Selecting the appropriate refrigerated circulator necessitates careful consideration of several critical factors. Foremost are the required temperature range (e.g., ultra-low, medium, or high), the necessary cooling capacity (measured in Watts) to efficiently manage the thermal load of the external application, and the pump's flow rate and pressure, which dictate fluid circulation efficiency. Other vital aspects include the bath volume or capacity, the type of external system to be connected (e.g., open-bath immersion or closed-loop circulation), and the desired temperature stability and uniformity. Additionally, users should evaluate control features (e.g., programmability, data logging, connectivity options), the type of refrigerant for environmental compliance, noise levels, instrument footprint, and budget constraints to ensure optimal performance and integration within the laboratory or industrial setting.

How are technological advancements, including AI and IoT, transforming the refrigerated circulators market?

Technological advancements, particularly the integration of Artificial Intelligence (AI) and the Internet of Things (IoT), are profoundly transforming the refrigerated circulators market. These innovations enable features like enhanced energy efficiency through AI-optimized cooling algorithms, predictive maintenance by analyzing operational data for early fault detection, and intelligent remote monitoring and control via IoT connectivity. Modern circulators offer advanced digital touchscreens, seamless integration with laboratory automation systems (LIMS), and the capability for automated data logging and analysis. This shift towards smart, connected, and data-driven instruments is improving experimental reproducibility, reducing operational costs, minimizing downtime, and enhancing overall laboratory productivity and safety in research and industrial environments.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager