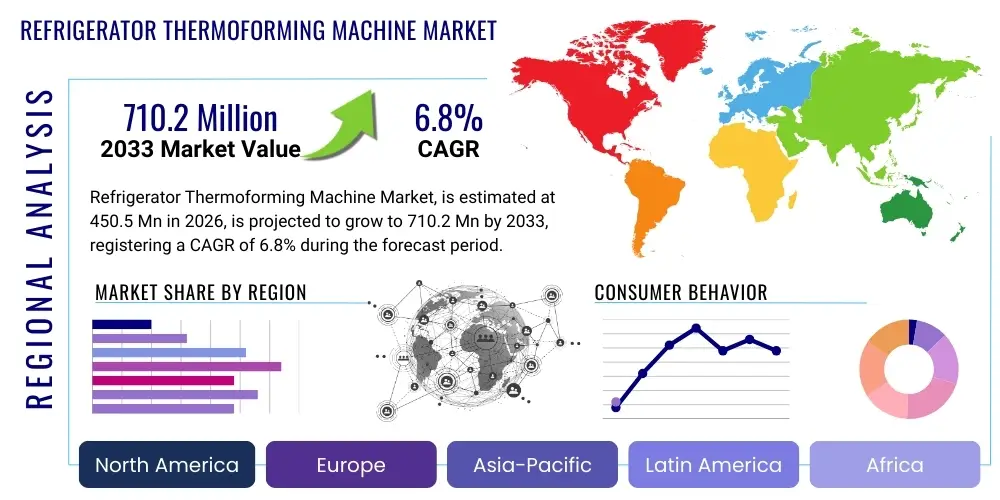

Refrigerator Thermoforming Machine Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 441098 | Date : Feb, 2026 | Pages : 246 | Region : Global | Publisher : MRU

Refrigerator Thermoforming Machine Market Size

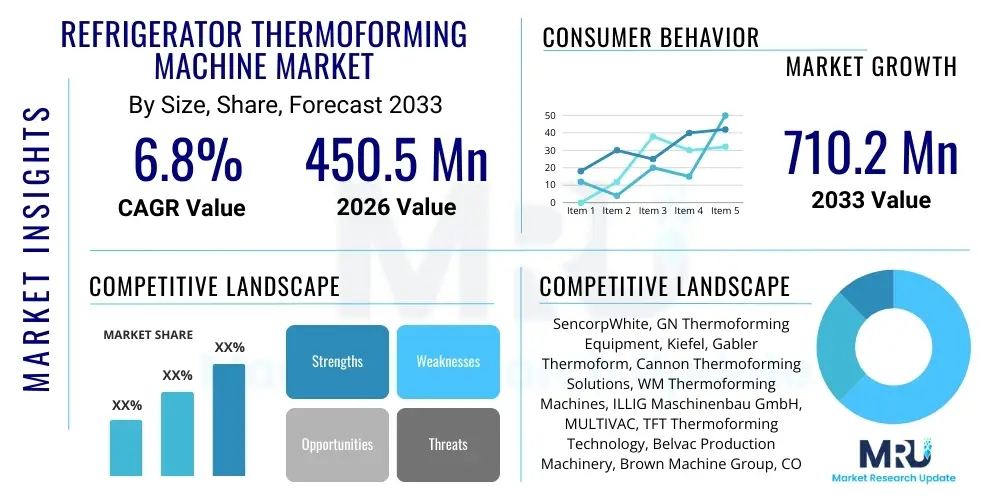

The Refrigerator Thermoforming Machine Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 450.5 Million in 2026 and is projected to reach USD 710.2 Million by the end of the forecast period in 2033. This consistent expansion is directly linked to the burgeoning global demand for household appliances, particularly in emerging economies where penetration rates for refrigeration units are rapidly increasing. Furthermore, technological advancements focused on enhancing energy efficiency and material optimization in thermoforming processes are driving significant investments within the manufacturing sector.

Refrigerator Thermoforming Machine Market introduction

The Refrigerator Thermoforming Machine Market encompasses specialized industrial equipment designed for the high-volume production of internal and external plastic components used in domestic and commercial refrigeration units. These machines utilize heat and vacuum pressure to shape large plastic sheets—typically High Impact Polystyrene (HIPS) or Acrylonitrile Butadiene Styrene (ABS)—into complex forms such as inner liners, door liners, and crisper drawers. The primary function of these components is to ensure thermal insulation and structural integrity within the refrigerator cavity, making precision and consistency critical requirements for the machinery involved.

Major applications for refrigerator thermoforming machines reside predominantly within the Original Equipment Manufacturers (OEMs) of home appliances and specialized plastics fabrication service providers catering to the white goods sector. The technology is favored due to its efficiency in producing large, thin-walled parts with intricate details, offering a favorable balance between material usage and structural performance. These machines are integral to modern appliance manufacturing lines, enabling the rapid production cycles necessary to meet consumer demand spikes, particularly those associated with seasonal purchasing and new regulatory introductions concerning energy efficiency standards.

Key driving factors influencing market growth include rapid urbanization, leading to higher housing starts and increased demand for essential durable goods, especially in the Asia Pacific region. The continuous need for replacing older, less efficient refrigerator models with modern, energy-star rated appliances also fuels machine sales. Benefits derived from deploying advanced thermoforming equipment include enhanced dimensional accuracy, reduced material scrap rates through sophisticated trimming systems, and improved overall production throughput, crucial for maintaining competitive pricing in the highly sensitive consumer appliance market.

Refrigerator Thermoforming Machine Market Executive Summary

The global Refrigerator Thermoforming Machine market is experiencing dynamic shifts, underpinned by strong business trends focusing on integration and automation, regional trends emphasizing capacity expansion in Asia-Pacific, and segment trends prioritizing high-speed rotary machines and advanced material compatibility. Business trends are dominated by the push toward Industry 4.0 integration, where manufacturers are increasingly demanding machines equipped with sophisticated sensor technology, integrated quality control systems, and data analytics capabilities to optimize uptime and predictive maintenance schedules. This modernization drive is necessitating substantial capital expenditure from major white goods producers globally, stimulating the machinery replacement cycle.

Regionally, the market landscape is being redefined by massive investments in manufacturing capacity within China, India, and Southeast Asian nations. These regions benefit from lower operational costs and surging domestic consumption, establishing them as global hubs for appliance production. While North America and Europe maintain technological leadership, focusing on highly customized and specialty thermoforming applications, the volume growth is overwhelmingly centered in APAC. This geographical distribution of manufacturing requires suppliers to establish robust service networks and localized production facilities to effectively support their extensive installed bases across diverse regulatory environments.

Segmentation trends indicate a marked preference for sophisticated multi-station and rotary thermoforming systems over traditional single-station machines, driven by the requirement for higher throughput and reduced cycle times. Furthermore, there is growing emphasis on machinery capable of handling advanced barrier polymers and recycled plastics (rPET/rABS) to meet escalating sustainability mandates and circular economy objectives imposed by governmental bodies and consumer preference. The intersection of these trends highlights a market moving towards greater technological complexity, requiring machinery vendors to continuously innovate in areas such as precision tooling, vacuum technology, and energy-efficient heating elements to maintain relevance.

AI Impact Analysis on Refrigerator Thermoforming Machine Market

Common user questions regarding AI's influence in the Refrigerator Thermoforming Machine market frequently center on how these advanced analytical tools can fundamentally alter production economics, specifically asking about predictive failure rates, optimization of heating profiles, and real-time defect detection. Users are concerned about the implementation costs and the expertise required to manage complex AI-driven systems but anticipate substantial gains in operational efficiency and material usage reduction. The prevailing expectation is that AI will transition thermoforming from a process heavily reliant on empirical operator adjustments to a precision-engineered, self-optimizing system, thereby ensuring zero-defect production runs and maximizing yield.

The integration of Artificial Intelligence (AI) into refrigerator thermoforming processes represents a transformative shift, moving beyond traditional automation toward cognitive manufacturing. AI algorithms, particularly those utilizing machine learning and deep learning, are increasingly being deployed to analyze vast streams of data generated by machine sensors, including temperature readings, vacuum pressure fluctuations, sheet thickness variations, and cycle timing metrics. This continuous data analysis allows the system to instantaneously detect subtle deviations from optimal parameters, predicting potential machine downtime or quality defects before they materialize, significantly enhancing overall equipment effectiveness (OEE) and reducing material waste which is a major cost factor in polymer processing.

Furthermore, AI is pivotal in optimizing the delicate thermal profiles required for shaping large polymer sheets, which historically required significant trial-and-error setup time. Machine learning models can simulate millions of parameter combinations to determine the exact heating distribution and cycle timing necessary for specific materials and part geometries, minimizing the risk of uneven cooling or warping. This AI-driven parameter tuning not only accelerates product changeovers but also ensures consistent quality across different batches and manufacturing sites, crucial for global white goods manufacturers seeking uniform product standards worldwide. The analytical capabilities of AI thus drive competitive differentiation based on operational excellence and material efficiency.

- AI-driven Predictive Maintenance: Forecasts component failure in heating zones, vacuum pumps, and cutting stations, reducing unscheduled downtime.

- Real-time Quality Control (QC): Utilizes vision systems and neural networks to detect micro-defects and dimensional inaccuracies in formed parts immediately after cooling.

- Material Optimization Algorithms: Dynamically adjusts sheet thickness and material feed rates based on real-time process stability, minimizing polymer scrap.

- Autonomous Parameter Tuning: Machine learning optimizes heating time, cooling rates, and vacuum duration for new tools and materials, drastically cutting setup time.

- Supply Chain Visibility: AI analyzes production data against material procurement schedules, ensuring optimal inventory levels for specialized polymer sheets.

DRO & Impact Forces Of Refrigerator Thermoforming Machine Market

The Refrigerator Thermoforming Machine market is shaped by a complex interplay of Drivers, Restraints, and Opportunities, collectively summarized as DRO & Impact Forces. The primary drivers include the escalating global demand for refrigerators fueled by population growth and rising disposable incomes, coupled with the mandatory shift towards more energy-efficient appliance designs that necessitate precision-formed internal components. Conversely, market growth is restrained by the high initial capital investment required for purchasing advanced, large-format thermoforming machinery, posing a significant barrier to entry for smaller manufacturers, alongside the technical complexities involved in processing specialized, often multi-layered, engineering plastics. The main opportunity lies in the rapid expansion of sustainable manufacturing practices, driving demand for machines capable of processing bio-based or recycled polymers efficiently, coupled with the opportunity presented by integrating advanced robotics for automated handling and trimming functions to enhance throughput and precision across production lines.

Segmentation Analysis

The Refrigerator Thermoforming Machine Market is rigorously segmented based on machine type, level of automation, application, and the type of material processed, providing a detailed view of current industry preferences and future technological trajectories. Segmentation by machine type primarily distinguishes between single-station, shuttle, and rotary thermoforming systems, reflecting varying requirements for production volume and component complexity. Automation level segmentation highlights the adoption curve from semi-automatic manual systems toward fully automated, integrated production lines often featuring robotic handling. Application-based segmentation is crucial, differentiating machines optimized for producing large inner liners from those dedicated to manufacturing smaller, detailed components like door panels and freezer compartments, each requiring distinct tooling and cycle characteristics.

- By Machine Type:

- Single-Station Thermoforming Machines

- Shuttle Thermoforming Machines

- Rotary Thermoforming Machines (Three-Station, Four-Station)

- By Operation Type:

- Automatic

- Semi-Automatic

- By Application:

- Refrigerator Inner Liner Production

- Door Liner Production

- Crisper Drawers and Accessory Manufacturing

- By Material Compatibility:

- High Impact Polystyrene (HIPS)

- Acrylonitrile Butadiene Styrene (ABS)

- Polyethylene Terephthalate (PET/rPET)

- Polypropylene (PP)

- By End-User Industry:

- Residential Refrigerator Manufacturing

- Commercial Refrigeration (Cold Storage, Display Units)

Value Chain Analysis For Refrigerator Thermoforming Machine Market

The value chain for the Refrigerator Thermoforming Machine Market commences with the upstream supply analysis, dominated by specialized component manufacturers and raw material suppliers. Key upstream inputs include precision steel and aluminum for machine frames and tooling, high-fidelity electrical components (PLCs, servo motors, sensors), and sophisticated heating elements (ceramic heaters, quartz lamps). The quality and reliability of these upstream suppliers directly influence the final machine's performance characteristics, requiring tight collaboration and stringent quality checks. Disruptions in the global supply chain for advanced microelectronics or specific high-temperature alloys can significantly impact machine manufacturing lead times and cost structures, thereby affecting pricing for the end-user.

Midstream activities involve the core machinery manufacturing process, encompassing R&D, design customization, assembly, and rigorous factory acceptance testing (FAT). Manufacturers of thermoforming machines must invest heavily in proprietary technologies, especially concerning vacuum efficiency, rapid tool change mechanisms, and integrated robotics. The competitive differentiation at this stage relies heavily on engineering expertise, ability to integrate software controls for Industry 4.0 compatibility, and efficiency in producing large, robust machinery platforms. This stage also includes the fabrication of precision tooling (molds), which are often custom-designed for specific refrigerator models, demanding specialized mold-making services.

Downstream analysis focuses on distribution channels, integration, and aftermarket support. Direct distribution is common for high-value, customized machinery, where manufacturers engage directly with major refrigerator OEMs to provide bespoke solutions, installation, and operator training. Indirect channels, involving regional distributors or specialized machinery agents, handle sales to smaller or geographically diverse clients. Post-sales services, including maintenance contracts, spare parts supply, and technology upgrades (e.g., retrofitting older machines with new sensor packages), represent a critical and profitable component of the value chain. Effective, localized service support is paramount given the high-production critical nature of these machines in appliance assembly lines.

Refrigerator Thermoforming Machine Market Potential Customers

The primary end-users and buyers in the Refrigerator Thermoforming Machine Market are large-scale global manufacturers of household and commercial refrigeration equipment. These organizations, often referred to as white goods OEMs, possess the necessary capital investment and high-volume production requirements that justify the purchase of advanced, automated thermoforming systems. Their purchasing decisions are primarily driven by the need for consistent component quality, maximum throughput capacity, compliance with stringent dimensional tolerances, and adherence to global energy efficiency standards, which are heavily dependent on the precision of the inner liner.

Secondary but significant customers include specialized contract plastics manufacturers and custom molders who serve the appliance industry. These companies often operate as tier-1 or tier-2 suppliers, providing components to multiple major OEMs. They require highly flexible thermoforming machines capable of quick changeovers between different material types and part geometries, serving as a critical buffer capacity for the peak production demands of their clients. Additionally, manufacturers focusing on the commercial refrigeration sector (e.g., refrigerated display cases for supermarkets, medical cold storage units) represent a growing niche market, demanding machines optimized for forming thicker, more robust materials necessary for industrial durability and stricter thermal regulations.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450.5 Million |

| Market Forecast in 2033 | USD 710.2 Million |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | SencorpWhite, GN Thermoforming Equipment, Kiefel, Gabler Thermoform, Cannon Thermoforming Solutions, WM Thermoforming Machines, ILLIG Maschinenbau GmbH, MULTIVAC, TFT Thermoforming Technology, Belvac Production Machinery, Brown Machine Group, COMI S.p.A., Frimo Group GmbH, ZMD AG, Cefla Finishing. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Refrigerator Thermoforming Machine Market Key Technology Landscape

The Refrigerator Thermoforming Machine Market is characterized by a rapidly evolving technology landscape focused on increasing efficiency, precision, and sustainability. A critical technological shift involves the widespread adoption of servo-motor driven systems replacing older hydraulic or pneumatic actuators. Servo systems offer unparalleled precision in controlling clamping forces, forming depth, and indexing speed, directly translating into tighter dimensional tolerances for the complex inner liner geometry and significantly reducing energy consumption compared to conventional drive mechanisms. This transition is essential for manufacturers dealing with increasingly thinner plastic sheets where subtle changes in movement control can lead to major defects like webbing or thinning.

Furthermore, innovations in heating technology are paramount to achieving rapid cycle times and uniform material preparation. The market is witnessing a strong preference for high-efficiency ceramic or quartz infrared (IR) heating elements, often configured in intelligent, segmented heating zones. These advanced systems allow operators to precisely tailor the heat profile across the plastic sheet before forming, compensating for sheet thickness variations or non-uniform cooling, thereby optimizing the material's elastic properties for the molding process. Advanced machines now incorporate pyrometers and thermal imaging cameras, integrated with machine control systems, to provide real-time thermal mapping and closed-loop feedback, ensuring that every sheet reaches the exact desired forming temperature regardless of ambient conditions.

The rise of Industry 4.0 has mandated the integration of advanced digitalization features. Modern thermoforming machines are equipped with comprehensive Programmable Logic Controllers (PLCs) and Human-Machine Interfaces (HMIs) that facilitate seamless communication with factory-wide Manufacturing Execution Systems (MES). Key features include modular tooling systems that allow for quick changeovers—reducing idle time between product runs—and integrated scrap recovery and pelletizing systems positioned adjacent to the machine. Moreover, the increasing use of in-line three-dimensional scanning and robotic trimming ensures that the finished refrigerator components are immediately trimmed and checked against Computer-Aided Design (CAD) models, automating the final quality assurance step which was traditionally labor-intensive and prone to human error.

Regional Highlights

- Asia Pacific (APAC): APAC is the dominant market shareholder and the fastest-growing region, driven by massive domestic consumption, particularly in China and India, and the establishment of global manufacturing hubs by major white goods companies. The region is characterized by high-volume production requirements, leading to strong demand for highly automated, rotary-type thermoforming machines for continuous operation.

- Europe: Europe represents a mature market focusing heavily on technological refinement, stringent energy efficiency regulations, and sustainability goals. Demand here is centered on high-precision machinery capable of processing advanced engineering polymers, including those with recycled content (rABS/rPET), and integrating fully automated handling and stacking systems to reduce labor costs and ensure compliance with high quality standards.

- North America: North America exhibits steady growth, primarily fueled by replacement cycles and a focus on integrating smart factory solutions (AI, IoT) into existing manufacturing plants. The market demands robust, highly durable machinery with advanced control systems, particularly in commercial refrigeration applications where reliability and longevity are critical performance metrics.

- Latin America (LATAM): LATAM is an emerging market characterized by localized manufacturing growth aiming to serve domestic and regional demand. The market sees demand for both semi-automatic and automatic machines, with cost-efficiency often being a primary selection criterion, although regulatory pressure for energy-efficient appliances is slowly pushing technology upgrades.

- Middle East and Africa (MEA): Growth in MEA is highly dependent on infrastructure investment and urbanization projects, particularly in Gulf Cooperation Council (GCC) countries and high-growth African economies. The demand is currently moderate but projected to accelerate as local appliance assembly operations increase their capacity, relying on imported or locally assembled machinery.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Refrigerator Thermoforming Machine Market.- SencorpWhite

- GN Thermoforming Equipment

- Kiefel

- Gabler Thermoform

- Cannon Thermoforming Solutions

- WM Thermoforming Machines

- ILLIG Maschinenbau GmbH

- MULTIVAC

- TFT Thermoforming Technology

- Belvac Production Machinery

- Brown Machine Group

- COMI S.p.A.

- Frimo Group GmbH

- ZMD AG

- Cefla Finishing

- Beijing Shuangyi Extrusion Machinery Co., Ltd.

- Plastisys Machinery

- Formech International Ltd.

- Thermoforming Systems LLC

- Geiss AG

Frequently Asked Questions

Analyze common user questions about the Refrigerator Thermoforming Machine market and generate a concise list of summarized FAQs reflecting key topics and concerns.What materials are primarily formed by refrigerator thermoforming machines?

The machines primarily form High Impact Polystyrene (HIPS) and Acrylonitrile Butadiene Styrene (ABS). Increasingly, advanced models are adapted for recycled PET (rPET) and specialized barrier polymers to meet sustainability standards and insulation requirements.

What is the main advantage of using rotary thermoforming machines over single-station models?

Rotary thermoforming machines offer significantly higher production throughput due to parallel processing capabilities (heating, forming, and cooling occurring simultaneously across multiple stations), drastically reducing the overall cycle time per part for high-volume manufacturing.

How does Industry 4.0 impact the operational efficiency of new thermoforming equipment?

Industry 4.0 integration, through sensors and IoT connectivity, enables real-time data monitoring, remote diagnostics, and predictive maintenance. This drastically reduces unscheduled downtime, optimizes material usage, and ensures consistent quality control through closed-loop process adjustments.

Which geographical region exhibits the highest growth potential for this market?

The Asia Pacific (APAC) region, driven by robust appliance manufacturing expansions in China and India, holds the highest growth potential due to increasing domestic demand for refrigerators and substantial capital investments in high-capacity production lines.

What is the typical lifespan and required maintenance for a high-volume thermoforming machine?

With proper maintenance, a high-volume machine can operate effectively for 15 to 25 years. Required maintenance focuses on tooling integrity, calibration of heating elements, and routine servicing of vacuum pumps and servo-drive systems, often managed through manufacturer-provided service contracts.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager