Robotic Gripping System Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 442109 | Date : Feb, 2026 | Pages : 251 | Region : Global | Publisher : MRU

Robotic Gripping System Market Size

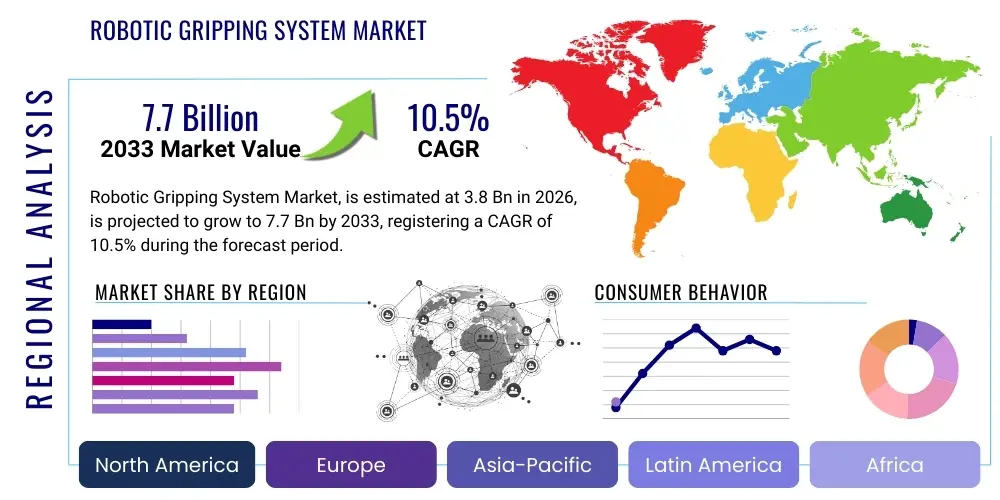

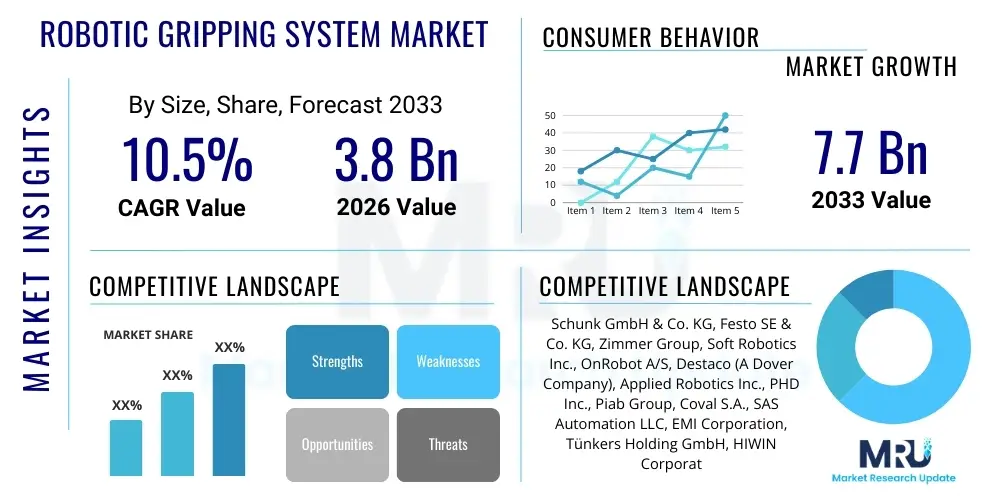

The Robotic Gripping System Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 10.5% between 2026 and 2033. The market is estimated at USD 3.8 Billion in 2026 and is projected to reach USD 7.7 Billion by the end of the forecast period in 2033.

Robotic Gripping System Market introduction

The Robotic Gripping System Market encompasses a diverse range of end-of-arm tooling (EOAT) designed to interact with and manipulate objects in automated manufacturing and logistics environments. These systems are crucial components of industrial and collaborative robots, enabling tasks such as picking, placing, assembly, welding, and inspection. Grippers are highly specialized, ranging from mechanical parallel grippers and angular grippers to advanced vacuum suction cups, magnetic grippers, and sophisticated soft grippers utilizing compliant materials. The fundamental driver for adopting these systems is the imperative for precision, repeatability, and speed in high-volume production lines, replacing manual labor in strenuous, repetitive, or hazardous tasks. Modern robotic gripping solutions integrate advanced sensing technologies, including tactile feedback and vision systems, enhancing adaptability to handle complex geometries and delicate materials without causing damage, thereby justifying significant capital expenditure through improvements in overall equipment effectiveness (OEE).

Product complexity is rapidly increasing, moving beyond simple on/off pneumatic functionality towards electric, servo-driven, and adaptive mechanisms that offer greater control over gripping force and position. Major applications span across the automotive industry for heavy component handling, electronics manufacturing for micro-assembly, pharmaceuticals for sterile handling, and the burgeoning e-commerce sector for dynamic fulfillment and packaging operations. The essential benefits derived from implementing these systems include minimized production cycle times, significantly reduced human error, consistent quality assurance, and improved workplace safety by mitigating human interaction with moving machinery. Furthermore, the modular design prevalent in many newer gripping systems allows for quick changeovers, substantially increasing the flexibility of production lines to accommodate varying product specifications and batch sizes without extensive retooling, which is a major competitive advantage in fast-paced market segments.

Key driving factors accelerating market expansion include the global push towards Industry 4.0 and smart factory integration, where seamless data exchange between grippers, robots, and centralized manufacturing execution systems (MES) is critical for optimization. The decreasing cost and increasing capability of collaborative robots (cobots) have also lowered the entry barrier for small and medium-sized enterprises (SMEs) to automate their processes, demanding versatile and user-friendly gripping solutions. Moreover, stringent quality requirements in highly regulated sectors, coupled with labor shortages in developed economies, mandate automated material handling solutions, favoring complex gripping systems that can handle diverse product mixes reliably. This continuous technological refinement, coupled with sustained investment in automation infrastructure worldwide, solidifies the market's trajectory towards substantial growth over the forecast period.

Robotic Gripping System Market Executive Summary

The Robotic Gripping System Market is characterized by vigorous innovation driven primarily by the shift towards high-mix, low-volume production and the necessity for increased robotic dexterity. Business trends indicate a strong move away from traditional pneumatic grippers towards electric servo grippers, offering higher precision, energy efficiency, and programmability, which directly aligns with sustainable manufacturing goals and reduced operational expenditure. Strategic alliances and mergers among component manufacturers and system integrators are intensifying competition and accelerating technology adoption, particularly in areas concerning standardized interfaces and modular tooling. Furthermore, the rise of specialized gripper types, such as soft robotics and compliant mechanisms derived from biomimicry, signals a fundamental change in how delicate or irregularly shaped objects are handled, broadening the addressable market beyond traditional hard industrial applications into food processing and consumer goods manufacturing.

Geographically, Asia Pacific (APAC) currently dominates the market, propelled by massive industrial automation investments in China, Japan, and South Korea, particularly within the automotive and electronics industries, which require high-speed and high-precision gripping solutions. North America and Europe, however, exhibit the highest growth rates, driven by the increasing adoption of collaborative robots (cobots) in SME manufacturing environments and significant modernization efforts in logistics and warehouse automation. European growth is further bolstered by stringent safety standards and the widespread integration of Industry 4.0 initiatives, necessitating data-rich and highly interconnected gripping tools. While APAC focuses on sheer volume and speed, Western markets prioritize flexibility, adaptability, and integration capability, leading to distinct regional demand profiles for gripping technology.

Segment trends reveal that electric grippers are expected to witness the fastest revenue growth due to their inherent advantages in control and feedback capabilities compared to pneumatic alternatives. In terms of application, the pick-and-place segment remains the largest volume driver, but the assembly and testing segments are generating rapidly increasing demand for advanced, multi-finger grippers with sophisticated tactile sensing. The gripper type segmentation highlights the emerging dominance of adaptive grippers capable of handling unpredictable variations, directly addressing the core requirement for flexibility in modern manufacturing setups. The software and control systems associated with these grippers, including sophisticated path planning and force control algorithms, are increasingly viewed as differentiators, transforming the gripper from a simple mechanical tool into an intelligent peripheral device within the robotic ecosystem.

AI Impact Analysis on Robotic Gripping System Market

Common user questions regarding AI's influence on robotic gripping systems primarily revolve around how machine learning can enhance reliability and adaptability, whether AI will standardize complex handling tasks, and the required data infrastructure necessary to support smart gripping operations. Users frequently inquire about the potential for AI-driven vision systems to accurately detect and grasp randomly presented objects (bin picking) and the role of reinforcement learning in optimizing gripping force in unstructured environments without human intervention. The underlying theme is a strong expectation that AI will solve the longstanding challenges associated with handling high variability, reducing the need for extensive, predefined programming and significantly lowering deployment complexity. Users are also concerned about the cybersecurity implications of highly connected, AI-enabled EOAT and the integration complexity with legacy robotic platforms.

The influence of Artificial Intelligence (AI) is rapidly transforming robotic gripping systems from reactive tools into proactive, decision-making components. AI algorithms, particularly those utilizing deep learning and reinforcement learning, are enabling grippers to perceive, understand, and adapt to their environment in real-time. This capability is pivotal in unstructured environments like logistics sorting facilities or flexible assembly lines where objects are presented randomly, often termed as ‘bin picking’ challenges. AI-driven vision systems coupled with the gripper allow for instantaneous object recognition, pose estimation, and path planning, ensuring a successful grasp on the first attempt, dramatically increasing throughput and minimizing product damage.

Furthermore, AI facilitates predictive maintenance and optimizes operational parameters. By continuously analyzing sensor data streams—including motor torque, temperature, and force feedback—AI models can predict potential mechanical failures in the gripper before they occur, scheduling proactive maintenance and maximizing uptime. This data-centric approach extends to optimizing the actual gripping process itself; reinforcement learning allows the robot to "practice" grasping various objects in a simulation environment and apply the optimal force and trajectory in the real world, achieving superior handling finesse, particularly crucial for delicate components like wafer handling in semiconductor manufacturing or fragile food items. This integration of intelligence shifts the competitive landscape toward suppliers offering comprehensive software ecosystems alongside their physical gripping hardware.

- Enhanced Bin Picking: AI-driven vision processing enables robots to accurately grasp randomly oriented parts from cluttered containers, a critical bottleneck in automation.

- Adaptive Force Control: Machine learning algorithms dynamically adjust gripping force based on real-time tactile feedback and object characteristics, preventing damage to sensitive components.

- Predictive Maintenance: AI analyzes sensor data (e.g., vibration, current draw) to forecast gripper wear and schedule maintenance, maximizing operational uptime.

- Task Optimization: Reinforcement learning optimizes the grasping sequence and trajectory, leading to faster cycle times and increased efficiency in complex assembly tasks.

- Programming Simplification: AI reduces the need for extensive manual programming through generalized object recognition and autonomous grasp planning.

DRO & Impact Forces Of Robotic Gripping System Market

The dynamics of the Robotic Gripping System Market are fundamentally shaped by a confluence of powerful drivers, structural restraints, and emerging opportunities, all subjected to the impact forces of macroeconomic shifts and technological convergence. Key drivers include the overwhelming global demand for automation across diverse industries, exacerbated by consistent labor cost inflation and demographic shifts limiting manual labor availability. The opportunity space is heavily defined by the rapid evolution of soft robotics, which allows robots to handle extremely delicate and non-rigid objects, opening up entirely new application areas previously inaccessible to conventional automation. However, the high initial capital investment required for specialized, high-precision gripping systems, coupled with the inherent complexity in integrating diverse EOAT with various robot brands and legacy systems, acts as a significant restraint, particularly for smaller manufacturing entities hesitant to undertake major technological overhauls.

The primary impact force driving rapid market adoption is the relentless pursuit of manufacturing efficiency and consistency. Manufacturers globally are under pressure to produce goods faster, with zero defects, and at a lower cost, which necessitates the precision and repeatability offered exclusively by advanced robotic grippers. This force is amplified by the competitive environment in sectors like automotive and consumer electronics, where marginal gains in production cycle time translate into substantial economic advantages. Conversely, a major impact force restraining growth is the technical challenge associated with true universal gripping—while adaptive grippers exist, handling a truly infinite variety of shapes and materials with a single tool remains elusive, often requiring time-consuming tooling changes which erode the benefits of flexibility.

Opportunities for disruptive growth are concentrated in the development of intelligent gripping systems that offer plug-and-play functionality and enhanced self-diagnosis capabilities. The convergence of 5G connectivity and edge computing is creating a technological framework where gripping decisions can be made instantaneously based on centralized cloud data or localized intelligence, further optimizing dynamic tasks. Furthermore, the increasing focus on sustainable manufacturing promotes the use of energy-efficient electric grippers over less efficient pneumatic alternatives. Navigating these forces requires companies to focus heavily on standardization initiatives (e.g., VDMA, OPC UA) to simplify integration, thereby transforming a major restraint into a pathway for broader market access and easier adoption by end-users.

Segmentation Analysis

The Robotic Gripping System Market is comprehensively segmented based on several critical dimensions, including product type, operational technology, gripping force capability, and application sector, allowing for a detailed analysis of demand patterns and technological maturity across different industry verticals. This segmentation is essential for understanding the varying needs of end-users, where high-speed electronics assembly demands precise, lightweight electric grippers, while heavy machinery manufacturing requires robust pneumatic or hydraulic solutions capable of exerting immense force. The proliferation of collaborative robotics has also introduced the segmentation of grippers into traditional industrial types and specialized collaborative grippers, which inherently incorporate safety features necessary for human-robot interaction environments, significantly influencing their design and cost structure.

Analyzing the market through the lens of gripper technology reveals the ongoing transition from legacy systems towards advanced, intelligent solutions. While pneumatic grippers maintain a stronghold due to their low initial cost and simplicity, especially in rough environments, the demand momentum is clearly favoring electric, servo-controlled grippers because of their superior control over speed, acceleration, and gripping force profiles, which is crucial for handling variable payloads. Furthermore, the segmentation by end-use application highlights disparate growth trajectories; the fastest growth is observed in the logistics and e-commerce sector, driven by the massive requirement for high-throughput parcel and package handling, demanding adaptable and scalable gripping solutions like vacuum and soft grippers that can handle diverse packaging materials efficiently.

Segmentation by force type—categorized typically into low, medium, and high—allows manufacturers to tailor their product lines to specific industrial requirements, from microliters in medical device manufacturing (low force) to hundreds of kilograms in metal fabrication (high force). This granular detail in market structure ensures that product development aligns directly with verified industrial needs, enabling targeted marketing and channel strategies. The continuous evolution of materials science is further influencing segmentation, particularly through the introduction of advanced materials used in soft grippers, which offer compliance and gentleness unmatched by traditional metallic jaws, carving out niche segments in delicate handling tasks within the food and beverage industry.

- By Type:

- Standard Parallel Grippers

- Angular Grippers

- Collet/Internal Grippers

- Specialty Grippers (Magnetic, Needle, Ultrasonic)

- By Technology:

- Pneumatic Grippers

- Electric Grippers (Servo-Electric, Stepper Motor)

- Hydraulic Grippers

- Vacuum Grippers

- By Gripper Function:

- Two-Finger Grippers

- Three-Finger Grippers

- Adaptive/Multi-Finger Grippers

- Soft Grippers

- By Application:

- Pick and Place

- Assembly

- Welding

- Machine Tending

- Palletizing and Packaging

- Quality Inspection and Testing

- By End-Use Industry:

- Automotive

- Electronics and Semiconductor

- Logistics and Warehouse Automation

- Food and Beverage

- Pharmaceuticals and Healthcare

- Metal and Machinery

Value Chain Analysis For Robotic Gripping System Market

The value chain for the Robotic Gripping System Market begins with the upstream suppliers responsible for providing highly specialized raw materials and critical electronic and mechanical components. This upstream segment is characterized by providers of precision machined metal parts (aluminum, stainless steel), advanced sensors (force-torque sensors, tactile feedback systems), and complex actuation mechanisms (servo motors, stepper motors, pneumatic cylinders). The quality and reliability of these components are paramount, as the entire performance envelope of the final gripper system is dependent upon their precision. Strong relationships with reliable component suppliers, especially those providing advanced microprocessors and industrial-grade electronics for control boards, are crucial for maintaining manufacturing throughput and ensuring product longevity in demanding industrial environments. Pricing fluctuations and supply chain resilience in electronic components, such as microcontrollers and specialized silicon chips, significantly influence the cost and production agility of the core gripper manufacturers.

The central manufacturing phase involves core gripper manufacturers (OEMs) who design, assemble, and integrate these components into functional robotic end-of-arm tooling. This stage adds substantial value through proprietary design, software development for control algorithms, and rigorous testing protocols to ensure compatibility with various industrial robots (e.g., compatibility with KUKA, FANUC, ABB protocols). Following manufacturing, the distribution channel plays a vital role. Direct distribution is often favored for large-scale, complex projects involving strategic partnerships with major automotive or aerospace clients, allowing for customized support and direct technical consultancy. Indirect channels, primarily through authorized distributors, specialized system integrators, and value-added resellers (VARs), are crucial for reaching the fragmented SME market, providing localized sales support, installation services, and post-sale maintenance, bridging the technical expertise gap often found in smaller enterprises.

The downstream segment encompasses the system integrators and the ultimate end-users. System integrators are arguably the most critical players downstream, taking the manufactured gripper, integrating it with a specific robotic arm and vision system, and programming the entire cell to perform the required application task efficiently. Their expertise in customizing standard products for unique handling challenges adds immense value. End-users, the final destination, realize the value through improved productivity, consistent quality, and reduced operational costs. The feedback loop from end-users regarding performance, durability, and ease of use is essential for driving future product innovation back up the value chain. As automation intensity increases, the demand for highly modular, easily deployable systems minimizes integration costs, placing pressure on manufacturers to standardize mechanical and electrical interfaces.

Robotic Gripping System Market Potential Customers

Potential customers for robotic gripping systems span a broad spectrum of industrial and commercial entities that require automated handling, assembly, or manipulation of products. The primary demographic of end-users consists of large-scale manufacturers in the automotive sector, which utilizes robust, high-force grippers for engine block handling, body-in-white assembly, and precision welding tasks within high-volume production lines. Similarly, electronics and semiconductor fabricators represent a crucial customer base, demanding ultra-precise, contamination-free, electric grippers and vacuum tools for handling delicate wafers, micro-components, and printed circuit boards, where repeatability and positional accuracy are measured in microns. These customers prioritize compliance, ESD protection, and sophisticated sensing capabilities to avoid catastrophic component damage during handling.

Another rapidly expanding segment of potential customers includes logistics, e-commerce fulfillment centers, and large warehouses. These operations face massive variability in object size, weight, and packaging material, driving demand for flexible, adaptive grippers, notably high-speed vacuum suction systems and soft robotic grippers designed for random singulation and depalletizing. The imperative here is scalability and throughput; customers seek systems that can operate continuously, seven days a week, and handle the unpredictable mix of parcels generated by consumer demand. The Food and Beverage industry also constitutes a significant target market, focusing on customers requiring sanitary, wash-down compliant materials and gentle handling capabilities, suchor soft grippers, to manipulate delicate items like fresh produce or packaged foods without bruising or contamination, complying with strict hygiene regulations.

Small and Medium-sized Enterprises (SMEs) are increasingly becoming potential customers, particularly those adopting collaborative robots (cobots). This shift is driven by the availability of affordable, safe, and easy-to-program collaborative grippers that lower the barrier to automation. While SMEs often require simpler, multi-purpose gripping tools, their cumulative demand for versatile, quick-change systems is substantial. Furthermore, the healthcare sector, encompassing pharmaceutical manufacturing, medical device assembly, and laboratory automation (e.g., high-throughput screening), relies on specialized robotic grippers to ensure sterile, high-precision movement of vials, syringes, and diagnostic samples, representing a niche but high-value customer segment focused heavily on regulatory compliance and reliability.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 3.8 Billion |

| Market Forecast in 2033 | USD 7.7 Billion |

| Growth Rate | 10.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Schunk GmbH & Co. KG, Festo SE & Co. KG, Zimmer Group, Soft Robotics Inc., OnRobot A/S, Destaco (A Dover Company), Applied Robotics Inc., PHD Inc., Piab Group, Coval S.A., SAS Automation LLC, EMI Corporation, Tünkers Holding GmbH, HIWIN Corporation, SMC Corporation, ATI Industrial Automation, Robotiq, ABB Ltd., FANUC Corporation, KUKA AG |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Robotic Gripping System Market Key Technology Landscape

The technology landscape of the Robotic Gripping System Market is undergoing a fundamental transformation, shifting focus from rigid, dedicated tooling to highly flexible, sensor-rich, and intelligent systems. A central innovation driving this change is the rapid advancement in Soft Robotics. Soft grippers utilize compliant materials, often silicone or rubber, driven by air pressure or hydraulic fluid, mimicking biological structures. This technology enables the safe and gentle handling of irregularly shaped, fragile, or deformable objects (such as fresh produce or complex medical devices) that traditional hard grippers would crush or fail to secure. The inherent compliance of soft grippers eliminates the need for extremely precise positioning and programming, significantly reducing deployment time and enhancing the versatility of robotic cells in previously unautomated industries like food handling and cosmetics packaging, where product variation is high.

Another defining technological trend is the pervasive integration of advanced sensory feedback mechanisms and machine vision systems. Modern electric grippers often incorporate force-torque sensors directly into the jaws, providing instantaneous haptic feedback to the robot controller, allowing for closed-loop control over gripping force. This tactile sensing capability is crucial for assembly tasks requiring specific insertion forces or for quality inspection where texture or surface integrity must be monitored. Simultaneously, 3D vision systems utilizing structured light or laser scanners are becoming standard for bin-picking applications. These systems feed real-time positional data into AI algorithms, enabling the robot to identify the optimal grasp point on randomly oriented objects, dramatically improving the success rate and efficiency of tasks that were once considered prohibitively complex for automation.

Furthermore, the move towards modularity and interoperability is simplifying system deployment and maintenance. Leading manufacturers are adopting standardized communication protocols, such as IO-Link and Ethernet/IP, ensuring seamless data exchange between the gripper, the robot, and the programmable logic controller (PLC). This focus on "smart tool" integration allows for rapid tool change systems (ATC) that enable a single robot to use multiple types of grippers depending on the task, maximizing machine utilization. The development of collaborative grippers, which are explicitly designed with rounded edges, inherent force limits, and safety-rated controls, is crucial for the proliferation of human-robot collaborative environments, ensuring that the technology is safe and accessible for interaction alongside human operators without requiring extensive safety guarding.

- Soft Robotics: Utilization of compliant materials (silicone, polymer) for handling fragile, delicate, and non-rigid items with minimized damage risk.

- Advanced Sensing: Integration of high-resolution force-torque sensors, tactile sensors, and proximity sensors for real-time closed-loop control and adaptive grasping.

- Vision Systems: Deployment of 2D/3D vision and AI for object recognition, pose estimation, and complex bin picking applications in unstructured environments.

- Electric Servo Drives: Precision control over position, speed, and force profiles, offering superior energy efficiency and programmability compared to traditional pneumatic systems.

- Modular End-of-Arm Tooling (EOAT): Standardization of interfaces and quick-change mechanisms (Automatic Tool Changers) to enhance flexibility and reduce changeover times in high-mix production.

- Fieldbus Connectivity: Implementation of industrial communication standards (e.g., IO-Link, Profinet) to facilitate seamless data integration and remote diagnostics within Industry 4.0 frameworks.

Regional Highlights

Asia Pacific (APAC) Market Overview: APAC currently commands the largest share of the global robotic gripping system market, driven by its unparalleled manufacturing capacity, particularly in China, South Korea, and Japan. The region’s dominance stems from extensive capital expenditure in automating sectors like automotive assembly, high-volume consumer electronics production, and increasing investments in localized logistics infrastructure spurred by burgeoning e-commerce. China, in particular, is witnessing rapid deployment of industrial robotics, fueled by supportive government policies aimed at upgrading manufacturing capabilities (e.g., 'Made in China 2025') and addressing rising domestic labor costs. Demand here is characterized by a strong appetite for high-speed, durable pneumatic and electric grippers used in continuous, large-scale production runs. Local manufacturers are intensely competitive, offering cost-effective solutions that sometimes lack the advanced sensing features of Western counterparts but excel in sheer throughput and robustness, creating a competitive environment focused on price-performance ratios and rapid scalability across multiple factory sites.

North America Market Overview: North America represents a market characterized by high-value applications and rapid adoption of cutting-edge technology, particularly collaborative robotics and AI-driven systems. The primary growth drivers include significant investments in warehouse and supply chain automation, driven by Amazon and other large retailers seeking to optimize fulfillment processes and enhance last-mile delivery efficiency. Additionally, the region is modernizing its traditional manufacturing base, emphasizing advanced assembly, metal fabrication, and reshoring initiatives requiring flexible, precision gripping. Demand leans heavily towards sophisticated electric grippers and advanced multi-finger systems capable of complex tasks and high-variability handling, supporting the high-mix, low-volume production characteristic of the defense, aerospace, and advanced medical device manufacturing sectors. High labor costs justify substantial initial technology investments, making ROI calculations favorable for advanced, high-efficiency gripping solutions.

Europe Market Overview: Europe maintains a strong position, distinguished by its focus on regulatory compliance, quality precision, and comprehensive integration into the Industry 4.0 framework. Countries like Germany, Italy, and Scandinavia are pioneers in adopting smart factory concepts, requiring grippers that are not only highly accurate but also fully network-integrated, providing extensive diagnostic and performance data. The European market shows a strong preference for high-end, servo-electric grippers and specialized adaptive tools, particularly in the automotive, machinery, and precision engineering sectors. Environmental and safety regulations, including collaborative robot standards, drive demand for intrinsically safe and energy-efficient gripping technologies. Furthermore, the region is a global leader in the development and initial deployment of soft robotic gripping solutions, especially within the sensitive food and pharmaceutical processing industries, driven by strict hygiene standards and the need for non-destructive handling of delicate products.

- Asia Pacific (APAC): Highest volume market; driven by electronics and automotive manufacturing; focuses on mass production speed and affordability; massive governmental support for automation.

- North America: High growth in logistics and collaborative robotics (cobots); strong demand for AI-integrated bin picking systems and high-precision aerospace/medical grippers.

- Europe: Emphasis on Industry 4.0 integration and network connectivity; strong preference for electric, energy-efficient grippers; leading adoption of soft robotics in food processing.

- Latin America (LATAM): Emerging market growth; localized automation efforts primarily in automotive and food sectors; cost sensitivity dictates higher adoption of pneumatic systems initially.

- Middle East & Africa (MEA): Growth tied to diversification efforts (oil and gas, defense, logistics hubs); initial stages of large-scale automation projects; significant reliance on imported technology and specialized systems.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Robotic Gripping System Market.- Schunk GmbH & Co. KG

- Festo SE & Co. KG

- Zimmer Group

- Soft Robotics Inc.

- OnRobot A/S

- Destaco (A Dover Company)

- Applied Robotics Inc.

- PHD Inc.

- Piab Group

- Coval S.A.

- SAS Automation LLC

- EMI Corporation

- Tünkers Holding GmbH

- HIWIN Corporation

- SMC Corporation

- ATI Industrial Automation

- Robotiq

- ABB Ltd.

- FANUC Corporation

- KUKA AG

- igus GmbH

- Gimatic S.r.l.

- Bastian Solutions (A Toyota Company)

- Universal Robots A/S (EOAT partners)

Frequently Asked Questions

Analyze common user questions about the Robotic Gripping System market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary difference between pneumatic and electric robotic grippers?

Pneumatic grippers operate using compressed air, offering high gripping force for their size and fast actuation speeds, often at a lower initial cost. Electric grippers use servo or stepper motors, providing precise control over force, position, and acceleration, along with integrated data feedback, making them superior for tasks requiring high repeatability and flexibility, albeit at a higher capital investment.

How is Industry 4.0 influencing the design of modern robotic gripping systems?

Industry 4.0 necessitates that grippers are 'smart' peripherals capable of data exchange. This is achieved through integrated sensors, standardized communication protocols (like IO-Link), and embedded processing power, allowing the gripper to perform self-diagnostics, communicate performance metrics, and execute adaptive grasping decisions autonomously within the smart factory ecosystem.

What are soft grippers and in which applications are they most effective?

Soft grippers are end-of-arm tools constructed from compliant materials, designed to conform to the shape of an object upon contact. They are highly effective in handling delicate, easily deformable, or irregularly shaped items, such as in the food and beverage industry (e.g., picking fresh produce), complex packaging, and sterile medical device manufacturing, minimizing the risk of damage.

Which end-use industry is expected to drive the fastest growth in the robotic gripping system market?

The Logistics and Warehouse Automation sector is projected to drive the fastest growth. The massive demand from e-commerce fulfillment centers for flexible, high-speed material handling, coupled with the necessity to automate complex bin-picking and sortation tasks involving varied product sizes, significantly boosts the adoption of adaptive vacuum and multi-finger gripping solutions globally.

What role does Artificial Intelligence play in enhancing robotic gripper performance?

AI, leveraging machine vision and deep learning, enables grippers to analyze unstructured environments and determine the optimal grasp strategy and force profile in real-time, greatly improving performance in tasks like bin picking and assembly of highly variable parts. AI also powers predictive maintenance by analyzing sensor data to preemptively schedule service, maximizing uptime.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager