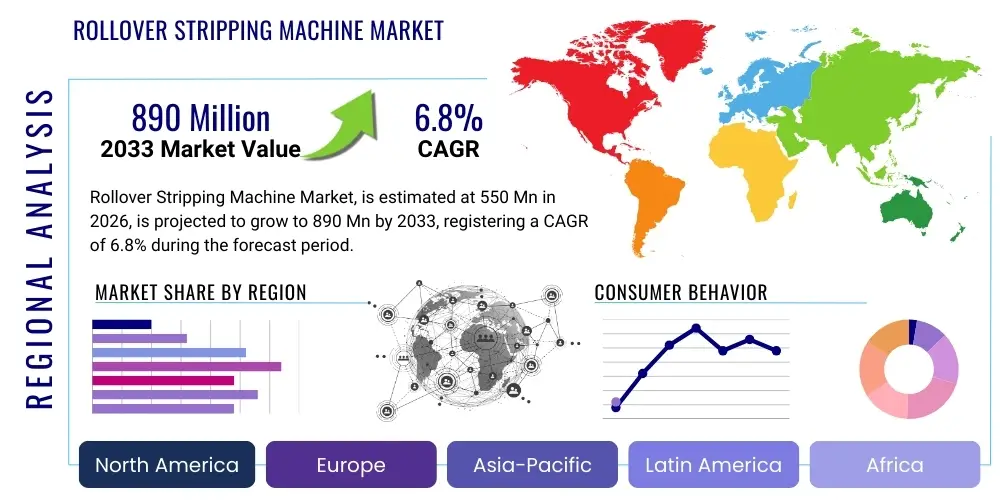

Rollover Stripping Machine Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 441906 | Date : Feb, 2026 | Pages : 242 | Region : Global | Publisher : MRU

Rollover Stripping Machine Market Size

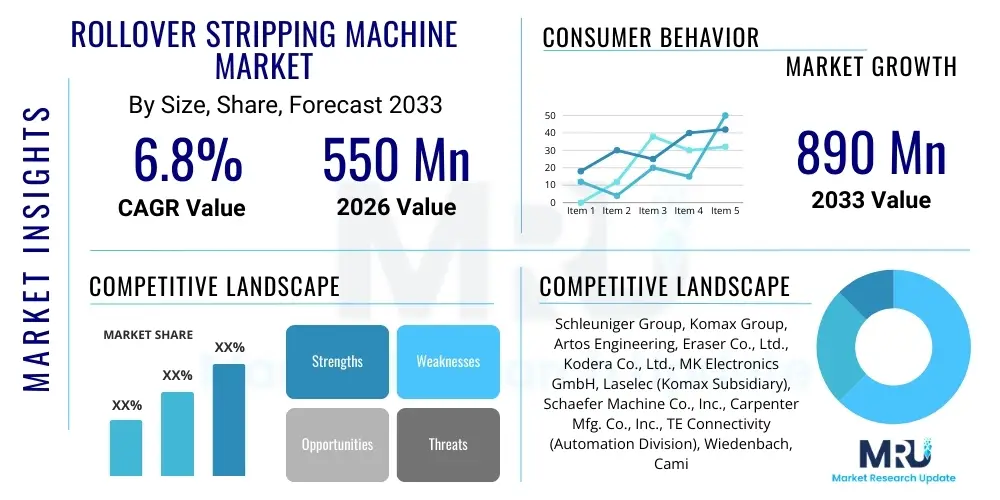

The Rollover Stripping Machine Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 550 Million in 2026 and is projected to reach USD 890 Million by the end of the forecast period in 2033. This substantial expansion is fundamentally driven by the escalating demand for complex wire harnesses, particularly within the automotive, aerospace, and advanced medical device manufacturing sectors. Rollover stripping machines, characterized by their precision and ability to process various wire types and sizes—often involving demanding insulation materials—are becoming indispensable components in high-volume, automated production lines globally, replacing less efficient, traditional manual or semi-automated processes.

The forecasted growth trajectory is strongly supported by global industrial automation trends and the necessity for superior quality control in connectivity solutions. As electric vehicles (EVs) and sophisticated electronic systems become standard, the requirement for flawlessly stripped and terminated wires intensifies, directly benefiting the market for high-precision rollover stripping technology. Furthermore, manufacturers are increasingly investing in next-generation machinery that offers enhanced flexibility, faster cycle times, and reduced material waste, thereby improving overall operational efficiency and justifying the initial capital expenditure associated with these advanced systems.

Rollover Stripping Machine Market introduction

The Rollover Stripping Machine Market encompasses automated and semi-automated equipment designed for the high-precision removal of insulation from electrical wires and cables. This machinery is critical for preparing wires for subsequent processing steps, such as crimping, tinning, or welding, ensuring reliable electrical connections. Rollover stripping mechanisms utilize specialized rotating blades or dies that precisely cut and remove the insulation jacket without damaging the internal conductors, distinguishing them from simpler radial cutting mechanisms through their ability to handle complex, multi-layered, or difficult-to-strip insulations like Teflon, PTFE, and high-temperature polymers. These machines are engineered to provide exceptional repeatability and accuracy across a vast range of wire gauges, from fine medical wires to heavy-duty automotive cables.

Major applications for rollover stripping technology span highly regulated and demanding industries, including the production of automotive wire harnesses, especially for advanced driver-assistance systems (ADAS) and EV battery management systems; consumer electronics manufacturing requiring miniaturized connections; and the aerospace and defense sectors where failure tolerance is near zero. The fundamental benefits driving the adoption of these machines include vastly increased throughput compared to manual methods, superior quality assurance ensuring minimal conductor damage, reduced labor costs, and the flexibility to rapidly switch between different product specifications, supporting highly customized manufacturing environments. Key driving factors accelerating market expansion include the exponential growth in global vehicle electrification, the relentless demand for higher data transmission speeds requiring precise cable preparation, and increasing regulatory pressure for manufacturing traceability and quality control in critical applications.

Rollover Stripping Machine Market Executive Summary

The Rollover Stripping Machine Market is defined by intense competition centered on technological innovation, specifically in integrating advanced sensor technology and sophisticated control software to achieve unparalleled precision and adaptability. Current business trends indicate a significant shift toward modular machine design, allowing end-users to integrate stripping functions seamlessly with upstream wire preparation and downstream termination processes within comprehensive automated production lines. Regional trends emphasize Asia Pacific's dominance, driven by massive investments in automotive manufacturing hubs, particularly in China and India, alongside the established high-tech manufacturing sectors in Japan and South Korea. Conversely, North America and Europe prioritize sophisticated, highly automated systems capable of processing specialized, high-performance materials necessary for niche markets such as aerospace and electric vehicle infrastructure, focusing on efficiency and Industry 4.0 compliance rather than sheer volume.

Segmentation trends reveal strong growth in the fully automated segment, capitalizing on the industry-wide push for lights-out manufacturing and maximum operational throughput, especially in large-scale harness assembly operations. Furthermore, the application segment highlights the Automotive Industry as the primary revenue generator, owing to the complexity and volume requirements associated with modern vehicle wiring systems, including high-voltage cables and sensor wiring. The ongoing development of specialized stripping heads capable of handling new eco-friendly or high-temperature insulation materials is also driving market growth, dictating investment priorities for leading manufacturers. These strategic moves underline the market's trajectory towards digitalization and enhanced material processing capability, ensuring future relevance in high-tech manufacturing environments.

The primary strategic objectives for market participants involve geographical expansion into emerging economies coupled with rigorous R&D investment focused on minimizing setup times and improving diagnostic capabilities using embedded intelligence. The competitive landscape is characterized by a balance of established global leaders offering comprehensive wire processing solutions and specialized regional players focusing solely on high-precision stripping for specific industries like medical devices or telecommunications. The successful integration of these machines into existing Manufacturing Execution Systems (MES) is becoming a critical competitive differentiator, allowing manufacturers to leverage real-time data for preventative maintenance and production scheduling optimization.

AI Impact Analysis on Rollover Stripping Machine Market

Common user questions regarding the impact of Artificial Intelligence (AI) on the Rollover Stripping Machine Market generally revolve around four key themes: predictive maintenance accuracy, optimization of stripping parameters for novel materials, enhancing quality control capabilities (zero-defect manufacturing), and integration with broader smart factory ecosystems. Users are keenly interested in how AI algorithms can predict imminent component failure, such as blade wear or motor degradation, drastically reducing unplanned downtime. There is also significant anticipation regarding AI's ability to analyze material properties—like insulation thickness variability or temperature sensitivity—in real-time and automatically adjust stripping forces and speeds, thereby optimizing yield and material utilization. Key concerns often center on data privacy, the cost of retrofitting existing machinery, and the necessary skill set transformation required for operators to manage AI-driven systems effectively, indicating a high expectation for operational autonomy and efficiency gains derived from intelligent processing.

The integration of AI into rollover stripping machinery is fundamentally transforming operations from reactive maintenance models to proactive, data-driven management. AI systems leverage deep learning to analyze continuous streams of operational data, including current consumption, vibration patterns, and cycle time deviations, establishing a baseline of normal operation. Any divergence from this baseline triggers early warnings, allowing maintenance teams to intervene before catastrophic failure occurs. This capability is paramount in high-volume production environments where even marginal downtime translates into significant financial losses, solidifying AI's role as a critical enabler of uninterrupted, high-throughput manufacturing.

- AI-driven Predictive Maintenance (PdM) minimizes machine downtime by anticipating component failures, especially blade wear and mechanical stress points.

- Real-time Parameter Optimization utilizes machine learning to adjust stripping depth, speed, and force based on material feedback, maximizing precision across diverse cable specifications.

- Enhanced Quality Inspection through Computer Vision AI detects microscopic defects in the stripped insulation or conductor surface, ensuring zero-defect output.

- Process Self-Optimization algorithms continuously refine batch processing settings, adapting quickly to changes in wire batch quality or environmental conditions.

- Integration with MES/ERP systems facilitates autonomous production scheduling and resource allocation, positioning the machine within the broader Industry 4.0 infrastructure.

DRO & Impact Forces Of Rollover Stripping Machine Market

The Rollover Stripping Machine Market is propelled by significant global drivers, primarily the rapid proliferation of electronic content in the automotive sector, driven by ADAS adoption and the transition to electric powertrains, which necessitates extremely high-quality and repeatable wire preparation for complex, high-voltage harnesses. Concurrently, the increasing automation levels in manufacturing worldwide dictate the necessity for fully integrated stripping solutions that can operate seamlessly within high-speed assembly lines, replacing slower, less consistent manual processes. However, the market faces significant restraints, notably the substantial initial capital investment required for high-precision, fully automated rollover systems, which can be prohibitive for smaller and medium-sized enterprises (SMEs). Furthermore, the scarcity of skilled technicians capable of operating, programming, and maintaining these highly complex, technologically advanced machines presents a continuous operational bottleneck across various manufacturing regions, particularly in developing economies.

Opportunities for market expansion are abundant, particularly in developing specialized stripping solutions for emerging material science applications, such as high-temperature superconductors or extremely thin, high-density coaxial cables used in 5G infrastructure and advanced medical imaging equipment. Furthermore, developing nations represent untapped potential, as they rapidly modernize their manufacturing infrastructure and seek to adopt standardized, high-quality production methods essential for global supply chain participation. Innovation focusing on modularity, ease of programming through intuitive human-machine interfaces (HMIs), and simplified maintenance procedures are key to unlocking these opportunities and mitigating existing restraints related to cost and skill requirements. The successful hybridization of stripping techniques, blending mechanical precision with laser ablation for handling delicate insulation types, also represents a promising technological pathway for future market entrants.

The key impact forces shaping the market involve intense quality demands imposed by end-user industries (especially automotive safety standards), requiring continuous improvement in stripping accuracy (Impact Force 1). Technological advancements in blade materials and sensor feedback systems drive continuous machine performance enhancement, reducing conductor damage risk to near zero (Impact Force 2). Economic factors, such as volatile raw material costs and global supply chain disruptions, influence the cost of both the machinery and the materials being processed, creating pressure for increased efficiency and reduced waste (Impact Force 3). Lastly, regulatory compliance, particularly related to product traceability and environmental standards, compels manufacturers to adopt machines that offer robust data logging and minimal environmental footprint (Impact Force 4).

Segmentation Analysis

The Rollover Stripping Machine Market is comprehensively segmented based on its technological complexity, automation level, processing capacity, and core end-use application. Analyzing these segments provides critical insights into purchasing patterns, technological adoption rates, and regional demand dynamics. The segmentation by automation level—Full-Automatic, Semi-Automatic, and Manual—is perhaps the most revealing, showing a distinct market preference shift toward fully automated systems capable of integrating advanced features like automatic wire length measurement, sequential stripping, and connection to upstream dereeling and prefeeding systems. This shift is directly correlated with global manufacturing trends that prioritize high-volume, continuous production with minimal human intervention, thereby boosting labor efficiency and overall output reliability.

Further segmentation by stripping capacity, typically categorized by wire gauge (AWG) compatibility, delineates between micro-precision machines utilized for very fine wires (e.g., medical and microelectronics) and heavy-duty machines designed for large gauge cables (e.g., power distribution and high-voltage EV applications). The application segmentation remains fundamental, highlighting the significant dependence of the market on the robust and accelerating demand from the automotive industry, followed by electronics and telecommunications. This structured analysis allows market participants to tailor their product development strategies and marketing efforts toward the highest-growth and highest-margin sub-segments, ensuring focused resource allocation and competitive advantage in specialized areas like ribbon cable processing or highly abrasive insulation handling.

- By Automation Level:

- Full-Automatic Rollover Stripping Machines

- Semi-Automatic Rollover Stripping Machines

- Manual/Benchtop Stripping Devices (Specialty Tools)

- By Wire Type and Capacity:

- Fine Wire (AWG 30 and smaller)

- Medium Wire (AWG 10 to AWG 29)

- Heavy Gauge Cable (AWG 9 and larger)

- Coaxial and Triaxial Cable Specialized Systems

- By End-Use Application:

- Automotive (EV, ADAS, Standard Harnesses)

- Electronics and Consumer Devices

- Aerospace and Defense

- Telecommunications and Data Centers

- Industrial Equipment and Machinery

- Medical Devices and Diagnostics

- By Technology:

- Mechanical Blade Stripping

- Thermal Stripping (Combined Systems)

- Laser Stripping (High-Precision/Non-Contact)

Value Chain Analysis For Rollover Stripping Machine Market

The value chain for the Rollover Stripping Machine Market commences with upstream activities involving raw material procurement, specialized component manufacturing, and software development. Upstream suppliers are critical, providing high-grade steels for precision blades, advanced servo motors for repeatable movements, sensor technology (optical and proximity), and integrated circuit boards for control systems. The performance and reliability of the end machine are heavily dependent on the quality and longevity of these procured mechanical and electronic components; thus, strong partnerships with specialized component manufacturers are vital for machine builders. Innovation in this segment focuses on developing wear-resistant tooling materials and faster, more accurate motion control systems, directly influencing the machine's throughput and lifetime cost of ownership.

The midstream stage involves the machine manufacturers themselves, who focus on design, assembly, integration of complex mechanisms, software programming, calibration, and rigorous quality testing. This stage adds significant value through intellectual property related to precision engineering, unique rollover mechanism designs, and proprietary control algorithms that ensure non-destructive stripping. Distribution channels are bifurcated into direct and indirect routes. Direct sales are common for large, complex, and customized full-automatic systems, typically involving direct negotiation and technical support contracts between the machine builder and large Tier 1 automotive suppliers or major harness makers. Indirect distribution involves leveraging specialized industrial equipment distributors, system integrators, and regional sales agents, particularly for standard semi-automatic or benchtop models, allowing for wider geographic reach and localized technical service support.

Downstream activities center on the end-users—the wire harness producers, electronics assembly plants, and contract manufacturers—who integrate the stripping machines into their production lines. After-sales support, including installation, technical training, spare parts supply (especially consumable stripping blades), and software updates, constitutes a significant portion of the downstream value. The efficiency of the machine in the end-user’s facility dictates its perceived value; therefore, machine uptime and precision are paramount. The flow of value is optimized when machine builders provide robust remote diagnostics and support, minimizing downtime and maximizing the return on investment for the customer, solidifying a continuous loop of service and supply.

Rollover Stripping Machine Market Potential Customers

The primary end-users and buyers of rollover stripping machines are entities involved in the high-precision processing of electrical conductors for connectivity applications where reliability and quality are non-negotiable prerequisites. The Automotive Industry remains the dominant customer base, encompassing original equipment manufacturers (OEMs) and, more significantly, Tier 1 and Tier 2 automotive harness suppliers (e.g., Yazaki, Aptiv, Sumitomo Electric), which require continuous, high-speed processing of vast volumes of intricate wire harnesses for vehicle platforms ranging from internal combustion engines (ICE) to hybrid and battery electric vehicles (BEVs). The demand from this sector is driven by the increasing complexity of vehicle electronics, the need for high-voltage cable processing, and stringent safety standards requiring perfect termination preparation.

A secondary, high-growth segment includes manufacturers within the electronics and telecommunications sectors. This involves companies producing intricate consumer electronics, complex server and data center cabling, and components for advanced networking infrastructure (5G deployment). These customers prioritize micro-precision stripping capabilities, as they often deal with extremely fine gauge wires and highly sensitive insulation materials. The third key customer group comprises aerospace and defense contractors, who demand machines capable of processing high-performance, often radiation-resistant or high-temperature wiring used in aircraft, military vehicles, and satellites, where machine reliability and verifiable quality documentation are critical purchasing criteria. Finally, medical device manufacturers, producing specialized cables for imaging equipment, surgical robotics, and implantable devices, form a niche but highly lucrative segment requiring machines with validation capabilities and the highest degree of processing finesse.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 550 Million |

| Market Forecast in 2033 | USD 890 Million |

| Growth Rate | CAGR 6.8% |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Schleuniger Group, Komax Group, Artos Engineering, Eraser Co., Ltd., Kodera Co., Ltd., MK Electronics GmbH, Laselec (Komax Subsidiary), Schaefer Machine Co., Inc., Carpenter Mfg. Co., Inc., TE Connectivity (Automation Division), Wiedenbach, Cami Assembly, Kingsing Machinery, Ramatech Systems AG, Ideal Industries, Inc., Kokusai Inc., Metzner, Ruesch Machine Tool Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Rollover Stripping Machine Market Key Technology Landscape

The technological landscape of the Rollover Stripping Machine Market is rapidly evolving, moving beyond simple mechanical blade systems toward highly integrated, intelligent processing platforms. A core technological advancement involves the refinement of blade geometry and materials, utilizing specialized coatings (e.g., Titanium Nitride or diamond-like carbon) to enhance durability when processing tough, abrasive insulation materials common in aerospace and EV cabling. Furthermore, the integration of non-contact technologies, such as CO2 or Nd:YAG laser stripping systems, is gaining traction. These laser-based systems are essential for ultra-fine wires or heat-sensitive insulation where mechanical contact poses a high risk of conductor nicking or insulation deformation, offering unparalleled precision and repeatability, though at a higher initial equipment cost.

Advanced sensor technology and closed-loop feedback systems represent another crucial technological pillar. Modern rollover strippers incorporate high-resolution optical cameras and micrometers to measure the stripped length and conductor diameter post-process in real-time. This data is fed back to the machine’s CNC controls, allowing for instantaneous micro-adjustments of the cutting depth and clamping force. This closed-loop system ensures that variances in raw wire material (e.g., inconsistent insulation thickness) are automatically compensated for, ensuring output quality consistency compliant with zero-defect mandates. This level of process control minimizes waste and significantly reduces the reliance on manual quality checks, optimizing the overall efficiency of the wire processing workflow in high-stakes applications.

Finally, the proliferation of Industry 4.0 principles is driving the integration of sophisticated connectivity features, primarily through OPC UA (Open Platform Communications Unified Architecture) and secure Ethernet connections. This enables the rollover strippers to communicate seamlessly with centralized Manufacturing Execution Systems (MES) for detailed production monitoring, remote diagnostics, and automated recipe downloads based on job order specifications. This interconnectedness allows for predictive maintenance algorithms, remote troubleshooting by the manufacturer, and deep data logging necessary for compliance and quality traceability. The adoption of modular tooling systems that allow for quick, tool-less changeovers further enhances operational flexibility and reduces changeover downtime, a critical metric for production environments handling a diverse mix of wire types and product variants.

Regional Highlights

- Asia Pacific (APAC): APAC is projected to dominate the global market, accounting for the largest share in both value and volume terms. This dominance is primarily fueled by the region’s status as the global manufacturing powerhouse for automotive components, consumer electronics, and general industrial machinery. Countries like China, South Korea, and Japan are massive consumers of rollover stripping technology due to their high production output volumes. Furthermore, the burgeoning electric vehicle manufacturing sector across East and Southeast Asia is creating an immense, sustained demand for advanced machinery capable of high-precision processing of high-voltage wiring harnesses. Government initiatives supporting infrastructure modernization and industrial automation, particularly in India and Southeast Asia, further solidify APAC's leading position.

- North America: The North American market is characterized by a strong emphasis on technological sophistication and advanced automation rather than sheer volume. Demand is concentrated in high-value sectors such as aerospace, defense, medical devices, and specialized high-performance automotive platforms. Customers in this region prioritize fully automated systems that integrate seamlessly with MES and robotics, focusing heavily on quality compliance (e.g., AS9100) and lifecycle cost. The rapid expansion of electric vehicle manufacturing capacity in the US and Canada necessitates continuous investment in high-precision, high-throughput stripping solutions for battery management systems and power distribution units, driving steady market growth.

- Europe: Europe represents a mature but highly innovation-driven market, led by Germany, Switzerland, and Italy—countries renowned for precision engineering and advanced machinery manufacturing. The European market exhibits high demand for specialized stripping technologies, particularly systems integrating laser and mechanical methods, to handle complex and exotic insulation materials required by the high-end automotive, telecommunications, and industrial automation sectors. Strict regulatory frameworks regarding quality control and environmental performance also influence purchasing decisions, favoring machines that offer comprehensive data traceability and energy efficiency.

- Latin America (LATAM): LATAM remains an emerging market, showing moderate growth primarily driven by the expansion of local automotive manufacturing and increased foreign direct investment in electronics assembly plants, particularly in Mexico and Brazil. The region generally favors cost-effective, durable semi-automatic stripping solutions, though the demand for fully automated systems is gradually increasing as manufacturers seek to compete on a global quality level. Market expansion is dependent on sustained economic stability and continued industrial modernization efforts.

- Middle East and Africa (MEA): The MEA market is the smallest but exhibits growth potential linked to large-scale infrastructure projects, including investments in power generation, transmission networks, and specialized defense industries. Demand is largely project-specific, requiring robust and reliable machinery. Stripping equipment adoption is centered in rapidly industrializing economies like the UAE and Saudi Arabia, with key opportunities arising from new construction and diversification away from hydrocarbon-dependent industries.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Rollover Stripping Machine Market, encompassing global leaders recognized for comprehensive portfolios and specialized innovators focused on niche applications.- Schleuniger Group

- Komax Group

- Artos Engineering

- Eraser Co., Ltd.

- Kodera Co., Ltd.

- MK Electronics GmbH

- Laselec (Komax Subsidiary)

- Schaefer Machine Co., Inc.

- Carpenter Mfg. Co., Inc.

- TE Connectivity (Automation Division)

- Wiedenbach

- Cami Assembly

- Kingsing Machinery

- Ramatech Systems AG

- Ideal Industries, Inc.

- Kokusai Inc.

- Metzner

- Ruesch Machine Tool Inc.

- StripMeister

- WireProcess GmbH

Frequently Asked Questions

Analyze common user questions about the Rollover Stripping Machine market and generate a concise list of summarized FAQs reflecting key topics and concerns.What distinguishes a rollover stripping machine from standard stripping equipment?

A rollover stripping machine employs a specialized rotary blade mechanism that cuts the insulation circumference and then pulls it off axially (rolling it over) in a single, controlled motion. This technique minimizes the risk of conductor nicking, making it essential for high-precision applications involving complex, multi-layered, or high-temperature insulations (e.g., PTFE, Teflon) where standard radial cutters might fail or damage the wire core.

Which key industries are driving the current demand for high-precision rollover stripping technology?

The primary driver is the Automotive Industry, particularly the rapid expansion of Electric Vehicle (EV) manufacturing and Advanced Driver-Assistance Systems (ADAS). These applications require flawless processing of high-voltage and complex sensor wiring harnesses. Secondary drivers include Aerospace and Defense, and the Medical Device sector, all demanding certified quality and zero-tolerance for conductor damage.

How is Industry 4.0 impacting the design and operation of new rollover stripping systems?

Industry 4.0 mandates the integration of connectivity (IoT), AI, and sensor technology. New machines feature closed-loop quality control systems, real-time data exchange with MES platforms for production scheduling, and AI-driven predictive maintenance (PdM). This shift enables complete process traceability, minimizes unplanned downtime, and allows for automatic parameter adjustment based on real-time material feedback.

What are the major challenges restraining market growth, particularly for smaller manufacturers?

The primary restraint is the significant initial capital expenditure required for acquiring advanced, fully automated, high-precision rollover stripping machines, which often includes sophisticated sensor and software packages. Furthermore, the specialized training necessary for operational staff to program, maintain, and troubleshoot these highly complex, CNC-controlled systems presents an ongoing operational challenge globally.

Are laser stripping technologies replacing mechanical rollover stripping, or are they complementary?

Laser stripping (using systems like CO2 or Nd:YAG lasers) is generally complementary to mechanical rollover stripping. Lasers excel in non-contact stripping of ultra-fine wires or extremely delicate insulation where mechanical force is unacceptable. However, mechanical rollover stripping remains superior in cost-effectiveness, throughput, and efficiency for high-volume processing of medium to heavy-gauge wires with standard or robust insulation types.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager