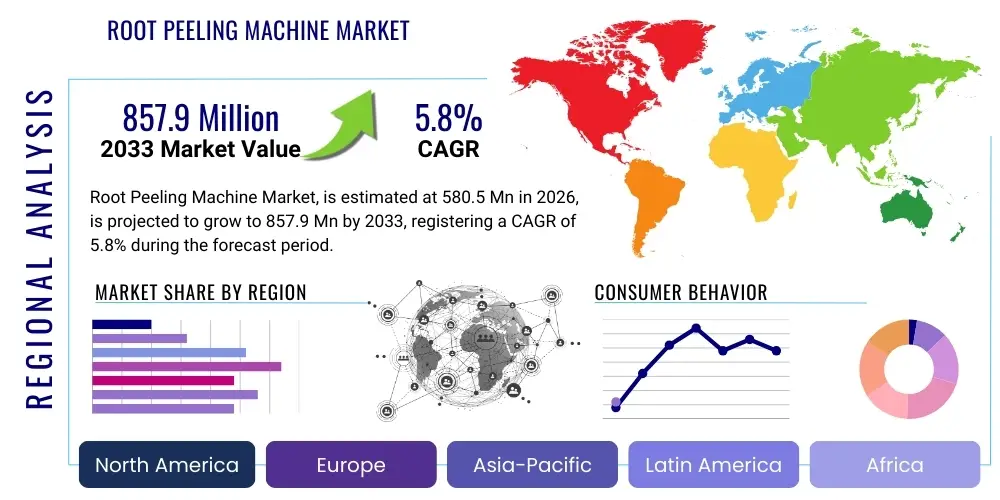

Root Peeling Machine Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 443492 | Date : Feb, 2026 | Pages : 246 | Region : Global | Publisher : MRU

Root Peeling Machine Market Size

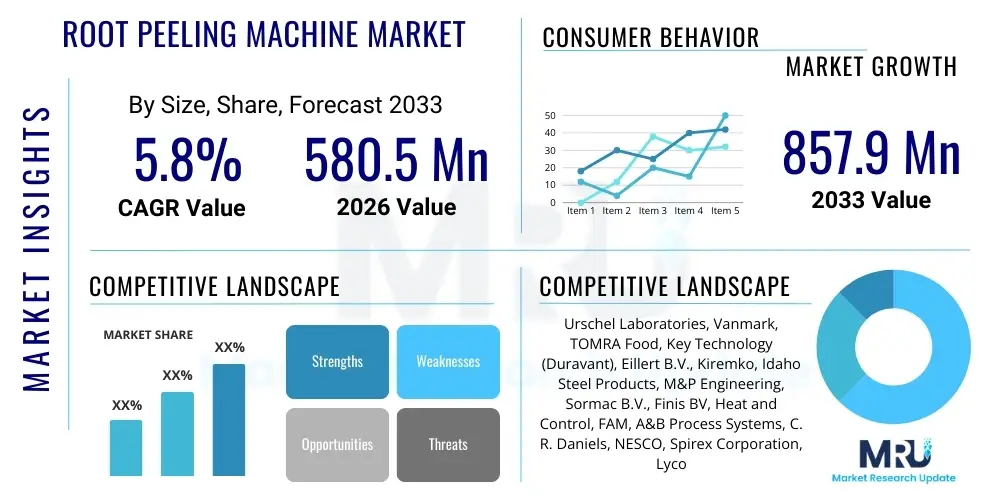

The Root Peeling Machine Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 580.5 Million in 2026 and is projected to reach USD 857.9 Million by the end of the forecast period in 2033. This growth trajectory is fundamentally supported by the accelerating global demand for processed and convenience foods, necessitating high-throughput, efficient, and hygienic preparation methods for root vegetables such as potatoes, carrots, cassava, and ginger. The shift towards large-scale industrial processing facilities, particularly in developing economies, mandates the adoption of sophisticated automation technologies, placing root peeling machines at the core of preliminary food preparation lines. Furthermore, stringent regulatory standards concerning food safety and hygiene in North America and Europe compel processors to upgrade from manual or semi-automated peeling techniques to fully mechanized systems, which offer superior control over yield, waste minimization, and microbial contamination risk.

The valuation reflects robust investment across various segments, notably driven by advancements in steam peeling technology, which offers higher efficiency and reduced material loss compared to traditional abrasive methods. The increasing integration of smart sensors and predictive maintenance capabilities within high-end peeling equipment is enhancing operational uptime and productivity, thereby justifying the substantial capital expenditure required for these systems. Market dynamics are also influenced by sustainability mandates, pushing manufacturers to innovate machines that consume less water and energy, thus aligning with global environmental, social, and governance (ESG) criteria. These innovations are critical for maintaining competitive advantage, especially among suppliers targeting major global food conglomerates that prioritize resource efficiency in their supply chain operations.

Root Peeling Machine Market introduction

The Root Peeling Machine Market encompasses the manufacturing, distribution, and utilization of specialized industrial equipment designed to remove the outer skin or peel from various root vegetables and tubers, including potatoes, carrots, yams, ginger, and cassava, prior to further processing. These machines are integral components of automated food production lines, ensuring uniformity, speed, and hygienic preparation necessary for large-scale operations. Products range from abrasive peelers, which use rough interior surfaces to remove the skin through friction, to advanced steam peelers, which utilize high-pressure steam to rapidly loosen the skin layer, followed by a sudden depressurization for removal. Knife peelers and caustic peelers represent other established technologies within this diverse product landscape, each catering to specific vegetable types and required peel depth specifications.

Major applications of root peeling machines span the frozen food industry, snack food manufacturing (e.g., potato chips), canned vegetable production, and the fresh-cut produce sector. The primary benefits derived from the adoption of these machines include significantly enhanced processing speed compared to manual labor, superior product consistency, substantial reduction in labor costs, and minimization of product waste, thereby improving overall yield efficiency. Crucial driving factors accelerating market expansion include rapid global urbanization leading to increased consumption of packaged and ready-to-eat meals, escalating food processing volumes, and the continuous need for improved sanitation and quality control in industrial food preparation environments. Furthermore, emerging economies are experiencing rapid infrastructural development in their food sectors, generating considerable demand for high-capacity machinery to support burgeoning domestic and export markets.

Root Peeling Machine Market Executive Summary

The Root Peeling Machine Market is characterized by intense technological competition and a clear shift towards automation and sustainability. Key business trends indicate manufacturers are prioritizing the development of high-efficiency steam peeling solutions, integrating advanced sensor technology for optimized peel loss control, and designing modular systems that offer flexibility across diverse root vegetable processing needs. Strategic partnerships between equipment manufacturers and large food processors are becoming common, focused on tailoring machinery to specific production demands and achieving higher throughput rates while adhering to stringent food safety regulations. Furthermore, mergers and acquisitions are observed as companies seek to consolidate technological expertise, particularly in areas related to digital controls and predictive maintenance capabilities.

Regional trends highlight Asia Pacific (APAC) as the fastest-growing market, driven by massive increases in local food consumption, expansion of industrial-scale food processing infrastructure in countries like China and India, and government initiatives promoting agricultural modernization. North America and Europe maintain dominance in terms of technology adoption, exhibiting strong demand for premium, highly automated, and energy-efficient peeling systems capable of complying with demanding environmental standards. Segment trends reveal that the Automatic Operation segment holds the largest market share due to its superior efficiency and reduced reliance on manual intervention, particularly in large industrial facilities. In terms of peeling technology, steam peelers are expected to exhibit the highest growth rate, fueled by their high yield recovery and suitability for hard-to-peel root crops, challenging the dominance of traditional abrasive peelers.

AI Impact Analysis on Root Peeling Machine Market

User inquiries regarding AI's influence on the Root Peeling Machine Market predominantly focus on how intelligent systems can optimize peeling processes, minimize waste, and enhance quality control in real-time. Common concerns revolve around the integration cost of AI components, the required skills gap for operation and maintenance of AI-driven machinery, and the practical application of machine learning algorithms to reduce peel thickness variations across different batches of incoming raw materials. Users anticipate that AI could lead to 'zero-waste' peeling cycles and improved predictive diagnostics, moving the industry away from historical, batch-based adjustments towards continuous, adaptive processing. The overarching expectation is for AI to transform peeling from a standardized mechanical process into a precision-engineered, data-driven operation that maximizes yield and reduces operational variability.

- Real-time Quality Monitoring: AI-powered vision systems analyze vegetable surface topography before and during peeling, identifying defects and ensuring optimal peel removal without damaging the underlying flesh.

- Predictive Maintenance: Machine learning algorithms process sensor data (vibration, temperature, power consumption) to anticipate component failures, scheduling maintenance proactively and minimizing unplanned downtime.

- Optimized Process Parameters: AI systems dynamically adjust peeling duration, pressure (in steam peelers), and rotation speed based on the specific attributes (size, shape, skin thickness) of the incoming root batch, maximizing material yield.

- Automated Sorting and Grading: Integration of AI-driven robotics post-peeling for high-speed inspection and sorting based on peel quality, size, and defect removal efficiency.

- Energy Efficiency Optimization: Algorithms fine-tune steam generation or abrasive intensity to meet required outputs with minimum energy expenditure, contributing to sustainability targets.

DRO & Impact Forces Of Root Peeling Machine Market

The Root Peeling Machine Market expansion is robustly driven by the increasing automation requirements across the global food processing sector, specifically linked to rising production volumes of convenience foods and snacks derived from root vegetables. The constant pressure on processors to maintain high hygiene standards and minimize labor costs serves as a primary driver for investment in highly automated peeling solutions. Conversely, the market faces significant restraints, chiefly concerning the high initial capital investment required for advanced steam peeling and large-capacity abrasive systems, which can be prohibitive for small and medium-sized enterprises (SMEs). Furthermore, technical complexities associated with maintaining and troubleshooting highly sophisticated machinery, coupled with the variability of raw root vegetable input (size, dirt content, shape), pose operational challenges that restrain seamless adoption.

Opportunities in this market are vast, centered around the untapped potential of emerging markets, particularly in Africa and Southeast Asia, where processing infrastructure is rapidly modernizing and scaling up to meet domestic demand. The development of modular, multi-functional peeling units capable of handling diverse root crops offers a significant avenue for growth, appealing to processors seeking operational flexibility. Furthermore, ongoing innovations focusing on water and energy recovery systems integrated into peeling equipment address critical sustainability concerns, opening doors for suppliers who champion eco-efficient technologies. The market is also heavily influenced by impact forces such as stringent food safety regulations (e.g., FSMA in the US, HACCP globally), which necessitate precision peeling equipment to avoid contamination, and fluctuating raw material costs, which increase the urgency for equipment that maximizes product yield and minimizes waste.

Segmentation Analysis

The Root Peeling Machine Market is broadly segmented based on technology type, application, operating capacity, and geographic region. Understanding these segmentations is critical for market participants to tailor their product offerings and marketing strategies effectively. The technology segment defines the fundamental peeling mechanism employed, distinguishing between methods that apply mechanical friction, heat shock, or chemical interaction. The Application segmentation dictates the primary end product, highlighting distinct requirements for high-volume potato processing versus specialized ginger or cassava preparation. The capacity segment, critical for industrial planning, separates equipment based on throughput, ranging from batch-mode systems suitable for food service to continuous, high-capacity lines necessary for major industrial processors. These segmentations collectively reveal shifting demand patterns favoring automated, high-yield, and multi-functional machinery capable of supporting expansive global food processing operations.

- By Type:

- Abrasive Peelers

- Knife Peelers (Lye Peelers, Mechanical Knife Peelers)

- Steam Peelers (High-Pressure Peelers)

- Caustic Peelers (Chemical Peelers)

- By Operation:

- Automatic

- Semi-Automatic

- By Application:

- Potato Processing (Frozen Fries, Chips, Flakes)

- Vegetable Processing (Carrots, Turnips, Radishes)

- Cassava and Tapioca Processing

- Other Root Processing (Ginger, Turmeric, Yams)

- By End-User:

- Industrial Food Processors

- Commercial Food Service (Large Institutional Kitchens)

- Small & Medium-Sized Enterprises (SMEs)

Value Chain Analysis For Root Peeling Machine Market

The value chain for the Root Peeling Machine Market begins with upstream activities, encompassing the sourcing and processing of raw materials such as specialized high-grade stainless steel (essential for hygiene and corrosion resistance), electrical components, sophisticated control systems, and specialized abrasive materials. Key upstream suppliers include steel mills, component manufacturers for programmable logic controllers (PLCs), and sensor technology providers. Efficiency at this stage is crucial, as the quality and durability of the finished machine are directly dependent on the integrity of these inputs. Manufacturers focus on optimizing inventory management and establishing resilient supply chains, particularly for advanced components like high-pressure vessels used in steam peelers, which require precision engineering and rigorous certification.

The central phase involves the manufacturing and assembly of the peeling machines, incorporating R&D activities focused on improving peeling efficiency, minimizing peel loss, and enhancing sanitation design (e.g., easy cleanability, CIP compatibility). This phase is heavily capital-intensive, requiring advanced machining and fabrication capabilities. Distribution channels are varied, including direct sales from the manufacturer, especially for large, custom-engineered industrial lines, and indirect sales facilitated through authorized distributors, system integrators, and regional representatives who provide localized technical support and installation services. System integrators play a vital role by incorporating the peeling machine into a complete processing line (which might include washing, cutting, and packaging machinery).

The downstream analysis focuses on the end-users—primarily industrial food processors, which represent the largest consumption segment. Customer service, post-sales support, maintenance contracts, and the availability of spare parts constitute crucial downstream activities that influence purchasing decisions and brand loyalty. The shift toward digitized, connected machinery (IoT integration) requires distributors and service providers to possess advanced IT and operational technology (OT) expertise. The final layer of the value chain is recycling and decommissioning, where manufacturers are increasingly required to take responsibility for the equipment’s end-of-life cycle, driven by circular economy principles, further emphasizing design for disassembly and material recovery.

Root Peeling Machine Market Potential Customers

The primary customer base for root peeling machines is highly concentrated within the industrial food processing sector, specifically those organizations involved in high-volume processing of tuber and root vegetables. These include large multinational corporations specializing in potato products, such as frozen french fries, potato chips, and dehydrated flakes, demanding continuous, high-capacity peeling lines, often utilizing advanced steam peeling technology for maximum yield. Another significant segment comprises manufacturers of canned and fresh-cut vegetables, including carrots, parsnips, and turnips, requiring hygienic, gentle peeling methods to maintain product appearance and quality. These industrial buyers prioritize throughput capacity, low maintenance requirements, minimal peel loss, and compliance with global food safety standards.

Secondary but rapidly growing customer segments include large-scale commercial kitchens, institutional food service providers (e.g., hospitals, military bases, flight catering facilities), and small to medium-sized vegetable processing enterprises (SMEs) focused on niche or local markets. These buyers often opt for semi-automatic or smaller-capacity automatic abrasive or knife peelers, balancing efficiency gains against lower initial investment costs. Furthermore, agricultural cooperatives in regions focused on staple crops like cassava and yams, particularly across Africa and Southeast Asia, represent a burgeoning potential market as they transition from traditional processing methods to mechanized systems to enhance the value of their agricultural output for both domestic consumption and export markets. Suppliers must tailor their product offerings, focusing on robust construction and ease of operation, to effectively serve this diverse global customer landscape.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 580.5 Million |

| Market Forecast in 2033 | USD 857.9 Million |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Urschel Laboratories, Vanmark, TOMRA Food, Key Technology (Duravant), Eillert B.V., Kiremko, Idaho Steel Products, M&P Engineering, Sormac B.V., Finis BV, Heat and Control, FAM, A&B Process Systems, C. R. Daniels, NESCO, Spirex Corporation, Lyco Manufacturing, Flo-Mech Ltd, VEMAG, GEA Group. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Root Peeling Machine Market Key Technology Landscape

The technological landscape of the Root Peeling Machine Market is predominantly defined by four core processing methods: abrasive, knife, steam, and caustic peeling, with continuous innovation focused on optimizing yield and minimizing environmental impact. Abrasive peelers, the oldest and most widespread technology, utilize rotating drums lined with carborundum or similar rough surfaces to remove the skin through friction. Recent advancements in this segment focus on developing specialized abrasive materials and precise rotational speed control mechanisms to reduce product damage and improve the consistency of the final product finish. Knife peelers, often employed for crops requiring very light skin removal or specific surface finishes, have seen improvements through computerized numerical control (CNC) driven blade systems that automatically adjust blade angles and pressure based on real-time potato or root shape analysis, drastically reducing manual adjustment time and enhancing precision.

Steam peeling technology currently represents the leading edge of innovation, particularly favored by large-scale industrial processors due to its high throughput and superior material yield (often achieving peel loss below 5-7%). This method involves exposing the roots to high-pressure steam in a pressure vessel for a brief period, followed by instantaneous depressurization, which causes the skin layer to separate from the flesh due to rapid expansion. Key technological breakthroughs here include the development of proprietary vessel designs that maximize steam penetration and coverage uniformity, coupled with advanced process control systems that precisely manage steam duration and pressure based on the specific root variety, size distribution, and moisture content of the batch. Furthermore, modern steam peelers are integrating sophisticated exhaust and condensation systems to recover heat and reduce water usage, addressing critical sustainability concerns raised by large processors.

The future trajectory of the technological landscape is increasingly leaning toward digitalization and smart integration. This involves the incorporation of sophisticated sensors (3D scanners, hyperspectral imaging) at both the input and output stages of the peeling process. These sensors feed real-time data into integrated control systems, often utilizing AI/ML algorithms, to ensure continuous, dynamic adjustment of peeling parameters, regardless of variations in the raw material supply. Furthermore, the development of modular and hybrid peeling systems is gaining traction, allowing processors to quickly switch between steam, abrasive, or combined methods on the same platform, offering unparalleled flexibility to handle seasonal crop changes or diversified product portfolios. Emphasis is also placed on designing equipment that facilitates easy sanitation, adhering to strict clean-in-place (CIP) protocols, and utilizing antimicrobial materials in contact surfaces to minimize biological contamination risks.

Regional Highlights

- North America: This region is characterized by high levels of automation and a strong regulatory environment promoting food safety and hygiene. The market is dominated by large-scale frozen food and snack processors who demand high-capacity, sophisticated steam peeling systems equipped with advanced data analytics capabilities for yield optimization. Innovation in the US and Canada focuses heavily on reducing water and energy consumption, leading to rapid adoption of the latest eco-efficient peeling technologies. The presence of major global equipment manufacturers and large food corporations ensures continuous investment in machinery upgrades and automation integration.

- Europe: Europe represents a mature market with significant emphasis on sustainability, precision processing, and minimal food waste. Strict EU regulations regarding food contact materials and energy efficiency drive demand for premium, stainless steel, highly controlled abrasive and steam peeling equipment. Countries such as Germany, the Netherlands, and Italy, with strong food engineering sectors, serve as key manufacturing hubs and early adopters of predictive maintenance and IoT-enabled peeling solutions. Demand is consistent across potato processing and the diverse market for prepared fresh-cut vegetables.

- Asia Pacific (APAC): APAC is the fastest-growing region globally, fueled by expanding populations, rising disposable incomes, and the rapid shift towards processed, packaged, and convenience foods across China, India, and Southeast Asia. The market exhibits high demand for both affordable, robust abrasive peelers for smaller operations and advanced, high-throughput steam peelers to support large, newly established processing hubs aimed at export markets. Growth is particularly vigorous in the cassava and tropical root processing segments, necessitating specialized, heavy-duty machinery capable of handling tougher skins and higher fiber content roots.

- Latin America: The market in Latin America is driven by increased industrialization in countries like Brazil and Mexico, focusing on optimizing local crop processing, particularly potatoes and tropical roots. Investment is primarily directed towards increasing capacity and improving efficiency to cater to both domestic consumption and regional export needs. While price sensitivity remains a factor, there is growing acceptance of semi-automatic and mid-range automatic peeling solutions as processors seek improved yield recovery over traditional methods.

- Middle East and Africa (MEA): This region is emerging, with growth highly concentrated in specific areas characterized by agricultural modernization programs and increased focus on developing local food security and processing capabilities. Africa, in particular, shows immense potential for mechanized cassava and yam peeling systems, driven by initiatives to reduce post-harvest losses and enhance the efficiency of staple food production. Demand is focused on durable, reliable, and relatively low-maintenance equipment suited for challenging operational environments.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Root Peeling Machine Market.- Urschel Laboratories

- Vanmark

- TOMRA Food

- Key Technology (Duravant)

- Eillert B.V.

- Kiremko

- Idaho Steel Products

- M&P Engineering

- Sormac B.V.

- Finis BV

- Heat and Control

- FAM

- A&B Process Systems

- C. R. Daniels

- NESCO

- Spirex Corporation

- Lyco Manufacturing

- Flo-Mech Ltd

- VEMAG

- GEA Group

Frequently Asked Questions

Analyze common user questions about the Root Peeling Machine market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the projected growth rate (CAGR) for the Root Peeling Machine Market?

The Root Peeling Machine Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033, driven by increased industrial automation and rising demand for processed root vegetables globally.

Which peeling technology dominates the industrial food processing sector?

Steam peeling technology is increasingly preferred and dominates large-scale industrial operations due to its ability to achieve superior material yield, high throughput, and minimal peel loss compared to traditional abrasive or knife methods.

Which geographic region is expected to show the fastest growth?

The Asia Pacific (APAC) region is forecasted to exhibit the highest growth rate, fueled by substantial investments in new food processing infrastructure and the accelerating consumer demand for packaged and convenience foods in countries like China and India.

How is AI impacting the efficiency of root peeling machines?

AI integration, specifically through vision systems and machine learning, is optimizing machine efficiency by enabling real-time quality monitoring, predictive maintenance scheduling, and dynamic adjustment of peeling parameters to maximize yield and consistency.

What are the key restraint factors affecting market expansion?

The primary restraint factors include the high initial capital investment required for advanced, high-capacity machinery and the operational challenges posed by significant variability in the size, shape, and skin thickness of incoming raw root vegetables.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager