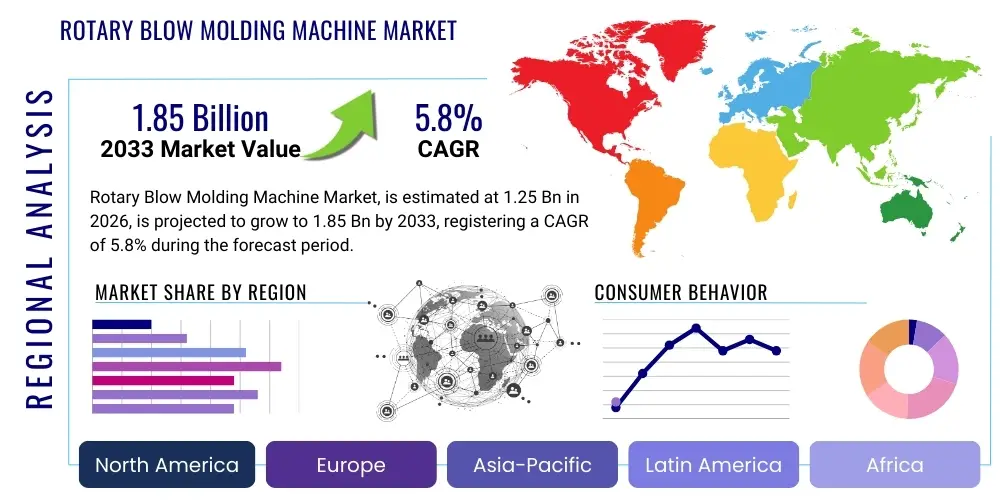

Rotary Blow Molding Machine Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 442639 | Date : Feb, 2026 | Pages : 257 | Region : Global | Publisher : MRU

Rotary Blow Molding Machine Market Size

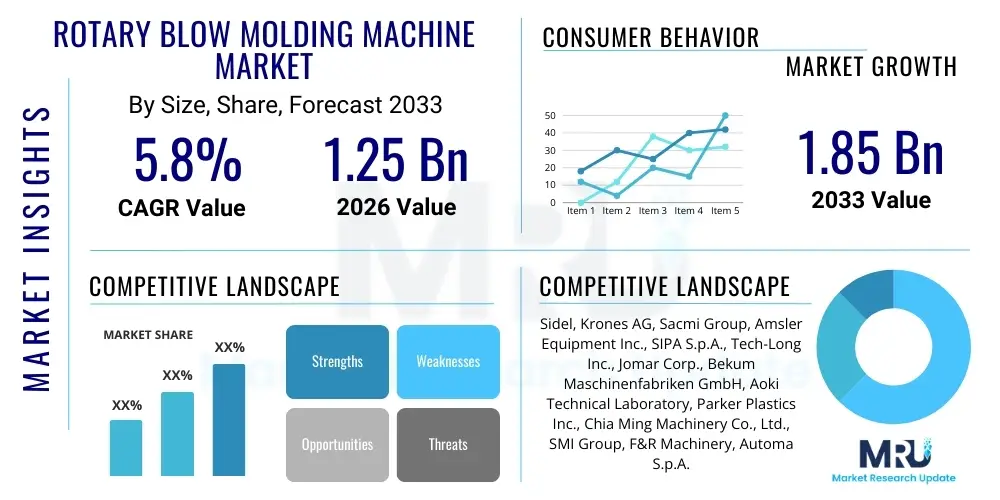

The Rotary Blow Molding Machine Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% (CAGR) between 2026 and 2033. The market is estimated at USD 1.25 Billion in 2026 and is projected to reach USD 1.85 Billion by the end of the forecast period in 2033.

Rotary Blow Molding Machine Market introduction

The Rotary Blow Molding Machine Market encompasses sophisticated industrial equipment designed for the high-volume production of hollow plastic articles, predominantly bottles and containers, utilizing thermoplastic resins such as Polyethylene Terephthalate (PET), High-Density Polyethylene (HDPE), and Polypropylene (PP). These machines operate on a continuous, multi-station basis, offering significantly higher output rates compared to traditional shuttle or linear blow molding systems. The core mechanism involves rotating molds that move through various stages—parison extrusion/injection, blowing, cooling, and deflashing—ensuring seamless, fast-paced manufacturing essential for mass consumer goods production.

Rotary blow molding technology is critical for industries demanding stringent quality control and high throughput, primarily serving the fast-moving consumer goods (FMCG) sector. Major applications include packaging for beverages (carbonated soft drinks, water), dairy products, personal care items (shampoos, lotions), and various household chemicals. The superior efficiency of rotary systems, characterized by minimized cycle times and robust process repeatability, provides substantial benefits to manufacturers seeking to lower unit costs and accelerate time-to-market. Furthermore, the inherent design flexibility allows for the rapid changeover between different container sizes and shapes, adapting quickly to evolving consumer packaging trends.

Key driving factors propelling the expansion of this market include the global surge in demand for packaged drinking water and soft drinks, particularly in emerging economies with rapidly urbanizing populations. The increasing focus on lightweight packaging to reduce material costs and transportation emissions also favors advanced rotary blow molding solutions capable of precise wall thickness control. Additionally, continuous technological advancements, such as the integration of electric drive systems for enhanced energy efficiency and lower maintenance requirements, are making these high-performance machines more attractive investments for large-scale packaging operations worldwide, cementing their role as indispensable assets in modern manufacturing environments.

Rotary Blow Molding Machine Market Executive Summary

The global Rotary Blow Molding Machine Market is experiencing robust expansion driven by sustained demand from the beverage and pharmaceutical sectors for high-speed, high-quality container production. Key business trends indicate a definitive shift toward fully electric and hybrid rotary machines, prioritizing sustainability and operational efficiency over traditional hydraulic systems. Manufacturers are increasingly focusing on incorporating modular designs and quick-change tooling to minimize downtime and maximize production flexibility, addressing the growing complexity of SKU diversification in consumer markets. Furthermore, competitive strategies are centered around offering comprehensive service contracts, integrating Industry 4.0 capabilities, and developing solutions optimized for recycling-compatible materials, reinforcing long-term client relationships and securing market share.

Regional trends reveal the Asia Pacific (APAC) region as the primary growth engine, fueled by massive industrialization, expanding domestic consumer bases, and significant foreign direct investment in manufacturing infrastructure, particularly in China, India, and Southeast Asia. North America and Europe, while mature markets, emphasize technological superiority, demanding machines capable of processing specialized bio-plastics and recycled PET (rPET), often driven by strict environmental regulations and corporate sustainability mandates. Segment trends highlight the dominance of the PET material segment due to its widespread use in clear packaging, although HDPE continues to hold substantial ground in the industrial and household product categories. The market is also seeing rapid growth in the application of machines specifically designed for pharmaceutical packaging, requiring extremely high standards of hygiene and precision.

Overall, the market structure is characterized by intense competition among a few large, established global players who invest heavily in R&D, and a diverse range of smaller, regional specialists focusing on cost-effective or niche solutions. Successful participants are those who can effectively balance high throughput capacity with energy efficiency and precision molding, while also navigating complex supply chain dynamics for specialized components. The shift toward digitalization and smart manufacturing processes is not just an optional upgrade but a fundamental requirement for maintaining relevance, enabling predictive maintenance, real-time quality assurance, and optimal resource utilization across global production lines.

AI Impact Analysis on Rotary Blow Molding Machine Market

User inquiries regarding the integration of Artificial Intelligence (AI) into the Rotary Blow Molding Machine Market primarily revolve around operational efficiency gains, predictive maintenance capabilities, and enhanced quality assurance systems. Users frequently ask how AI can reduce scrap rates, optimize energy consumption across high-volume production cycles, and transition from reactive or preventative maintenance to truly predictive strategies. A significant concern is the complexity and cost of retrofitting existing machinery versus investing in new, AI-native systems. The consensus expectation is that AI will revolutionize process control by analyzing vast datasets of temperature, pressure, and cycle time parameters in real-time, moving beyond traditional statistical process control (SPC) to anticipate and correct flaws before they manifest, thereby driving significant improvements in Overall Equipment Effectiveness (OEE) and minimizing material wastage, which is crucial for maximizing profitability in high-speed manufacturing environments.

- AI-driven Predictive Maintenance: Analyzing machine sensor data (vibration, heat, current draw) to forecast component failure, drastically reducing unscheduled downtime.

- Real-time Quality Control: Utilizing vision systems coupled with deep learning algorithms to detect subtle defects in parison formation or finished container geometry instantly, ensuring 100% compliance.

- Process Parameter Optimization: AI algorithms constantly adjust blow air pressure, heating profiles, and cooling times based on environmental factors and material batch variations to maximize cycle speed and minimize energy usage.

- Energy Management: Optimizing machine operation schedules and load distribution to reduce peak energy demand and improve overall machine energy efficiency.

- Automated Troubleshooting: Providing operators with immediate, AI-diagnosed solutions for operational disruptions, accelerating recovery time and lowering reliance on highly specialized technical staff.

DRO & Impact Forces Of Rotary Blow Molding Machine Market

The Rotary Blow Molding Machine Market is profoundly influenced by a convergence of technological drivers, operational restraints, and strategic opportunities that collectively shape investment decisions and market direction. The primary drivers include the escalating global demand for packaged goods, especially within the non-alcoholic beverage and pharmaceutical sectors, requiring continuous high-speed production capabilities. Coupled with this is the continuous drive by manufacturers to adopt automation and integrated production lines (Industry 4.0), where rotary machines offer the throughput and connectivity necessary for modern smart factories. Restraints primarily involve the substantial initial capital investment required for purchasing and installing these complex, high-capacity machines, which can deter small and medium-sized enterprises (SMEs), alongside the technical complexity requiring specialized maintenance personnel and rigorous operational training. Opportunities lie strongly in the development of machinery optimized for handling sustainable materials, such as bio-plastics and higher percentages of post-consumer recycled (PCR) resin, meeting increasing regulatory pressures and consumer preference for eco-friendly packaging solutions. The impactful forces driving market growth are rooted in economic development leading to increased consumption, technological innovation enhancing machine capabilities, and pervasive environmental regulations compelling packaging companies to adopt efficient, material-saving machinery.

Segmentation Analysis

The Rotary Blow Molding Machine Market is comprehensively segmented based on machine type, the material processed, the end-use application, and the primary mechanism utilized, offering a granular view of market dynamics and demand distribution. Segmentation by type typically differentiates between continuous extrusion rotary machines, utilized for products like tanks and large containers using HDPE or PP, and injection stretch blow molding (ISBM) rotary machines, which are indispensable for producing high-clarity PET bottles used extensively in the beverage industry. The distinction in these categories reflects the differing requirements for material preparation and final product characteristics, influencing purchasing decisions based on the required output material and shape complexity. Furthermore, understanding the application landscape, ranging from standardized beverage packaging to specialized medical containers, allows manufacturers to tailor machine specifications, focusing on areas like cleanroom compatibility or high-pressure resistance requirements, ensuring that technological development aligns precisely with sectoral needs across the global manufacturing landscape.

- By Technology: Extrusion Blow Molding (EBM), Injection Blow Molding (IBM), Injection Stretch Blow Molding (ISBM)

- By Material: PET (Polyethylene Terephthalate), HDPE (High-Density Polyethylene), PP (Polypropylene), PVC (Polyvinyl Chloride), Others (e.g., PC, PLA)

- By End-Use Industry: Beverages (Carbonated Soft Drinks, Water, Juices), Food (Jars, Edible Oil), Pharmaceuticals & Medical (Vials, IV solutions), Personal Care & Cosmetics (Shampoos, Lotions), Chemical & Industrial (Detergents, Lubricants)

- By Operation: Hydraulic, Electric, Hybrid

Value Chain Analysis For Rotary Blow Molding Machine Market

The value chain for the Rotary Blow Molding Machine Market begins with the upstream sourcing of highly specialized components, including precision mechanical parts, sophisticated electrical drive systems (especially for fully electric machines), advanced mold tooling, and complex programmable logic controllers (PLCs). Key upstream activities involve meticulous supplier qualification and long-term partnerships with specialized engineering firms to ensure the delivery of components that meet the high standards of speed, precision, and durability required for continuous industrial operation. The midstream manufacturing phase involves the complex integration of these components, rigorous machine assembly, testing, and quality certification, ensuring that the assembled rotary systems meet international safety and performance benchmarks before they are deployed to end-user facilities globally.

The distribution channel is multifaceted, relying on a combination of direct sales models for major, custom-engineered projects, and indirect channels involving specialized regional distributors or agents for standard machine sales and aftermarket services. Direct engagement is common for market leaders serving large multinational packaging corporations, enabling customized configurations and streamlined technical support. Conversely, regional agents often handle sales into emerging markets or to smaller manufacturers, providing localized support, installation, and maintenance services, which are critical given the high complexity of the machinery. Effective distribution requires not just logistical efficiency but also a strong technical sales force capable of articulating the cost-saving and efficiency benefits of rotary technology versus linear alternatives.

Downstream activities center on deployment, installation, operator training, and continuous aftermarket service, including the supply of spare parts and software updates, which often represents a significant revenue stream for machine manufacturers. The ultimate customers, typically large-scale packaging converters or major brand owners (e.g., beverage companies), integrate these machines into highly automated production lines. The final value delivered is the ability to produce millions of high-quality, standardized containers per year with minimal labor input, linking the initial investment directly to market consumption and product distribution efficiency. The continuous feedback loop from the downstream users regarding performance, reliability, and desired material processing capabilities is essential for driving upstream R&D and technological refinement.

Rotary Blow Molding Machine Market Potential Customers

The primary customers for Rotary Blow Molding Machines are high-volume manufacturers within the consumer packaging industry, characterized by continuous operational requirements and strict demands for product consistency and output capacity. The most significant buying segments include multinational beverage conglomerates requiring millions of high-clarity PET bottles for water, soft drinks, and juices, where the throughput of rotary ISBM machines is indispensable for meeting national and international distribution scales. These customers prioritize machine speed, efficiency in using rPET, and low total cost of ownership (TCO) over the machine's lifecycle, often negotiating long-term service and maintenance agreements.

Another crucial customer segment is the pharmaceutical and medical device manufacturing industry, particularly for sterile packaging such as IV solution bottles, specialized vials, and medical containers. These buyers demand machines that adhere to extremely stringent regulatory standards (e.g., FDA, EMEA), featuring cleanroom compatibility, precise dosing capability, and robust validation protocols, often favoring all-electric rotary systems for their superior hygiene and control. Additionally, major global players in the personal care, cosmetics, and household chemical sectors (e.g., producers of shampoos, detergents, and lotions) represent strong potential customers, utilizing both EBM and ISBM rotary systems to produce aesthetically diverse, robust, and cost-effective packaging for their extensive product lines, valuing flexibility and rapid changeover capabilities.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.25 Billion |

| Market Forecast in 2033 | USD 1.85 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Sidel, Krones AG, Sacmi Group, Amsler Equipment Inc., SIPA S.p.A., Tech-Long Inc., Jomar Corp., Bekum Maschinenfabriken GmbH, Aoki Technical Laboratory, Parker Plastics Inc., Chia Ming Machinery Co., Ltd., SMI Group, F&R Machinery, Automa S.p.A., Zhejiang Meide Blow Molding Machine Co., Ltd., Magic MP S.p.A., Graham Engineering Corporation, Wilmington Machinery, ASB International, KHS Group |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Rotary Blow Molding Machine Market Key Technology Landscape

The technological landscape of the Rotary Blow Molding Machine Market is characterized by a strong emphasis on automation, energy efficiency, and material handling flexibility, aligning with global manufacturing trends. A critical development is the widespread adoption of all-electric rotary platforms, which utilize high-precision servo motors instead of traditional hydraulic systems. This transition significantly reduces energy consumption, enhances operational cleanliness, minimizes noise pollution, and provides superior repeatability in mold clamping and stretching processes, crucial for lightweighting initiatives. Furthermore, electric systems offer finer control over the entire molding cycle, resulting in reduced scrap rates and optimized wall thickness distribution, a paramount concern for manufacturers aiming to conserve material and meet sustainability goals while maintaining container integrity and shelf life.

Advanced tooling and rapid changeover systems represent another major technological thrust. Modern rotary machines are being designed with modular components and automatic mold-changing capabilities, drastically cutting the time required to switch between different container specifications (e.g., bottle volumes or neck finishes). This flexibility is vital in a market defined by short product lifecycles and highly customized packaging demands. Alongside hardware improvements, software integration is accelerating, leveraging Industrial Internet of Things (IIoT) sensors to collect vast amounts of operational data. This data enables sophisticated process visualization, remote diagnostics, and condition monitoring, allowing for proactive intervention and optimized maintenance scheduling, thereby maximizing the Overall Equipment Effectiveness (OEE) of these expensive assets.

In the context of Injection Stretch Blow Molding (ISBM) rotary machines, the focus is heavily on optimizing the preform heating process, often employing advanced near-infrared (NIR) or microwave heating technologies to ensure uniform material temperature distribution throughout the preform wall. This precision heating is essential for successfully stretching challenging materials like recycled PET (rPET) or new bio-polymers, which have tighter processing windows than virgin resins. Manufacturers are also integrating barrier technology within the rotary process, such as multi-layer co-injection or co-extrusion, to enhance the shelf-life properties of containers used for oxygen-sensitive products like beer, juices, or pharmaceuticals, showcasing continuous innovation to meet specialized application requirements across diverse end-use sectors.

Regional Highlights

- Asia Pacific (APAC): APAC represents the fastest-growing and largest market for Rotary Blow Molding Machines, primarily driven by explosive growth in consumer packaging demand across China, India, and Southeast Asia. Rapid urbanization, increasing disposable incomes, and the massive expansion of the food and beverage industry necessitate high-throughput, continuous production solutions. Government initiatives supporting manufacturing infrastructure and the localized presence of major packaging converters further solidify APAC's dominance, focusing investments on high-capacity ISBM machines for bottled water and soft drinks.

- North America: The North American market is characterized by high adoption rates of advanced, energy-efficient, and fully automated electric rotary machines. Growth here is not volume-driven but innovation-driven, focusing on utilizing rotary technology for sophisticated applications like specialty pharmaceutical containers and sustainable packaging using high percentages of post-consumer recycled (PCR) resin and bio-based plastics, aligning with stringent corporate social responsibility goals and high labor costs necessitating full automation.

- Europe: Europe maintains a strong market position, heavily influenced by strict environmental regulations mandating circular economy principles. The demand centers on machinery optimized for handling high levels of rPET and ensuring minimal energy consumption (Total Cost of Ownership focus). Western European countries prioritize retrofitting existing hydraulic rotary machines with electric components and investing in cutting-edge ISBM technology capable of manufacturing lightweight, complex container geometries while maintaining high quality standards.

- Latin America (LATAM): The LATAM market, including key countries like Brazil and Mexico, demonstrates solid growth fueled by increasing local demand for packaged beverages and personal care items. Investment in rotary machinery is often strategic, focused on expanding capacity to serve large domestic markets and improve export competitiveness. Economic volatility can sometimes restrain large capital expenditure, favoring reliable, mid-range capacity machines from regional suppliers or established global manufacturers offering favorable financing terms.

- Middle East and Africa (MEA): The MEA region shows emerging potential, particularly within the Gulf Cooperation Council (GCC) nations, driven by large investments in infrastructure and rapid growth in the bottled water and industrial packaging sectors. The market is primarily focused on acquiring robust, high-output rotary extrusion blow molding machines for industrial chemicals and high-capacity ISBM systems for beverage production in high-temperature environments. Political stability and oil price volatility remain key external factors influencing capital investment cycles.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Rotary Blow Molding Machine Market.- Sidel

- Krones AG

- Sacmi Group

- Amsler Equipment Inc.

- SIPA S.p.A.

- Tech-Long Inc.

- Jomar Corp.

- Bekum Maschinenfabriken GmbH

- Aoki Technical Laboratory

- Parker Plastics Inc.

- Chia Ming Machinery Co., Ltd.

- SMI Group

- F&R Machinery

- Automa S.p.A.

- Zhejiang Meide Blow Molding Machine Co., Ltd.

- Magic MP S.p.A.

- Graham Engineering Corporation

- Wilmington Machinery

- ASB International

- KHS Group

Frequently Asked Questions

Analyze common user questions about the Rotary Blow Molding Machine market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary advantage of rotary blow molding over linear systems?

The key advantage of rotary blow molding machines lies in their superior production speed and continuous operation, enabling significantly higher throughput (bottles per hour) essential for mass packaging industries like beverages and pharmaceuticals, leading to lower unit manufacturing costs.

Which plastic material segment dominates the rotary blow molding market?

The Polyethylene Terephthalate (PET) segment dominates, primarily driven by the massive global demand for transparent packaging in the bottled water, carbonated soft drink, and juice industries, which heavily rely on Injection Stretch Blow Molding (ISBM) rotary technology for clear, strong, and lightweight containers.

How is sustainability impacting the purchasing decisions for new rotary machines?

Sustainability is a crucial factor, driving demand for machines optimized to handle post-consumer recycled (PCR) PET and bio-plastics, as well as those offering lightweighting capabilities and superior energy efficiency (e.g., all-electric models) to comply with circular economy targets and reduce carbon footprint.

Which geographical region exhibits the highest growth potential in this market?

Asia Pacific (APAC) exhibits the highest growth potential, fueled by massive population growth, expanding urbanization, and continuous investment in the food and beverage production sectors across developing economies like China and India, resulting in escalating demand for packaged goods.

What role does Industry 4.0 integration play in modern rotary blow molding equipment?

Industry 4.0 integration, utilizing IIoT sensors and AI, is essential for implementing predictive maintenance, achieving real-time quality assurance, optimizing complex process parameters, and reducing unscheduled downtime, thereby maximizing the Overall Equipment Effectiveness (OEE) and operational efficiency.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager