Rubber Waterstop Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 441662 | Date : Feb, 2026 | Pages : 245 | Region : Global | Publisher : MRU

Rubber Waterstop Market Size

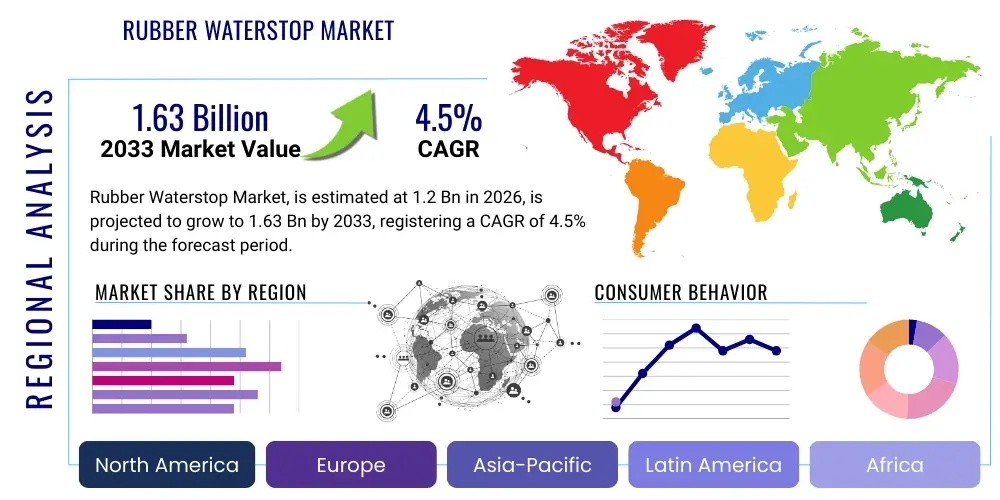

The Rubber Waterstop Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 4.5% between 2026 and 2033. The market is estimated at USD 1.2 Billion in 2026 and is projected to reach USD 1.63 Billion by the end of the forecast period in 2033.

Rubber Waterstop Market introduction

The Rubber Waterstop Market encompasses the production and supply of specialized sealing profiles made primarily from natural or synthetic rubber compounds, designed to be embedded in concrete joints to prevent the passage of water under hydrostatic pressure. These critical components are essential in complex construction projects, particularly those involving water retention, containment, or subterranean structures. Rubber waterstops function by providing a flexible yet impermeable barrier within expansion, contraction, and construction joints, ensuring structural integrity and longevity against environmental ingress.

Key product types include internal (embedded within the joint) and external (placed on the surface) varieties, utilizing materials such as Styrene-Butadiene Rubber (SBR), Neoprene (Polychloroprene), and high-grade Natural Rubber (NR). The superior elasticity, tensile strength, and resistance to chemical degradation offered by rubber materials make them preferred over traditional metallic or PVC alternatives in demanding applications like large-scale dam construction, nuclear power facilities, and wastewater treatment plants. Their ability to accommodate significant joint movement without fracturing the seal is paramount to their function.

Major applications driving market demand include the construction of reservoirs, tunnels, bridges, sewage facilities, parking structures, and basements where absolute waterproofing is non-negotiable. The underlying driving factors for market growth stem from escalating global investments in public infrastructure, particularly in developing economies, coupled with increasing regulatory mandates for durable and waterproof civil structures. Furthermore, the rising awareness regarding the financial implications of water damage and structural corrosion reinforces the mandatory incorporation of high-performance waterstop systems.

Rubber Waterstop Market Executive Summary

The global Rubber Waterstop Market is characterized by robust demand, primarily fueled by massive infrastructural expenditure across Asia Pacific and ongoing critical maintenance and replacement of aging water infrastructure in North America and Europe. Business trends indicate a strong shift towards high-performance synthetic rubber variants (like EPDM and Neoprene) due to their enhanced chemical resistance and ozone stability, making them suitable for aggressive environments such as chemical storage facilities and municipal sewage systems. Manufacturers are focusing on developing custom-engineered profiles and easy-to-weld systems to reduce installation time and complexity on site, thereby improving overall project efficiency and reliability.

Regional trends highlight the Asia Pacific region, particularly China and India, as the foremost growth engine, driven by extensive investment in transportation networks, urbanization projects, and hydroelectric dams. North America remains a mature but stable market, focusing on innovation in installation techniques and compliance with stringent environmental standards. European trends emphasize sustainability and lifecycle analysis, pushing the demand for durable, long-lasting rubber compounds that minimize maintenance requirements and adhere to high-level civil engineering specifications (e.g., DIN and ASTM standards).

Segment trends reveal that the Application segment dominated by water retaining structures (dams, canals, reservoirs) due to the sheer volume and critical nature of these projects, which necessitates large quantities of high-specification rubber profiles. Within the Material Type segment, Synthetic Rubber is rapidly gaining traction over Natural Rubber, particularly in industrial and commercial building sectors, owing to its consistent performance and superior resistance to oils, fuels, and varying temperatures. Strategic alliances between rubber compound suppliers and large construction contractors are increasingly observed, aimed at securing supply chains and optimizing material specifications early in the project design phase.

AI Impact Analysis on Rubber Waterstop Market

User queries regarding the impact of Artificial Intelligence (AI) on the Rubber Waterstop Market primarily revolve around how AI can enhance material quality verification, optimize complex installation procedures, and contribute to the predictive maintenance of large-scale concrete structures where waterstops are employed. Users are concerned about the digitalization of construction planning and whether AI algorithms can predict joint movement dynamics more accurately than traditional engineering models, thus leading to the selection of the optimal waterstop type and profile. Furthermore, there is significant interest in using AI-driven image processing for non-destructive testing and quality assurance (QA/QC) during the waterstop installation phase, ensuring zero defects and compliance before concrete pouring, thereby mitigating costly future repairs associated with water ingress failure.

- AI-driven optimization of rubber compound formulation for specific environmental stressors (e.g., optimizing EPDM blends for UV and chemical exposure).

- Predictive modeling using machine learning to forecast joint expansion/contraction under extreme weather and seismic activity, guiding profile selection.

- AI integration into Building Information Modeling (BIM) for automated waterstop placement and collision detection in complex structural joints.

- Enhanced quality control through computer vision systems monitoring the extrusion process for consistent profile geometry and dimensional tolerance.

- Robot-assisted installation and welding of waterstop sections, guided by AI to ensure perfect alignment and homogeneous splicing, reducing manual error.

- Analysis of historical structural monitoring data (e.g., strain gauges near joints) using AI to predict potential failure points and necessary preventative waterstop replacement cycles.

- Streamlining supply chain logistics and inventory management for project sites using AI to forecast material requirements based on construction pace and segment usage.

DRO & Impact Forces Of Rubber Waterstop Market

The Rubber Waterstop Market is profoundly influenced by dynamic macroeconomic factors, regulatory frameworks, and technological advancements. Key drivers include aggressive global governmental spending on civil infrastructure, especially transportation (high-speed rail, metro tunnels) and water management systems (dams, canals). The urgent need for resilient infrastructure capable of withstanding increasing climate variability, such as prolonged heavy rainfall and rising sea levels, mandates the use of highly durable sealing solutions like rubber waterstops. Furthermore, stricter building codes demanding extended service life for concrete structures significantly propel demand across all major geographies.

Restraints primarily revolve around the volatility of raw material prices, particularly synthetic rubbers derived from petrochemicals, and the fluctuating cost of natural rubber, which impacts manufacturing profitability. Another significant constraint is the high dependency on skilled labor for proper installation and splicing of waterstop profiles on construction sites. Improper welding or positioning can lead to seal failure, which necessitates costly remedial work, thereby increasing perceived project risk. The availability of substitute products, such as PVC and bentonite-based waterstops, in price-sensitive markets also acts as a competitive restraint, though rubber retains a performance advantage in high-movement joints.

Opportunities for market expansion are abundant in the development of specialized, chemical-resistant rubber compounds for industrial applications (e.g., secondary containment for hazardous waste) and the evolution of pre-fabricated waterstop systems that minimize on-site labor requirements and improve installation quality assurance. The adoption of sustainable rubber sourcing practices and the development of recycled or bio-based synthetic elastomers also present a long-term strategic opportunity to appeal to environmentally conscious builders and governments. The impact forces are generally high, driven by persistent demand in the infrastructure sector and the non-negotiable requirement for waterproofing in critical civil engineering applications, meaning even economic slowdowns often spare essential infrastructure projects where these components are vital.

Segmentation Analysis

The Rubber Waterstop Market is meticulously segmented based on material type, product profile, and application area, reflecting the diverse and specialized requirements of the construction industry. Segmentation is crucial as the performance requirements for a waterstop used in a large dam structure (requiring high tensile strength and long-term durability) differ significantly from one used in a basement wall (requiring ease of installation and moderate movement capacity). Understanding these segments allows manufacturers to tailor product specifications, focusing research and development efforts on specific performance characteristics, such as resistance to UV exposure, ozone, or specific chemical agents found in wastewater.

The segmentation structure highlights the dominance of the Application segment, particularly within the public works sector. Water retaining structures remain the largest consumer due to the scale and inherent risk associated with their failure. However, the commercial and residential construction segment is growing rapidly, driven by the increasing construction of subterranean structures and multi-level parking garages that require rigorous waterproofing solutions. Geographical segmentation underscores regional differences in material preference and regulatory adherence; for instance, high-quality Neoprene might be preferred in North America for its stability, while Natural Rubber might still hold a strong position in price-sensitive Asian markets.

The strategic differentiation achieved through material type segmentation—Natural vs. Synthetic rubber—is pivotal. Synthetic rubbers like EPDM offer superior resistance to aging and harsh chemicals, often commanding a premium, whereas Natural Rubber provides excellent tensile strength and resilience, making it a cost-effective choice for general-purpose water retention applications. This granularity in segmentation provides a clear framework for competitive positioning and market entry strategies for new players.

- Material Type:

- Natural Rubber (NR)

- Synthetic Rubber (SBR, Neoprene/CR, EPDM)

- Recycled/Blended Rubber Compounds

- Product Profile:

- Dumbbell Waterstops (Flat profiles)

- Ribbed Waterstops (More effective anchoring)

- Centerbulb Waterstops (High movement capacity)

- Base Seal/External Waterstops

- Joint Filler Combinations

- Application:

- Water Retaining Structures (Dams, Reservoirs, Canals, Aqueducts)

- Tunnels and Underground Structures (Metro, Road, Utility Tunnels)

- Buildings and Commercial Structures (Basements, Parking Decks, Foundations)

- Water and Wastewater Treatment Facilities (STP, WTP)

- Nuclear Power and Industrial Containment

- Bridges and Highways

- End-Use Sector:

- Civil Engineering Contractors (EPC Firms)

- Government and Public Works Agencies

- Utility Providers

- Industrial Facilities Owners

Value Chain Analysis For Rubber Waterstop Market

The value chain for the Rubber Waterstop Market begins with the upstream sourcing of raw materials, involving the extraction and processing of natural rubber latex or the synthesis of petroleum-derived polymers like Styrene-Butadiene Rubber (SBR) and EPDM. This upstream segment is characterized by global commodity pricing volatility and high capital investment in petrochemical refining and rubber processing infrastructure. Key activities include compounding—the precise mixing of rubber polymers with additives, reinforcing agents, and vulcanizing chemicals to achieve desired performance specifications like elasticity, durability, and chemical resistance. Specialized compounders play a critical role in developing high-performance, project-specific rubber mixes.

The midstream stage involves the core manufacturing process, primarily extrusion and molding, where the compounded rubber is processed into various standard and custom profiles (e.g., dumbbell, ribbed, centerbulb). Manufacturers invest heavily in precision machinery to maintain tight dimensional tolerances, which are crucial for effective sealing. Efficiency in this stage dictates production cost and capacity. Distribution forms the critical linkage to the downstream market. Due to the project-specific nature of waterstops, direct sales and established relationships with large Engineering, Procurement, and Construction (EPC) firms are predominant for major infrastructure projects.

Indirect distribution relies on a network of specialized construction material distributors and wholesalers who service smaller commercial and residential projects. Downstream activities involve on-site installation, including the crucial task of splicing and welding waterstop lengths to form continuous, seamless barriers, which typically requires specialized equipment and certified technicians. End-users (project owners and government agencies) ultimately drive the demand based on specific project requirements, focusing heavily on product certifications (e.g., ASTM D412, D2240) and long-term performance warranties provided by the manufacturer.

Rubber Waterstop Market Potential Customers

Potential customers for rubber waterstops are predominantly large entities involved in the design, construction, and long-term maintenance of civil and industrial structures where concrete joints are exposed to water or moisture. The primary buyers are not individuals but professional organizations operating within the public and private infrastructure sectors. Governmental agencies responsible for large public works—such as departments of transportation, water resource ministries, and municipal utility districts—constitute a massive segment, demanding high volumes and premium specifications for critical infrastructure like dams, sewage tunnels, and metropolitan subway systems.

Another significant customer segment includes multinational Engineering, Procurement, and Construction (EPC) companies and general contractors specializing in large-scale commercial and civil projects. These customers prioritize reliability, compliant product documentation, and timely delivery, often seeking long-term supply agreements or pre-qualification of specific rubber waterstop brands. Their procurement decisions are driven by strict project specifications and the need to minimize construction risk associated with structural water ingress, making high-quality rubber products a preferred choice over cheaper alternatives.

Furthermore, specialized segments include owners and operators of industrial facilities, such as chemical processing plants, oil and gas storage terminals (for secondary containment areas), and nuclear power plants. These end-users require highly specialized rubber compounds (e.g., oil-resistant Neoprene) and demand stringent quality assurance and compliance with industry-specific safety standards. Architectural and civil engineering consulting firms also act as key influencers, specifying the exact type and material of the waterstop during the design phase, thus directing the purchasing decisions of the ultimate buyers.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.2 Billion |

| Market Forecast in 2033 | USD 1.63 Billion |

| Growth Rate | 4.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Sika AG, GCP Applied Technologies, BASF SE, Trelleborg AB, Carlisle Construction Materials, KGS Group, JP Specialties, Inc., Fosroc International, Greenstreak, Hongda Waterstop, MBCC Group (Master Builders Solutions), Henry Company, W. R. Meadows, Inc., Nanjing Daji Steel Waterstop, BoMetals, Inc., Cera-Chem Private Ltd., Mapei S.p.A., Alchimica Building Chemicals, Laticrete International, Tremco CPG. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Rubber Waterstop Market Key Technology Landscape

The core technology in the Rubber Waterstop Market centers on specialized polymer compounding and advanced rubber extrusion techniques designed to ensure product integrity and superior performance under high pressure and constant movement. Technological advancements are focused on developing customized rubber formulations, moving beyond generic materials to specific blends of EPDM, Neoprene, or highly stabilized Natural Rubber that offer optimized resistance to specific site conditions, such as high ozone levels, industrial chemicals, or microbial attack common in sewage systems. Precision extrusion technology is paramount, utilizing laser scanning and feedback control systems to maintain ultra-precise dimensional tolerances, which is critical for ensuring effective seal performance when the waterstop is embedded in the concrete joint.

Another crucial technological area is the development of robust and reliable on-site splicing and welding equipment. Rubber waterstops must form a continuous, monolithic barrier, and the junctions between lengths are often the weakest point. Manufacturers are providing advanced heat-welding kits and vulcanizing presses that ensure the joints possess mechanical strength and chemical resistance equivalent to the parent material, minimizing installation errors and maximizing long-term performance. The focus is shifting towards thermostatically controlled, user-friendly welding jigs that require minimal specialized training, addressing the constraint of relying on highly skilled labor.

Emerging technology includes the integration of smart materials and Internet of Things (IoT) capabilities. While still nascent, some advanced waterstop systems incorporate small, embeddable sensors or conductive elements that allow engineers to monitor structural movement or detect the onset of water ingress near the joint early on. This predictive monitoring capability, often coupled with remote data analysis, allows for proactive maintenance before catastrophic failure occurs, positioning rubber waterstops not just as passive barriers but as active components within structural health monitoring systems for critical infrastructure projects like dams and nuclear facilities.

Regional Highlights

Regional dynamics significantly shape the Rubber Waterstop Market, driven by differential rates of infrastructure development, varying regulatory standards, and regional climatic conditions. The Asia Pacific (APAC) region stands out as the largest and fastest-growing market, primarily due to rapid urbanization, massive public sector investment in transportation (roads, metros, high-speed rail), and extensive development of hydro and water resource management projects in countries like China, India, and Southeast Asian nations. The sheer scale of dam and tunnel construction in APAC necessitates high volumes of rubber waterstops, particularly those offering excellent price-to-performance ratios, often favoring high-quality natural rubber and SBR variants. Demand is increasingly shifting towards synthetic rubber as projects become more complex and require superior chemical resistance.

North America (NA) represents a mature market characterized by a strong focus on maintenance, repair, and replacement of aging infrastructure, particularly bridges, utility tunnels, and wastewater systems. The market here emphasizes high-specification, premium synthetic materials like EPDM and Neoprene, driven by stringent engineering standards and an expectation of 50 to 100-year service life for critical components. Innovation in installation technology, including pre-fabricated corner units and specialized mechanical splicing systems, is particularly strong in the US and Canada to address labor efficiency and quality control concerns.

Europe maintains a consistent demand, fueled by strict adherence to environmental regulations and high construction quality benchmarks (such as European Norms). The European market exhibits a preference for durable, certified rubber compounds and systems that integrate well with complex multi-layer waterproofing protocols. Western European countries focus heavily on underground construction, basement waterproofing for dense urban centers, and rehabilitation projects. The Middle East and Africa (MEA) market shows robust growth linked to mega-projects in the Gulf Cooperation Council (GCC) states (e.g., massive tunnel projects, artificial islands) and infrastructure development in emerging African economies, often demanding materials capable of withstanding extreme temperature fluctuations and high salinity exposure.

- Asia Pacific (APAC): Dominates market volume; driven by China, India, and Southeast Asia infrastructure spending (dams, metros, high-speed rail). Strong demand for both cost-effective NR and specialized Synthetic rubber.

- North America (NA): Focus on high-specification replacement and maintenance of aging infrastructure (bridges, sewage systems). High preference for EPDM and Neoprene due to rigorous standards and long service life requirements.

- Europe: Stable growth underpinned by stringent EU construction and environmental standards. Emphasis on high quality, certified materials, and solutions for urban subterranean structures and rehabilitation projects.

- Middle East & Africa (MEA): Growth tied to diversification efforts in GCC nations (infrastructure mega-projects) and essential water management projects across Africa. Requires materials with excellent thermal and chemical resistance.

- Latin America (LATAM): Moderate growth driven by hydroelectric projects and mining infrastructure, often balancing performance requirements with local sourcing and cost considerations.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Rubber Waterstop Market.- Sika AG

- GCP Applied Technologies

- BASF SE

- Trelleborg AB

- Carlisle Construction Materials

- KGS Group

- JP Specialties, Inc.

- Fosroc International

- Greenstreak

- MBCC Group (Master Builders Solutions)

- Henry Company

- W. R. Meadows, Inc.

- Nanjing Daji Steel Waterstop

- BoMetals, Inc.

- Cera-Chem Private Ltd.

- Mapei S.p.A.

- Alchimica Building Chemicals

- Laticrete International

- Tremco CPG

- Hongda Waterstop

Frequently Asked Questions

Analyze common user questions about the Rubber Waterstop market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary difference between natural rubber and synthetic rubber waterstops?

Natural Rubber (NR) waterstops offer superior elasticity and tensile strength, making them excellent for joints with high movement expectations but are less resistant to oils, ozone, and harsh chemicals. Synthetic rubbers (like EPDM or Neoprene) provide enhanced resistance to chemical attack, weathering, and heat aging, making them ideal for specialized industrial and sewage applications, often at a higher cost.

In which type of construction project are rubber waterstops mandatory for structural integrity?

Rubber waterstops are considered mandatory and essential for maintaining the structural integrity of concrete structures designed to retain or exclude water under hydrostatic pressure. Key applications include major hydraulic structures (dams, reservoirs, canals), subterranean installations (tunnels, basements), and wastewater treatment facilities, where joint movement and durability are critical factors.

What are the typical failure mechanisms associated with rubber waterstops?

The most common failure mechanism is improper installation, specifically poor welding or splicing of joints on site, creating weak points where water can penetrate. Other failures include excessive movement beyond the waterstop's capacity, chemical degradation (especially in industrial environments if the wrong material is selected), or premature aging due to poor quality rubber compounding or exposure to ozone/UV during storage.

How do manufacturers ensure the quality and longevity of rubber waterstops?

Quality assurance is achieved through rigorous testing, including tensile strength (ASTM D412), hardness (ASTM D2240), tear resistance, and acceleration aging tests. Leading manufacturers also provide extensive technical support, certified welding training for contractors, and adherence to international standards like CE marking and specific regional civil engineering specifications to ensure product reliability over decades of service life.

What is the significance of the Centerbulb profile in waterstop design?

The Centerbulb profile is crucial for joints expected to undergo significant cyclic movement (expansion and contraction). The hollow bulb allows the waterstop to stretch and compress substantially without putting excessive stress on the surrounding concrete or the main sealing elements, thereby maintaining a watertight seal across dynamic joints in large infrastructure like bridges and dam abutments.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager