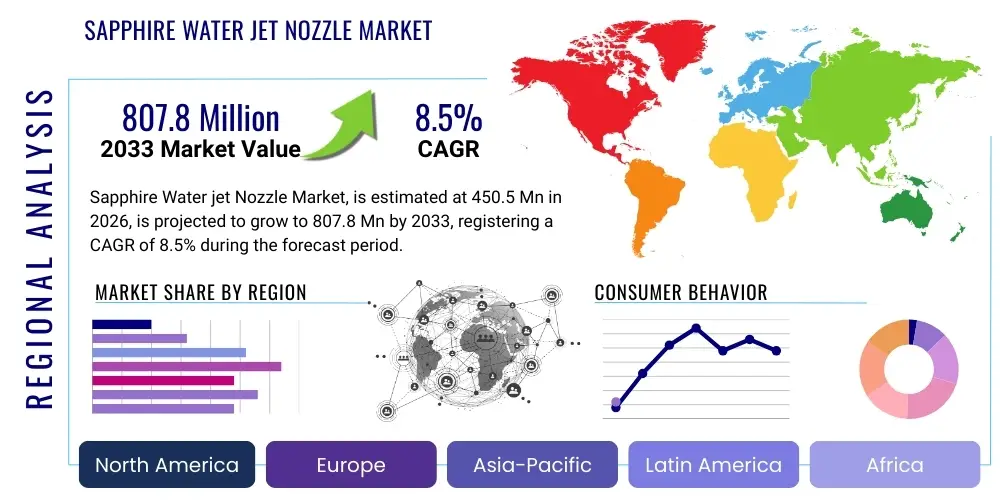

Sapphire Water jet Nozzle Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 442374 | Date : Feb, 2026 | Pages : 258 | Region : Global | Publisher : MRU

Sapphire Water jet Nozzle Market Size

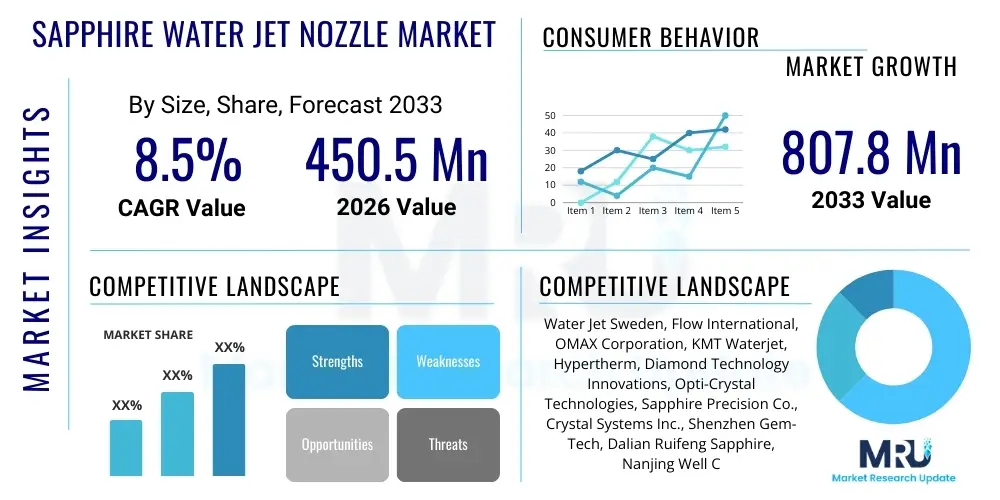

The Sapphire Water jet Nozzle Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.5% between 2026 and 2033. The market is estimated at USD 450.5 Million in 2026 and is projected to reach USD 807.8 Million by the end of the forecast period in 2033. This robust growth trajectory is primarily driven by the increasing global demand for high-precision cutting solutions across complex materials, coupled with the inherent superior wear resistance and durability offered by synthetic sapphire when subjected to ultra-high pressure water flow. The market expansion reflects a critical shift within industries such as aerospace, automotive, and specialized electronics towards materials capable of sustaining extreme operational demands.

Sapphire Water jet Nozzle Market introduction

The Sapphire Water jet Nozzle Market encompasses the manufacturing, distribution, and utilization of nozzles crafted from synthetic sapphire, a material chosen for its exceptional hardness, chemical inertness, and resistance to erosion under immense fluid pressure. These nozzles serve as the critical interface in waterjet cutting systems, shaping the high-velocity water stream—often exceeding 60,000 PSI—to deliver precise cutting power. The product range includes standard orifices, focusing nozzles, and highly specialized micro-nozzles used for extremely intricate tasks.

Major applications of sapphire nozzles span diverse high-value industries, including the precision trimming of composite materials in aerospace, intricate metal cutting in the automotive sector, detailed stone and tile fabrication, and micro-machining within electronics manufacturing. The inherent benefits of using sapphire, such as extended operational life, minimized nozzle replacement downtime, and the ability to maintain a consistent jet stream diameter, translate directly into improved cutting accuracy and overall operational efficiency for end-users. Unlike less durable materials, sapphire resists the abrasive action of water and accompanying garnet particles (in abrasive waterjet applications) for significantly longer periods.

Driving factors for this market include the global expansion of advanced manufacturing processes requiring tighter tolerances and superior edge finishes, particularly in regions investing heavily in infrastructure and high-tech production like Asia Pacific. Furthermore, the increasing complexity of modern materials, such as carbon fiber reinforced polymers (CFRPs) and specialized metal alloys, necessitates non-thermal cutting methods, thereby bolstering the demand for reliable, high-performance sapphire waterjet nozzles. Regulatory emphasis on reducing material waste and improving production sustainability also favors precision cutting technologies.

Sapphire Water jet Nozzle Market Executive Summary

The global Sapphire Water jet Nozzle Market is exhibiting strong business trends characterized by sustained technological advancements focused on optimizing nozzle geometry and enhancing synthetic sapphire purity to improve lifespan and precision. Key market players are concentrating on developing ultra-micro nozzles for emerging applications in medical device manufacturing and semiconductor fabrication, pushing the boundaries of waterjet technology into the realm of micro-machining. Consolidation among raw material suppliers and specialized nozzle manufacturers is also influencing pricing dynamics and supply chain stability, demanding competitive differentiation based on quality assurance and specialized coating technologies.

Regionally, the Asia Pacific (APAC) stands out as the primary growth engine, fueled by massive industrialization, particularly in China, Japan, and South Korea, where the automotive and consumer electronics sectors require constant, high-volume, and precise cutting capabilities. North America and Europe maintain significant market shares, characterized by high adoption rates of advanced, automated waterjet systems in aerospace and specialized fabrication shops, emphasizing longevity and minimal maintenance intervals. These mature markets are driving the demand for specialized, custom-designed sapphire solutions rather than merely standard components.

Segment trends reveal that the Ultra-High Pressure (UHP) segment, defined by operational pressures exceeding 90,000 PSI, is witnessing the fastest expansion due to its requirement for maximum material removal efficiency and fine detail cutting, making sapphire the material of choice for enduring such extreme conditions. By application, the Aerospace & Defense sector remains a highly lucrative segment, valued for its strict quality requirements regarding non-delaminating cuts on layered composites. Furthermore, the increasing availability of specialized sapphire orifice drilling techniques (e.g., laser drilling, focused ion beam milling) is contributing significantly to the market’s positive trajectory by enabling reproducible quality and complex geometric designs.

AI Impact Analysis on Sapphire Water jet Nozzle Market

Analysis of common user questions regarding AI's influence on the Sapphire Water jet Nozzle Market indicates key thematic concerns revolving around automated quality control, predictive nozzle lifespan, and optimization of cutting parameters. Users are primarily asking: "How can AI predict when a sapphire nozzle will fail?", "Can machine learning optimize cutting paths to reduce nozzle wear?", and "Will AI integrated quality inspection systems replace manual checks?" These inquiries highlight the market's expectation that AI will transition waterjet operations from reactive maintenance schedules to proactive, highly efficient processes, ensuring maximum utilization of expensive sapphire components and minimizing unexpected downtime.

AI's role is evolving beyond simple automation into complex system optimization. By utilizing sensor data regarding pump pressure fluctuations, acoustic signatures during cutting, and visual feedback from machine vision systems, AI algorithms can accurately model the current erosion state of the sapphire orifice. This capability allows for highly granular predictions of remaining useful life (RUL), prompting maintenance actions precisely when needed, thereby preventing material wastage due to degraded jet quality and maximizing the value extracted from each sapphire nozzle.

Furthermore, Machine Learning (ML) is instrumental in optimizing the entire cutting process. ML models trained on vast datasets of material properties, cutting speeds, and nozzle performance metrics can dynamically adjust parameters like standoff distance, traverse rate, and pressure settings in real-time. This dynamic optimization reduces localized stresses on the sapphire surface, significantly extending the effective operating duration of the nozzle while ensuring consistent product quality, thus embedding AI as a critical tool for operational excellence in high-precision waterjet cutting.

- Implementation of Predictive Maintenance (PdM) models to forecast nozzle erosion and failure points, maximizing operational uptime.

- Integration of Machine Vision Systems (MVS) and AI algorithms for real-time quality inspection and automatic cut correction, maintaining precision.

- Optimization of complex cutting paths and pressure profiles using Machine Learning to minimize excessive mechanical and thermal stress on the sapphire orifice.

- Automated feedback loops connecting sensor data from pump performance to cutting head health, allowing for proactive adjustments in flow dynamics.

- Enhanced inventory management systems driven by AI demand forecasting for specific nozzle types based on scheduled production requirements.

DRO & Impact Forces Of Sapphire Water jet Nozzle Market

The market for Sapphire Water jet Nozzles is shaped by a confluence of strong drivers pushing adoption, specific restraints limiting widespread use, and significant opportunities for future growth, all influenced by internal and external impact forces. The primary driver remains the unmatched combination of superior hardness, chemical resistance, and thermal stability offered by synthetic sapphire, which is crucial for enduring the erosive environment of Ultra-High Pressure (UHP) waterjet cutting. This technical advantage directly translates into prolonged component life and higher precision outputs compared to traditional tungsten carbide or ceramic options, essential for industries dealing with expensive raw materials.

However, the market faces notable restraints, most prominently the relatively high initial acquisition cost of sapphire nozzles compared to commodity alternatives. While the total cost of ownership (TCO) often favors sapphire due to longevity, the upfront investment can deter smaller enterprises or those with lower-precision requirements. Furthermore, while sapphire is extremely hard, it exhibits a degree of brittleness, making it susceptible to chipping or fracture if subjected to sudden mechanical shocks or extreme pump cavitation, necessitating rigorous operational protocols and specialized maintenance personnel, which adds to the operational complexity.

Significant opportunities exist in emerging high-precision domains, such as the micro-machining of silicon wafers, precision cutting in medical instrumentation (e.g., stents and surgical tools), and the rapidly expanding market for recycling and reclamation processes where clean, non-thermal cutting of complex assemblies is required. The key impact force driving innovation is the continuous advancement in UHP pump technology, which pushes operational pressures higher, mandating corresponding increases in nozzle material performance, positioning sapphire as a crucial enabler for next-generation waterjet systems. Standardization efforts within material grading and nozzle geometry are also internal forces stabilizing supply and enhancing customer confidence.

Segmentation Analysis

The Sapphire Water jet Nozzle Market is thoroughly segmented based on the product characteristics (Type), the operational environment (Pressure), and the specific industry utilizing the cutting equipment (Application). This segmentation helps in understanding the varying demands placed upon sapphire components, ranging from high-throughput industrial cutting to delicate micro-scale precision work. The market structure reflects the technological diversity inherent in modern waterjet cutting, where nozzle characteristics such as orifice size, geometry, and material purity are customized to meet specific performance criteria, driving specialization among manufacturers.

By Type, the distinction is primarily made between standard orifices, typically used for basic abrasive cutting and bulk material removal, and highly engineered precision micro-nozzles, which are critical for applications requiring tolerances below 50 microns, such as in the electronics and medical sectors. The Pressure segmentation is highly critical as it dictates the required purity and structural integrity of the sapphire material. The Ultra-High Pressure (UHP) segment, operating above 60,000 PSI and often reaching 94,000 PSI or more, is the most demanding, requiring flawless synthetic sapphire crystal structures to prevent internal erosion and catastrophic failure, thus capturing the premium end of the market.

The Application segmentation illustrates the primary revenue streams. While traditional heavy industries like Automotive and Stone/Tile remain strong users, the fastest growth is observed in high-value sectors like Aerospace & Defense and Electronics Manufacturing. These sectors prioritize material integrity, non-thermal processing, and exact repeatability, making the consistent performance of sapphire nozzles an indispensable requirement for quality assurance and compliance with rigorous industry standards. This diversity ensures market resilience across various economic cycles.

- By Type:

- Standard Orifice Nozzles

- Focusing Nozzles

- Precision Micro-Nozzles (Small Diameter Orifices)

- By Application:

- Aerospace & Defense

- Automotive Manufacturing

- Stone & Tile Cutting

- Electronics Manufacturing (Semiconductors, PCBs)

- General Machining and Job Shops

- Medical Device Manufacturing

- By Pressure:

- Low-Pressure (Below 30,000 PSI)

- High-Pressure (30,000 - 60,000 PSI)

- Ultra-High Pressure (Above 60,000 PSI)

Value Chain Analysis For Sapphire Water jet Nozzle Market

The value chain for the Sapphire Water jet Nozzle Market begins with the upstream procurement and processing of high-purity raw materials, specifically the growth and synthesis of large, defect-free sapphire boules, typically through methods like the Czochralski or Kyropoulos processes. This initial stage is capital-intensive and highly specialized, with material quality directly correlating to the nozzle’s eventual performance and longevity under UHP conditions. Key players in this phase focus on achieving crystal clarity and minimizing inclusions, which are crucial precursors for durability.

The midstream involves the precision manufacturing of the nozzle itself, which includes slicing the boules, sophisticated laser drilling or mechanical milling to create the precise orifice geometry, and advanced polishing techniques to ensure flawless internal surfaces. Manufacturing quality is paramount, as micro-scratches or irregularities can become initiation points for catastrophic erosion under ultra-high pressure. Downstream activities involve distribution and end-user integration. Distribution channels are bifurcated into direct sales by major waterjet system manufacturers (OEMs), who bundle the nozzles with their equipment, and specialized aftermarket suppliers, who focus on replacements and customized nozzle solutions for existing installations.

The distribution channel is heavily reliant on specialized technical support, given the precise calibration and installation requirements of UHP components. Indirect channels, such as authorized distributors and regional agents, play a critical role, especially in geographically dispersed markets like APAC, ensuring rapid supply and localized technical assistance. The effectiveness of the value chain is determined by the seamless transition from high-purity material science to precision engineering and, finally, to efficient, technically informed distribution, guaranteeing the end-user receives a product capable of sustaining mission-critical precision cutting operations.

Sapphire Water jet Nozzle Market Potential Customers

The primary consumers, or potential customers, in the Sapphire Water jet Nozzle Market are highly specialized industrial entities that require non-thermal, high-precision cutting methods for expensive or complex materials where minimizing material waste and maintaining structural integrity is paramount. These end-users typically operate in environments where component failure leads to significant financial losses and regulatory non-compliance. The ideal customer utilizes Ultra-High Pressure (UHP) waterjet systems in a continuous operation mode, thereby valuing the long lifespan and consistency offered by sapphire over cheaper, less durable alternatives.

Key segments include Tier 1 and Tier 2 suppliers within the Aerospace and Defense industry, specifically those involved in fabricating composite panels, turbine components, and structural elements using advanced alloys and carbon fiber materials. These customers demand strict process control, making the superior dimensional stability of sapphire nozzles non-negotiable. Another crucial customer base resides within the Electronics Manufacturing sector, comprising companies that need to precisely cut printed circuit boards (PCBs), glass substrates for displays, and intricate semiconductor materials without inducing thermal stress or contamination.

Furthermore, large-scale automotive manufacturing plants, particularly those focusing on electric vehicles (EVs) and lightweight alloy components, represent significant potential buyers. These facilities leverage waterjet technology for trimming hydroformed parts and intricate interior components. Finally, specialized medical device manufacturers, particularly those producing micro-components like catheter tips or orthopedic implants, rely entirely on the micro-precision cutting capabilities enabled by the smallest gauge sapphire micro-nozzles, positioning them as high-value, niche customers essential for market growth.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450.5 Million |

| Market Forecast in 2033 | USD 807.8 Million |

| Growth Rate | 8.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Water Jet Sweden, Flow International, OMAX Corporation, KMT Waterjet, Hypertherm, Diamond Technology Innovations, Opti-Crystal Technologies, Sapphire Precision Co., Crystal Systems Inc., Shenzhen Gem-Tech, Dalian Ruifeng Sapphire, Nanjing Well Crystal, Wuxi Haijie Sapphire, Tech-Diamond Tools, Water Jet Corporation, Jet Edge, Resato International, WardJet, Techni Waterjet, CMS Industries. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Sapphire Water jet Nozzle Market Key Technology Landscape

The technological landscape of the Sapphire Water jet Nozzle Market is driven by advancements in three primary areas: sapphire material synthesis, precision orifice manufacturing, and integrated system monitoring. In material synthesis, manufacturers are increasingly focusing on hydrothermal growth and advanced heat treatment processes to create perfectly single-crystalline sapphire with zero internal defects (inclusions or bubbles). This technological focus is critical because imperfections in the crystal structure drastically reduce the nozzle's lifespan when exposed to the severe internal stresses induced by ultra-high pressure water flow, which requires materials capable of enduring cyclic fatigue and erosion.

Precision orifice manufacturing techniques represent the second technological pillar. Traditional mechanical drilling is being superseded by highly controlled processes such as femtosecond laser drilling and Focused Ion Beam (FIB) milling, especially for micro-nozzles (under 100 microns). These non-contact methods allow for the creation of extremely smooth internal walls and complex hydrodynamic geometries—such as venturi or tapered shapes—that optimize the water stream’s coherence and velocity while minimizing cavitation effects, thereby enhancing cutting efficiency and reducing wear rates.

The third critical technology involves the integration of advanced monitoring and diagnostic tools within the waterjet system. Modern UHP pumps are coupled with sensors that track pressure stability, vibration, and flow rates. Crucially, sophisticated acoustic emission sensors and in-situ imaging systems are being developed to detect the onset of internal nozzle erosion or jet stream degradation in real-time. This technological convergence enables the system to proactively adjust operational parameters or flag the need for nozzle replacement, fully leveraging the performance characteristics of the sapphire material through intelligent feedback mechanisms.

Regional Highlights

- Asia Pacific (APAC): APAC dominates the market, primarily driven by mass manufacturing hubs in China, India, Japan, and South Korea. Rapid industrial expansion in the automotive (especially EV components), consumer electronics, and general machinery sectors necessitates reliable, high-speed, and precise cutting solutions. Government initiatives supporting advanced manufacturing techniques further propel the adoption of UHP sapphire waterjet systems, establishing this region as the global growth frontier.

- North America: North America is characterized by high technological maturity and a strong demand from the Aerospace & Defense industry and specialized job shops requiring stringent quality control and complex material processing. The market here focuses on replacement and upgrade cycles, emphasizing highly customized nozzles and integrated AI-driven operational systems to maintain competitive advantage and minimize labor costs.

- Europe: Europe maintains a significant share, driven by stringent quality standards in the German automotive sector and widespread use in specialized machining and medical device production across the continent. The emphasis is on sustainability and automation, leading to strong uptake of high-efficiency, long-life sapphire nozzles that reduce waste and environmental impact.

- Latin America (LATAM): This region is an emerging market, showing steady growth driven by investment in infrastructure and the development of local automotive and mining machinery manufacturing. Adoption is primarily concentrated in industrial centers like Brazil and Mexico, favoring cost-effective, durable solutions where sapphire's long life offsets initial cost hurdles.

- Middle East & Africa (MEA): The MEA market, while smaller, is growing due to diversification efforts in industrialized countries like Saudi Arabia and UAE. Investments in construction, oil and gas infrastructure, and specialized material fabrication create niche demand for reliable waterjet cutting tools, often supplied through international system integrators.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Sapphire Water jet Nozzle Market.- Water Jet Sweden

- Flow International Corporation

- OMAX Corporation

- KMT Waterjet Systems

- Hypertherm Inc.

- Diamond Technology Innovations (DTI)

- Opti-Crystal Technologies

- Sapphire Precision Co., Ltd.

- Crystal Systems Inc.

- Shenzhen Gem-Tech Co., Ltd.

- Dalian Ruifeng Sapphire Technology Co., Ltd.

- Nanjing Well Crystal Co., Ltd.

- Wuxi Haijie Sapphire Technology Co., Ltd.

- Tech-Diamond Tools

- Water Jet Corporation S.r.l.

- Jet Edge Inc.

- Resato International B.V.

- WardJet

- Techni Waterjet

- CMS Industries

Frequently Asked Questions

Analyze common user questions about the Sapphire Water jet Nozzle market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary advantage of using sapphire over ruby or diamond in waterjet nozzles?

Sapphire (synthetic single-crystal corundum) offers superior hardness and is highly erosion-resistant, providing an excellent balance of durability and cost-effectiveness compared to ruby, which is less pure, and diamond, which is more expensive, especially in larger orifice sizes. Sapphire maintains consistent performance under the extreme pressures required for Ultra-High Pressure (UHP) cutting.

How does the lifespan of a Sapphire Water jet Nozzle compare to standard carbide nozzles?

Sapphire nozzles typically offer significantly extended operational life compared to traditional carbide or ceramic alternatives, often lasting hundreds of hours in UHP applications. The precise lifespan depends heavily on the water quality, operational pressure, and whether the system uses abrasive materials, but sapphire's superior structural integrity drastically reduces the frequency of replacement.

Which application segment is driving the highest growth rate for micro-nozzles?

The Electronics Manufacturing and Medical Device Manufacturing sectors are driving the highest growth for precision micro-nozzles. These industries require extremely fine, non-thermal cuts on delicate materials like semiconductors, PCBs, and medical polymers, tasks achievable only with highly accurate, small-diameter sapphire orifices capable of maintaining tight tolerances.

What is the main restraining factor affecting the widespread adoption of sapphire nozzles?

The primary restraining factor is the higher initial acquisition cost compared to conventional nozzle materials. Although the long-term Total Cost of Ownership (TCO) often favors sapphire due to reduced downtime and replacements, the upfront investment can pose a barrier, particularly for small-to-medium enterprises (SMEs) or those not engaged in high-precision, critical cutting operations.

How are AI and automation influencing the efficiency of sapphire waterjet nozzle usage?

AI is influencing efficiency through Predictive Maintenance (PdM) and process optimization. AI algorithms analyze operational data to predict the precise moment a sapphire nozzle requires replacement, minimizing unexpected failures and material waste. Automation ensures the cutting parameters (speed, pressure) are continuously optimized to extend the nozzle’s effective working life while maintaining quality output.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager