Sausage Enema Machine Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 441516 | Date : Feb, 2026 | Pages : 246 | Region : Global | Publisher : MRU

Sausage Enema Machine Market Size

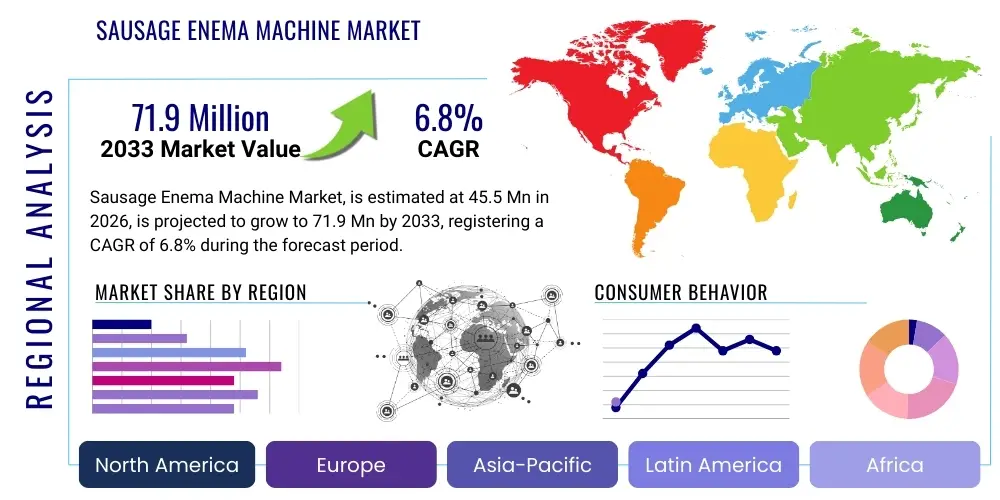

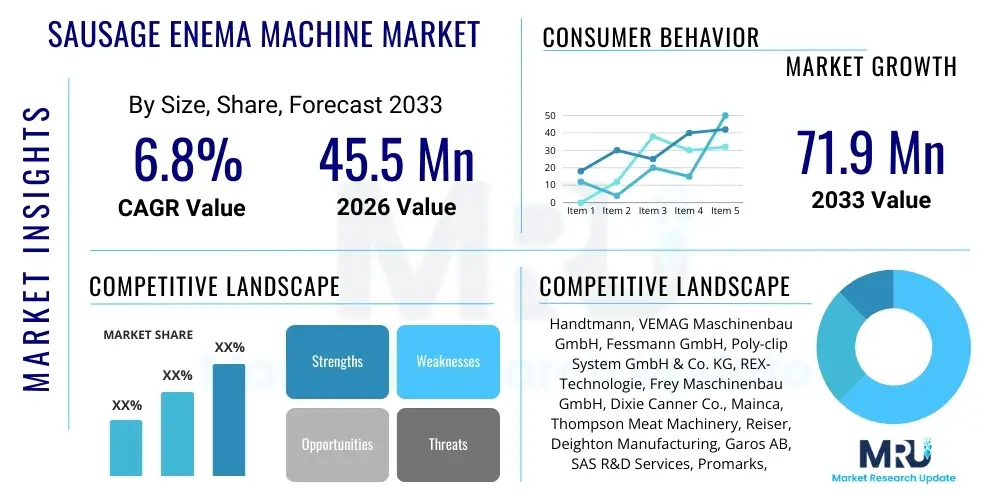

The Sausage Enema Machine Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 45.5 million in 2026 and is projected to reach USD 71.9 million by the end of the forecast period in 2033. This consistent expansion is driven by the global increase in processed meat consumption, stringent food safety regulations necessitating highly specialized and hygienic processing equipment, and the persistent need for automation in high-volume food production facilities worldwide.

Sausage Enema Machine Market introduction

The Sausage Enema Machine Market encompasses specialized industrial equipment primarily utilized in the high-precision stuffing and preparation stages of sausage manufacturing, ensuring uniformity, density control, and casing integrity. While traditionally defined as industrial stuffer and filler systems, the "Enema Machine" designation specifically refers to high-pressure, vacuum-assisted mechanisms crucial for eliminating air pockets and ensuring dense, structurally sound finished products, often incorporating advanced cleansing or preparatory fluid dispensing functionalities for natural casings. Major applications span industrial meat processing plants, small-to-medium enterprise (SME) butcheries, and increasingly, in niche laboratory and specialized chemical processing environments requiring controlled viscous material handling. Key benefits include dramatically improved production efficiency, consistent product quality, reduction in material waste, and enhanced compliance with international hygiene standards (HACCP, ISO 22000). The market is primarily driven by rising global demand for processed foods, technological advancements such as servo-motor integration for precise control, and the critical global imperative to minimize labor costs through automation.

Sausage Enema Machine Market Executive Summary

The Sausage Enema Machine Market is poised for steady growth, characterized by significant business trends favoring automation and precision engineering. Regionally, Asia Pacific is emerging as the fastest-growing market, propelled by rapid industrialization of the food sector and expanding middle-class consumption patterns, while North America and Europe maintain dominance in terms of technological adoption and market maturity due to strict regulatory frameworks. Segment trends indicate a strong shift towards hydraulic and vacuum-based machines, preferred for high-volume continuous operations, alongside substantial investment in machines offering integrated sanitation and monitoring capabilities (IoT sensors). The market structure remains moderately consolidated, with fierce competition centered around equipment reliability, total cost of ownership (TCO), and the provision of comprehensive maintenance services. Strategic initiatives, including mergers and acquisitions focusing on specialized nozzle technology and stainless steel fabrication expertise, are expected to shape the competitive landscape over the forecast period, emphasizing efficiency and longevity.

AI Impact Analysis on Sausage Enema Machine Market

Common user inquiries regarding the impact of Artificial Intelligence (AI) in this specialized machinery sector frequently revolve around predictive maintenance capabilities, quality assurance via visual inspection, and optimization of processing parameters. Users are highly interested in how AI can minimize downtime by forecasting component failure (e.g., piston seals, servo motor issues) before they occur, thus moving operations from reactive to predictive maintenance models. Concerns also center on integrating AI-driven computer vision systems to ensure precise filling consistency, detect foreign material, and verify casing condition in real-time, thereby reducing manual quality control checks and enhancing food safety compliance. Expectations are high regarding AI's ability to automatically adjust stuffing pressures and speeds based on input material viscosity and ambient conditions, leading to optimal yield and minimal product loss. The key themes summarize a desire for increased operational autonomy, improved efficiency, and enhanced verifiable food safety records enabled by sophisticated algorithmic controls.

- AI integration facilitates predictive maintenance scheduling, minimizing unexpected operational downtime.

- Computer Vision Systems (CVS) use AI to ensure precise product consistency and instantaneous quality defect detection.

- Machine Learning (ML) algorithms optimize operational parameters, such as stuffing pressure and vacuum levels, maximizing throughput and material efficiency.

- AI enhances traceability and data logging by correlating raw material batches with specific machine performance metrics.

- Sophisticated AI models assist in supply chain optimization, predicting spare parts demand and inventory levels for critical machine components.

DRO & Impact Forces Of Sausage Enema Machine Market

The Sausage Enema Machine Market is fundamentally shaped by a confluence of accelerating demand for processed food products (Drivers), significant capital investment hurdles and regulatory complexities (Restraints), and the untapped potential for customization and technological convergence (Opportunities), all modulated by high competition and strict safety compliance (Impact Forces). Major drivers include the increasing global population, urbanization leading to reliance on convenience foods, and the escalating need for high-speed, continuous processing equipment capable of handling diverse product specifications. However, the high initial acquisition cost of advanced hydraulic and vacuum stuffers, coupled with the specialized training required for operation and maintenance, acts as a significant restraint, particularly for smaller enterprises in emerging economies. Opportunities exist in developing modular, easily scalable machinery and integrating technologies like remote diagnostics and decentralized control systems (IoT) to provide value-added services. These forces collectively drive manufacturers to invest heavily in R&D focusing on material durability, sanitation features, and energy efficiency, ensuring long-term market sustainability and compliance with ever-evolving global safety standards.

Segmentation Analysis

The Sausage Enema Machine Market is strategically segmented based on factors critical to operational scale, application specificity, and technological complexity, allowing for targeted product development and market penetration strategies. These segments help differentiate high-volume industrial solutions from flexible, smaller-scale commercial units, offering clarity on where capital investment and technological upgrades are most concentrated. The analysis typically covers the type of operational mechanism (Hydraulic, Vacuum, Pneumatic), the degree of automation (Automatic, Semi-Automatic), the end-user application (Commercial, Industrial), and the operational capacity (Low, Medium, High Throughput). Understanding these distinctions is vital for stakeholders assessing market viability and tailoring solutions to specific regional or regulatory demands, particularly regarding sanitation protocols and energy consumption benchmarks.

- By Type:

- Hydraulic Sausage Enema Machines

- Vacuum Sausage Enema Machines

- Pneumatic Sausage Enema Machines

- By Operation Mode:

- Automatic Systems

- Semi-Automatic Systems

- Manual/Batch Systems

- By Capacity:

- Low Capacity (Up to 500 kg/hr)

- Medium Capacity (500 kg/hr to 2,000 kg/hr)

- High Capacity (Above 2,000 kg/hr)

- By End-User Application:

- Industrial Meat Processing Plants

- Commercial Butcheries and Specialty Shops

- Food Testing Laboratories and R&D

- Pharmaceutical and Chemical Processing (Niche Applications)

- By Material of Construction:

- Stainless Steel 304 Grade

- Stainless Steel 316 Grade (High Corrosion Resistance)

Value Chain Analysis For Sausage Enema Machine Market

The value chain for the Sausage Enema Machine Market begins with upstream activities focused on the procurement of high-grade, food-safe materials, primarily specialized stainless steel alloys (304 and 316), precision servo-motors, advanced hydraulic components, and sensor technologies. Component suppliers, often global specialized manufacturers, are crucial in determining the final quality and longevity of the machinery; strict quality control at this initial stage ensures compliance with international food contact standards. Efficiency in upstream logistics, including optimized sourcing of high-precision parts and sub-assemblies (e.g., dosing pumps and vacuum systems), directly impacts the final equipment cost and the manufacturer's ability to maintain competitive pricing and high fabrication standards, requiring strong long-term relationships with certified material providers.

The core manufacturing stage involves complex assembly, welding, and system integration, converting raw materials and sourced components into finished, certified machinery. Downstream analysis focuses on distribution channels and end-user engagement. Direct distribution channels are prevalent for high-value, customized industrial machines, where manufacturers provide installation, specialized training, and ongoing technical support directly to major industrial meat processors. This direct relationship allows for better customization feedback loops and faster resolution of technical issues, which are critical given the high costs of machine downtime in industrial settings.

Conversely, indirect channels, involving authorized distributors, regional agents, and specialized industrial equipment resellers, primarily serve smaller commercial butcheries and niche applications. These intermediaries often manage local inventory, provide first-line maintenance support, and facilitate financing options, acting as critical conduits in fragmented regional markets. The profitability across the value chain is significantly influenced by effective inventory management, adherence to rigorous certification requirements (e.g., CE marking, USDA approval), and the ability to monetize robust after-sales service contracts, including the provision of specialized consumables and genuine spare parts.

Sausage Enema Machine Market Potential Customers

The primary end-users and buyers of Sausage Enema Machines are large-scale industrial meat processors, characterized by high-throughput requirements and continuous production cycles, needing automated systems capable of handling thousands of kilograms of product per hour while maintaining stringent quality control. These industrial clients prioritize machinery robust enough for 24/7 operation, featuring advanced CIP (Clean-In-Place) capabilities, seamless integration with existing processing lines (such as slicers and packaging systems), and precise material dosing controls to ensure minimal variance across product batches. The decision-making process for these major buyers is often centralized, involving engineering teams, procurement specialists, and quality assurance departments, focusing heavily on TCO, reliability metrics, and compliance certifications.

A secondary, yet rapidly expanding, customer segment includes commercial butcheries, regional specialty meat producers, and gourmet food manufacturers. These customers typically require smaller, more flexible, semi-automatic or medium-capacity machines that can handle smaller batches and frequent product changeovers, catering to diverse, high-value specialty sausage recipes. For these buyers, ease of use, smaller physical footprint, and lower initial capital outlay are critical purchasing factors, often favoring reliable, well-supported machinery offered through local distributors or regional equipment suppliers who can provide immediate localized servicing.

Furthermore, niche potential customers include academic and commercial food research laboratories and specific sectors within the pharmaceutical and veterinary industries where precise, hygienic handling and dosing of viscous or semi-solid materials are mandatory. These specialized applications often demand machines constructed of the highest-grade materials (316L stainless steel), requiring precise volumetric accuracy and validated sterilization protocols. Their purchasing decisions are driven less by throughput volume and more by verifiable precision, sterility assurance, and the machine's ability to interface with sophisticated testing or compounding apparatus, often justifying premium pricing for highly customized units.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 45.5 million |

| Market Forecast in 2033 | USD 71.9 million |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Handtmann, VEMAG Maschinenbau GmbH, Fessmann GmbH, Poly-clip System GmbH & Co. KG, REX-Technologie, Frey Maschinenbau GmbH, Dixie Canner Co., Mainca, Thompson Meat Machinery, Reiser, Deighton Manufacturing, Garos AB, SAS R&D Services, Promarks, Marel, GEA Group, FPS Food Process Solutions, Laska, Risco SpA, JBT Corporation |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Sausage Enema Machine Market Key Technology Landscape

The technological landscape of the Sausage Enema Machine Market is increasingly dominated by servo-motor driven technology, which offers superior precision, faster response times, and higher energy efficiency compared to traditional hydraulic systems, particularly in large industrial stuffing applications. These advanced machines integrate sophisticated Programmable Logic Controllers (PLCs) and HMI (Human-Machine Interface) touchscreens, allowing operators precise digital control over vacuum levels, stuffing speeds, twisting frequency, and portion weights, drastically minimizing product variance. The shift towards electromechanical actuation facilitates faster cleaning and reduced contamination risk by eliminating hydraulic fluids, aligning with contemporary global food safety mandates. Manufacturers are prioritizing modular construction and tool-less assembly designs to optimize sanitation processes, featuring sloped surfaces and minimal exposed wiring to prevent bacteria accumulation (hygienic design principles).

Another crucial technological development involves integrated real-time monitoring and connectivity, leveraging IoT sensors embedded in critical components like pistons, rotating cutters, and vacuum pumps. This connectivity allows for continuous performance data logging, remote diagnostics, and integration into overall factory automation systems (Industry 4.0 principles). The data collected informs predictive maintenance algorithms, significantly improving operational uptime by allowing parts replacement before failure occurs. Furthermore, advancements in specialized nozzle and filling head designs enable the machinery to handle an ever-wider array of casing materials, including natural, collagen, and sophisticated fibrous casings, while maintaining high product integrity and reducing breakage rates during high-speed processing.

Material science also plays a vital role, with a focus on employing specialized high-grade, corrosion-resistant stainless steel (often 316L for high-acidity environments) and FDA-approved polymers for contact parts, extending machine lifespan and resisting chemical cleaning agents. The development of advanced vacuum technology is critical, ensuring maximum air removal from the meat emulsion prior to stuffing, which is essential for texture quality, shelf life extension, and accurate portion control. Finally, the incorporation of automated linking and clipping mechanisms directly integrated with the stuffer represents a key technological convergence, creating highly efficient, single-operator continuous production lines, maximizing efficiency per square foot of factory floor space.

Regional Highlights

- North America: This region maintains a mature market driven by high labor costs, which necessitates maximum automation, and some of the world's most stringent regulatory standards (USDA/FDA). Demand is centered on high-capacity, fully automatic vacuum stuffers featuring advanced IoT integration for predictive maintenance and verifiable traceability features. The market sees consistent investment in replacing older hydraulic equipment with energy-efficient servo-driven models.

- Europe: Characterized by highly diverse national food cultures, the European market is split between large centralized industrial processors (Germany, Spain, Netherlands) and numerous specialty producers who prioritize flexibility and product quality. The region leads in hygienic design and sustainable practices, demanding machines with optimal water and energy usage. Compliance with EU regulations (like the Machinery Directive and specific hygiene legislation) dictates machine specifications, favoring manufacturers who can provide comprehensive certification documentation.

- Asia Pacific (APAC): The APAC region represents the fastest-growing market, primarily fueled by increasing meat consumption, rapid urbanization, and significant foreign direct investment into food processing infrastructure, particularly in China, India, and Southeast Asian nations. While price sensitivity remains a factor, the shift is rapidly moving toward acquiring medium to high-capacity semi-automatic and automatic machines to meet escalating domestic and export demands, with a strong emphasis on reliability and ease of local servicing.

- Latin America: Market growth here is linked to the strong domestic beef and pork production industries (Brazil, Argentina). Demand often focuses on durable, robust machinery that can handle varied meat qualities and operating conditions, often with less dependence on complex electronic controls due to potential infrastructure volatility. Investment decisions are highly sensitive to import tariffs and currency fluctuations, favoring suppliers with localized assembly or strong regional distribution partnerships.

- Middle East and Africa (MEA): This is an emerging market driven by the construction of modern food processing facilities, particularly in Gulf Cooperation Council (GCC) countries focused on food security and export diversification. The demand profile is bifurcated, with high-end machinery purchased for new, large-scale facilities, and more budget-conscious, reliable, entry-level equipment sought in other African countries where market infrastructure is still developing.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Sausage Enema Machine Market.- Handtmann

- VEMAG Maschinenbau GmbH

- Fessmann GmbH

- Poly-clip System GmbH & Co. KG

- REX-Technologie

- Frey Maschinenbau GmbH

- Dixie Canner Co.

- Mainca

- Thompson Meat Machinery

- Reiser

- Deighton Manufacturing

- Garos AB

- SAS R&D Services

- Promarks

- Marel

- GEA Group

- FPS Food Process Solutions

- Laska

- Risco SpA

- JBT Corporation

- Kramer Grebe

- Selo

- Hoegger Food Technology

- Holac Maschinenbau GmbH

Frequently Asked Questions

Analyze common user questions about the Sausage Enema Machine market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary advantages of Vacuum Sausage Enema Machines over Hydraulic models?

Vacuum Sausage Enema Machines offer superior product quality by removing air pockets from the filling material prior to stuffing, resulting in denser, more consistent products with improved shelf life and reduced oxidation. While hydraulic systems offer robust power for extremely stiff fillings, vacuum systems provide greater filling precision and are often better suited for high-speed automatic linking and portion control, leading to higher yield efficiency.

How do stringent food safety regulations influence the design and cost of Sausage Enema Machinery?

Food safety regulations mandate hygienic design principles, requiring machines to utilize food-grade stainless steel (often 316L), feature easily accessible components for thorough cleaning, and incorporate Clean-In-Place (CIP) technology. This focus on sanitation increases fabrication complexity and material costs but is essential for regulatory compliance (HACCP, USDA) and minimizing cross-contamination risks for the end-user.

Which geographical region exhibits the highest growth potential for industrial Sausage Enema Machines?

The Asia Pacific (APAC) region is projected to demonstrate the highest growth potential, driven by rapid industrialization, increasing urbanization leading to greater processed food consumption, and large-scale government investments in modernizing food processing infrastructure across key economies like China, India, and Southeast Asia, creating significant demand for mid- to high-capacity automatic systems.

What role does automation play in the competitive landscape of this market?

Automation is a critical competitive differentiator, driving the demand for fully automatic systems integrated with computerized control and linking mechanisms. High levels of automation minimize manual labor costs, maximize throughput capacity, and ensure superior product weight and length consistency, offering a lower Total Cost of Ownership (TCO) for large industrial processors, thereby favoring manufacturers specializing in advanced servo technology.

How is Industry 4.0 technology, such as IoT and AI, being applied to Sausage Enema Machines?

Industry 4.0 principles are realized through the integration of IoT sensors for real-time performance monitoring and data logging, facilitating predictive maintenance to minimize unscheduled downtime. AI algorithms utilize this data to optimize operational settings, such as stuffing pressure and speed, based on material characteristics, leading to enhanced quality control, improved traceability, and overall operational efficiency improvements.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager