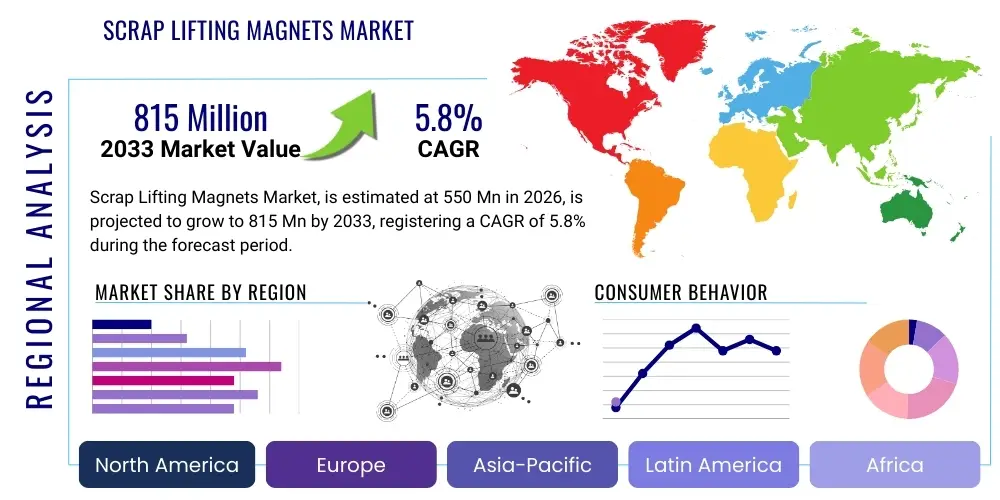

Scrap Lifting Magnets Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 441999 | Date : Feb, 2026 | Pages : 258 | Region : Global | Publisher : MRU

Scrap Lifting Magnets Market Size

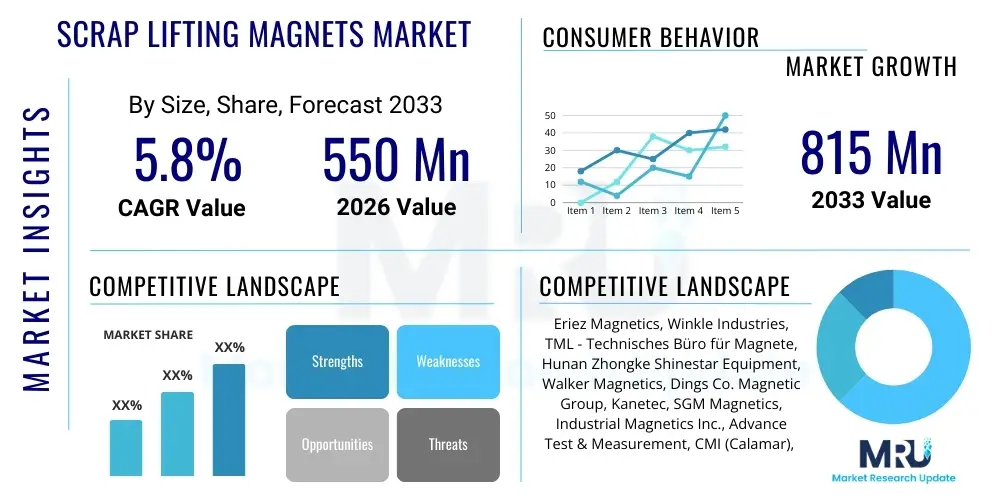

The Scrap Lifting Magnets Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 550 Million in 2026 and is projected to reach USD 815 Million by the end of the forecast period in 2033.

Scrap Lifting Magnets Market introduction

Scrap lifting magnets are industrial tools essential for the efficient handling and transportation of ferrous materials, primarily utilized across the metal recycling, steel production, and shipbuilding sectors. These devices, which operate based on powerful electromagnetic or permanent magnetic principles, are designed to securely lift, sort, and move large volumes of metal scrap, reducing manual labor requirements and significantly enhancing operational safety and throughput in environments characterized by heavy-duty material handling. The core function involves generating a strong magnetic field sufficient to penetrate dense loads of mixed metallic debris, ensuring secure conveyance to processing areas or loading docks.

The primary applications of these magnets are concentrated in environments where high-volume ferrous waste sorting and movement are critical, such as electric arc furnace (EAF) steel mills, major scrap processing yards, foundries, and ports handling large shipments of salvaged metal. Beyond basic lifting, modern magnets often feature advanced heat dissipation systems and rugged construction to withstand harsh operating conditions, including high temperatures and abrasive material contact. This durability is crucial given the demanding duty cycles required in 24/7 industrial settings, making the selection of the appropriate magnet type (deep-field, standard-lift, or battery-operated) paramount to optimizing workflow.

Driving factors propelling market expansion include the global push toward sustainable resource management, necessitating higher recycling rates for steel and iron, and concurrent infrastructural growth, particularly in developing economies, which fuels massive demand for ferrous metals. The benefits derived from employing specialized scrap magnets—including reduced processing time, minimized risk of physical injury associated with manual handling, and improved purity of sorted scrap streams—further solidify their irreplaceable role in the global metallurgical and recycling value chain. Continuous technological advancements focused on reducing energy consumption and increasing lift capacity are also sustaining market momentum.

Scrap Lifting Magnets Market Executive Summary

The Scrap Lifting Magnets Market exhibits robust growth driven primarily by surging global steel production, the increasing necessity for highly efficient scrap processing to meet stringent quality standards, and favorable government policies promoting circular economy practices across major industrial nations. Current business trends indicate a significant shift toward high-duty cycle electromagnets and the adoption of portable, battery-powered solutions designed for mobile operations and reduced reliance on dedicated power sources. Furthermore, integration with automated handling systems, such as overhead cranes and excavators equipped with quick-change mechanisms, is becoming standard practice to maximize utilization and operational flexibility, thus optimizing total cost of ownership (TCO) for end-users.

Regional trends highlight the Asia Pacific (APAC) region, spearheaded by China and India, as the foremost growth engine, owing to massive infrastructure projects, burgeoning steel manufacturing capacities, and the region's concentration of ship breaking and large-scale industrial dismantling activities. Conversely, markets in North America and Europe, while mature, are characterized by high adoption rates of premium, technologically advanced magnets focusing on safety features, advanced power management systems, and digitalization features like remote monitoring and predictive maintenance interfaces. These mature markets are demanding magnets that not only lift efficiently but also integrate seamlessly with sophisticated operational planning software.

Segmentation analysis underscores the dominance of the Electromagnet segment, valued for its superior lift capacity and controllable magnetic field, especially in heavy-duty, high-volume applications like steel mills. However, the Permanent and Electro-Permanent magnet segments are gaining traction in applications where power availability is limited or energy efficiency is prioritized, such as in smaller scrap yards or temporary sites. Application-wise, the steel manufacturing industry remains the largest consumer, though the recycling and dismantling sectors are projected to show the fastest growth rate as global recycling mandates intensify, dictating continuous innovation in magnet design to handle increasingly complex and mixed scrap materials effectively.

AI Impact Analysis on Scrap Lifting Magnets Market

Common user inquiries regarding the impact of Artificial Intelligence (AI) on the Scrap Lifting Magnets Market frequently center on predictive maintenance scheduling, optimization of power consumption relative to material density, and the integration of machine vision for enhanced scrap sorting and identification. Users are keen to understand how AI algorithms can leverage real-time operational data (such as voltage levels, temperature readings, and duty cycle duration) to forecast potential component failure, thereby minimizing unexpected downtime which is highly costly in capital-intensive industries. Furthermore, substantial interest exists in utilizing AI to fine-tune magnetic strength dynamically based on load characteristics, ensuring maximum lift efficiency while preventing premature magnet wear or excessive energy expenditure. The consensus theme emerging from these inquiries is the expectation that AI will transform scrap handling from a heavy mechanical process into an optimized, data-driven operation, directly impacting profitability and operational lifespan.

AI's primary influence is moving beyond simple data logging toward creating truly intelligent material handling systems. By integrating AI-powered analytics with crane control systems and magnet power units, operators can achieve unprecedented levels of efficiency. For example, machine learning models can analyze historical lift data combined with current scrap chemical composition (if coupled with rapid testing mechanisms) to determine the exact magnetic field required for optimal lift and release, minimizing residual adhesion and maximizing cycle time. This transition represents a significant leap from traditional, fixed-parameter operations to dynamic, self-optimizing material flow management.

Additionally, AI-driven visual inspection systems are set to revolutionize the quality control aspect of scrap processing. When paired with high-definition cameras mounted on the magnet rig, AI can identify non-ferrous contaminants or high-value alloy pieces mixed within the general ferrous scrap stream. This advanced sorting capability increases the purity of the end product sold to steel mills, commanding higher prices and enhancing the overall profitability of the recycling operation. The integration of these intelligent systems ensures that scrap yards evolve into sophisticated material recovery facilities, positioning AI as a crucial enabler for market growth, safety improvement, and environmental compliance.

- AI-driven Predictive Maintenance: Analyzing current usage parameters (heat, voltage, vibration) to predict magnet failure and schedule proactive maintenance, maximizing uptime.

- Dynamic Power Optimization: Machine learning algorithms adjust magnetic field intensity based on real-time scrap density and load weight, reducing energy waste per lift cycle.

- Automated Scrap Sorting and Identification: Integrating AI vision systems with magnets to differentiate ferrous grades and identify non-ferrous contamination, enhancing scrap purity.

- Autonomous Crane Operation Integration: Enabling magnets to interface with fully autonomous crane and robotic systems for consistent, high-speed material handling.

- Optimized Inventory Management: Using AI to map and track the location and type of scrap piles in large yards, optimizing retrieval routes and storage efficiency.

DRO & Impact Forces Of Scrap Lifting Magnets Market

The Scrap Lifting Magnets Market is fundamentally driven by the escalating global demand for steel, particularly from rapidly industrializing regions, which necessitates a parallel expansion in cost-effective and reliable methods for sourcing scrap metal. Regulatory pressures worldwide, aimed at achieving carbon neutrality and encouraging resource conservation, actively favor the use of recycled steel (EAF route) over virgin steel production (BF-BOF route), directly boosting the demand for high-performance lifting magnets capable of maximizing scrap utilization. Furthermore, continuous product innovation, such as the development of lightweight, robust magnetic systems with improved duty cycles and enhanced heat resistance, addresses key operational pain points and acts as a significant market accelerant, ensuring magnets remain essential capital equipment.

Conversely, the market faces notable restraints, including the high initial capital expenditure associated with purchasing heavy-duty, advanced electromagnetic systems and the fluctuating prices of core raw materials such as copper windings and specialized steel alloys, which impact manufacturing costs. Power consumption remains a long-standing challenge for traditional electromagnets, placing an operational cost burden on end-users, especially those in regions with expensive energy tariffs. Moreover, the stringent safety regulations governing heavy lifting equipment require substantial compliance costs, though these regulations also drive innovation in safety features, creating a dual effect on market dynamics.

Significant opportunities lie in the rapidly expanding marine and offshore decommissioning sector, which generates vast quantities of ferrous scrap requiring specialized, high-capacity lifting solutions. The proliferation of battery-powered and electro-permanent magnets presents a major avenue for growth by offering energy efficiency and operational flexibility, especially in mobile applications or remote sites where continuous power supply is problematic. The increasing integration of IoT and remote monitoring capabilities into magnet systems provides an opportunity for manufacturers to offer high-value services, such as predictive maintenance contracts and operational efficiency consulting, thereby creating new revenue streams beyond hardware sales and strengthening manufacturer-customer relationships.

- Drivers: High global steel demand; strict environmental mandates favoring steel recycling; increased efficiency and safety provided by modern magnetic systems; growth in construction and automotive industries.

- Restraints: High upfront investment and installation costs; vulnerability to fluctuating raw material prices (copper, steel); significant power consumption of traditional electromagnetic models; specialized maintenance requirements.

- Opportunities: Growing adoption of energy-efficient battery-powered magnets; expansion into emerging economies infrastructure projects; rising demand in specialized applications (e.g., shipbreaking, rail dismantling); integration with advanced IoT and automation systems.

- Impact Forces: Technological advances (high-duty cycle, low energy consumption) create competitive pressure; market concentration among a few major global players; economic volatility impacting infrastructure spending; regulatory landscape governing crane and lifting equipment safety standards.

Segmentation Analysis

The Scrap Lifting Magnets Market is comprehensively segmented based on technology type, application area, lifting capacity, and specific design characteristics, offering granular insight into market dynamics and end-user preferences. The segmentation by type is crucial as it determines the fundamental operational mechanism—Electromagnetic, which provides high lift capacity and magnetic field control, versus Permanent and Electro-Permanent, which emphasize energy efficiency and sustained lifting without constant power input. Analyzing these segments helps stakeholders understand where technological investment is most required and how product offerings should be tailored to match varying operational requirements, such as duty cycle demands and available power infrastructure.

Further analysis by application highlights the distinct requirements of different end-user industries. Steel mills demand magnets optimized for handling hot materials and continuous duty cycles, often requiring robust, high-temperature designs, while scrap yards prioritize versatility and portability for sorting mixed loads across expansive outdoor spaces. The capacity segmentation, categorized by weight capability, is critical for manufacturers to align product portfolios with the size and scale of operations—ranging from small, portable units used on excavators to massive magnets mounted on dedicated gantry cranes in major steel production facilities, ensuring appropriate power-to-weight ratios are maintained.

The convergence of these segments defines the competitive landscape. For instance, the demand for Electro-Permanent magnets in the recycling application segment is growing due to their safety benefits (maintaining lift even during power failure) and reduced running costs, positioning them as a premium solution. This detailed segmentation allows market participants to identify lucrative niches, such as high-temperature magnets for specialized foundry applications or robust, weather-proof magnets for port and marine use, ultimately guiding strategic resource allocation and targeted marketing efforts within the global industrial market.

- By Type:

- Electromagnetic Lifting Magnets (Circular, Rectangular, Bipolar)

- Permanent Lifting Magnets

- Electro-Permanent Lifting Magnets

- By Application:

- Steel Mills and Foundries

- Scrap Processing and Recycling Yards

- Ports and Shipbuilding

- Railroad Maintenance and Dismantling

- Automotive and Manufacturing

- By Lifting Capacity:

- Light Duty (Below 5 Tons)

- Medium Duty (5 to 15 Tons)

- Heavy Duty (Above 15 Tons)

- By Power Source:

- Electric-Powered (Generator/Line Power)

- Battery-Powered

Value Chain Analysis For Scrap Lifting Magnets Market

The value chain for the Scrap Lifting Magnets Market begins with upstream analysis, which encompasses the sourcing and processing of critical raw materials. Key inputs include high-grade ferrous alloys (steel casings), non-ferrous metals (primarily copper for magnet windings), and advanced insulation materials designed for high-temperature and harsh industrial environments. Price volatility in global copper and steel markets significantly impacts the manufacturing costs and final pricing of the magnets. Efficiency in sourcing these materials and maintaining stable supply agreements are paramount for controlling production costs and ensuring timely delivery of components to the assembly stage.

The manufacturing and assembly stage involves core specialization, where manufacturers focus heavily on robust design, efficient coil winding techniques, and integrating power control systems. Quality control during this phase is crucial, particularly testing magnetic field strength, heat dissipation efficiency, and overall durability to meet stringent industry safety standards. Distribution channels are varied, including direct sales from manufacturers to large steel corporations or integrated scrap processing companies, indirect sales through a network of specialized industrial equipment distributors, and engagement with Original Equipment Manufacturers (OEMs) who integrate the magnets onto cranes or excavators as part of a complete material handling package.

Downstream analysis focuses on the end-users—scrap processors, steel mills, and foundries—who utilize the magnets for sorting, loading, and handling scrap metal. Post-sales service, including maintenance, repair, and the provision of replacement parts (such as control panels or power cables), forms a crucial component of the value chain, ensuring prolonged product lifespan and maximizing asset utilization for the customer. The shift toward digital integration (IoT sensors) is increasingly blurring the line between product and service, as manufacturers offer sophisticated monitoring and predictive maintenance services, adding significant value downstream and strengthening customer loyalty.

Scrap Lifting Magnets Market Potential Customers

Potential customers for scrap lifting magnets primarily consist of heavy industrial organizations involved in the generation, processing, and consumption of ferrous scrap metal. The largest customer segment remains integrated steel mills and Electric Arc Furnace (EAF) operators. These high-volume users require continuous, high-duty cycle electromagnetic systems to quickly load scrap into furnaces, necessitating magnets with maximum lift capacity and high thermal resistance to handle preheated or hot materials. Their purchasing decisions are driven by total cost of ownership, energy efficiency, and reliable uptime, making long-term performance guarantees a key factor.

The second major group includes independent scrap metal processing and recycling yards. These entities require a versatile fleet of magnets, ranging from large crane-mounted units for bulk loading to smaller, mobile magnets attached to excavators for detailed sorting and yard clean-up. Buyers in this segment prioritize magnet portability, the ability to operate effectively on battery power in decentralized locations, and resistance to harsh weather conditions. Their demand for sorting accuracy is also increasing due to tightening regulations on scrap purity, making advanced magnet designs appealing.

Other significant buyers encompass port authorities, shipbuilding and ship repair facilities, and large-scale industrial dismantling contractors. Port customers use magnets to load and unload bulk ferrous cargo efficiently, demanding durability against saltwater exposure and consistent performance. Dismantling contractors, particularly those involved in railway or infrastructure demolition, require robust, often rectangular magnets capable of lifting long, heavy sections of metal structure. These diverse customer needs underscore the necessity for manufacturers to maintain a wide product portfolio optimized for highly specific operational environments and regulatory compliance.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 550 Million |

| Market Forecast in 2033 | USD 815 Million |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Eriez Magnetics, Winkle Industries, TML - Technisches Büro für Magnete, Hunan Zhongke Shinestar Equipment, Walker Magnetics, Dings Co. Magnetic Group, Kanetec, SGM Magnetics, Industrial Magnetics Inc., Advance Test & Measurement, CMI (Calamar), Master Magnets (Bunting Magnetics), Magna-Power, Moley Magnetics, SIBRE Siegerland, Magnets and More, Atlas Material Handling, Anhui Guandong Magnetic, Nanjing KELK Electric Co., Hangzhou Hengli Magnetic |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Scrap Lifting Magnets Market Key Technology Landscape

The technology landscape in the Scrap Lifting Magnets Market is undergoing significant evolution, primarily driven by the imperative to increase energy efficiency, enhance operational safety, and integrate with modern automation systems. A central innovation is the widespread adoption of high-duty cycle electromagnets, which incorporate advanced cooling techniques, often utilizing forced air or specialized thermal insulation materials, allowing them to operate effectively for longer periods without overheating. This technological shift is crucial for high-throughput environments like continuous steel production, where minimizing recovery time between lift cycles directly translates to substantial productivity gains and energy savings by reducing the thermal load on the electrical components.

Furthermore, the development and refinement of battery-powered magnetic systems represent a major disruptive technology. These units utilize high-capacity, often lithium-ion, batteries to provide power, eliminating the need for trailing cables or dedicated generator sets, thereby enhancing the mobility and flexibility of the magnet, especially when paired with mobile machinery like excavators and loaders. The electro-permanent magnet technology, which uses a momentary current pulse to turn the magnetic field on or off while maintaining the lift through permanent magnets, offers a compelling balance of high holding force and near-zero power consumption during the actual lifting phase. This focus on portable and energy-independent solutions is opening up new market segments and driving magnet penetration into smaller-scale operations.

Digitalization is another critical technological frontier, with manufacturers integrating Internet of Things (IoT) sensors and telemetry systems directly into the magnet structure and control units. These smart systems monitor key performance indicators such as temperature, voltage stability, lift duration, and total usage cycles in real-time. This data is leveraged for sophisticated remote diagnostics and predictive maintenance scheduling, allowing operators to preemptively address coil degradation or power unit failures, significantly reducing unscheduled downtime. This integration of smart technology transforms the magnet from a simple mechanical lifting device into a data-generating asset essential for optimizing overall material flow and operational planning.

Regional Highlights

- Asia Pacific (APAC): APAC dominates the global scrap lifting magnets market, largely attributed to rapid industrialization, massive government spending on infrastructure, and the region's status as the world's primary hub for steel production (especially China and India). The strong presence of ship breaking yards and a growing emphasis on localized metal recycling contribute significantly to high demand. Market growth is further accelerated by the introduction of stringent environmental regulations requiring high-purity scrap input, thereby fueling demand for advanced sorting and lifting magnets. Investment here is focused on volume, capacity, and increasingly, high-temperature magnet applications in booming foundry sectors.

- North America: North America represents a mature yet technologically advanced market. Demand is steady, primarily driven by the replacement of aging equipment and the adoption of premium, high-efficiency magnet systems. The key trend here is the shift toward battery-powered and electro-permanent magnets for enhanced operational safety and flexibility in recycling yards. Regulatory adherence to OSHA standards mandates investments in state-of-the-art safety features and integrated monitoring systems, making the U.S. and Canada key markets for manufacturers specializing in advanced magnet controls and IoT integration.

- Europe: The European market is characterized by high environmental consciousness and a strong commitment to circular economy principles, leading to sustained demand for scrap processing equipment. European companies prioritize energy efficiency and low noise operation. Strict regulations on industrial emissions and waste management ensure a steady replacement cycle for older, less efficient magnetic systems. Germany, Italy, and the UK are primary markets, showing high demand for customized magnetic solutions integrated into fully automated material recovery facilities (MRFs).

- Latin America (LATAM): LATAM is an emerging high-growth market, spurred by regional economic recovery, increased foreign direct investment in mining and construction, and expanding local steel production capacity, particularly in Brazil and Mexico. The market is highly price-sensitive, with increasing adoption of standard electromagnetic magnets to boost initial efficiency in foundational recycling infrastructure. Opportunities abound as local regulations slowly tighten, driving the necessity for more formalized and mechanized scrap processing operations.

- Middle East and Africa (MEA): The MEA region is experiencing accelerated growth, driven largely by significant infrastructure development related to oil & gas and urban expansion projects, especially in the GCC nations. Demand is focused on heavy-duty magnets for port operations, construction, and emerging steel production facilities. The market is gradually moving toward advanced, ruggedized magnets capable of withstanding the extreme high temperatures and dust prevalent in the regional climate, representing strong potential for specialized product sales.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Scrap Lifting Magnets Market.- Eriez Magnetics

- Winkle Industries

- TML - Technisches Büro für Magnete

- Hunan Zhongke Shinestar Equipment

- Walker Magnetics

- Dings Co. Magnetic Group

- Kanetec

- SGM Magnetics

- Industrial Magnetics Inc.

- Advance Test & Measurement

- CMI (Calamar)

- Master Magnets (Bunting Magnetics)

- SIBRE Siegerland

- Magna-Power

- Moley Magnetics

- Atlas Material Handling

- Anhui Guandong Magnetic

- Nanjing KELK Electric Co.

- Hangzhou Hengli Magnetic

- Electro-Magnetic Systems (EMS)

Frequently Asked Questions

Analyze common user questions about the Scrap Lifting Magnets market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary advantages of Electromagnetic Scrap Lifters over Permanent Magnets?

Electromagnetic scrap lifters offer significantly higher lifting capacity and the ability to instantly turn the magnetic field completely off, ensuring precise release of the load. They are ideal for heavy-duty, continuous operation in large steel mills or recycling yards where controlled release is critical, whereas permanent magnets are chosen for energy efficiency and fail-safe lifting during power outages.

How does magnet duty cycle affect operational efficiency and selection?

The duty cycle (percentage of time the magnet can be safely energized within a fixed period, usually 10 minutes) is crucial for efficiency. A high-duty cycle magnet (e.g., 75%) is essential for continuous loading operations like feeding an EAF, minimizing downtime due to magnet overheating and maximizing throughput, justifying a higher initial investment.

What is the current trend regarding battery-powered scrap lifting magnets?

Battery-powered magnets are a rapidly growing segment, driven by the need for increased mobility and reduced energy costs. They eliminate complex cabling, enhance safety, and are primarily used on mobile equipment like excavators for sorting and clean-up in yards and remote sites, offering superior flexibility compared to traditional line-powered units.

Which geographical region exhibits the fastest growth potential in this market?

The Asia Pacific (APAC) region, particularly driven by China and India, shows the fastest growth potential due to massive infrastructure development, escalating steel production demands, and expanding industrial recycling initiatives that require high volumes of scrap handling equipment.

What maintenance considerations are critical for maximizing the lifespan of scrap lifting magnets?

Critical maintenance includes regularly inspecting the magnet casing for physical damage, checking electrical connections and insulation integrity, and closely monitoring the control system for signs of thermal stress. Implementing predictive maintenance using integrated IoT sensors is the modern best practice to prevent catastrophic coil failure and ensure optimal operational life.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Scrap Lifting Magnets Market Statistics 2025 Analysis By Application (Metal Industries, Recycling Industries, Quarrying Industries, Others), By Type (Round Scrap Lifting Magnets, Rectangular Scrap Lifting Magnets), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Scrap Lifting Magnets Market Statistics 2025 Analysis By Application (Foundry Industries, Recycling Industries), By Type (Rectangular Magnets, Circular Magnets), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager