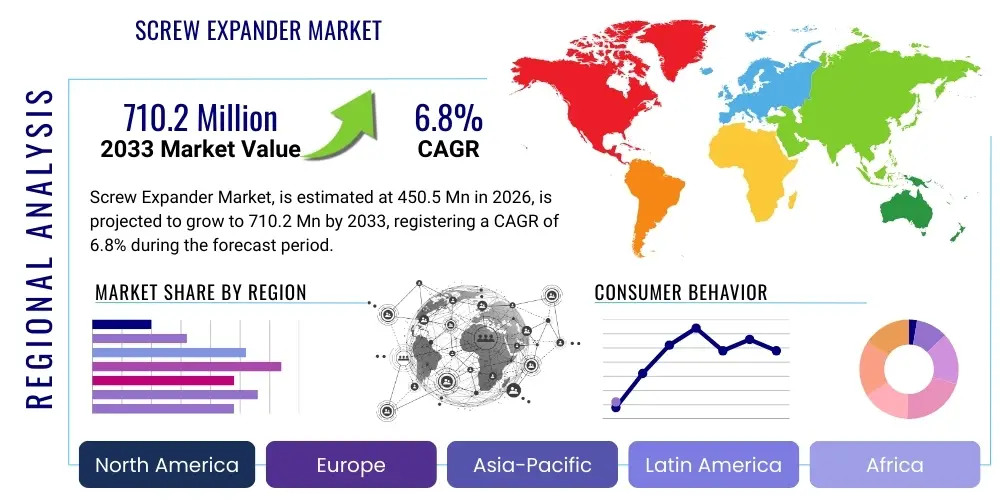

Screw Expander Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 443394 | Date : Feb, 2026 | Pages : 246 | Region : Global | Publisher : MRU

Screw Expander Market Size

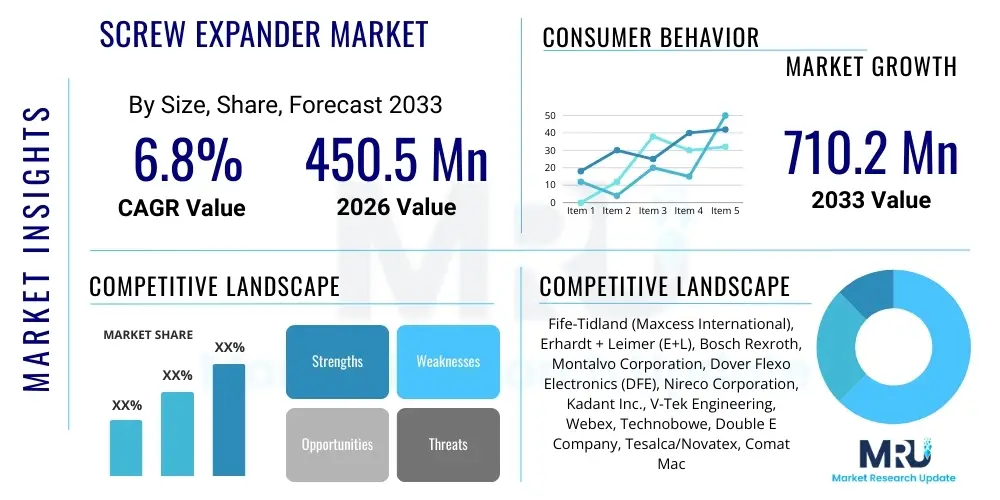

The Screw Expander Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 450.5 Million in 2026 and is projected to reach USD 710.2 Million by the end of the forecast period in 2033.

Screw Expander Market introduction

The Screw Expander Market encompasses the global trade and utilization of industrial machinery components, primarily specialized rollers or spreaders designed to eliminate wrinkles, creases, and slack edges in web processing applications across various industries such as textiles, paper and pulp, plastic films, and printing. These devices, often known as bowed rollers or banana rolls, utilize a fixed or variable degree of curvature and rotation to laterally spread the material web, ensuring optimal flatness and tension control before subsequent processes like coating, laminating, or winding. The fundamental mechanism involves applying tangential force to the moving material, thereby preventing dimensional instabilities that can compromise product quality and operational efficiency. The market growth is fundamentally driven by the increasing demand for high-speed, high-precision manufacturing processes and the necessity to handle sophisticated, thin-gauge materials like advanced polymer films and non-woven fabrics, which are inherently prone to wrinkling. Furthermore, the expansion of packaging and flexible electronics manufacturing sectors necessitates robust web handling solutions that Screw Expanders provide.

Screw Expander Market Executive Summary

The global Screw Expander market is experiencing robust expansion, fundamentally underpinned by aggressive industrial automation trends and capacity expansions in Asia Pacific’s manufacturing hubs, particularly in the flexible packaging and textile industries. Key business trends indicate a shift towards technologically advanced screw expanders offering automated adjustment capabilities (smart bows) and materials resistant to high heat and abrasive environments, catering to specialty film production. Regionally, while North America and Europe maintain stable demand driven by modernization projects and stringent quality standards, APAC is forecasted to exhibit the highest CAGR due to massive investments in new production lines and the accelerating domestic consumption of packaged goods. Segment-wise, the Rubber Sleeved Screw Expander segment continues to hold a significant market share owing to its versatility and cost-effectiveness in standard applications, yet the Metal Covered segment is rapidly gaining traction in high-tension, high-temperature, and sterile environments such as medical packaging and technical textiles, requiring specialized analysis of material interaction and durability. The market competitive landscape is highly fragmented, necessitating strategic mergers and acquisitions focused on consolidating technological expertise and geographical reach, ensuring long-term sustainable growth trajectories.

AI Impact Analysis on Screw Expander Market

Common user questions regarding AI's impact on the Screw Expander Market center on its ability to transition from reactive maintenance models to predictive quality control and dynamic web tension management. Users frequently inquire about the feasibility of integrating AI algorithms for real-time curvature adjustment based on instantaneous defect detection, and how machine learning can optimize the lifespan and performance of complex mechanical components like bearings and sleeves. The overarching expectations are focused on achieving 'zero-defect' production runs, minimizing material wastage, and reducing downtime associated with manual adjustments or unplanned component failure. This shift signifies a move from purely mechanical solutions to integrated cyber-physical systems where AI acts as the core decision-making unit for optimizing the web spreading process under variable operational conditions.

The integration of Artificial Intelligence (AI) and Machine Learning (ML) is fundamentally transforming the operational paradigm of Screw Expander technology, moving it towards intelligent web guiding systems. AI algorithms are now deployed to analyze vast streams of sensor data—including web tension readings, wrinkle incidence, speed variations, and temperature fluctuations—in real-time, allowing the expander curvature to be dynamically adjusted milliseconds before a crease forms, thus maintaining impeccable web quality. This level of predictive and prescriptive control significantly surpasses traditional static or manually-adjusted systems, leading to substantial reductions in scrap rates and considerable improvements in overall equipment effectiveness (OEE), particularly crucial in high-volume, high-value material processing environments.

Furthermore, AI plays a pivotal role in the predictive maintenance of Screw Expander components. By analyzing vibration signatures and load profiles, ML models can accurately predict the remaining useful life (RUL) of critical parts, such as internal bearings and outer sleeves, allowing maintenance teams to schedule interventions precisely when needed, minimizing unplanned outages. This advanced diagnostic capability not only extends the operational lifespan of the equipment but also optimizes inventory management for replacement parts. This technological evolution transforms the Screw Expander from a simple mechanical device into an essential, self-optimizing component within the broader Industry 4.0 manufacturing ecosystem.

- AI-driven predictive maintenance enhancing component longevity and minimizing unplanned downtime.

- Real-time dynamic curvature adjustment based on sensor feedback for proactive wrinkle elimination.

- Optimization of web tension profiles using machine learning to maximize material throughput and quality consistency.

- Enhanced quality control systems integrating computer vision and AI for instantaneous defect classification and process correction.

- Automated system calibration reducing setup time and dependence on operator expertise.

DRO & Impact Forces Of Screw Expander Market

The Screw Expander Market is significantly influenced by a confluence of accelerating drivers (D), persistent restraints (R), and emerging opportunities (O), which collectively shape the market’s trajectory and define the competitive landscape. A primary driver is the global increase in demand for high-quality packaging materials, including thin films and flexible laminates, especially driven by e-commerce expansion and consumer preferences for specialized packaging designs, necessitating pristine, crease-free materials. Restraints predominantly involve the high initial capital investment required for installing advanced, automated expander systems, particularly in small and medium-sized enterprises (SMEs), alongside the technical complexity associated with integrating these systems into highly sensitive web handling lines. Opportunities are primarily centered around the development of application-specific screw expanders for high-growth sectors such as battery separator films, medical packaging, and photovoltaic back sheets, requiring specialized materials and ultra-precise dimensional control, opening new high-margin revenue streams for innovative market players.

The overall impact forces are rated as moderately high and positive. The rapid pace of technological innovation, particularly in composite materials for sleeves and advanced bearing technologies, exerts a strong positive pull on the market, enhancing product performance and durability under severe operating conditions. However, the cyclical nature of end-user industries, such as paper and textiles, introduces volatility, acting as a constraining force on consistent year-over-year growth, requiring manufacturers to maintain flexible production capabilities. Furthermore, global supply chain disruptions affecting raw material sourcing (e.g., specialized rubbers, alloys) present a medium-term impact force that necessitates diversified sourcing strategies and resilient inventory management practices to mitigate price fluctuations and lead time extensions, maintaining operational continuity in the face of macro-economic instability.

Segmentation Analysis

The Screw Expander Market is segmented based on critical technical and application parameters, providing a detailed understanding of market dynamics across different product functionalities, material types, and end-user requirements. Key segmentations include classification by product type (e.g., Rubber Covered Screw Expanders, Metal Covered Screw Expanders), which dictates the expander's friction properties and durability; classification by roll type (e.g., Fixed Bow, Variable Bow), determining the adaptability of the system to different web widths and materials; and segmentation by end-user industry (e.g., Printing, Packaging, Textile), reflecting the dominant application areas and specific regulatory compliance needs. These distinct categories allow stakeholders to target specific niches requiring specialized web handling solutions, offering tailored products that optimize production efficiency and final product quality.

- By Product Type:

- Rubber Sleeved Screw Expander (Standard applications, High friction requirement)

- Metal Covered Screw Expander (High temperature, High tension, Abrasive materials)

- Composite Material Expander (Specialty films, Lightweight materials)

- By Bow Adjustability:

- Fixed Bow Expander (Constant web applications)

- Variable Bow Expander (Frequent material changes, Automated lines)

- By Roll Diameter:

- Small Diameter (High-speed, precision applications)

- Medium Diameter

- Large Diameter (Heavy paper, wide textiles)

- By End-User Industry:

- Packaging Industry (Flexible packaging, Labelling)

- Printing Industry (Offset, Gravure, Flexography)

- Textile Industry (Woven, Non-woven, Technical textiles)

- Paper and Pulp Industry

- Film and Sheet Extrusion

- Specialty Materials (Battery Separator, Medical Films)

Value Chain Analysis For Screw Expander Market

The value chain for the Screw Expander Market begins with upstream activities dominated by the procurement of specialized raw materials, including high-grade steel alloys for core construction, precision ball bearings, and advanced elastomers (rubber, silicone, polyurethane) for external sleeves. Raw material suppliers specializing in high-tolerance components are crucial as the performance and longevity of the screw expander are highly dependent on the quality of these inputs. Manufacturing processes involve high-precision machining, dynamic balancing of rolls to prevent vibration at high speeds, and the careful application and curing of outer covers, representing the core value-added steps in the midstream segment. Leading manufacturers often differentiate themselves through proprietary sleeve materials and advanced internal bearing designs that minimize friction and maximize operational life under continuous stress.

Downstream activities involve the highly specialized distribution and installation of the final product. Distribution channels typically bifurcate into direct sales models, where large OEM machine builders (Original Equipment Manufacturers of printing presses, laminators, slitters) purchase expanders directly, and indirect channels relying on technical distributors and system integrators. These intermediaries play a vital role in providing local support, maintenance, and complex integration services, especially in emerging markets where direct manufacturer presence is limited. Technical expertise in application engineering is mandatory at the downstream level, as the screw expander must be precisely configured—including bow angle, wrap angle, and placement—to effectively solve specific web handling issues unique to each customer’s production line.

The efficiency of the value chain is increasingly reliant on digitalization and streamlined logistics. Direct distribution allows manufacturers better control over branding and service quality, crucial for proprietary high-end variable bow systems. Conversely, the indirect channel leverages existing infrastructure to serve the voluminous replacement and retrofitting market for standard rubber-sleeved expanders. The primary challenge lies in maintaining the quality of installation and after-sales service across diverse geographical regions, requiring continuous training and certification of third-party system integrators to ensure optimal expander performance and customer satisfaction post-sale.

Screw Expander Market Potential Customers

The potential customer base for the Screw Expander Market is broad yet highly concentrated within sectors involved in continuous web material processing where product quality is directly proportional to material flatness and dimensional stability. Primary end-users include major multinational corporations and specialized SMEs operating gravure, flexographic, and offset printing facilities, requiring flawless surface quality for high-resolution graphics on substrates ranging from films to paperboard. Furthermore, companies specializing in flexible packaging conversion, which encompasses lamination, coating, and slitting operations for food, beverage, and consumer goods packaging, constitute a significant purchasing power, driven by stringent aesthetic and functional requirements for their end products. These customers prioritize expanders offering precise tension control and reliable performance across varying film thicknesses and processing speeds, often integrating them into closed-loop control systems.

Another crucial customer segment resides within the textile manufacturing domain, particularly those producing technical textiles, non-wovens, and finished fabrics. In these applications, screw expanders are vital for maintaining fabric width (weft straightening) and preventing edge curling before finishing processes like drying, calendering, or heat setting. The demand here focuses on wide-width expanders, robust construction, and resistance to chemical environments common in textile processing. Finally, the growing market for specialized films, such as those used in rechargeable battery separators, solar panel components, and medical barrier films, represents a high-growth customer segment. These industries require ultra-precision expanders that handle extremely delicate, thin materials without inducing mechanical damage or electrostatic discharge, driving demand for advanced, non-contact or ultra-low friction expansion technologies customized for high-purity environments.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450.5 Million |

| Market Forecast in 2033 | USD 710.2 Million |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Fife-Tidland (Maxcess International), Erhardt + Leimer (E+L), Bosch Rexroth, Montalvo Corporation, Dover Flexo Electronics (DFE), Nireco Corporation, Kadant Inc., V-Tek Engineering, Webex, Technobowe, Double E Company, Tesalca/Novatex, Comat Machine Tools, Swastik Roller, SVECOM. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Screw Expander Market Key Technology Landscape

The technological landscape of the Screw Expander market is continuously evolving, driven by the need for higher speeds, tighter tolerance control, and handling of increasingly delicate and specialized materials. A cornerstone technology remains the precision engineering of the internal mechanical mechanism, focusing on bearing technology that minimizes running torque and maximizes lifespan, crucial for maintaining web integrity at processing speeds exceeding 1,000 meters per minute. Recent advancements emphasize hermetically sealed bearing arrangements and frictionless magnetic bearings in high-end applications to prevent contamination and drastically reduce required maintenance, offering significant performance advantages in cleanroom environments utilized in medical or battery film production.

Material science innovation is equally critical, particularly concerning the composition of the outer sleeve. Traditional natural rubber is increasingly being supplemented or replaced by advanced synthetic elastomers, polyurethane, and specialized silicone compounds designed for specific chemical resistance, heat tolerance, and surface energy requirements. For example, high-release surfaces are necessary for adhesive materials or specialty coatings, while high-grip materials are crucial for maximizing the spreading effect on slippery plastic films. Furthermore, the integration of composite materials, such as carbon fiber reinforced polymers, is gaining traction for roll bodies, significantly reducing inertia and mass, which improves dynamic responsiveness during acceleration and deceleration cycles.

The paradigm shift towards Industry 4.0 has mandated the adoption of smart expander technology. Modern systems incorporate sophisticated sensors for monitoring vibration, temperature, and actual rotational speed, feeding data back into a centralized PLC or AI-driven control system. Key technology includes high-resolution linear actuators for precise, repeatable, automated bow adjustment (Variable Bow technology). This allows operators to store and instantly recall pre-set bow profiles tailored to specific product recipes, drastically reducing changeover time and minimizing human error, positioning these intelligent expanders as critical components in fully automated web handling systems designed for maximum production efficiency and minimum scrap generation.

Regional Highlights

- Asia Pacific (APAC): APAC is projected to be the fastest-growing market globally, driven primarily by the colossal expansion of packaging, printing, and textile manufacturing capacities in China, India, and Southeast Asian nations. The region benefits from lower manufacturing costs, increasing domestic consumption necessitating more advanced packaging solutions, and significant governmental investment in infrastructure and industrial modernization. The high volume of production lines being established necessitates the mass procurement of web handling equipment, including screw expanders, often prioritizing cost-effective yet reliable rubber-sleeved options alongside a growing demand for high-end variable bow systems for exporting high-quality goods.

- North America: This region represents a mature market characterized by a strong emphasis on automation, high-precision engineering, and stringent quality control standards, particularly in the flexible electronics, medical packaging, and high-performance material sectors. Growth here is primarily driven by the need to upgrade existing machinery with advanced, AI-integrated variable bow expanders and specialized metal-covered expanders designed for abrasive and high-tension materials. The market favors technological leadership and long-term durability over initial cost, positioning U.S. and Canadian manufacturers as key innovators in the smart web handling space.

- Europe: Europe is characterized by a strong presence in specialized, high-value manufacturing, notably in technical textiles, luxury packaging, and security printing. Demand is robust for highly customized, energy-efficient screw expanders compliant with strict environmental and operational safety standards (e.g., CE marking). Countries like Germany and Italy, leaders in machinery manufacturing, drive demand for highly customized systems tailored for unique web substrates and demanding processing environments, focusing heavily on sustainability and precision engineering. Retrofitting older European manufacturing lines with modern, high-efficiency expanders is a key market activity.

- Latin America (LATAM): The LATAM market, while smaller in absolute size, is showing steady, incremental growth, largely fueled by industrialization and the growing consumer demand for locally produced packaged goods in major economies like Brazil and Mexico. The market often seeks cost-effective, durable, and easily maintainable fixed bow expanders for standard paper, film, and textile applications. Investment decisions are often sensitive to exchange rate fluctuations and macroeconomic stability, emphasizing the need for robust, long-lasting equipment that minimizes long-term operational expenditures and maintenance complexities.

- Middle East and Africa (MEA): Growth in the MEA region is sector-specific, primarily concentrated in petrochemical-related downstream industries (plastic films, non-woven fabrics) and nascent packaging industries in the GCC states and South Africa. Screw expander adoption is driven by new facility development and the localization of manufacturing capabilities. The market requires equipment capable of withstanding harsh operating climates (high temperature, dust), leading to a preference for rugged, low-maintenance designs, often sourced through international distribution networks providing comprehensive installation and support services tailored to regionally specific operational challenges.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Screw Expander Market.- Fife-Tidland (Maxcess International)

- Erhardt + Leimer (E+L)

- Bosch Rexroth

- Montalvo Corporation

- Dover Flexo Electronics (DFE)

- Nireco Corporation

- Kadant Inc.

- V-Tek Engineering

- Webex (A Maxcess International Company)

- Technobowe

- Double E Company

- Tesalca/Novatex

- Comat Machine Tools

- Swastik Roller

- SVECOM P.E. s.r.l.

- Mukunda Industries

- A.R.B.S. Engineering

- Zhejiang Aishun Industrial Equipment

- Tirupati Flexo

- Rolmacon Global Engineering

Frequently Asked Questions

Analyze common user questions about the Screw Expander market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary performance advantages of a Variable Bow Screw Expander over a Fixed Bow system?

The primary advantage of a Variable Bow Screw Expander lies in its dynamic adaptability. Unlike fixed bow systems, variable systems allow the operator or automated control system to adjust the degree of curvature in real-time, optimizing the spreading effect for different web widths, tensions, and material types without stopping the machine. This significantly reduces setup time, minimizes material waste during changeovers, and ensures optimal crease removal across a diverse production portfolio, crucial for job shops and converters handling multiple substrate types daily.

Which end-user industries are currently driving the highest demand for specialized Metal Covered Screw Expanders?

Specialized Metal Covered Screw Expanders are seeing the highest demand from industries requiring high-temperature resistance, chemical inertness, and extreme durability under high web tension. Key drivers include the production of technical films (e.g., battery separator films and photovoltaic materials), high-speed lamination lines utilizing hot melts, and certain segments of the technical textile industry where chemical baths or abrasive dust particles necessitate a robust, non-elastomeric surface that can be precisely cleaned and maintained in sterile or harsh environments.

How does the integration of Industry 4.0 principles affect the procurement of Screw Expander systems?

Industry 4.0 principles mandate that newly procured Screw Expander systems must be 'smart,' meaning they incorporate advanced sensors, secure data transmission capabilities (IoT), and network connectivity for integration into centralized manufacturing execution systems (MES). Procurement decisions are increasingly prioritizing systems that support predictive maintenance through condition monitoring and offer closed-loop control functionality, enabling autonomous adjustments and generating comprehensive performance metrics necessary for overall equipment effectiveness (OEE) calculations, moving away from purely mechanical cost analysis.

What are the key technical constraints manufacturers face when designing screw expanders for thin-gauge polymer films?

Designing screw expanders for delicate, thin-gauge polymer films presents unique challenges related to minimizing contact pressure and surface friction while maximizing the required spreading action. Constraints include preventing localized stretching or necking of the film, avoiding static electricity buildup that attracts particulates, and ensuring the surface coating (e.g., specialized non-stick rubber or plasma-coated metal) does not micro-scratch the substrate. Manufacturers must utilize low-inertia designs, specialized low-friction bearings, and precise dynamic balancing to handle these high-speed, sensitive materials without damage.

Why is the Asia Pacific region dominating the forecasted market growth for Screw Expanders?

The Asia Pacific region's dominance in forecasted growth stems from a combination of massive infrastructure investment in manufacturing and high consumer demand. Rapid industrialization, particularly the expansion of the packaging and printing sectors in China, India, and Southeast Asia, leads to the construction of numerous new web processing lines requiring modern web handling equipment. Additionally, the region serves as a global production hub for textiles and flexible electronics, driving both high volume replacement demand and a parallel need for advanced expander technology to meet global export quality standards and rapidly evolving domestic consumption patterns.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager