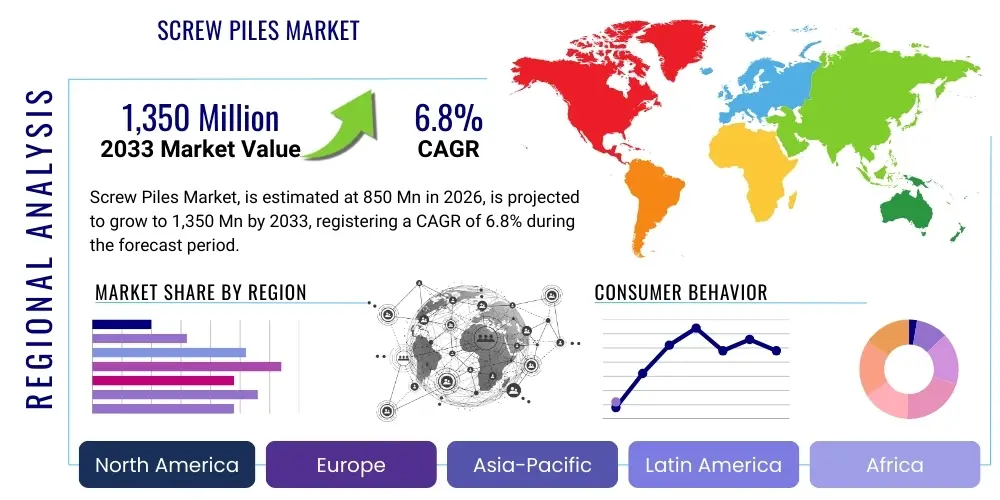

Screw Piles Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 443620 | Date : Feb, 2026 | Pages : 257 | Region : Global | Publisher : MRU

Screw Piles Market Size

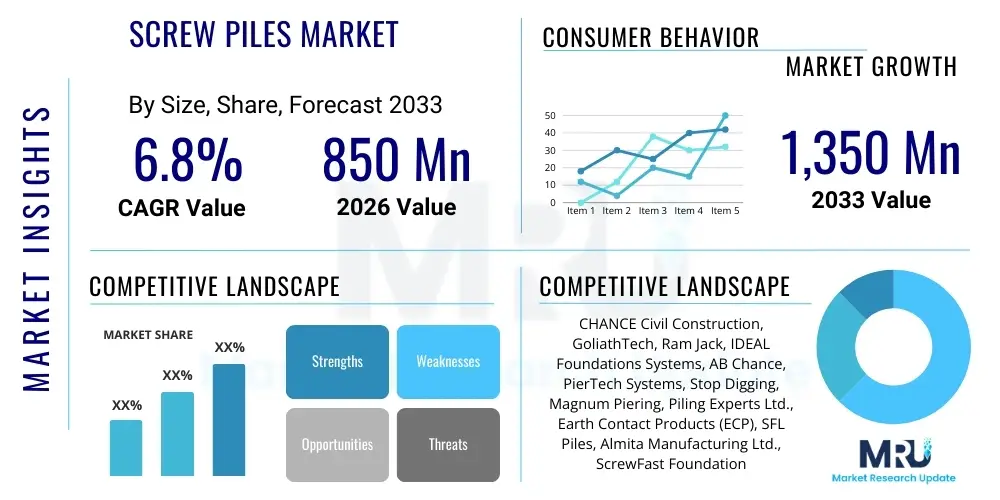

The Screw Piles Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 850 Million in 2026 and is projected to reach USD 1,350 Million by the end of the forecast period in 2033. This consistent expansion is fundamentally driven by the escalating demand for rapid and environmentally sustainable foundation solutions across various construction sectors globally. Infrastructure projects, particularly in renewable energy such as solar farms and wind turbine installations, rely heavily on the efficiency and reduced environmental footprint provided by screw piles, solidifying their market trajectory and financial scalability over the projection period.

The market expansion is not uniform across all geographical regions; however, high growth is anticipated in emerging economies experiencing rapid urbanization and significant investment in new utility infrastructure. Developed nations, conversely, are focusing on retrofitting and enhancing existing structures, where the minimal vibration and soil disturbance properties of screw piles provide a critical advantage over traditional concrete foundations. Regulatory shifts prioritizing construction efficiency and reduced project timelines further bolster the financial viability and overall market penetration of screw pile technology, making it an indispensable element in modern civil engineering practices and high-density urban development projects.

Screw Piles Market introduction

The Screw Piles Market encompasses the manufacturing, distribution, and installation services of helical steel foundations, recognized globally for their superior load-bearing capacity and versatility in diverse soil conditions. Screw piles, also known as helical piles or screw anchors, are deep foundation solutions characterized by a central steel shaft and one or more helical bearing plates or blades. These elements are twisted or screwed into the ground utilizing specialized hydraulic installation equipment, transferring structural loads to the competent bearing strata without the need for extensive excavation or concreting. The core technology leverages the principle of minimum disturbance, ensuring fast installation, immediate load application capability, and minimal environmental impact compared to conventional piling methods, positioning them as an essential resource in time-sensitive and ecologically sensitive construction environments.

Major applications of screw piles span the gamut of civil and infrastructure projects, prominently including residential and commercial building foundations, utility transmission towers, oil and gas pipelines, telecommunication masts, and crucial supports for renewable energy installations like solar photovoltaic arrays and small to medium-sized wind turbines. These foundations are increasingly favored in challenging geotechnical environments, such as areas with high water tables, expansive clays, or unstable soils, where traditional methods prove costly or infeasible. The inherent scalability of screw pile systems, ranging from small deck supports to heavy-duty industrial foundations, ensures broad applicability and sustained market relevancy across various project scopes and complexities, driving sustained demand from foundation engineers and construction contractors worldwide.

Key driving factors accelerating the adoption of screw piles include the global push for reduced carbon footprints in construction, the imperative for quicker project completion cycles, and technological advancements improving installation precision and load capacity verification. The economic benefits derived from eliminating curing time, reducing material waste, and streamlining site logistics further compel developers to integrate screw pile solutions into foundational designs. Furthermore, the capacity for simple removal and reuse offers a compelling advantage in temporary structures or environmentally sensitive areas requiring full site restoration, aligning perfectly with modern circular economy principles within the construction industry and reinforcing the long-term structural integrity and cost-effectiveness inherent in this foundation solution.

Screw Piles Market Executive Summary

The Screw Piles Market is experiencing dynamic growth, predominantly fueled by accelerated infrastructure spending in North America and Asia Pacific, coupled with the global transition towards renewable energy infrastructure that demands rapid, non-invasive foundation solutions. Business trends indicate a strong move toward product standardization and enhanced customization, allowing manufacturers to cater simultaneously to high-volume residential projects and highly specialized industrial applications requiring tailored load specifications. Furthermore, strategic mergers and acquisitions among key market players are consolidating expertise in advanced installation techniques and material science, particularly concerning anti-corrosion treatments and high-strength steel alloys, ensuring prolonged lifespan and operational resilience of installed piles under severe environmental conditions, thereby capturing a greater share of high-value projects.

Regionally, the Asia Pacific market is poised for the most rapid expansion, driven by massive urbanization projects in countries like India and China, coupled with significant governmental focus on utility infrastructure modernization. North America maintains a mature but steady growth trajectory, particularly in the telecommunications and residential housing sectors, where speed and minimal site disruption are paramount. Conversely, Europe, characterized by stringent environmental regulations and a focus on sustainable construction practices, acts as an innovation hub, driving demand for recycled steel screw piles and systems certified under rigorous sustainability frameworks. These regional dynamics create varied growth vectors, requiring multinational firms to deploy regionally tailored market entry and penetration strategies focusing on local regulatory compliance and construction material availability.

Segmentation trends highlight the increasing dominance of the standard capacity segment due to its widespread applicability in residential and light commercial construction, while the heavy-duty segment, though smaller in volume, commands higher average selling prices and superior profit margins, driven by complex industrial and bridge construction projects. By material, galvanized steel remains the preferred choice due to its corrosion resistance, crucial for longevity, particularly in marine or chemically aggressive soil environments. Application-wise, the renewable energy sector, especially solar, demonstrates the highest CAGR, reflecting global energy policy shifts, while the traditional residential and commercial segments provide stable base demand, emphasizing the diversification of end-user profiles leveraging the foundational benefits of helical piles for improved structural stability.

AI Impact Analysis on Screw Piles Market

User queries regarding AI's influence in the screw piles domain primarily revolve around three critical areas: optimization of geotechnical site investigation, predictive maintenance schedules, and automation of the installation process itself. Users are keenly interested in how machine learning algorithms can rapidly analyze complex soil testing data (cone penetration tests, borehole logs) to determine optimal screw pile design parameters (helix size, depth, angle) with greater accuracy than traditional manual engineering calculations. There is also significant concern regarding the integration of sensors into piles post-installation, allowing AI to monitor structural integrity, predict failure points based on accumulated load and environmental stress data, and thus optimize maintenance cycles, minimizing costly unscheduled interventions. Expectations are high that AI will eventually automate the calibration and real-time guidance of installation machinery, improving speed and ensuring geometric precision, which are crucial for large-scale projects like utility infrastructure or solar farms, ultimately aiming for zero-defect installation and superior foundational reliability.

The application of Artificial Intelligence within the screw piles market is transitioning from theoretical potential to practical implementation, focusing primarily on data-driven design optimization and construction efficiency enhancements. AI models, particularly deep learning networks, are increasingly employed to process vast historical project datasets, correlating soil profiles, pile specifications, and installation performance metrics to generate prescriptive recommendations. This results in significant material savings by precisely sizing piles and reducing over-engineering contingencies often necessary in conventional design processes. Furthermore, the integration of Building Information Modeling (BIM) with AI allows for clash detection and sequencing optimization specifically related to pile placement, drastically shortening the pre-construction phase and enhancing cross-disciplinary collaboration among architects, structural engineers, and foundation contractors, thereby improving overall project predictability and cost control across the construction lifecycle.

Beyond the design phase, AI is fundamentally changing the execution and monitoring aspects of foundation construction. Real-time data feeds from installation equipment, including torque measurements, rotation speed, and depth penetration rates, are fed into predictive algorithms. These algorithms provide immediate feedback to the operator, ensuring that the critical torque-to-capacity correlation is consistently met, standardizing quality assurance regardless of operator experience. Post-installation, the deployment of Internet of Things (IoT) sensors embedded within or attached to screw piles enables continuous structural health monitoring (SHM). AI analyzes these streams of data—including vibration, tilt, and strain—to detect minute deviations indicative of settling or structural fatigue long before they become critical issues, thereby maximizing the operational lifespan of the supported structure and offering unprecedented levels of asset management precision and reliability to end-users such as infrastructure operators and renewable energy providers.

- AI-driven geotechnical data analysis for optimized pile design (depth, pitch, diameter).

- Predictive maintenance scheduling using sensor data (IoT) embedded in installed piles.

- Automated real-time torque and depth control for enhanced installation precision.

- Integration with BIM platforms for sequential and geometric optimization of pile fields.

- Simulation models for stress testing piles under extreme environmental conditions.

- Supply chain optimization for steel procurement and logistics based on project demand forecasts.

DRO & Impact Forces Of Screw Piles Market

The Screw Piles Market is influenced by a complex interplay of Drivers, Restraints, and Opportunities (DRO), generating dynamic impact forces that shape investment decisions and technological focus. The primary drivers are centered around regulatory push for sustainable construction practices, the accelerated pace of global infrastructure development, particularly in renewable energy, and the inherent cost and time efficiencies offered by helical foundations over traditional concrete solutions. These factors create strong upward market momentum, encouraging construction firms to adopt new methodologies. However, this growth is restrained by challenges such as a general lack of widespread awareness and standardized certification processes in certain developing markets, as well as the initial higher material cost of high-grade steel compared to bulk concrete, posing initial resistance for cost-sensitive projects and requiring significant educational outreach to change established construction norms and engineer preferences globally.

Opportunities for market expansion are significant, primarily stemming from the vast potential in retrofitting and remediation projects where accessing foundations is difficult, making screw piles the ideal low-impact solution for stabilizing existing buildings or infrastructure. Furthermore, technological advancements in composite materials and specialized coating treatments present opportunities to enhance corrosion resistance and durability, opening up previously inaccessible markets, such as highly aggressive chemical processing plants or deep-sea marine structures. The market’s impact forces are high, characterized by strong driver influence derived from governmental spending on critical infrastructure and renewable energy mandates, which collectively outweigh the current restraints, indicating a robust positive growth outlook for the foreseeable future, contingent upon sustained innovation in material science and installation technology integration.

The impact forces generated by the intersection of these DRO elements drive market behavior toward innovation and specialization. The need to overcome the restraint of initial material cost is pushing manufacturers to optimize steel usage through advanced engineering designs and introduce lighter, yet equally strong, structural configurations. The driver related to renewable energy provides a predictable demand stream, prompting large-scale investment in dedicated screw pile manufacturing facilities capable of high-volume production. Ultimately, the market benefits from a strong positive feedback loop where increased adoption leads to lower manufacturing costs through economies of scale, further strengthening the competitive position of screw piles against conventional methods and ensuring their continued relevance and integration into modern, resilient foundation engineering standards worldwide.

Segmentation Analysis

The Screw Piles Market is comprehensively segmented based on three primary dimensions: product type, end-user application, and material. Product type segmentation typically differentiates between light-duty (primarily residential and utility pole applications), standard capacity (commercial buildings and bridges), and heavy-duty piles (large-scale industrial, oil & gas, and transmission towers), reflecting the varying load requirements and structural demands of different projects. The material segment is largely dominated by high-grade steel, categorized by its protective coating—namely galvanized steel for superior corrosion resistance and black steel used mainly in dry, controlled environments or where external corrosion protection is applied post-installation. This granular segmentation allows market participants to tailor their offerings, distribution strategies, and marketing efforts to specific structural needs and environmental constraints.

Segmentation by end-user application is critical for understanding market dynamics and future growth pockets. Key applications include the high-growth renewable energy sector (solar and wind), the consistently stable residential and commercial construction sector, and the cyclical but high-value infrastructure and industrial segments (telecommunications, railways, pipelines). The differential growth rates among these applications underscore the importance of diversification for manufacturers; for instance, reliance on renewable energy provides exposure to governmental sustainability targets, while stability in residential construction offers a hedge against fluctuating infrastructure spending. Analyzing these segments provides strategic clarity for firms looking to allocate resources toward the highest return segments, ensuring product development aligns with evolving industry needs.

Furthermore, geographic segmentation plays a pivotal role, reflecting variances in construction standards, regulatory landscapes, and climatic challenges (e.g., frost heave in Northern latitudes, seismic activity, or highly saline coastal environments). These geographical variances necessitate distinct product specifications and installation methodologies. For instance, deeper penetration piles are required in areas prone to seasonal ground movement, while highly robust anti-corrosion treatments are mandatory in coastal regions or brownfield sites. The complexity of these segmented needs mandates that successful market players maintain highly adaptable product portfolios and localized technical expertise to meet the specific foundational challenges presented by diverse regional operating environments, thereby ensuring maximized market penetration and enduring customer loyalty.

- By Product Type:

- Light-Duty Screw Piles

- Standard Capacity Screw Piles

- Heavy-Duty Screw Piles

- By Application:

- Residential Construction

- Commercial Construction

- Renewable Energy (Solar & Wind Farms)

- Infrastructure (Roads, Bridges, Telecommunications)

- Industrial (Oil & Gas, Processing Plants)

- By Material:

- Galvanized Steel Screw Piles

- Black Steel Screw Piles (Uncoated or with specialized coatings)

- Composite Screw Piles (Emerging)

Value Chain Analysis For Screw Piles Market

The value chain for the Screw Piles Market begins with upstream activities centered on the procurement and processing of raw materials, primarily high-grade steel (often requiring specific tensile strength and yield properties), alongside the necessary galvanization or protective coating materials. Key upstream suppliers include steel mills and specialized coating manufacturers. Efficiency at this stage is crucial, as steel costs constitute the largest variable expense; thus, managing commodity price volatility and securing long-term supply contracts are paramount for maintaining competitive manufacturing costs. Manufacturers then engage in specialized fabrication, involving precision cutting, welding of helices to the shaft, and finishing processes, often leveraging advanced robotic welding and quality control systems to ensure adherence to stringent structural specifications and minimize material waste, thereby maximizing overall operational profitability and product integrity.

Midstream activities encompass the core manufacturing and distribution phases. Manufacturers produce the standardized and customized piles, followed by the logistical organization of inventory and transport to project sites or regional distribution centers. Given the size and weight of screw piles, efficient logistics and reliable distribution channels—both direct sales to large construction firms and indirect sales through specialized dealer networks—are vital for timely project delivery and maintaining client satisfaction across dispersed geographical markets. The downstream segment is dominated by the installation service providers, who use proprietary or specialized hydraulic machinery to install the piles. These installers, often certified by the manufacturers, represent the final interface with the end-client and are crucial for ensuring proper application and guaranteeing the load-bearing performance, essentially translating the engineered product into a foundational reality.

The distribution channel is bifurcated into direct and indirect routes. Direct sales are typically favored for high-volume, large-scale industrial or infrastructure projects, allowing manufacturers direct control over the technical specifications, delivery schedule, and installation support, thereby maximizing profit margins and ensuring quality control. Indirect distribution leverages a network of specialized foundation contractors, authorized dealers, and construction supply houses, which are essential for reaching smaller residential and light commercial projects scattered geographically. This indirect model relies heavily on training and technical support provided by the manufacturer to maintain product quality and installation standards across the extended network. Effective value chain management, from sourcing high-quality steel to ensuring precise final installation, is the differentiator for market leaders, offering superior quality assurance and reducing the total cost of ownership for the end-user.

Screw Piles Market Potential Customers

The primary end-users and buyers in the Screw Piles Market are diverse, encompassing both private developers and governmental agencies across multiple critical sectors. Infrastructure operators, including national electricity grid providers, telecommunication companies (for cellular towers and data center foundations), and transportation authorities (for bridge supports, sound barriers, and railway electrification), represent a consistently large and high-value customer base. These entities prioritize durability, speed of installation to minimize service disruption, and the ability of foundations to withstand extreme loading conditions and environmental stresses over prolonged service lives. The increasing global focus on decarbonization and smart grid expansion means these customers are often seeking solutions that are not only robust but also environmentally compliant and easily deployable in remote or sensitive locations.

Another significant customer segment is the renewable energy sector, particularly utility-scale solar farm developers. The rapid deployment required for photovoltaic (PV) arrays, often across vast, undulating, or geotechnically challenging terrains, makes screw piles the preferred foundational choice due to their minimal civil works requirement and the absence of curing time. Similarly, wind energy developers utilize heavy-duty screw piles for supporting meteorological towers and, increasingly, for smaller land-based wind turbine foundations where conventional concrete footings are prohibitively expensive or time-consuming. These customers value the scalable, repeatable installation process and the significant reduction in overall project completion timelines that screw pile technology facilitates, directly translating into quicker energy generation and return on investment.

Finally, the traditional building and construction industry, encompassing residential home builders, modular housing manufacturers, and commercial developers, forms the foundational volume segment of the market. Screw piles are highly attractive in urban infill projects where site access is restricted, or in areas prone to geotechnical risks such as expansive soils or liquefaction potential. Residential customers, in particular, appreciate the non-invasive nature of the installation process, which minimizes disruption to existing landscapes and adjacent properties. Specialized remediation contractors, focusing on retrofitting existing structures and stabilizing slopes, also constitute a niche but high-demand customer base, relying on the precision and flexibility of screw piles to address complex structural failures efficiently and cost-effectively without relying on disruptive heavy excavation machinery.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 850 Million |

| Market Forecast in 2033 | USD 1,350 Million |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | CHANCE Civil Construction, GoliathTech, Ram Jack, IDEAL Foundations Systems, AB Chance, PierTech Systems, Stop Digging, Magnum Piering, Piling Experts Ltd., Earth Contact Products (ECP), SFL Piles, Almita Manufacturing Ltd., ScrewFast Foundations, Fortress Stabilization Systems, Surefoot Footings, Techno Metal Post, Patriot Foundations, Postech Screw Piles, Ground Hog Systems, Helical Anchors Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Screw Piles Market Key Technology Landscape

The technological landscape of the Screw Piles Market is characterized by innovation in three major areas: material science, installation equipment, and digital integration for quality assurance. Material advancements focus primarily on developing superior corrosion-resistant coatings beyond standard galvanization, including advanced polymer wraps, fusion-bonded epoxy, and specialized cathodic protection systems tailored for highly corrosive soil profiles, such as those found in marine environments or contaminated industrial sites. Furthermore, research into high-strength steel alloys and the emerging use of composite materials (e.g., fiber-reinforced polymers) for the pile shaft seeks to enhance the strength-to-weight ratio, allowing for lighter, yet structurally robust, piles that reduce transportation costs and simplify on-site handling, thereby improving the overall economic viability of large-scale foundation projects and meeting stringent engineering demands for extreme load conditions.

In terms of installation equipment, the key technological development is the transition toward higher torque, compact hydraulic drive heads mounted on agile machinery, often track-mounted excavators or specialized skid-steer loaders. These modern systems offer greater precision in aligning the piles vertically and ensuring continuous, uninterrupted torque application, which is crucial for achieving the required installation depth and verifying load capacity via the torque correlation method. Sophisticated instrumentation integrated into the drive heads provides real-time data capture, including precise GPS location, torque logging, and depth measurement. This immediate data availability enhances quality control on site, allowing engineers to verify installation parameters instantly against design specifications, thus reducing post-installation inspection requirements and associated project risks inherent in traditional piling methods.

Digital integration, underpinned by IoT and cloud computing, represents the cutting edge of technological evolution in the screw piles industry. Advanced software platforms now integrate design (BIM models), real-time installation data logging, and post-installation monitoring. These systems allow project managers to remotely track the progress and quality of multiple installation teams across vast sites, ensuring standardized execution across the entire foundation field. The convergence of these technologies—stronger materials, precision installation machinery, and comprehensive digital quality assurance systems—is fundamentally transforming screw piles from a simple structural component into an intelligent foundation solution, offering unparalleled reliability, predictable performance, and verifiable compliance with the most rigorous engineering and regulatory standards globally, driving competitive advantages for firms investing in this sophisticated technology stack.

Regional Highlights

- North America: This region is characterized by a mature market with high adoption rates, particularly in residential construction, telecommunications infrastructure (5G network rollout), and solar power generation. The U.S. and Canada benefit from standardized engineering practices favoring rapid deployment solutions. Growth is steady, focused on advanced engineering solutions for seismic resistance and extreme weather environments.

- Europe: Driven by strict environmental regulations and a strong commitment to sustainable construction, Europe is a hub for innovation in screw pile materials (recycled steel) and installation techniques. Key drivers include government support for offshore and onshore wind farms and the remediation of brownfield sites. Scandinavia and the UK show particularly high penetration rates.

- Asia Pacific (APAC): Expected to exhibit the highest growth rate due to massive governmental spending on infrastructure, rapid urbanization, and extensive renewable energy project development in countries like China, India, and Australia. The demand for cost-effective, time-saving foundation methods to support new cities and utilities is immense, compensating for initial technological learning curves and driving high-volume sales.

- Latin America (LATAM): Growth is accelerating, primarily driven by mining expansion and increasing infrastructure investment, particularly in Brazil and Chile. The market remains relatively fragmented but is showing strong potential as multinational developers introduce advanced foundation technologies to meet international project standards and improve construction efficiency in areas with complex geological conditions.

- Middle East and Africa (MEA): This region offers significant opportunities due to large-scale oil and gas infrastructure expansion, alongside major diversification projects focusing on tourism and utility-scale solar projects (e.g., Saudi Arabia’s Vision 2030). Challenges include extreme heat, corrosive coastal environments, and logistics complexity, requiring highly specialized, durable screw pile solutions and localized logistical partnerships for successful market penetration and long-term asset management.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Screw Piles Market.- CHANCE Civil Construction

- GoliathTech

- Ram Jack

- IDEAL Foundations Systems

- AB Chance

- PierTech Systems

- Stop Digging

- Magnum Piering

- Piling Experts Ltd.

- Earth Contact Products (ECP)

- SFL Piles

- Almita Manufacturing Ltd.

- ScrewFast Foundations

- Fortress Stabilization Systems

- Surefoot Footings

- Techno Metal Post

- Patriot Foundations

- Postech Screw Piles

- Ground Hog Systems

- Helical Anchors Inc.

Frequently Asked Questions

Analyze common user questions about the Screw Piles market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary advantage of screw piles over traditional concrete foundations?

Screw piles offer significantly faster installation times with immediate load-bearing capacity, eliminate curing delays, and involve minimal soil excavation or disturbance, making them highly cost-effective and environmentally superior for rapid construction projects.

In which applications are heavy-duty screw piles most frequently utilized?

Heavy-duty screw piles are essential for supporting large industrial structures, major infrastructure like bridges and transmission towers, oil and gas pipelines, and large utility-scale wind turbine foundations, where maximum load capacity and structural rigidity are non-negotiable requirements.

How does the material of screw piles affect their longevity and performance?

The use of galvanized steel is crucial for longevity, providing superior corrosion resistance, especially in high-moisture or aggressive soil environments. Performance is further optimized through material science innovations focused on high-strength alloys to maximize the torque-to-capacity ratio and ensure structural integrity over decades of use.

Which geographical region is currently demonstrating the fastest growth in the screw piles market?

The Asia Pacific region, fueled by unprecedented governmental infrastructure spending, rapid urbanization, and large-scale deployment of solar and wind energy projects, is projected to experience the highest Compound Annual Growth Rate (CAGR) throughout the forecast period.

Is AI used in the installation process of screw piles?

Yes, AI is increasingly integrated to optimize installation precision by analyzing real-time torque and depth data from hydraulic drive heads, providing immediate quality assurance feedback and ensuring the pile capacity meets exact design specifications efficiently across diverse geological conditions.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager