Screw Press Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 443397 | Date : Feb, 2026 | Pages : 246 | Region : Global | Publisher : MRU

Screw Press Market Size

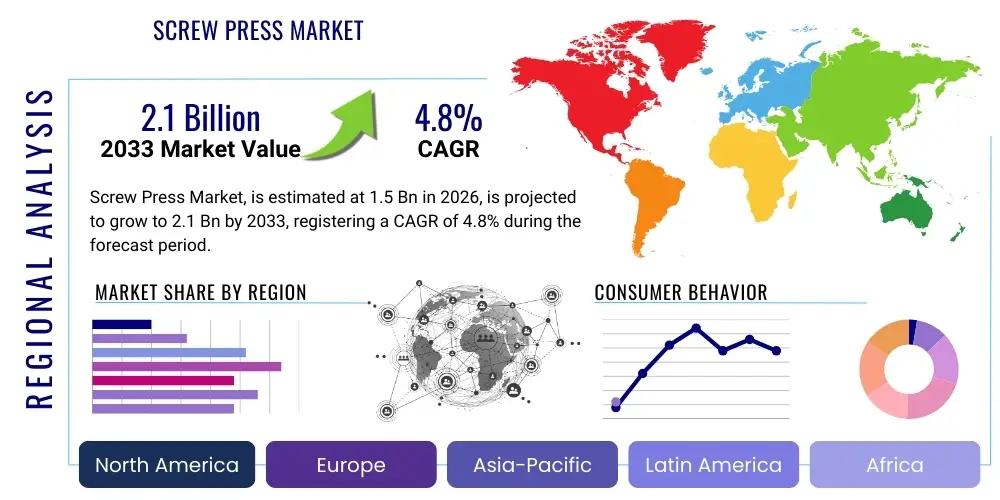

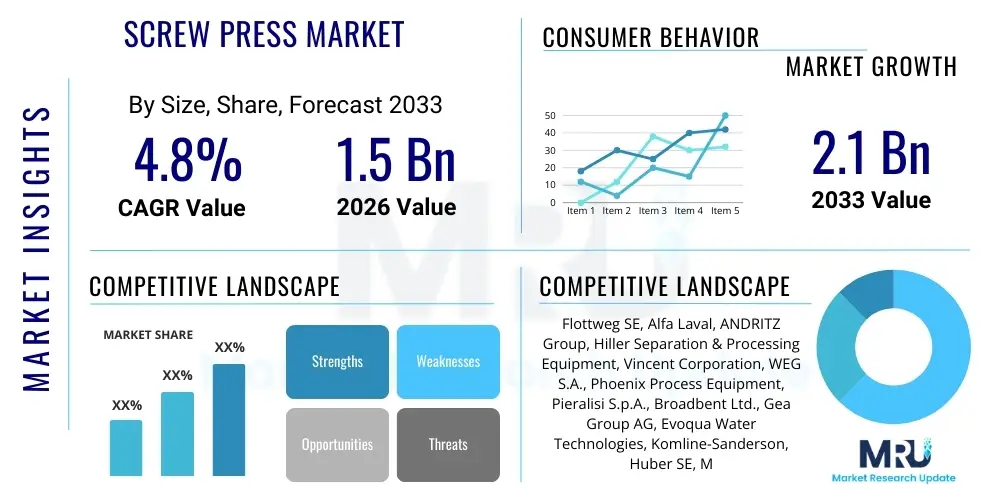

The Screw Press Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 4.8% between 2026 and 2033. The market is estimated at USD 1.5 Billion in 2026 and is projected to reach USD 2.1 Billion by the end of the forecast period in 2033.

Screw Press Market introduction

The Screw Press Market encompasses equipment designed for continuous mechanical separation processes, primarily focused on dewatering, liquid-solid separation, and volume reduction in various industrial and municipal applications. These devices operate by utilizing a rotating helical screw, contained within a cylindrical screen or housing, to compress material, forcing liquid through the screen while conveying and discharging the thickened or dewatered solids. The robust design and efficiency of screw presses make them indispensable across sectors requiring reliable separation, particularly in handling challenging materials like municipal sludge, industrial waste streams, and complex food processing residues. Their ability to operate continuously with relatively low power consumption compared to other dewatering technologies positions them favorably in sustainability-focused environments, driving adoption globally.

A primary application area for screw presses is wastewater treatment, where they are essential for sludge dewatering, significantly reducing the volume and weight of sludge before disposal or further processing, thereby cutting transportation and handling costs. Beyond municipal infrastructure, screw presses are vital in the food and beverage industry for juice extraction, oil seed pressing, and pulp dewatering; in the pulp and paper sector for black liquor recovery and fiber processing; and in rendering and biofuel production for solid-liquid separation of biomass. The core benefit of modern screw presses lies in their high dryness achievable, minimal maintenance requirements, enclosed operation minimizing odor, and adaptability to fluctuating feedstock characteristics. These technical advantages ensure consistent performance even with highly viscous or difficult-to-dewater materials, enhancing operational efficiency for end-users.

Key market driving factors include stringent global environmental regulations mandating better waste management and sludge reduction practices, particularly in rapidly urbanizing regions. The increasing scarcity of water resources necessitates efficient water recovery and recycling systems, where screw presses play a crucial role in improving effluent quality and minimizing waste volume. Furthermore, the growing demand for renewable energy and high-efficiency biofuel production boosts the need for effective biomass dewatering equipment. Technological advancements focusing on automated control systems, variable pitch screws, and enhanced material construction (such as duplex stainless steel) contribute significantly to improving press longevity and maximizing dewatering performance across diverse industrial matrices, collectively fueling the market's sustained growth trajectory over the forecast period.

Screw Press Market Executive Summary

The global Screw Press Market is characterized by robust growth, primarily propelled by escalating global investments in wastewater treatment infrastructure and heightened industrial demand for solid-liquid separation efficiency. Business trends indicate a shift towards modular and integrated dewatering solutions, allowing for easier scalability and reduced installation footprints, particularly appealing to industrial facilities with limited operational space. Manufacturers are increasingly focusing on developing presses optimized for specific challenging materials, such as high-fiber sludges or abrasive industrial wastes, incorporating advanced materials like specialized alloys and polymeric components to resist corrosion and wear. The competitive landscape is moderately fragmented, with large international manufacturers dominating the high-throughput segments, while regional specialists focus on customized solutions and localized service offerings, driving innovation in automated monitoring and remote diagnostic capabilities.

Regional trends highlight the Asia Pacific (APAC) as the fastest-growing market, driven by massive urbanization, rapid industrialization, and subsequent government mandates addressing severe water pollution issues in countries like China and India. North America and Europe, representing mature markets, show steady growth primarily stemming from the replacement of aging equipment, upgrades to existing facilities to meet stricter effluent standards, and the adoption of energy-efficient models in municipal and industrial settings. Demand in Latin America and the Middle East and Africa (MEA) is accelerating due to infrastructure development projects in mining, oil and gas, and burgeoning agricultural processing sectors, where screw presses offer cost-effective and reliable dewatering solutions compared to filter presses or centrifuges in certain applications. The maturity of environmental regulations is a key differentiator in regional demand patterns and technological adoption rates.

Segment trends confirm that the municipal wastewater treatment sector remains the largest end-user segment due to the consistent, high-volume production of sludge globally. However, the industrial sector, particularly the food and beverage and chemical processing segments, is exhibiting higher growth rates, attributed to the need for product quality assurance and efficient byproduct recovery, such as separating valuable solids from liquid streams in brewing or dairy operations. Based on press type, the continuous screw press segment maintains dominance due owing to its high throughput and uninterrupted operation capability, preferred for large-scale applications. Furthermore, the increasing focus on the Internet of Things (IoT) integration is enhancing the value proposition across all segments, allowing for predictive maintenance and real-time operational optimization, reducing downtime and operational expenditures for end-users across various processing stages.

AI Impact Analysis on Screw Press Market

Common user questions regarding AI's impact on the Screw Press Market often center on how these traditional mechanical devices can leverage advanced analytics and machine learning to improve efficiency and reduce operational costs. Users frequently inquire about the potential for AI-driven predictive maintenance, asking if algorithms can accurately forecast component failure (like screw or screen wear) based on real-time sensor data (vibration, torque, motor load). Another key theme revolves around process optimization, specifically how AI can automatically adjust press parameters—such as backpressure, rotation speed, or polymer dosage in the case of sludge conditioning—to maintain optimal dewatering performance despite variations in feedstock composition. Concerns also include the required capital investment for sensor integration, the reliability of AI models in harsh industrial environments, and the overall economic justification for adopting such high-tech solutions within conventional dewatering facilities.

The implementation of Artificial Intelligence and machine learning models is fundamentally transforming the operational dynamics of the Screw Press Market, shifting the focus from manual supervision to automated, self-regulating systems. AI facilitates advanced process control by analyzing multivariate data streams, including flow rate, polymer concentration, dryness output, and energy consumption. This capability allows the system to instantaneously calculate the optimal set points, ensuring maximum dewatering efficiency while minimizing chemical consumption and energy use. For example, in wastewater treatment, fluctuations in sludge consistency are common, and AI algorithms can preemptively adjust the press settings faster and more accurately than human operators, leading to consistent cake dryness, reduced disposal weight, and substantial long-term cost savings for municipal utilities.

Furthermore, AI significantly enhances the maintenance lifecycle of screw press equipment, a crucial factor given the abrasive nature of many materials processed. By employing machine learning models on sensor data related to vibration and motor current signatures, systems can identify anomalies indicative of impending mechanical failure hours or even days before catastrophic breakdown occurs. This transition to predictive maintenance minimizes unscheduled downtime, maximizes the operational lifespan of expensive components, and optimizes inventory management for spare parts. The long-term impact of AI integration will lead to a new generation of smart screw presses that are highly interconnected (IoT-enabled), energy-efficient, and capable of autonomous operation, significantly raising the industry benchmark for dewatering performance and asset utilization.

- AI-driven Predictive Maintenance: Forecasting mechanical wear and failure based on vibration and torque analysis, minimizing unplanned downtime.

- Automated Process Optimization: Real-time adjustment of screw speed, pressure settings, and polymer dosing to maximize cake dryness and minimize chemical use.

- Energy Consumption Optimization: Machine learning models identify operational patterns to reduce motor power consumption during low-load conditions.

- Remote Diagnostics and Performance Monitoring: Enhancing operational transparency and enabling rapid troubleshooting through cloud-based analytics platforms.

- Feedstock Consistency Adaptability: Algorithms automatically compensate for rapid changes in sludge or process material composition, ensuring stable output quality.

DRO & Impact Forces Of Screw Press Market

The Screw Press Market is shaped by a critical balance of Drivers, Restraints, and Opportunities (DRO), collectively forming the Impact Forces that determine market direction. Key drivers include stringent global mandates concerning waste reduction and sludge disposal, the need for cost-effective dewatering solutions in energy-intensive industries, and the continuous expansion of municipal wastewater infrastructure across developing economies. These factors create an unavoidable demand floor for separation technologies. Conversely, the market faces restraints such as the high initial capital investment required for high-capacity screw press systems and the operational complexity involved in processing highly viscous or oily sludges which may require significant pre-treatment, posing a barrier to smaller enterprises. Opportunities emerge from the innovation landscape, specifically the integration of smart technologies (AI, IoT) for superior performance monitoring and the expansion into niche applications like biomass dewatering for renewable energy and industrial resource recovery.

Impact forces are predominantly driven by environmental legislation and economic efficiency pressures. Globally, governments are enforcing zero-liquid discharge (ZLD) policies and significantly limiting the landfilling of wet sludge, forcing industries and municipalities to adopt highly efficient dewatering technologies like screw presses to achieve dry cake solids content greater than 20-25%. Economically, the continuous drive to reduce operational expenditure (OPEX) favors screw presses due to their lower energy consumption and lower requirement for high-cost filtering consumables compared to alternative technologies like belt presses or centrifuges, making the total cost of ownership highly competitive over the equipment lifespan. This combination of regulatory push and economic pull ensures sustained market growth, prioritizing equipment that offers reliability and low labor input, which screw presses inherently provide through their enclosed, automated nature.

The market's long-term trajectory is heavily influenced by opportunities in resource recovery and circular economy initiatives. Screw presses are becoming central to the separation of valuable byproducts from waste streams, such as extracting nutrients from agricultural waste or recovering usable fibers and chemicals from industrial effluence. The ongoing refinement of screw press designs, including multi-stage configurations and improved materials science, is addressing historical restraints related to wear and complex material handling. These technological leaps broaden the addressable market beyond traditional wastewater treatment into complex chemical manufacturing and pharmaceutical waste separation, solidifying the screw press’s role as a versatile and environmentally crucial piece of processing equipment across the industrial spectrum.

Segmentation Analysis

The Screw Press Market is comprehensively segmented based on the type of equipment, the processing capacity, the critical end-user application, and geographical regions. This segmentation provides a granular view of market dynamics, revealing key areas of growth and specific technological requirements. Analysis by type, such as continuous vs. batch presses, indicates the dominance of continuous systems favored for high-volume, uninterrupted industrial processes, while batch systems maintain relevance in smaller or highly specialized separation tasks. Capacity segmentation highlights the growing demand for medium-to-high capacity presses (500 kg/hr to 3000 kg/hr) as facilities seek consolidation and efficiency improvements, particularly in municipal waste handling, while smaller units cater to decentralized industrial operations.

End-user segmentation is crucial for understanding demand elasticity and specific product needs. The Municipal Wastewater segment demands durability, high throughput, and minimal operator attention, whereas the Food & Beverage industry requires hygienic design (e.g., polished stainless steel) and compliance with strict sanitary standards for applications like fruit juice extraction or spent grain dewatering. The Chemical and Pharmaceutical sectors demand corrosion resistance and precision separation capabilities. This diversity necessitates specialized engineering and material choice by manufacturers, leading to tailored product offerings and differential pricing strategies across these varied application matrices.

Ultimately, the segmentation framework underscores the versatility of screw press technology. Geographic segmentation confirms regional disparities in adoption rates, with regulatory environments being a primary determinant. The robust growth in Asia Pacific is driven by sheer volume of new infrastructure projects, contrasted with the value-driven replacement and upgrade cycle observed in mature markets like North America and Europe. Understanding these segments is vital for stakeholders to align their production, marketing, and distribution strategies effectively to capture high-growth opportunities within the highly diverse application landscape of solid-liquid separation.

- By Type:

- Continuous Screw Press

- Batch Screw Press

- By Capacity:

- Low Capacity (< 500 kg/hr)

- Medium Capacity (500 kg/hr – 3000 kg/hr)

- High Capacity (> 3000 kg/hr)

- By End-User:

- Municipal Wastewater Treatment

- Industrial Wastewater Treatment

- Food & Beverage (Juice, Dairy, Brewing)

- Pulp and Paper

- Chemical and Pharmaceutical

- Oil and Gas / Mining

- Agriculture and Biomass

- By Region:

- North America

- Europe

- Asia Pacific (APAC)

- Latin America (LATAM)

- Middle East & Africa (MEA)

Value Chain Analysis For Screw Press Market

The Value Chain for the Screw Press Market begins with the Upstream Analysis, which focuses on the sourcing and processing of raw materials, primarily high-grade steels (such as stainless and specialty alloys like Duplex steel for corrosion resistance), motors, gearboxes, and control components (PLCs, sensors). Suppliers in this stage wield moderate bargaining power, particularly those providing specialized, wear-resistant materials essential for the screw and screen components, which dictates the longevity and performance of the final product. Efficiency and quality control at the manufacturing stage—involving precision machining, welding, and assembly—are paramount, as screw press performance is highly sensitive to the geometric accuracy of the rotating parts and the filtering screen tolerance, requiring specialized expertise in mechanical engineering.

Midstream activities involve the design, manufacturing, and marketing of the screw press units. Key manufacturers invest heavily in Research and Development (R&D) to enhance dewatering efficiency, optimize energy consumption, and integrate advanced monitoring technologies (IoT/AI). The distribution channel structure is multi-faceted, utilizing both direct sales and specialized indirect channels. Direct sales are typically employed for large-scale municipal projects or complex industrial installations where customization and close engineering consultation are required. Indirect channels, involving authorized distributors, system integrators, and engineering, procurement, and construction (EPC) contractors, are critical for penetrating regional markets and providing localized after-sales support and installation services, especially in emerging economies. The selection of the channel depends heavily on the scale of the project and the technical complexity required.

Downstream analysis centers on the installation, operation, and maintenance (O&M) activities performed by the end-users. The performance of the screw press is often reliant on effective integration into existing treatment systems, requiring coordination with sludge thickening, flocculation, and polymer conditioning units. After-market services, including the supply of spare parts (screens, screws, bearings), regular servicing, and technical upgrades, represent a significant revenue stream for manufacturers and specialized service providers. Effective maintenance and prompt spare parts availability are crucial to customer satisfaction and machine uptime, making the after-sales network a competitive differentiator in the market. The robust structure of this value chain ensures product quality from material sourcing through to sustained operational performance at the customer site.

Screw Press Market Potential Customers

The core potential customers and end-users of screw press technology are entities facing significant challenges in solid-liquid separation and waste volume reduction across both public infrastructure and private industry. Municipal wastewater treatment plants (WWTPs) represent the largest foundational customer base globally, seeking reliable, continuous dewatering solutions for sewage sludge to meet stringent environmental discharge standards and minimize high landfill tipping fees. These buyers prioritize operational simplicity, long lifespan, and low energy costs, often procuring high-capacity continuous presses through public tender processes managed by municipal authorities or specialized water utilities. The increasing trend of retrofitting older plants with more efficient dewatering equipment drives consistent demand from this public sector segment.

The second major category encompasses a diverse range of industrial processors, where the purchase decision is often driven by efficiency, product quality, and resource recovery objectives. The Food & Beverage sector, including juice, beer, wine, and dairy manufacturers, uses screw presses not only for waste reduction (e.g., spent grains) but also for high-value extraction (e.g., fruit pressing), demanding highly hygienic, food-grade stainless steel equipment that complies with sanitary regulations. Similarly, the Pulp and Paper industry utilizes these presses for concentrating fiber slurries and recovering black liquor, requiring extremely robust, corrosion-resistant machines capable of handling high temperatures and abrasive materials.

Emerging and high-growth potential customers include the Biomass and Biofuel production sectors, which require efficient dewatering of organic feedstock prior to fermentation or thermal processing to maximize energy output and reduce transportation mass. Furthermore, mining and metallurgical operations are increasingly adopting screw presses for tailings management and mineral concentrate dewatering, valuing the technology's ability to handle high solids content and aggressive slurries. These industrial customers look for highly customized solutions that offer optimized dewatering rates specific to their unique chemical matrix and particle size distribution, making technical consultation and system integration capabilities key differentiators for suppliers.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.5 Billion |

| Market Forecast in 2033 | USD 2.1 Billion |

| Growth Rate | 4.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Flottweg SE, Alfa Laval, ANDRITZ Group, Hiller Separation & Processing Equipment, Vincent Corporation, WEG S.A., Phoenix Process Equipment, Pieralisi S.p.A., Broadbent Ltd., Gea Group AG, Evoqua Water Technologies, Komline-Sanderson, Huber SE, M&C Soluciones, Sepro Mineral Systems |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Screw Press Market Key Technology Landscape

The technological landscape of the Screw Press Market is characterized by continuous refinement aimed at maximizing efficiency, reducing wear, and enhancing automation. Modern screw presses incorporate several key design innovations to handle varied and challenging feedstocks. One primary technological advancement involves the implementation of variable-pitch screws and multi-zone pressure adjustments. Variable pitch geometry allows the compression ratio to be optimized along the screw axis, ensuring maximum liquid extraction without excessive power consumption or plugging. Multi-zone systems utilize adjustable back-pressure mechanisms, often hydraulic or pneumatic, which can be fine-tuned dynamically based on the input material consistency, thereby guaranteeing consistent cake dryness regardless of process fluctuations. This level of control represents a significant step forward from older, fixed-geometry designs, greatly enhancing the press's versatility across different industrial applications.

Materials science also plays a crucial role, particularly in combating abrasion and corrosion, which are significant operational challenges in wastewater and chemical processing. Manufacturers are increasingly utilizing hardened stainless steels, specialized coatings (such as chrome carbide or ceramics), and composite materials for the screw flights and filter screens. For instance, the use of wedge wire screens, specifically designed with precise slot widths and geometric strength, maximizes flow capacity while minimizing blinding or plugging, a common operational headache. Furthermore, the integration of self-cleaning systems, such as automated water spray rings or mechanical brushes, ensures that the filter medium remains unobstructed, allowing for continuous, long-term operation with minimal manual intervention, which reduces labor costs and enhances equipment uptime.

The most significant modern technological shift lies in digitalization and connectivity. New screw presses are frequently equipped with advanced sensor packages (IoT capabilities) that monitor parameters like torque, vibration, temperature, and motor load in real time. This data is fed into sophisticated PLC control systems, often leveraging the aforementioned AI models, for predictive maintenance and automated performance adjustment. This integration into the industrial internet of things (IIoT) facilitates remote monitoring, diagnostics, and data logging, allowing operators to track historical performance, optimize energy use, and receive early warnings about potential mechanical issues. These smart technologies not only improve operational efficiency but also reduce the overall total cost of ownership by extending the equipment life and minimizing unexpected failures.

Regional Highlights

- Asia Pacific (APAC): APAC is anticipated to demonstrate the highest Compound Annual Growth Rate (CAGR) during the forecast period. This rapid expansion is fundamentally driven by unprecedented population growth, rapid industrialization, and subsequent massive government investments into modernizing and expanding urban and industrial wastewater treatment capabilities, particularly in China, India, and Southeast Asian nations. Regulatory pressures to treat industrial effluent and municipal sewage before discharge, coupled with governmental incentives for resource recovery, create a massive Greenfield opportunity for screw press deployment. Manufacturers focusing on cost-effective, high-throughput, and reliable dewatering solutions tailored to complex, highly varied sludges prevalent in the region are poised for maximum market capture.

- North America: North America represents a mature, stable market characterized by high regulatory standards, demanding efficient dewatering to minimize landfill volumes and transportation costs. Growth here is primarily driven by the replacement cycle of aging infrastructure, technological upgrades (adopting smart, energy-efficient presses), and increasing use in industrial sectors such as food processing and mining tailings management. The region shows strong adoption of advanced features like AI integration for predictive diagnostics and remote operation, valued by utilities seeking to optimize labor efficiency and asset utilization across decentralized facilities.

- Europe: The European market is highly sophisticated, emphasizing circular economy principles, energy efficiency, and low-odor, aesthetically integrated wastewater treatment solutions. Growth is stable, propelled by strict EU directives on sewage sludge treatment, aiming for pathogen reduction and increased recovery of phosphorus and other nutrients. European end-users often favor highly customized, robust, and reliable screw presses that offer superior cake dryness to facilitate thermal drying or incineration processes. Germany, France, and the UK are key markets, focusing intensely on reducing carbon footprint and implementing best available technology (BAT) standards.

- Latin America (LATAM): The LATAM region presents significant long-term growth potential tied to ongoing infrastructure development in metropolitan areas and the growth of heavy industries like mining, agriculture, and oil production. Market penetration is accelerating as countries like Brazil and Mexico invest heavily in water treatment facilities to combat increasing pollution. The demand is often concentrated in affordable, robust presses that can operate reliably in challenging environmental conditions, though investment security and economic stability remain variable factors influencing procurement timelines and technology choices across the continent.

- Middle East and Africa (MEA): The MEA market is heavily influenced by large-scale oil and gas projects, desalination plant waste management, and urbanization projects in the GCC countries (UAE, Saudi Arabia). Screw presses are utilized in managing complex industrial sludges and treating effluent from rapid construction activities. Growth in Africa is more nascent but accelerating, particularly in South Africa and Egypt, driven by the need for basic sanitation improvements and mineral processing expansion. The high cost of water transport in arid regions places a premium on highly efficient dewatering to minimize logistical burdens.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Screw Press Market.- Flottweg SE

- Alfa Laval

- ANDRITZ Group

- Hiller Separation & Processing Equipment

- Vincent Corporation

- WEG S.A.

- Phoenix Process Equipment

- Pieralisi S.p.A.

- Broadbent Ltd.

- Gea Group AG

- Evoqua Water Technologies

- Komline-Sanderson

- Huber SE

- M&C Soluciones

- Sepro Mineral Systems

- Four Seasons Environmental

- Screw Press Solutions Inc.

- Tecnicas de Deshidratacion S.A.

- Drycake Inc.

- Global Water Treatment Systems

Frequently Asked Questions

Analyze common user questions about the Screw Press market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary function and advantage of a screw press in wastewater treatment?

The primary function of a screw press in wastewater treatment is sludge dewatering, which mechanically separates liquid from solid sewage sludge. Its main advantage is continuous operation, low energy consumption, minimal noise, and the ability to handle varying sludge consistencies while achieving a high percentage of cake dryness, thus substantially reducing disposal volume and associated costs.

How does a screw press compare to a centrifuge or belt filter press?

A screw press offers lower energy usage and lower maintenance complexity compared to centrifuges, which rely on high-speed rotational energy. Compared to belt filter presses, screw presses typically achieve higher dryness levels, require less wash water, and have a smaller physical footprint, making them highly cost-effective over the equipment's lifespan, especially for smaller to medium-sized facilities.

Which industries, besides municipal wastewater, are the major consumers of screw presses?

Major industrial consumers include the Food and Beverage sector (for fruit juice extraction, spent grain dewatering, and dairy waste processing), the Pulp and Paper industry (for fiber recovery and black liquor processing), Chemical Manufacturing (for slurry dewatering), and the Agricultural/Biomass sector (for nutrient and biofuel feedstock preparation).

What factors determine the optimal screw press capacity for an industrial facility?

Optimal capacity is determined by the required solids throughput (in kg/hr or tons/day), the initial solids concentration of the feed material, the target cake dryness level, and the physical characteristics of the sludge or slurry, such as viscosity, particle size distribution, and abrasiveness. Detailed pilot testing is often conducted to accurately size the equipment.

What impact is IoT and AI technology having on the reliability of screw presses?

IoT and AI significantly enhance reliability by enabling predictive maintenance through real-time monitoring of vibration, torque, and motor health. This data allows operators to anticipate mechanical failures, optimize operational parameters autonomously for peak efficiency, and minimize unscheduled downtime, thereby extending the equipment's operational life and improving performance consistency.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Screw Press Market Size Report By Type (Single Screw Press, Twin Screw Press), By Application (Industrial Waste Treatment, Paper Mills, Municipal Sludge Treatment, Water Treatment, Others), By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Share, Trends, Outlook and Forecast 2025-2032

- Single Screw Press Market Statistics 2025 Analysis By Application (Industrial Waste Treatment, Paper Mills, Municipal Sludge Treatment, Others), By Type (Small Capacity, Large Capacity), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Screw Press Market Statistics 2025 Analysis By Application (Industrial Waste Treatment, Paper Mills, Municipal Sludge Treatment, Water Treatment), By Type (Single Screw Press, Twin Screw Press), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Slurry Separator Market Statistics 2025 Analysis By Application (Agriculture and Livestock Breeding, Biogass Plant, Food & Beverage Industry, Pulp and Paper Industry), By Type (Scream Separator, Screw Press Separator, Roller Press Separator, Other Separators), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager