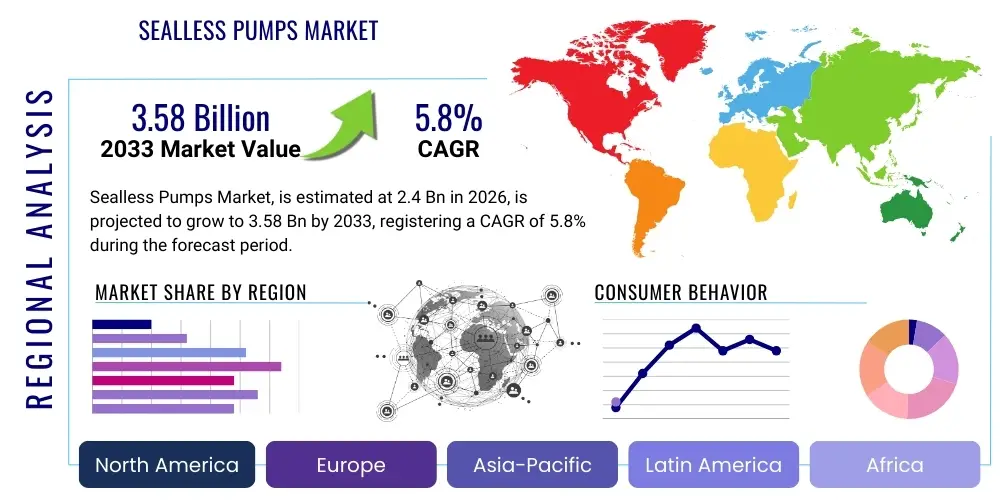

Sealless Pumps Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 441050 | Date : Feb, 2026 | Pages : 248 | Region : Global | Publisher : MRU

Sealless Pumps Market Size

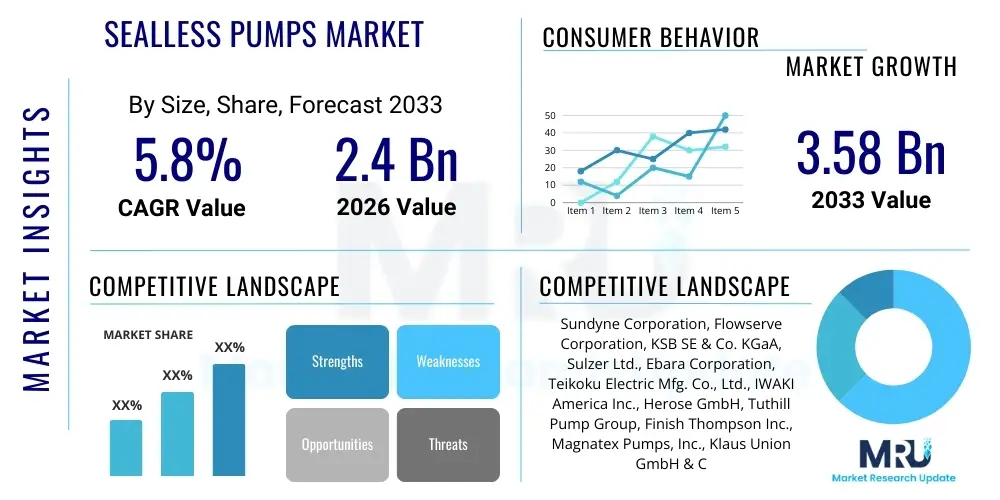

The Sealless Pumps Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at $2.4 Billion in 2026 and is projected to reach $3.58 Billion by the end of the forecast period in 2033. This consistent expansion is primarily driven by increasingly stringent environmental regulations concerning fugitive emissions and enhanced safety protocols across high-risk industries, including chemical processing, oil and gas, and pharmaceutical manufacturing. The inherent design advantages of sealless pumps, which eliminate potential leakage points associated with conventional mechanical seals, are bolstering their adoption globally, positioning them as critical components in sustainable and safe industrial infrastructure.

Sealless Pumps Market introduction

The Sealless Pumps Market encompasses industrial fluid handling equipment specifically engineered to prevent the leakage of hazardous, corrosive, or high-purity media by eliminating traditional mechanical seals. These pumps, predominantly utilizing magnetic drive or canned motor technologies, are indispensable in applications where containment integrity is paramount, thereby ensuring operational safety, minimizing environmental impact, and reducing maintenance overhead. Major applications span critical sectors, including the transfer of volatile organic compounds (VOCs) in chemical synthesis, handling supercritical fluids in power generation, and circulating highly aggressive media in refinery processes.

The core benefit driving the market's growth is the absolute assurance of zero leakage, which dramatically lowers operational expenditures related to lost fluid, cleanup procedures, and regulatory fines associated with environmental non-compliance. Furthermore, the absence of friction-generating seals translates into lower power consumption and extended mean time between failures (MTBF), enhancing overall system reliability. This reliability is particularly valued in remote or difficult-to-access installations where routine maintenance is costly and impractical.

Key driving factors include global regulatory mandates such as the stringent air quality standards set by governmental bodies in North America and Europe, which necessitate leak-proof equipment for toxic substances. The expansion of the global chemical industry, particularly specialty chemicals and petrochemicals, which often handle highly corrosive or flammable liquids, further accelerates demand. Additionally, technological advancements in material science, leading to more robust and chemically resistant containment shells and magnetic couplings, are improving pump efficiency and widening the range of achievable operational parameters, ensuring strong market momentum throughout the forecast period.

Sealless Pumps Market Executive Summary

The Sealless Pumps Market is characterized by robust business trends centered on sustainability and safety, driving significant investment into product innovation. Geographically, Asia Pacific (APAC) is emerging as the fastest-growing region due to rapid industrialization, particularly in chemical and pharmaceutical manufacturing across China, India, and Southeast Asian nations, although North America and Europe maintain dominance in terms of technology adoption and regulatory influence. Companies are increasingly focusing on modular designs, higher pressure ratings, and incorporating smart monitoring capabilities to enhance predictive maintenance schedules and maximize uptime for end-users operating high-value assets. Merger and acquisition activities remain critical as key players seek to expand their technological portfolios and regional distribution networks, especially targeting niche applications like high-pressure pumping for upstream oil and gas processes where containment failure risk is unacceptable.

Segment-wise, magnetic drive pumps currently hold the largest market share owing to their versatility and ability to handle highly viscous fluids, though the canned motor pump segment is expected to witness substantial growth, particularly in nuclear and high-temperature liquid applications due to their compact and hermetically sealed design. The chemical processing segment remains the primary end-user, accounting for the highest volume consumption, driven by the need to handle complex, hazardous intermediary and final products. However, the oil and gas segment, specifically within refining and petrochemicals, presents the most significant opportunities for high-margin, large-scale pump installations, requiring specialized metallurgy and extremely high reliability standards. Manufacturers are prioritizing solutions that integrate seamlessly into existing plant infrastructure while offering superior energy efficiency compliant with evolving global energy standards.

Overall, the market trajectory is strongly positive, fueled by the non-negotiable requirement for environmental protection and worker safety in industrial operations. Regulatory compliance acts as a powerful non-optional driver, pushing laggards toward adopting sealless technology. Future growth will hinge on the successful deployment of next-generation pumps featuring advanced materials, such as specialized ceramics and composites, capable of enduring harsher environments (e.g., extremely high temperatures or abrasive slurries) without compromising the integrity of the containment shell. Furthermore, the integration of Industrial Internet of Things (IIoT) sensors for real-time diagnostics and condition monitoring will define competitive advantage, transitioning the market from a component sale model to a comprehensive fluid handling service model, thereby ensuring sustainable long-term revenue streams.

AI Impact Analysis on Sealless Pumps Market

User inquiries regarding the integration of Artificial Intelligence (AI) and Machine Learning (ML) in the Sealless Pumps Market primarily revolve around predictive maintenance capabilities, optimization of pump performance under varying load conditions, and enhancing design processes. Users are specifically concerned about how AI can mitigate the infrequent but potentially catastrophic failure of containment shells or magnetic couplings, which are zero-leak systems but require high integrity checks. Key themes include the feasibility of using ML algorithms to analyze real-time vibration, temperature, and pressure data streams to predict bearing wear, coupling slippage, or impeller cavitation long before mechanical failure occurs. Expectations center on AI-driven diagnostics reducing the reliance on costly scheduled maintenance, extending the lifespan of expensive components, and optimizing energy consumption by dynamically adjusting pump speed and flow rates based on demand and fluid properties, ultimately lowering the total cost of ownership (TCO) for these critical assets.

- AI-Enhanced Predictive Maintenance: Utilizing ML models to analyze sensor data (vibration, temperature, current draw) for early detection of component degradation, particularly bearing failure and containment shell erosion, mitigating catastrophic zero-leak barrier breaches.

- Optimized Energy Consumption: Deploying algorithms to dynamically adjust variable frequency drives (VFDs) and pump settings in real-time based on process demands, maximizing hydraulic efficiency and minimizing power waste across fluctuating production schedules.

- Digital Twin Development: Creating virtual models of sealless pumps to simulate operational stress, fluid dynamics, and chemical interactions, allowing engineers to test material limits and optimize designs for specialized, highly corrosive applications before physical prototyping.

- Automated Fault Diagnostics: Instant identification and reporting of anomalies, differentiating between minor operational drifts and critical failure precursors, thereby reducing diagnostic time and improving response rates in hazardous environments.

- Supply Chain and Inventory Management: Using AI to forecast demand for specialized pump parts (e.g., specific magnetic couplings or containment shells) and scheduling just-in-time manufacturing, minimizing inventory holding costs while ensuring rapid availability for critical repairs.

- Remote Monitoring and Control: Enabling highly reliable, autonomous operation in remote or inaccessible locations (e.g., offshore platforms or nuclear facilities) where continuous human oversight is impractical, relying on AI to ensure containment integrity.

DRO & Impact Forces Of Sealless Pumps Market

The Sealless Pumps Market dynamics are fundamentally shaped by a powerful synergy between stringent regulatory pressures (Drivers) and the high initial capital investment required (Restraints), creating significant long-term growth Opportunities. The primary Drivers stem from global environmental regulations, such as the EPA’s National Emission Standards for Hazardous Air Pollutants (NESHAP) and European Union directives, which mandate zero leakage for toxic and volatile chemicals, making sealless technology a necessity rather than an option. Restraints include the higher initial purchasing cost compared to conventional sealed pumps, the complexity of magnetic coupling maintenance, and limitations on handling highly abrasive slurries or extremely large flows, which can challenge containment shell integrity. Opportunities reside in the rapid expansion of nuclear power generation globally, the growing adoption of smart factory automation (Industry 4.0), and the untapped potential in specialized food and beverage processing where hygiene and purity requirements necessitate hermetic sealing. These forces collectively exert a strong positive Impact, ensuring that while the market faces cost-related adoption hurdles, the overriding necessity for safety, compliance, and operational reliability guarantees sustained market expansion, particularly in high-value, high-risk industrial applications.

Segmentation Analysis

The Sealless Pumps market is systematically segmented based on technology type, end-user industry, fluid type, and material of construction, allowing manufacturers to tailor products precisely to diverse industrial requirements. Technology segmentation distinguishes between magnetic drive pumps (MDPs) and canned motor pumps (CMPs), each offering unique advantages regarding maintenance access, pressure capabilities, and compactness. End-user classification is crucial, highlighting the dominant demand from the chemical, oil & gas, and pharmaceutical sectors, while niche markets like water treatment and food processing provide stable secondary revenue streams. Analyzing the market through these lenses provides a clear roadmap for investment, focusing development efforts on materials that can withstand the harshest media, such as high-nickel alloys and non-metallic composites, which are essential for maintaining the zero-leak integrity across the operational spectrum.

- By Product Type:

- Magnetic Drive Pumps (MDP)

- Canned Motor Pumps (CMP)

- By Flow Type:

- Centrifugal Pumps

- Positive Displacement Pumps (Gear, Vane, Piston)

- By End-User Industry:

- Chemical and Petrochemical Processing

- Oil and Gas (Upstream, Midstream, Downstream Refining)

- Pharmaceuticals and Biotechnology

- Food and Beverage

- Water and Wastewater Treatment

- Nuclear Power Generation

- Semiconductors and Electronics

- By Material of Construction:

- Metallic (Stainless Steel, Hastelloy, Titanium)

- Non-Metallic (Plastics, Ceramics, Composites)

Value Chain Analysis For Sealless Pumps Market

The value chain for the Sealless Pumps Market begins with highly specialized Upstream activities focused on sourcing and processing advanced materials. Critical inputs include high-performance magnets (e.g., rare-earth magnets like Neodymium-Iron-Boron for strong coupling), chemically inert and high-strength metallic alloys (e.g., Hastelloy C276 or specific duplex stainless steels) for containment shells, and sophisticated non-metallic components (e.g., silicon carbide or carbon bearings) crucial for dry-running protection and longevity. The intellectual property associated with designing and manufacturing high-efficiency magnetic couplings and thin, robust containment shells is a major differentiator in this upstream segment, requiring significant R&D investment. Strategic partnerships with specialized material suppliers are essential to ensure quality and compliance with rigorous industrial standards, particularly for high-pressure and high-temperature applications.

The core manufacturing and assembly stage involves high-precision machining, especially for the pump internals and the static/rotating magnetic components, where minimal tolerances are necessary to ensure efficient magnetic transmission and prevent coupling slippage. Distribution Channels for sealless pumps are bifurcated into Direct Sales and Indirect Sales. Direct sales are predominantly utilized for large, custom-engineered projects, such as major refinery expansions or new chemical plants, where direct consultation and deep application engineering support from the manufacturer are necessary. This allows for greater margin capture and direct control over quality assurance and installation services, offering a highly personalized customer experience tailored to unique process requirements.

Indirect distribution relies heavily on a network of specialized industrial distributors, value-added resellers (VARs), and system integrators who possess localized market knowledge and can provide essential immediate services like installation, routine maintenance, and spare parts supply for standard models. The Downstream phase involves installation, commissioning, and long-term aftermarket services, which are critical revenue streams. Given the complexity and high cost of sealless pumps, end-users depend heavily on qualified service partners for diagnostics, preventive maintenance contracts, and rapid replacement of specialized parts like bearings and containment shells. This service component contributes significantly to customer retention and brand loyalty, making a robust, globally accessible service network a competitive necessity in the overall market structure.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $2.4 Billion |

| Market Forecast in 2033 | $3.58 Billion |

| Growth Rate | CAGR 5.8% |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Sundyne Corporation, Flowserve Corporation, KSB SE & Co. KGaA, Sulzer Ltd., Ebara Corporation, Teikoku Electric Mfg. Co., Ltd., IWAKI America Inc., Herose GmbH, Tuthill Pump Group, Finish Thompson Inc., Magnatex Pumps, Inc., Klaus Union GmbH & Co. KG, Richter Chemie-Technik GmbH, Griswold Pump Company, Vanton Pump & Equipment Corp., Haight Pump, Hayward Tyler, March Manufacturing, Inc., Nikkiso Co., Ltd., Ruhrpumpen Group |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Sealless Pumps Market Key Technology Landscape

The technological landscape of the Sealless Pumps market is dominated by two core designs: Magnetic Drive Pumps (MDPs) and Canned Motor Pumps (CMPs), both of which achieve zero leakage by eliminating the dynamic seal required in conventional pumps. MDPs use powerful rare-earth magnets mounted on the inner and outer rotors to transmit torque across a non-metallic containment shell, physically isolating the motor from the pumped fluid. Recent advancements in MDP technology focus heavily on enhancing the efficiency of the magnetic coupling, minimizing hysteresis losses, and developing robust secondary containment systems to manage risks associated with catastrophic primary containment failure. Furthermore, the development of specialized self-lubricating ceramic bearings (such as silicon carbide) is crucial, allowing the pumps to operate reliably for extended periods in environments where traditional fluid lubrication is challenging or where the process fluid itself has poor lubricating properties. This focus ensures higher MTBF and operational reliability, addressing a major concern among high-throughput chemical plant operators.

Canned Motor Pumps, conversely, enclose the motor rotor and stator within corrosion-resistant metal cans, effectively creating a single, hermetically sealed unit that shares the pumped fluid as the bearing lubricant. CMP technology is favored in highly critical applications, particularly in the nuclear industry and for high-pressure, high-temperature duties, due to their inherently robust, compact design and exceptional ability to withstand extreme operating conditions without external lubrication systems. Technological innovation in CMPs currently centers on improving the 'canning' materials to reduce eddy current losses, which traditionally impact motor efficiency, and integrating advanced monitoring systems to track internal pressure fluctuations and bearing wear. The goal is to maximize the wire-to-liquid efficiency and ensure that the pump remains a truly maintenance-free component for longer operational cycles, thereby justifying the higher initial equipment cost compared to MDPs or sealed counterparts.

A significant trend across the entire sealless pump landscape is the integration of digital capabilities, moving towards Smart Pumps compatible with Industry 4.0 architecture. This involves embedding sophisticated IIoT sensors, microprocessors, and communication modules capable of capturing detailed operating data—including minute vibrations, bearing temperature spikes, and power consumption anomalies. This data is then utilized for real-time diagnostics and predictive maintenance (PdM) algorithms, often running locally or in the cloud. Furthermore, material science is pivotal; manufacturers are continuously exploring advanced non-metallic linings and composite containment shells to handle increasingly aggressive and abrasive fluids (like concentrated acids or slurries) while maintaining thin wall sections necessary for efficient magnetic flux transmission, effectively broadening the application range where sealless technology can be reliably deployed.

Regional Highlights

The global demand for Sealless Pumps exhibits distinct regional variations driven by differing industrial concentration levels, regulatory enforcement rigor, and investment in critical infrastructure sectors like nuclear energy and specialized chemicals. North America and Europe, representing mature industrial economies, are characterized by highly stringent environmental regulations (e.g., EU Seveso Directive, EPA regulations) that make the adoption of zero-leak technology non-negotiable for handling toxic or flammable substances. Consequently, these regions have high penetration rates, stable demand, and serve as key hubs for technological innovation, particularly concerning advanced monitoring systems and high-efficiency pump designs. Demand here is often driven by replacement cycles and capacity expansion in high-value, niche chemical and pharmaceutical manufacturing.

Asia Pacific (APAC) is currently the fastest-growing region in the Sealless Pumps Market. This exponential growth is fueled by massive industrial expansion, particularly in China and India, where large-scale chemical complexes, new refinery installations, and robust investments in pharmaceutical manufacturing are rapidly increasing the installed base. While regulatory oversight is historically less uniform than in Western markets, local governments are increasingly adopting Western-style environmental standards, accelerating the demand for compliant, leak-proof pumping solutions. Furthermore, the rapid expansion of nuclear power programs in countries like China and South Korea significantly boosts demand for high-reliability Canned Motor Pumps.

The Middle East and Africa (MEA) region presents significant market potential, primarily driven by substantial investments in the oil and gas sector (both upstream production and large-scale refining capacity expansions) and petrochemical projects. Sealless pumps are crucial here for handling highly volatile liquids and maximizing operational safety in complex refinery environments where extreme temperatures are common. Latin America, though smaller, exhibits steady growth, mainly centered on modernization efforts in the domestic chemical and mining industries, where the prevention of ground and water contamination is becoming an increasingly critical operational requirement, driving the need for secure, containment-focused fluid transfer systems.

- North America: Market stability, high regulatory compliance, strong demand from specialty chemical and pharmaceutical R&D, and early adoption of IIoT-enabled smart pumps.

- Europe: Driven by strict environmental directives (REACH, ATEX compliance), focus on high-efficiency, energy-saving pump designs, and robust demand from the nuclear and high-end processing sectors.

- Asia Pacific (APAC): Highest growth rate due to rapid infrastructure development, expansion of chemical and petrochemical manufacturing bases, and significant state investment in nuclear power facilities.

- Middle East and Africa (MEA): Demand heavily concentrated in large-scale upstream oil and gas projects and refinery modernization programs focusing on high-pressure, hazardous fluid applications.

- Latin America: Steady demand from core industrial sectors, particularly mining process fluid handling and domestic chemical production, with increasing emphasis on environmental protection standards.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Sealless Pumps Market.- Sundyne Corporation

- Flowserve Corporation

- KSB SE & Co. KGaA

- Sulzer Ltd.

- Ebara Corporation

- Teikoku Electric Mfg. Co., Ltd.

- IWAKI America Inc.

- Herose GmbH

- Tuthill Pump Group

- Finish Thompson Inc.

- Magnatex Pumps, Inc.

- Klaus Union GmbH & Co. KG

- Richter Chemie-Technik GmbH

- Griswold Pump Company

- Vanton Pump & Equipment Corp.

- Haight Pump

- Hayward Tyler

- March Manufacturing, Inc.

- Nikkiso Co., Ltd.

- Ruhrpumpen Group

Frequently Asked Questions

Analyze common user questions about the Sealless Pumps market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary technical difference between magnetic drive and canned motor pumps?

Magnetic drive pumps (MDPs) use an external magnetic coupling to transmit power across a containment shell, separating the motor from the fluid. Canned motor pumps (CMPs) integrate the motor and pump rotor into a single, hermetically sealed unit where the pumped fluid is allowed to circulate within the motor section for cooling and bearing lubrication. MDPs typically offer easier maintenance access to the wet end, while CMPs are inherently more compact and robust for high-pressure, high-temperature duties, especially in the nuclear industry.

Why are sealless pumps essential for the chemical and pharmaceutical industries?

Sealless pumps are essential because they provide absolute assurance of zero fugitive emissions, which is mandated by global environmental regulations for handling volatile organic compounds (VOCs), toxic, flammable, or highly corrosive chemicals commonly found in these sectors. For pharmaceuticals, they ensure product purity and prevent cross-contamination by eliminating potential leakage points associated with traditional mechanical seals, thereby safeguarding both personnel and the high-value process media.

What are the key limitations of adopting sealless pump technology?

The main limitations include a significantly higher initial capital investment compared to standard sealed pumps, reduced efficiency in magnetic drive pumps due to eddy current losses across the containment shell, and challenges in reliably handling fluids that contain large amounts of abrasive solids or slurries. Abrasion can rapidly degrade the specialized, close-tolerance internal bearings (e.g., silicon carbide), leading to catastrophic failure if not monitored through advanced condition monitoring systems.

How do sealless pumps contribute to reduced operational expenditure (OPEX)?

Sealless pumps reduce OPEX by virtually eliminating costs associated with seal failure, including lost product, environmental fines, maintenance labor for seal replacement, and required cleanup operations for leakage incidents. Their design ensures longer mean time between failures (MTBF) and typically lower energy consumption over time compared to sealed counterparts that suffer from friction and degradation, resulting in lower total cost of ownership (TCO) despite the high upfront cost.

What role does Industry 4.0 play in the future development of the Sealless Pumps Market?

Industry 4.0 enables the integration of IIoT sensors and AI-driven predictive maintenance (PdM) systems into sealless pumps. This integration allows for continuous, real-time monitoring of critical parameters like temperature and vibration. This data allows operators to predict internal component wear, such as bearing degradation or magnetic coupling slippage, facilitating just-in-time repairs and maximizing operational uptime, transforming pump management from reactive to highly predictive and automated.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager