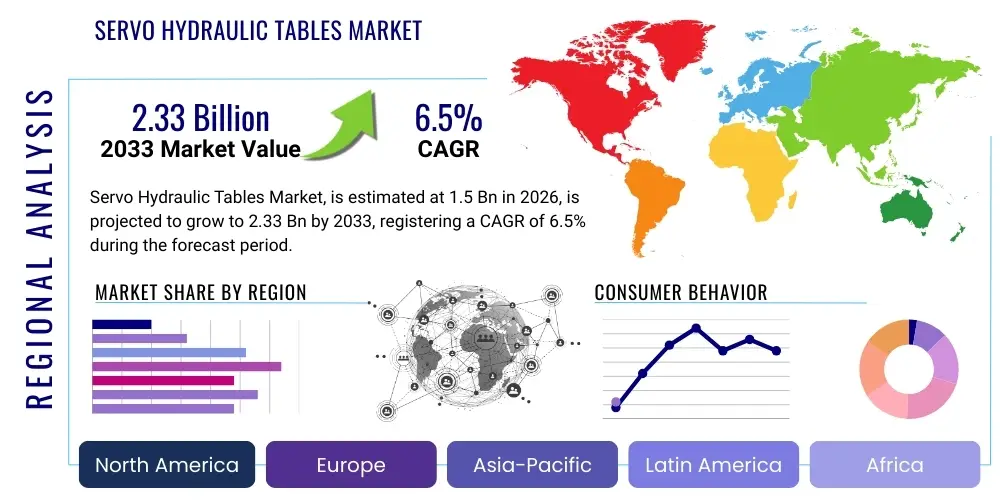

Servo Hydraulic Tables Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440897 | Date : Feb, 2026 | Pages : 257 | Region : Global | Publisher : MRU

Servo Hydraulic Tables Market Size

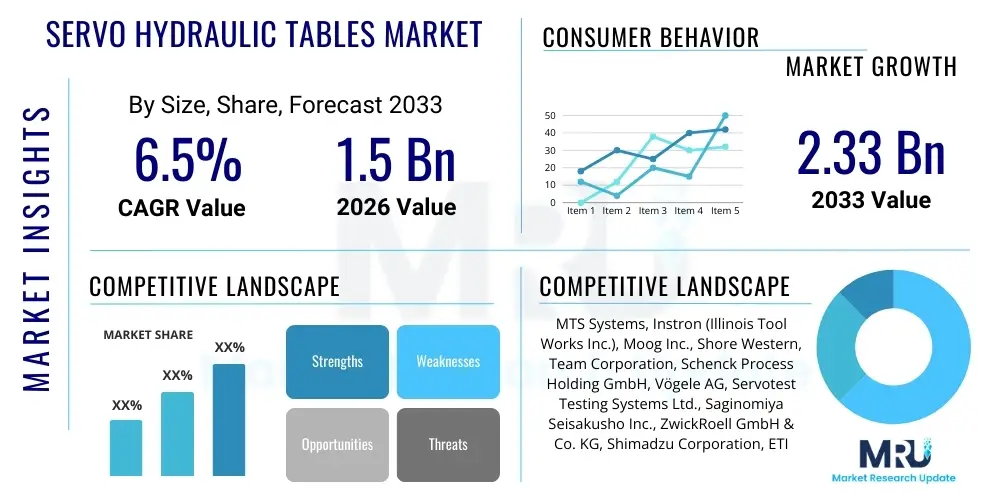

The Servo Hydraulic Tables Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5% between 2026 and 2033. The market is estimated at USD 1.5 Billion in 2026 and is projected to reach USD 2.33 Billion by the end of the forecast period in 2033. This consistent growth trajectory is fundamentally driven by the escalating global necessity for rigorous structural integrity testing and advanced material analysis across critical infrastructure and high-performance sectors such as aerospace and automotive manufacturing. The increasing stringency of international safety regulations, particularly those concerning seismic resilience and fatigue life of components, necessitates the adoption of high-fidelity, large-scale testing apparatus like servo hydraulic tables, ensuring sustained investment in this specialized capital equipment market throughout the forecast period.

Servo Hydraulic Tables Market introduction

The Servo Hydraulic Tables Market encompasses high-performance dynamic testing systems utilized primarily for structural, seismic, and durability testing of large specimens, components, or assemblies. These systems, often referred to as shaking tables or simulation tables, leverage advanced closed-loop servo-hydraulic technology to precisely replicate real-world environmental and load conditions, including complex, multi-axis dynamic inputs. The primary function is to validate the safety, longevity, and performance of critical structures under extreme operating scenarios, ensuring compliance with global engineering and safety standards. The sophisticated control algorithms inherent in modern servo hydraulic systems allow for exceptional accuracy in frequency response and displacement control, making them indispensable tools in advanced research and development settings, particularly within civil engineering and transportation industries.

Major applications of servo hydraulic tables span several high-value sectors. In civil engineering, they are crucial for seismic simulation, testing the resilience of bridges, buildings, and non-structural components against earthquake loads, thereby directly mitigating catastrophic risk. Within the automotive and aerospace industries, these tables are employed for accelerated fatigue testing, verifying the durability of vehicle chassis, aircraft wing sections, and engine mounts under highly controlled, high-frequency loading conditions. The benefits derived from employing these systems are substantial, including accelerated product development cycles, enhanced component reliability, and significant reduction in physical prototype costs due to superior simulation fidelity. These factors collectively contribute to the high capital investment willingness among leading industry participants.

The core driving factors fueling the market growth include the global surge in infrastructure development, especially in seismically active regions, demanding stringent validation of new construction materials and designs. Furthermore, the relentless pursuit of lighter, yet stronger, materials in the transportation sector mandates sophisticated testing capabilities to ensure structural integrity without compromising performance. Technological advancements, such as the integration of digital twins and real-time data acquisition systems with servo hydraulic controllers, are expanding the functional scope and testing efficiency of these tables, making them increasingly attractive investments for cutting-edge research facilities and large-scale manufacturing quality assurance departments worldwide. This confluence of regulatory pressure, application expansion, and technological refinement underpins the market's robust outlook.

Servo Hydraulic Tables Market Executive Summary

The Servo Hydraulic Tables Market is characterized by intense technological competition and a strong correlation with global capital expenditure in advanced R&D and critical infrastructure projects. Key business trends indicate a pivot towards modular and customizable testing solutions that offer flexibility in scale and application, moving away from monolithic, single-purpose installations. Furthermore, there is a distinct trend towards integrating high-channel data logging and visualization software directly into the control architecture, transforming the tables from mere testing platforms into sophisticated data generation centers. The stringent regulatory environment in developed economies, coupled with significant governmental funding directed towards structural resilience research, continues to stabilize demand and drive innovation in control precision and force capacity.

Regionally, the market exhibits a clear bifurcation: established stability and technological leadership in North America and Europe, versus aggressive expansion and capacity building in the Asia Pacific (APAC) region. North America, driven by demanding aerospace and defense contracts, prioritizes high-frequency, multi-axis testing systems, often leveraging governmental research labs and top-tier universities. Europe focuses heavily on standardization and environmental performance testing, underpinned by rigorous EU directives. Conversely, APAC, particularly China, India, and Japan, is experiencing explosive growth due to rapid urbanization, massive infrastructure investment (e.g., high-speed rail, skyscraper construction), and a heightened focus on seismic safety following recent large-scale natural disasters. This shift in infrastructure investment positioning APAC as the highest growth potential region for new installations.

In terms of segment trends, the demand for tables specifically designed for seismic simulation (high displacement, lower frequency) is outpacing standard fatigue testing tables, reflecting the global focus on civil resilience. Moreover, the component testing segment, covering subsystems like vehicle dashboards and battery packs (especially critical in the transition to Electric Vehicles), is seeing substantial growth, requiring smaller, yet highly responsive, servo hydraulic platforms. The hydraulic component manufacturers are concurrently investing heavily in more energy-efficient and quieter hydraulic power units (HPUs) to meet environmental and operational standards, enhancing the overall appeal and operational efficiency of new servo hydraulic table installations across all relevant market segments.

AI Impact Analysis on Servo Hydraulic Tables Market

User queries regarding the intersection of Artificial Intelligence (AI) and the Servo Hydraulic Tables Market overwhelmingly center on two key areas: the optimization of complex testing protocols and the establishment of advanced predictive maintenance routines for this high-value machinery. Users are concerned with how AI can reduce testing time without sacrificing accuracy, specifically looking at algorithms that can learn from previous test failures or successes to refine load profiles dynamically. There is also significant interest in leveraging machine learning models to analyze the vast streams of data generated during multi-axis simulations, extracting nuanced behavioral insights that traditional, rule-based analysis might overlook. The primary expectation is that AI integration will lead to higher operational uptime, significantly lower power consumption through optimized HPU management, and a deeper, more actionable understanding of material and structural failure mechanisms.

The integration of AI into the servo hydraulic ecosystem moves the testing process beyond simple execution towards intelligent optimization. AI algorithms are being developed to interpret real-time sensor data from the testing specimen and the table's hydraulic system itself, allowing for instantaneous adjustments to maintain optimal testing conditions, even under unforeseen transient loads. This intelligence drastically improves the repeatability and reproducibility of highly complex tests, which is critical for certification processes in aerospace and civil construction. Furthermore, AI facilitates the development of 'digital twin' models, where the physical test on the servo table is mirrored virtually, allowing analysts to iterate on design changes or failure scenarios much faster than purely physical testing permits, driving significant efficiency gains across the entire R&D lifecycle.

A crucial concern addressed by AI is the maintenance and operational reliability of these expensive, high-force systems. Predictive maintenance (PdM) using machine learning analyzes vibrations, pressure fluctuations, oil cleanliness, and temperature trends within the hydraulic power unit and actuators. By identifying subtle anomalies predictive of impending component failure (such as pump degradation or valve blockage) long before they cause operational shutdown, AI significantly reduces unexpected downtime and maintenance costs. This proactive approach ensures maximized utilization of the servo hydraulic table, which is essential given its high capital cost and central role in product validation timelines.

- AI optimizes complex test sequence generation, reducing the time required for structural validation.

- Machine Learning enhances predictive maintenance, forecasting HPU and actuator failures to maximize uptime.

- AI integrates real-time sensor data for dynamic control, improving test fidelity and minimizing human error.

- Generative AI assists in creating synthetic data sets to augment physical testing results and train failure prediction models.

- AI enables sophisticated post-processing analysis, identifying subtle material responses under dynamic loading conditions.

DRO & Impact Forces Of Servo Hydraulic Tables Market

The Servo Hydraulic Tables Market is shaped by a powerful interplay of drivers, restraints, and opportunities, collectively categorized as Dynamic Reshaping Opportunities (DRO) and broader impact forces. Key drivers include the ever-increasing globalization of engineering standards and mandatory safety certifications, particularly in high-risk applications like seismic zones and aircraft structures, forcing manufacturers to invest in rigorous testing equipment. Restraints primarily revolve around the exceptionally high initial capital expenditure associated with purchasing and installing multi-axis servo hydraulic systems, coupled with significant operational costs tied to power consumption and specialized maintenance. Opportunities emerge through geographic expansion into rapidly industrializing economies, coupled with the rising demand for highly specialized, smaller-scale tables designed for specific component testing in the growing electric vehicle (EV) battery and advanced materials segments. These factors dictate the market's short-term fluctuations and long-term strategic direction.

The impact forces within this market are substantial and systemic. Regulatory pressure is arguably the most potent force, as standards bodies like ASTM, ISO, and sector-specific authorities (e.g., FAA, IATA) continuously raise the bar for structural integrity and fatigue life, making advanced simulation testing mandatory rather than optional. Technological innovation acts as a force multiplier; advancements in digital control electronics, sensor technology, and high-flow servo valves increase the performance ceiling and efficiency of new systems, prompting replacement cycles in older installations. Economic stability also plays a critical role, as major purchases of servo hydraulic tables are capital projects highly sensitive to interest rates, governmental R&D funding allocation, and corporate profit margins across the automotive and aerospace industries. Geopolitical stability also influences supply chains for specialized hydraulic components and the construction of new regional testing centers.

Specific drivers include the heightened need for reliable infrastructure testing in regions prone to natural hazards, increasing global military spending necessitating high-fidelity component validation, and the transition toward lightweight composites and additive manufactured materials which require novel testing methodologies that only dynamic servo hydraulic systems can provide. The main restraints, beyond cost, include the requirement for highly skilled technical personnel to operate and calibrate these complex systems, posing a training bottleneck, and the significant physical footprint and associated infrastructure requirements (heavy foundations, dedicated power supply) necessary for large-scale tables. Opportunities center on providing modular solutions that can be scaled or reconfigured, servicing the growing retrofit market for existing tables, and developing integrated testing solutions that combine environmental chambers with dynamic loading capabilities, addressing a specialized niche demand for combined stress testing.

Segmentation Analysis

The Servo Hydraulic Tables market is comprehensively segmented based on three primary dimensions: the application end-use, the system type defined by capabilities, and the component type supplied. Application segmentation delineates demand characteristics across distinct high-value sectors such as Civil Engineering (dominated by seismic simulation needs), Automotive (focused on durability and road load simulation), and Aerospace (requiring high-frequency fatigue testing). System type segmentation often divides the market by the number of axes (single, dual, or multi-axis systems) and the maximum force or frequency capacity provided. Component segmentation covers the essential hardware elements, including the core control systems, hydraulic power units (HPUs), actuators, and the structural table itself. This multi-faceted segmentation helps manufacturers tailor product offerings and sales strategies to highly specific industry requirements and testing standards, allowing for precise market sizing and strategic targeting across regional demographics.

- By Application:

- Civil Engineering & Infrastructure Testing (Bridges, Buildings, Dams)

- Automotive & Transportation (Vehicle Chassis, Component Durability, NVH testing)

- Aerospace & Defense (Wing Fatigue, Landing Gear, Engine Mounts)

- Material Science & Research (Advanced Composites, Metals)

- Geotechnical Testing and Simulation

- By Type/Capacity:

- Small-Scale Tables (Component Testing, < 5 Tons Capacity)

- Medium-Scale Tables (Sub-assembly Testing, 5 – 50 Tons Capacity)

- Large-Scale Tables (Full-Scale Structural/Seismic Simulation, > 50 Tons Capacity)

- Single-Axis Testing Systems

- Multi-Axis Testing Systems (2-DOF, 3-DOF, 6-DOF)

- By Component:

- Hydraulic Power Units (HPUs)

- Servo Valves and Actuators

- Control Hardware & Software (Controllers, Data Acquisition Systems)

- Table Structures and Fixtures

- Sensor and Transducer Systems

Value Chain Analysis For Servo Hydraulic Tables Market

The value chain for the Servo Hydraulic Tables Market is characterized by a high degree of integration between specialized component suppliers and system integrators, reflecting the technical complexity of the final product. Upstream activities involve the procurement of highly specialized, high-tolerance components, including high-flow, low-noise hydraulic pumps, precision-machined actuators, and advanced digital servo control electronics. This segment is dominated by a relatively small number of highly specialized vendors who often maintain long-term supply relationships with the core table manufacturers. The manufacturing stage is capital intensive, involving rigorous machining, welding of heavy-duty steel structures (the table platform), and sophisticated assembly of the electro-hydraulic system, demanding exceptional quality control and adherence to structural integrity standards. Intellectual property, particularly relating to control algorithms and vibration isolation techniques, represents a substantial portion of the upstream value.

The distribution channel is predominantly characterized by direct sales and highly technical consultative selling, necessitated by the custom nature and high cost of these systems. Due to the requirement for specific site preparation, foundation design, and calibration, standard indirect distribution channels like general industrial distributors are rarely utilized. Instead, Original Equipment Manufacturers (OEMs) employ highly trained application engineers who work directly with the end-user (e.g., government labs or automotive OEMs) from the initial specification phase through installation, commissioning, and long-term service contracts. Indirect channels, where they exist, are typically limited to local sales representatives who facilitate initial contact but delegate technical discussions to the OEM's in-house experts. Aftermarket service, calibration, and software updates form a crucial, high-margin component of the distribution and post-sales segment.

Downstream activities center on installation, training, and ongoing service provision. The downstream market is highly service-dependent, generating recurring revenue through maintenance contracts, calibration services, and system modernization or retrofit programs. End-users require continuous support to ensure the system remains compliant with evolving testing standards and maximizes operational uptime. Furthermore, specialized training services are essential for end-user personnel to effectively program, run, and analyze results from multi-axis dynamic tests. The integration of data analysis software and connectivity tools often requires sustained collaboration between the supplier and the user, cementing a long-term relationship that extends well beyond the initial capital equipment sale, further consolidating the direct sales model within this specialized B2B environment.

Servo Hydraulic Tables Market Potential Customers

Potential customers for Servo Hydraulic Tables are concentrated in large organizations requiring definitive, accredited testing for critical components and infrastructure where failure carries severe consequences in terms of safety, financial loss, or regulatory penalties. The primary end-users, or buyers, are major entities in governmental and academic research sectors, followed closely by multinational corporations within regulated industries. This includes national laboratories focused on seismic hazard mitigation and structural materials development, such as the US National Science Foundation facilities or European Earthquake Engineering centers. These institutions often acquire the largest, highest-capacity multi-axis tables to simulate large-scale natural phenomena or full-scale vehicle tests, driven primarily by public safety mandates and large-scale research grants.

The second major cohort of potential customers consists of Original Equipment Manufacturers (OEMs) within the automotive, aerospace, and heavy machinery sectors. Automotive manufacturers, for instance, utilize these tables to perform road load simulation (RLS) and noise, vibration, and harshness (NVH) testing on entire vehicle bodies or critical subsystems like suspension and powertrain mounts, ensuring durability over simulated lifecycles. Aerospace companies rely on them for fatigue testing of critical flight control surfaces, engine mounts, and landing gear, where performance validation is strictly controlled by global aviation authorities. These corporate buyers are motivated by competitiveness, reducing warranty claims, and achieving rapid, cost-effective product certification.

A burgeoning segment of potential customers includes specialized contract testing houses and independent certification laboratories. As R&D budgets fluctuate and the need for accredited testing increases, many smaller manufacturers or those with lower test volumes opt to outsource their dynamic testing requirements to these specialized service providers. These testing houses invest in a diverse array of servo hydraulic tables to offer comprehensive services across various standards (e.g., MIL-STD, specific ISO protocols), acting as a crucial intermediary enabling widespread market access to these high-cost testing capabilities for companies that cannot justify the multi-million dollar capital expenditure for their own dedicated facility. The selection criteria for all these customers heavily favor reliability, precision, software capability, and long-term service support.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.5 Billion |

| Market Forecast in 2033 | USD 2.33 Billion |

| Growth Rate | 6.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | MTS Systems, Instron (Illinois Tool Works Inc.), Moog Inc., Shore Western, Team Corporation, Schenck Process Holding GmbH, Vögele AG, Servotest Testing Systems Ltd., Saginomiya Seisakusho Inc., ZwickRoell GmbH & Co. KG, Shimadzu Corporation, ETI Limited, Froude Hofmann Ltd., Labquip Limited, Tinius Olsen, Wipro Infrastructure Engineering, Galdabini S.p.A., BUEHLER, Ametek Inc., Sino-Test Equipment Co., Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Servo Hydraulic Tables Market Key Technology Landscape

The technological landscape of the Servo Hydraulic Tables Market is defined by continuous innovation in control systems, hydraulic components, and data management software, aiming for higher fidelity, greater energy efficiency, and enhanced user capability. The foundational technology remains the closed-loop servo control system, but modern implementations incorporate extremely high-speed digital controllers and field-programmable gate arrays (FPGAs) to achieve sub-millisecond control loops. This precision is essential for accurately replicating high-frequency dynamic inputs, such as those required in acoustic fatigue testing or complex road load simulation profiles. The migration from analog to purely digital control architecture has significantly reduced signal noise and drift, enabling unparalleled accuracy and repeatability in test results, which is a major purchasing criterion for accredited laboratories and defense contractors.

Another critical area of technological advancement is in the development of more sustainable and efficient Hydraulic Power Units (HPUs). Traditional HPUs are notorious for high energy consumption and noise pollution. The industry is rapidly adopting variable frequency drives (VFDs) and pump-on-demand technology, allowing the HPU to modulate oil flow and pressure based precisely on the instantaneous demand of the actuators, rather than running continuously at full capacity. This innovation not only drastically cuts power consumption, reducing the total cost of ownership (TCO), but also lowers operational noise, making the tables suitable for installation in university labs or urban R&D centers where noise restrictions are tight. This focus on efficiency aligns the industry with global environmental standards and provides a strong incentive for end-users to upgrade legacy equipment.

Furthermore, the sensor and data acquisition technology integrated into the tables is becoming vastly more sophisticated. Modern servo hydraulic tables are equipped with dozens, sometimes hundreds, of high-resolution sensors (force transducers, accelerometers, LVDTs) capable of simultaneous, synchronized data collection at extremely high sampling rates (e.g., 10 kHz or higher). This massive data capability is further enhanced by integrated software platforms that enable real-time visualization, advanced signal processing, and direct interfacing with external Finite Element Analysis (FEA) software. The ability to seamlessly correlate physical test data with numerical simulation models is revolutionizing product validation, establishing a hybrid testing paradigm that accelerates the design cycle, and reinforcing the competitive advantage of systems offering superior data throughput and analytical tools.

Regional Highlights

- North America: This region represents a mature, high-value segment characterized by early adoption of advanced multi-axis testing systems, particularly within the defense, aerospace, and high-end automotive sectors. The presence of major research institutions and governmental labs (e.g., those affiliated with NASA, FEMA) drives demand for large-scale, high-fidelity seismic tables. Stringent safety and operational standards, coupled with consistent R&D spending, ensure continued replacement and upgrading of existing infrastructure. The US remains the dominant market, focused on technological leadership and custom-built solutions.

- Europe: Europe is defined by rigorous standardization and a strong focus on structural safety, especially in high-speed rail and infrastructure development governed by the European Union. Germany, the UK, and France are core markets, investing significantly in fatigue testing for wind energy components and automotive durability. European manufacturers lead in developing energy-efficient HPU technology and modular table designs that adhere to strict environmental and workplace safety regulations. Public-private partnerships often fuel major investments in specialized testing facilities.

- Asia Pacific (APAC): APAC is the fastest-growing market globally, fueled by rapid urbanization, massive government investment in infrastructure (e.g., bridges, high-rise buildings), and the resulting urgent need for seismic risk mitigation and structural validation. China and Japan are leading consumers, with China aggressively expanding its testing capacity to support its vast manufacturing and construction output, often prioritizing high-capacity seismic and component testing tables. India is also emerging as a significant market due to increasing regulatory focus on civil infrastructure quality and safety.

- Latin America (LATAM): Growth in this region is moderate but highly focused on resource extraction and infrastructure repair. Demand is concentrated in countries like Brazil and Mexico, driven by oil and gas industry testing requirements and localized seismic safety mandates. Investment is often project-based, favoring smaller to medium-scale component durability testing rather than massive structural simulation tables. Economic volatility can sometimes restrain large-scale capital investments.

- Middle East and Africa (MEA): This region shows significant potential due to ongoing mega-projects in civil construction (e.g., Saudi Arabia’s Vision 2030) and burgeoning oil and gas R&D centers. Demand is specifically tailored to testing materials for extreme environmental conditions (high heat, desert environments). While still a nascent market for large-scale tables, the strong inflow of capital for defense and infrastructure creates specialized opportunities for providers of robust, high-durability testing systems.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Servo Hydraulic Tables Market.- MTS Systems

- Instron (Illinois Tool Works Inc.)

- Moog Inc.

- Shore Western

- Team Corporation

- Schenck Process Holding GmbH

- Vögele AG

- Servotest Testing Systems Ltd.

- Saginomiya Seisakusho Inc.

- ZwickRoell GmbH & Co. KG

- Shimadzu Corporation

- ETI Limited

- Froude Hofmann Ltd.

- Labquip Limited

- Tinius Olsen

- Wipro Infrastructure Engineering

- Galdabini S.p.A.

- BUEHLER

- Ametek Inc.

- Sino-Test Equipment Co., Ltd.

Frequently Asked Questions

Analyze common user questions about the Servo Hydraulic Tables market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary function of a servo hydraulic table?

The primary function is to perform high-fidelity, multi-axis dynamic and static testing on large structures, components, or materials. This is achieved by precisely replicating real-world loading conditions such as seismic events, road loads, or aero-dynamic fatigue profiles using advanced closed-loop hydraulic control systems to validate structural integrity and performance.

Which industries are the major users of large-scale servo hydraulic tables?

The major users are concentrated in Civil Engineering and Infrastructure testing (for seismic simulation and bridge components), the Aerospace sector (for fatigue testing of flight structures), and the Automotive industry (for durability and road load simulation of full vehicle chassis and battery packs).

How does AI technology influence the operational efficiency of these testing systems?

AI significantly enhances operational efficiency by optimizing test sequences, reducing setup time, and enabling highly accurate predictive maintenance (PdM) of the complex hydraulic components. This reduces unexpected downtime and ensures higher utilization rates of these high-cost capital assets.

What is the current growth driver for the Servo Hydraulic Tables Market in the Asia Pacific region?

The current growth driver in APAC is rapid, large-scale urbanization and infrastructure development, particularly the need for robust seismic simulation and validation of new building standards in seismically active areas, coupled with significant governmental investment in advanced R&D facilities.

What are the main financial constraints related to adopting servo hydraulic tables?

The main constraints are the exceptionally high initial capital expenditure required for purchasing and installing the systems, the associated costs of specialized foundational civil works, and high ongoing operational costs related to hydraulic fluid maintenance and significant electrical power consumption.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager