Sheet Membranes Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 441673 | Date : Feb, 2026 | Pages : 242 | Region : Global | Publisher : MRU

Sheet Membranes Market Size

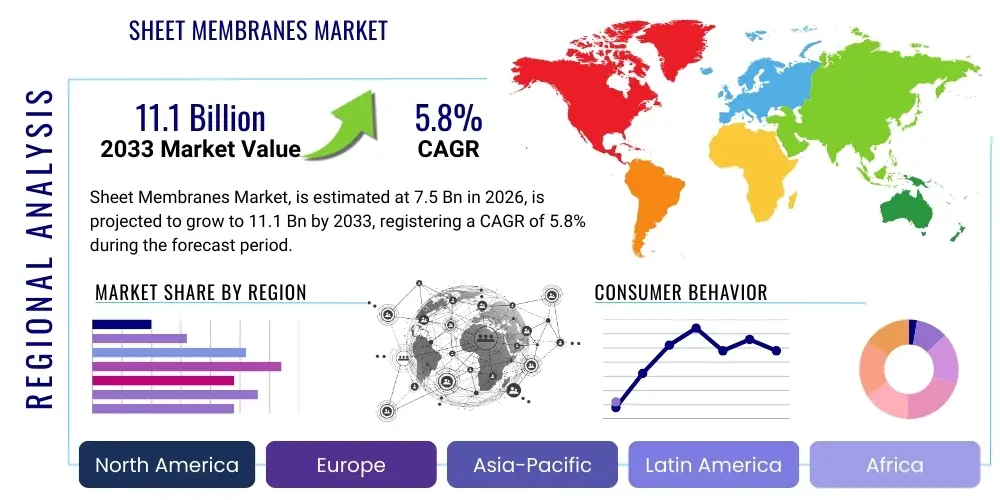

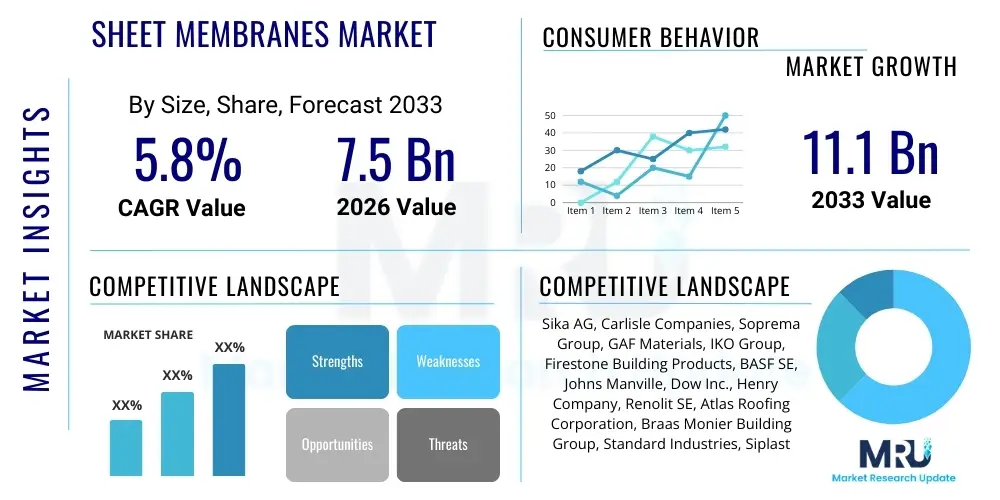

The Sheet Membranes Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at $7.5 Billion in 2026 and is projected to reach $11.1 Billion by the end of the forecast period in 2033.

This robust growth trajectory is primarily driven by escalating global infrastructure spending, particularly in rapidly developing economies, and the increasing stringency of building codes mandating effective waterproofing solutions. Sheet membranes, favored for their reliability, consistent thickness, and ease of inspection compared to liquid-applied systems, are seeing heightened demand across residential, commercial, and critical civil engineering projects. The market expansion is also supported by technological advancements, leading to the introduction of durable, flexible, and sustainable membrane types, such as advanced TPO and PVC formulations.

Sheet Membranes Market introduction

The Sheet Membranes Market encompasses pre-formed flexible or semi-rigid barriers utilized extensively in the construction industry for waterproofing, vapor blocking, and protective layering. These membranes, typically supplied in rolls or sheets, are engineered using various materials including modified bitumen (SBS, APP), synthetic polymers (PVC, TPO, EPDM), and rubberized asphalt. Their primary function is to prevent water ingress into building structures, below-grade foundations, roofing assemblies, and civil infrastructure like tunnels and bridges, thereby ensuring structural integrity and longevity.

Major applications of sheet membranes include roofing systems (both low-slope and steep-slope), basement and foundation waterproofing, green roof systems, and specialized civil engineering projects. The product description emphasizes uniformity in material composition and thickness, which minimizes application variance and ensures high performance. Benefits driving their adoption include superior resistance to hydrostatic pressure, excellent elongation and flexibility to bridge cracks, and rapid installation, often utilizing self-adhering or heat-welded application techniques. Furthermore, their proven long-term durability in extreme weather conditions makes them a preferred choice over alternative waterproofing methods.

Key factors driving market growth include rapid urbanization necessitating new construction, substantial investments in repairing and replacing aging public infrastructure globally, and stringent regulatory requirements regarding moisture control and energy efficiency in modern buildings. The shift towards sustainable construction practices also favors certain membrane types, such as highly reflective TPO and EPDM, which contribute to reduced cooling costs and compliance with green building standards.

Sheet Membranes Market Executive Summary

The Sheet Membranes Market is poised for significant expansion, fueled predominantly by robust business trends emphasizing durable, high-performance building materials and accelerated construction timelines. Key business trends include the strong adoption of self-adhering membranes (SAMs), which reduces labor time and reliance on specialized equipment, and the increasing focus of manufacturers on optimizing the supply chain to manage volatile raw material costs, particularly bitumen and petrochemical-derived polymers. Strategic mergers and acquisitions among major players are also consolidating market expertise and expanding geographical reach, particularly in high-growth construction markets.

Regionally, the Asia Pacific (APAC) stands out as the primary growth engine, driven by massive investments in residential complexes, commercial infrastructure, and large-scale public works in countries like China, India, and Southeast Asian nations. North America and Europe, while mature, continue to show stable demand, characterized by a strong focus on refurbishment, retrofitting aging infrastructure, and adherence to strict energy efficiency and green building regulations (e.g., LEED and BREEAM standards), favoring polymeric membranes like PVC and TPO for roofing applications. Latin America and the Middle East & Africa (MEA) are emerging as high-potential markets due to burgeoning real estate sectors and the need for waterproofing solutions tailored to diverse climatic extremes.

Segment trends highlight the dominance of bituminous membranes, specifically SBS modified bitumen, due to their cost-effectiveness and widespread use in traditional roofing and foundation waterproofing. However, the synthetic polymer segment, including TPO (Thermoplastic Polyolefin) and PVC (Polyvinyl Chloride), is projected to exhibit the highest CAGR, propelled by their superior UV resistance, energy-saving capabilities (reflective surfaces), and ease of heat-welded seam integrity, making them ideal for large-scale commercial roofing projects. The civil infrastructure segment is witnessing rapid growth, driven by extensive road, bridge, and tunnel construction that requires robust, long-lasting below-grade waterproofing solutions.

AI Impact Analysis on Sheet Membranes Market

User inquiries regarding the integration of Artificial Intelligence (AI) in the Sheet Membranes Market primarily revolve around enhancing manufacturing quality control, optimizing installation predictability, and automating supply chain logistics for raw materials. Common concerns address how AI can monitor membrane consistency during production, predict potential material failures based on environmental data, and streamline complex construction logistics to reduce waste and labor costs. Users are keenly interested in predictive analytics for material inventory management, especially given the historical volatility of petrochemical inputs, and the deployment of machine learning algorithms to assess real-time application quality on job sites, potentially via drone inspection and image analysis.

AI’s influence is moving beyond theoretical application into practical operational tools, particularly in large-scale manufacturing. AI-driven quality assurance systems use advanced sensors and computer vision to continuously inspect the sheet membrane production line, immediately identifying minor defects, variations in thickness, or inconsistencies in material blending that human inspection might miss. This precision manufacturing capability ensures that membranes meet the exact specifications required for high-stakes projects like critical infrastructure, thus enhancing overall product reliability and reducing the frequency of on-site application failures attributed to material quality issues. Furthermore, the use of AI algorithms in material formulation research is accelerating the development of next-generation, high-performance, and environmentally friendly polymer blends, shortening the typical R&D cycle for new products.

On the deployment and construction side, AI is instrumental in predictive maintenance and scheduling. Machine learning models analyze historical project data, weather patterns, and crew performance metrics to optimize membrane installation schedules, mitigating risks associated with unfavorable application conditions. For complex projects, such as large tunnel waterproofing, AI-powered tools can analyze sensor data from the site environment (temperature, humidity, substrate moisture content) to provide real-time recommendations for application adjustments, ensuring optimal bonding and longevity. This capability significantly elevates the quality of final installation, a critical factor often determining the ultimate performance of a sheet membrane system.

- AI optimizes manufacturing quality control through continuous, real-time computer vision inspection of membrane consistency and thickness.

- Predictive maintenance algorithms analyze installation conditions and environmental factors to forecast potential failure points and optimize application scheduling.

- Machine learning enhances supply chain resilience by accurately forecasting demand and managing inventory levels of volatile raw materials (bitumen, polymers).

- Robotic process automation (RPA) supported by AI facilitates highly precise cutting, handling, and packaging of sheet membranes, minimizing material waste.

- Drone-based AI image analysis enables rapid, non-destructive quality assessment of installed membrane systems on large roofs or substructures.

DRO & Impact Forces Of Sheet Membranes Market

The Sheet Membranes Market is profoundly influenced by a confluence of driving factors, market constraints, and emerging opportunities, collectively shaping its trajectory. The primary driver is the accelerating global pace of urbanization and the subsequent demand for durable, water-resistant building enclosures across commercial, residential, and industrial segments. Coupled with this is the critical need for infrastructure renewal, where governments worldwide are allocating substantial budgets to upgrade aging public works, including tunnels, bridges, and subterranean structures, all of which require specialized and robust waterproofing systems. Regulatory mandates, particularly in developed regions, demanding higher standards for energy efficiency and moisture mitigation, further amplify the demand for high-performance sheet membrane systems like TPO and PVC, which often boast high solar reflectivity and longevity.

However, the market faces significant restraints, most notably the high volatility and increasing cost of raw materials derived from petrochemicals (for synthetic polymers) and crude oil (for bitumen modification). These fluctuating input costs can compress profit margins for manufacturers and lead to unpredictable pricing for end-users, potentially favoring cheaper, less robust alternatives in price-sensitive markets. Additionally, the labor-intensive nature of traditional membrane installation, coupled with a shortage of skilled labor in many developed economies, poses a logistical challenge, although this is being partially mitigated by the rise of self-adhering technologies. Intense competition from liquid-applied waterproofing systems, which offer seamless application benefits, also acts as a constraint in certain application scenarios.

Significant opportunities exist in the shift towards sustainable construction materials, driving research into bio-based and recycled content membranes that appeal to environmentally conscious builders and regulatory bodies. The expansion into niche applications, such as specialized membranes for green roofs (requiring root penetration resistance) and highly demanding cryogenic storage facilities, offers substantial premium market potential. Furthermore, continuous technological refinement, focusing on enhancing membrane flexibility, puncture resistance, and integration with smart building technologies (e.g., leak detection sensors), provides a clear path for differentiation and sustained market growth. These DRO factors represent the primary impact forces dictating investment decisions, product innovation cycles, and competitive strategy within the sector.

Segmentation Analysis

The Sheet Membranes Market is comprehensively segmented based on material type, application, and end-use, allowing for precise market analysis tailored to specific construction needs and regulatory environments. This intricate segmentation reflects the diverse performance requirements placed on waterproofing and protective barriers, ranging from highly exposed roofing systems to subterranean foundations facing severe hydrostatic pressure. Understanding these segments is crucial as material choice directly impacts durability, cost, and installation method, influencing procurement decisions across various construction sectors globally.

- Material Type:

- Bituminous Membranes (SBS Modified Bitumen, APP Modified Bitumen, Oxidized Asphalt)

- Polymeric/Synthetic Membranes (PVC - Polyvinyl Chloride, TPO - Thermoplastic Polyolefin, EPDM - Ethylene Propylene Diene Monomer, HDPE - High-Density Polyethylene)

- Rubberized Asphalt Membranes

- Application:

- Roofing (Single-Ply Roofing, Multi-Ply Roofing, Green Roofs)

- Below Grade/Foundation Waterproofing (Basements, Subterranean Structures)

- Walls and Facades

- Civil Infrastructure (Tunnels, Bridges, Ponds, Landfills)

- End-Use:

- Residential Construction

- Commercial Construction (Offices, Retail, Hospitality)

- Industrial Construction (Factories, Warehouses)

- Civil and Public Infrastructure

- Installation Method:

- Self-Adhering Membranes (SAMs)

- Torch-Applied/Heat-Welded Membranes

- Mechanically Fastened Membranes

Value Chain Analysis For Sheet Membranes Market

The value chain for the Sheet Membranes Market is complex, beginning with the sourcing of primary raw materials and concluding with the application and maintenance on the construction site. Upstream analysis focuses heavily on key inputs, which include crude oil derivatives for bitumen modification and polymer production (PVC, TPO, EPDM), specialized reinforcing materials like fiberglass and polyester scrims, and various fillers and additives crucial for UV resistance and fire retardancy. The volatility in global oil prices directly impacts the cost structure of raw materials, making long-term supply agreements and strategic sourcing essential for manufacturers to maintain competitive pricing and stable production cycles. Manufacturing involves high-precision extrusion, calendering, and coating processes to ensure consistent thickness and material integrity across the sheet, requiring significant capital investment in machinery.

Midstream activities involve the primary manufacturing and formulation of the sheets, where key players differentiate themselves through patented material blends, self-adhering technologies, and sustainability certifications. The transition to the downstream segment involves complex distribution channels. Direct distribution is often utilized for large civil infrastructure projects or major commercial clients where technical expertise and customization are required. In these cases, manufacturers offer direct support, technical specification guidance, and certified applicator training. This direct engagement ensures optimal product selection and adherence to strict project requirements, reducing the risk of installation failure.

Indirect distribution channels dominate the residential and smaller commercial segments, relying on a robust network of specialized building material distributors, wholesalers, and roofing supply houses. These channels provide immediate availability and logistical support to a fragmented market of contractors and subcontractors. The final stage involves installation by professional contractors, whose certification and expertise are paramount to the membrane's long-term performance. The value chain heavily emphasizes training and technical service, as poor installation remains the single largest cause of waterproofing system failure, prompting manufacturers to invest significantly in applicator certification programs.

Sheet Membranes Market Potential Customers

Potential customers for sheet membranes are highly diverse, spanning the entire spectrum of the construction and infrastructure industries, characterized by entities requiring high-performance, long-term moisture protection for critical assets. The primary end-users can be broadly categorized into large general contractors specializing in commercial and high-rise development, public works departments responsible for maintaining civil infrastructure, and specialized subcontractors focused exclusively on roofing and waterproofing systems. These buyers are typically driven by specifications that prioritize durability, compliance with building codes (e.g., fire ratings, wind uplift resistance), life cycle cost, and supplier reliability.

Within the commercial sector, major real estate developers and property management firms are key buyers, particularly those managing large-scale logistics centers, shopping malls, and institutional buildings like hospitals and universities. For these customers, the emphasis is on installing systems that minimize disruption during application, offer high energy efficiency (via reflective membranes), and provide robust warranties, ensuring a low total cost of ownership over decades. They frequently utilize polymeric membranes (TPO, PVC) for exposed roofing applications due to their superior performance characteristics and ease of repair compared to traditional bitumen.

A crucial segment comprises government and municipal bodies involved in civil engineering projects. Buyers from public works agencies, infrastructure authorities, and transportation departments purchase specialized, heavy-duty membranes, often HDPE or reinforced bituminous sheets, for applications such as tunnel linings, bridge deck waterproofing, and subterranean utility infrastructure. Their buying decisions are governed by rigorous performance standards, longevity requirements (often exceeding 50 years), and the ability of the material to withstand extreme environmental stresses, making them premium segment buyers focused purely on specification adherence rather than just unit cost.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $7.5 Billion |

| Market Forecast in 2033 | $11.1 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Sika AG, Carlisle Companies, Soprema Group, GAF Materials, IKO Group, Firestone Building Products, BASF SE, Johns Manville, Dow Inc., Henry Company, Renolit SE, Atlas Roofing Corporation, Braas Monier Building Group, Standard Industries, Siplast, Polyglass USA, Fosroc International, GCP Applied Technologies, Oriental Yuhong, Tremco |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Sheet Membranes Market Key Technology Landscape

The technological landscape of the Sheet Membranes Market is characterized by continuous innovation focused on improving ease of application, long-term durability, and environmental compliance. A cornerstone technology is the advancement of self-adhering membranes (SAMs), which utilize highly specialized adhesive formulations—often proprietary blends of rubberized asphalt or synthetic polymers—protected by release liners. SAMs eliminate the need for torches, hot asphalt, or solvent-based adhesives, significantly enhancing worker safety, reducing installation complexity, and accelerating project timelines, making them increasingly popular in residential and light commercial applications.

Another major technological area is the refinement of polymeric sheet formulations, specifically for TPO and PVC membranes used predominantly in commercial roofing. Modern TPO sheets now incorporate advanced stabilizers and fire-retardants that provide superior resistance to UV degradation, thermal shock, and chemical exposure, ensuring membrane integrity over decades. Simultaneously, PVC membranes have benefited from the development of non-phthalate plasticizers, addressing environmental concerns while maintaining the material's excellent weldability and flexibility. Heat welding technology, using automated hot-air welding equipment, ensures continuous, monolithic seam integrity, a critical factor in the long-term watertight performance of these single-ply systems.

Furthermore, technology is enhancing the resilience and functionality of membranes designed for severe applications, such as below-grade waterproofing. Innovations include highly sophisticated HDPE sheets featuring textured surfaces and specialized locking mechanisms designed to mechanically bond to poured concrete, effectively creating a passive waterproofing barrier that resists hydrostatic migration. The integration of technology also extends to product diagnostics, with manufacturers embedding or recommending compatible sensor systems within the membrane layers to allow for non-destructive leak detection and monitoring throughout the lifecycle of the structure, transforming the membrane from a passive barrier to an integrated building envelope component.

Regional Highlights

Regional dynamics play a crucial role in shaping the Sheet Membranes Market, driven by variances in climate, construction practices, regulatory environments, and infrastructure investment levels across different geographies.

- Asia Pacific (APAC): APAC is projected to be the fastest-growing region, primarily due to unprecedented rates of urbanization and massive government-led investments in residential housing and civil infrastructure, including extensive metropolitan rail and tunnel networks. Countries like China, India, and Indonesia are witnessing high demand, particularly for cost-effective bituminous membranes in residential sectors and advanced polymeric sheets for large commercial roofing and high-rise foundation waterproofing. Stringent new building codes in coastal zones also bolster the need for reliable waterproofing solutions.

- North America: This region represents a mature yet highly lucrative market, characterized by significant demand for roof replacement, retrofitting, and rehabilitation projects. The focus here is on high-performance, energy-efficient single-ply systems (TPO and EPDM) compliant with strict energy codes (e.g., Title 24). The market benefits from a strong emphasis on self-adhering technologies for worker safety and reduced installation time, particularly in the residential and low-slope commercial sectors.

- Europe: Driven by sustainability mandates and the European Green Deal, the European market prioritizes environmentally friendly sheet membranes, leading to increased adoption of TPO, PVC with non-phthalate plasticizers, and membranes with high recycled content. Germany, the UK, and France are key contributors, emphasizing durability for flat roofing and specialized membranes for demanding applications like green roofs and large civil tunnels, where high-specification products are standard.

- Latin America (LATAM): Growth in LATAM is spurred by rising investment in commercial and industrial facilities, particularly in Brazil and Mexico. The market shows a mixed preference, with traditional bituminous products remaining strong for cost sensitivity, but a growing uptake of polymeric membranes in large-scale projects driven by international standards and foreign investment.

- Middle East and Africa (MEA): This region is characterized by extreme climatic conditions, driving demand for membranes with superior UV resistance, high thermal stability, and robust flexibility to withstand significant temperature swings. Major infrastructure projects (e.g., in Saudi Arabia and UAE) and rapidly expanding real estate sectors necessitate premium, durable membranes for both exposed roofs and critical foundation waterproofing against aggressive ground conditions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Sheet Membranes Market.- Sika AG

- Carlisle Companies Incorporated

- Soprema Group

- GAF Materials Corporation

- IKO Group

- Firestone Building Products (now part of Holcim)

- BASF SE

- Johns Manville

- Dow Inc.

- Henry Company

- Renolit SE

- Atlas Roofing Corporation

- Braas Monier Building Group

- Standard Industries

- Siplast

- Polyglass USA, Inc.

- Fosroc International

- GCP Applied Technologies (now Saint-Gobain Construction Chemicals)

- Oriental Yuhong

- Tremco CPG Inc.

Frequently Asked Questions

Analyze common user questions about the Sheet Membranes market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary advantages of synthetic polymeric membranes (TPO/PVC) over traditional bituminous sheets?

Synthetic polymeric membranes offer superior UV resistance, high solar reflectivity for energy efficiency (especially TPO), and allow for hot-air welded seams, creating a continuous, monolithic, and highly durable waterproofing layer. They generally have a longer lifespan and require less maintenance than asphalt-based systems.

How does the volatile cost of raw materials impact the Sheet Membranes Market?

Raw material cost volatility, particularly in petrochemical derivatives used for polymers (PVC, TPO) and bitumen, directly increases manufacturing costs. This often leads to price fluctuations in finished products, pressuring manufacturers' margins and necessitating effective hedging and supply chain optimization strategies to ensure stable product pricing.

Which application segment currently drives the highest demand for sheet membranes globally?

The Roofing application segment currently generates the highest demand by volume, encompassing both low-slope commercial roofing (dominated by single-ply systems like TPO and EPDM) and residential multi-ply roofing (often using modified bitumen). However, the Civil Infrastructure segment is experiencing the fastest growth rate due to global tunnel and foundation projects.

What role do Self-Adhering Membranes (SAMs) play in market growth and safety?

SAMs are crucial growth drivers as they simplify installation, reduce labor time, and significantly enhance worker safety by eliminating the need for open flames (torch-applied) or hot kettles (hot asphalt). This efficiency makes SAMs highly attractive for fast-track construction projects and complex residential installations.

Where is the fastest regional growth expected for the Sheet Membranes Market from 2026 to 2033?

The Asia Pacific (APAC) region is anticipated to demonstrate the fastest market growth, driven by rapid urbanization, substantial government investment in new housing and commercial infrastructure, and the continuous development of large-scale civil projects across key emerging economies like India and China.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager