Sicherheits Absaugssystem Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 442859 | Date : Feb, 2026 | Pages : 258 | Region : Global | Publisher : MRU

Sicherheits Absaugssystem Market Size

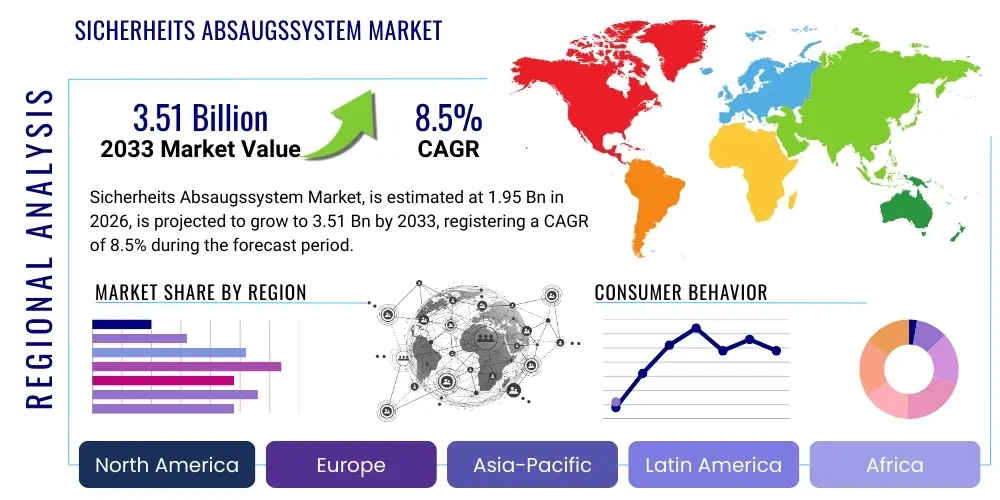

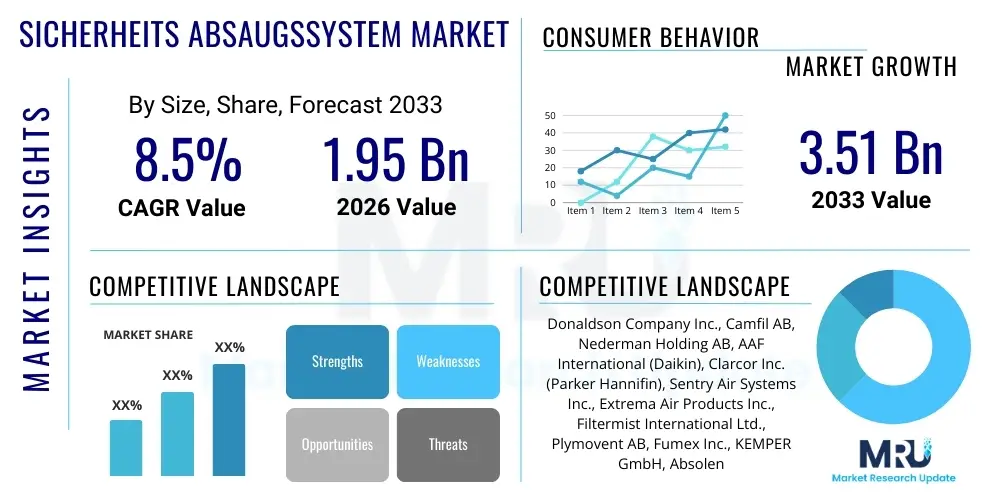

The Sicherheits Absaugssystem Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.5% between 2026 and 2033. The market is estimated at $1.95 Billion in 2026 and is projected to reach $3.51 Billion by the end of the forecast period in 2033. This substantial expansion is primarily fueled by increasing global awareness regarding occupational health and safety standards, particularly within highly regulated sectors such as pharmaceuticals, chemical manufacturing, and semiconductor production. The mandatory implementation of advanced ventilation and filtration technologies to minimize worker exposure to hazardous substances necessitates continuous investment in high-efficiency safety extraction systems.

Market expansion is also supported by technological advancements that enhance the efficiency and flexibility of these systems. Modern Sicherheits Absaugssysteme are increasingly integrated with smart monitoring capabilities, allowing for real-time performance tracking and predictive maintenance, thereby reducing operational downtime and optimizing energy consumption. Furthermore, the rising prevalence of highly potent active pharmaceutical ingredients (HPAPIs) and nanoscale materials across various industries mandates higher containment levels, driving demand for specialized extraction solutions that exceed baseline regulatory requirements.

Sicherheits Absaugssystem Market introduction

The Sicherheits Absaugssystem Market encompasses highly specialized industrial ventilation and filtration equipment designed to capture, contain, and remove hazardous airborne contaminants from the working environment. These systems are crucial for ensuring compliance with stringent governmental regulations concerning worker health and environmental protection, such as those mandated by OSHA in the US or various EU directives. Products range from localized extraction arms (LEVs) and bench-mounted fume cupboards to large-scale general ventilation systems integrated with advanced particulate and gas filtration units.

Major applications of Sicherheits Absaugssysteme span across diverse industrial settings, including cleanrooms, laboratories, production floors in chemical processing plants, welding and soldering operations, and pharmaceutical manufacturing facilities. The primary function is twofold: protecting personnel from exposure to toxic fumes, dust, aerosols, and vapors, and safeguarding sensitive processes or products from contamination. Key benefits derived from the adoption of these systems include improved air quality, reduced risk of occupational illnesses, enhanced operational safety, and assurance of regulatory adherence, which can prevent costly fines and operational shutdowns.

Driving factors for this market include the global trend toward stricter workplace safety legislation, particularly in emerging economies undergoing rapid industrialization. Additionally, the complexity of modern industrial processes, involving finer particulates and more volatile organic compounds (VOCs), necessitates increasingly sophisticated and effective extraction technologies. The push towards sustainable manufacturing also plays a role, as modern systems are designed for energy efficiency through features like variable air volume (VAV) control, ensuring that safety requirements are met without excessive energy expenditure.

Sicherheits Absaugssystem Market Executive Summary

The global Sicherheits Absaugssystem Market is characterized by strong business trends focusing on digitalization, modular design, and enhanced filter lifetime. Key manufacturers are aggressively investing in Internet of Things (IoT) capabilities to offer integrated monitoring solutions, enabling centralized control and optimized operational efficiency across large industrial complexes. The shift toward modular and scalable extraction systems allows end-users to adapt swiftly to changing production layouts and regulatory demands without extensive system overhaul, representing a significant capital expenditure advantage and driving market uptake, especially in high-growth sectors like battery manufacturing and advanced materials research.

Regionally, Europe and North America currently dominate the market due to established regulatory frameworks (e.g., ATEX directives, ACGIH guidelines) and a mature industrial base that prioritize occupational safety investments. However, the Asia Pacific (APAC) region is projected to exhibit the highest growth rate, fueled by massive infrastructure development, increasing foreign direct investment in manufacturing sectors (particularly China, India, and Southeast Asia), and gradually converging safety standards with Western norms. This regional dynamic is leading to increased localization of manufacturing and distribution channels by global market leaders to serve the rapidly expanding industrial footprint in APAC.

Segmentation trends reveal a strong preference for high-efficiency particulate air (HEPA) and ultra-low penetration air (ULPA) filtration systems, particularly in cleanroom and pharmaceutical applications, where containment levels are paramount. The stationary segment continues to hold the largest market share due to permanent infrastructure requirements in heavy industries, but the mobile and portable extraction systems segment is experiencing rapid growth, driven by flexibility needs in smaller workshops, construction sites, and specialized maintenance tasks. Furthermore, the consumables segment, specifically replacement filters and cartridges, remains a crucial revenue stream, necessitating robust supply chain management by market participants.

AI Impact Analysis on Sicherheits Absaugssystem Market

Common user questions regarding AI’s influence on the Sicherheits Absaugssystem Market center primarily on achieving predictive maintenance, optimizing filtration performance dynamically, ensuring continuous regulatory compliance reporting, and enhancing energy efficiency. Users are keenly interested in how machine learning algorithms can analyze real-time operational data—such as pressure differentials, airflow rates, and particulate counts—to anticipate filter saturation, detect system anomalies before failure, and automatically adjust fan speeds based on fluctuating contaminant loads. The summary of these themes highlights a high expectation for AI to transform these static, routine-maintenance systems into intelligent, adaptive, and highly reliable assets, moving beyond simple alarming systems toward comprehensive operational intelligence platforms.

AI’s integration is moving Sicherheits Absaugssysteme beyond reactive maintenance into proactive operational management. By analyzing patterns in sensor data that human operators might overlook, AI algorithms can precisely determine the optimal timing for component replacement, reducing waste and extending equipment lifespan. This shift from time-based scheduling to condition-based maintenance offers significant cost savings and reduces the risk associated with system performance degradation between scheduled inspections. Furthermore, AI-driven diagnostics enable remote troubleshooting and performance validation, crucial for managing systems deployed across geographically dispersed facilities and ensuring consistent adherence to global safety protocols.

The implementation of AI also directly addresses the growing pressure on industries to reduce their environmental footprint. By using sophisticated algorithms to model optimal air changes per hour (ACH) based on actual contamination levels rather than conservative maximum settings, AI minimizes unnecessary air movement and heating/cooling demands. This results in substantial energy savings while maintaining, or even improving, safety margins. This intelligent control contributes significantly to the operational technology (OT) optimization strategies of large corporations seeking to align safety protocols with sustainability objectives, positioning AI as a fundamental enabler of next-generation industrial hygiene systems.

- AI enables highly accurate predictive failure analysis for fans, motors, and monitoring sensors.

- Machine learning algorithms optimize Variable Air Volume (VAV) systems, reducing operational energy consumption by up to 30%.

- Automated compliance auditing and reporting based on continuous real-time data analysis minimizes human error in regulatory documentation.

- AI-driven sensor data fusion improves the identification and classification of complex contaminant mixtures (e.g., distinguishing nuisance dust from highly toxic particulates).

- Intelligent filter saturation prediction maximizes filter lifespan and minimizes replacement frequency, reducing operational expenditure and waste generation.

DRO & Impact Forces Of Sicherheits Absaugssystem Market

The market for Sicherheits Absaugssysteme is shaped by a complex interplay of Drivers, Restraints, and Opportunities (DRO), collectively forming the Impact Forces. A primary driver is the pervasive tightening of occupational safety regulations globally, particularly concerning exposure limits for carcinogens and respiratory sensitizers, compelling industries to invest in superior extraction technologies. However, a significant restraint is the high initial capital investment required for installing complex, high-efficiency filtration systems, coupled with ongoing maintenance costs, which can deter adoption, especially among small and medium-sized enterprises (SMEs). Opportunities arise from the convergence of industrial safety and digital technologies, promoting integrated IoT solutions that offer enhanced efficiency and remote management capabilities.

Impact forces are further magnified by technological innovation. The continuous development of advanced filtration media, such as nanofiber filters and specialized molecular sieves, allows systems to capture smaller and more challenging contaminants effectively, thus expanding the application scope into emerging high-tech sectors like additive manufacturing and nanotechnology. Conversely, the market faces restraints related to the complexity of customizing systems for highly specific industrial processes, requiring extensive engineering expertise and often leading to prolonged implementation cycles. The lack of standardized installation and maintenance protocols across different geographies also presents a challenge, impacting the scalability of global safety solutions.

The overall market trajectory is powerfully influenced by the increasing sophistication of industrial processes—requiring extreme containment—and the corresponding focus on corporate social responsibility (CSR), where protecting employee health is a key non-negotiable metric. This emphasis transforms safety extraction systems from mere compliance tools into strategic assets for talent retention and insurance liability reduction. The dynamic balance between mandatory regulatory compliance (Driver) and the persistent issue of initial cost barriers (Restraint) ultimately dictates the speed and magnitude of market growth, with digitalization (Opportunity) serving as the key differentiator for competitive market players.

Segmentation Analysis

The Sicherheits Absaugssystem Market is comprehensively segmented across several dimensions, including component type, system technology, mobility, and end-use application, providing a nuanced view of demand patterns. This segmentation is crucial for vendors to tailor their product offerings and marketing strategies to specific industry needs, ranging from cleanroom environments demanding ULPA filtration to heavy industrial settings requiring robust cyclone separators and dust collectors. The increasing specialization of industrial processes necessitates customized solutions, driving the growth of high-specification segments.

The component segment, comprising filters, fans and blowers, ductwork, and control units, accounts for the core revenue streams, with replacement filters constituting a recurring income source. Technological segmentation differentiates systems based on filtration mechanism (e.g., mechanical, electrostatic, adsorption), while the mobility distinction between stationary and mobile units addresses the varying degrees of permanence and flexibility required by end-users. Application segmentation provides the most granular insight into demand drivers, linking regulatory requirements directly to product specifications, such as stringent ventilation standards in pharmaceutical manufacturing compared to requirements in automotive paint booths.

Understanding these segments reveals key trends, such as the accelerating demand for energy-efficient VAV control systems within the component category and the significant growth of portable extraction systems favored by construction and temporary manufacturing operations. The detailed analysis of these segments is instrumental for strategic planning, enabling market participants to identify lucrative niches, such as solvent recovery systems utilizing activated carbon technology, or sterile environment containment solutions designed for biological safety levels (BSLs).

- By Component:

- Filtration Units (HEPA, ULPA, Activated Carbon, Pre-filters)

- Air Movement Devices (Centrifugal Fans, Axial Fans, Blowers)

- Ducting and Hoods (Localized Extraction Ventilation, Fume Arms, Capture Hoods)

- Control and Monitoring Systems (VAV Controllers, Pressure Sensors, IoT Gateways)

- By System Technology:

- Dust Collection Systems

- Fume and Smoke Extractors

- Mist and Oil Collectors

- Wet Scrubbers

- By Mobility:

- Stationary Systems (Centralized HVAC Integration)

- Mobile/Portable Systems (Wheeled Units, Benchtop Extractors)

- By End-Use Application:

- Pharmaceutical and Biotechnology

- Chemical Manufacturing and Processing

- Semiconductor and Electronics

- Automotive and Aerospace

- Food and Beverage Processing

- Metalworking and Welding

- Healthcare and Laboratories

Value Chain Analysis For Sicherheits Absaugssystem Market

The value chain for the Sicherheits Absaugssystem Market begins with the upstream procurement of critical raw materials, including specialized filtration media (fibrous materials, chemical adsorbents), high-grade steel and composite materials for housing and ductwork, and precision electronic components for control systems. Efficiency at this stage is crucial, as the quality and purity of filtration media directly dictate system performance and lifespan, often requiring long-term agreements with specialized material suppliers. The manufacturing stage involves complex processes such as precise sheet metal fabrication, assembly of fans and motors, and rigorous testing of integrated systems to meet efficiency and safety standards (e.g., leak testing for HEPA filters).

The midstream of the value chain is dominated by system integrators and specialized engineering firms that design and customize extraction solutions according to the specific layout and contaminant profile of the end-user facility. This step often includes consultative services, facility mapping, and compliance verification. The downstream segment involves distribution and installation. Distribution channels are typically a mix of direct sales channels, especially for large, bespoke industrial projects, and specialized indirect distributors (value-added resellers) who handle regional sales, installation, and post-sales maintenance services for standardized or smaller units. Direct channels ensure closer customer relationships and higher profit margins, while indirect channels provide broader market reach and specialized local technical support.

Effective management of the value chain requires strong collaboration between original equipment manufacturers (OEMs) and local service providers, ensuring timely availability of replacement parts, particularly high-value filters and specialized sensors. The growth in smart, connected systems is shifting value capture towards the downstream service segment, where ongoing monitoring, data analytics subscriptions, and preventative maintenance contracts are becoming increasingly important revenue drivers. Successful companies optimize their logistics to handle diverse product sizes, from small benchtop units to large, custom-fabricated air handling units, while strictly maintaining the integrity and certification of the supplied components.

Sicherheits Absaugssystem Market Potential Customers

Potential customers for Sicherheits Absaugssysteme are highly diversified across all industrial and institutional sectors where airborne hazardous materials or contamination risks exist. The primary buyers are organizations operating under strict regulatory oversight concerning occupational health, environmental emissions, and product quality control. This includes multi-national pharmaceutical corporations requiring BSL-level containment for drug development and manufacturing, chemical giants handling volatile organic compounds (VOCs) and corrosive fumes, and semiconductor fabrication plants demanding ultra-clean environments to prevent yield loss from particulates.

Beyond these high-compliance sectors, significant demand originates from heavy industries such as automotive manufacturing (for welding fumes, sanding dust, and paint overspray extraction), aerospace (for composite material dust and specialized chemical solvents), and primary metalworking facilities (for particulate dust and thermal fumes). Institutional buyers, including government research laboratories, university chemistry departments, and large hospital complexes (for pathological and compounding labs), also represent a substantial and constant customer base, driven by non-negotiable safety mandates for staff and researchers.

The increasing adoption of advanced technologies like 3D printing and nanotechnology further expands the customer base, as these processes generate fine, often toxic, particulates requiring sophisticated, dedicated extraction systems. Essentially, any entity whose operational processes generate dust, fumes, vapors, aerosols, or mist that could compromise worker health or product quality is a potential customer, demonstrating the pervasive necessity of effective Sicherheits Absaugssysteme across the global industrial landscape.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $1.95 Billion |

| Market Forecast in 2033 | $3.51 Billion |

| Growth Rate | 8.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Donaldson Company Inc., Camfil AB, Nederman Holding AB, AAF International (Daikin), Clarcor Inc. (Parker Hannifin), Sentry Air Systems Inc., Extrema Air Products Inc., Filtermist International Ltd., Plymovent AB, Fumex Inc., KEMPER GmbH, Absolent Group AB, 3M Company, Air Science LLC, Votsch Industrietechnik GmbH, Esco Global, Rentschler Biopharma SE, GEA Group Aktiengesellschaft, Alfa Laval AB, Munters Group AB |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Sicherheits Absaugssystem Market Key Technology Landscape

The technological landscape of the Sicherheits Absaugssystem Market is rapidly evolving, driven by the need for higher filtration efficiency, greater energy conservation, and improved system monitoring. A pivotal technology is the widespread adoption of High-Efficiency Particulate Air (HEPA) and Ultra-Low Penetration Air (ULPA) filtration, which are essential for applications requiring near-absolute air purity, such as pharmaceutical compounding and electronics manufacturing. These systems increasingly incorporate sophisticated filter integrity testing methods, including in-situ challenges (e.g., using dispersed oil particulate testing), to ensure guaranteed performance throughout the system's operational lifecycle, crucial for compliance validation.

Furthermore, connectivity through the Industrial Internet of Things (IIoT) is revolutionizing how these systems are managed. Modern extraction units are equipped with multiple embedded sensors monitoring parameters such as differential pressure, airflow velocity, motor vibration, and temperature. This sensor data is transmitted via secure gateways to cloud-based platforms, enabling sophisticated remote diagnostics, predictive maintenance scheduling, and real-time performance benchmarking against regulatory thresholds. The shift towards IoT minimizes reliance on manual checks, significantly improving system uptime and reducing human exposure to the systems themselves during maintenance routines, thereby enhancing safety protocols.

Variable Air Volume (VAV) technology represents another key advancement, moving away from constant volume systems that often consume excessive energy. VAV controllers automatically adjust fan speed and air flow rates based on actual contaminant detection or the precise operational status of the containment device (e.g., fume hood sash position). This demand-controlled ventilation approach ensures that safety requirements are met precisely, minimizing energy waste related to heating, cooling, and moving excess air volume. Coupled with advanced filtration media, including chemically impregnated carbons for gas phase contaminants and self-cleaning filter cartridges, these innovations underscore the market's commitment to efficiency, reliability, and precision.

Regional Highlights

- North America (Primarily the United States and Canada) represents a mature and dominant market for Sicherheits Absaugssysteme, characterized by exceptionally stringent regulatory bodies like the Occupational Safety and Health Administration (OSHA) and the Environmental Protection Agency (EPA). Demand is high across the pharmaceutical, semiconductor, and petrochemical sectors, driven by mandatory compliance for permissible exposure limits (PELs). The region is a pioneer in integrating IoT and smart system diagnostics into extraction technology, commanding premium pricing for technologically advanced, high-performance systems and contributing significantly to the global expenditure on industrial hygiene solutions.

- Europe maintains its position as a key market, distinguished by complex and overlapping regulatory frameworks, notably the Restriction of Hazardous Substances (RoHS) Directive, REACH regulations, and ATEX directives concerning explosive atmospheres. Germany, France, and the UK are major consumers, particularly in automotive manufacturing, specialty chemicals, and biotechnology. The market emphasizes energy efficiency (due to high regional energy costs) and sustainability, leading to strong adoption of highly optimized VAV systems and systems featuring long-life, reusable filtration components.

- Asia Pacific (APAC) is projected as the fastest-growing region, fueled by rapid industrialization, massive investments in manufacturing infrastructure, and the relocation of global production bases to countries like China, India, and South Korea. While historically lagging in strict enforcement, APAC countries are quickly adopting international safety standards, particularly in new, high-value manufacturing segments (e.g., battery production, advanced materials). This explosive growth is driven by the need for new installations and upgrades in facilities striving for international quality certifications and foreign market access.

- Latin America and the Middle East & Africa (MEA) represent emerging markets where growth is concentrated in specific industrial hubs, such as oil and gas processing in the MEA and mining and basic chemical production in Latin America. Market adoption is often localized and influenced heavily by international corporate subsidiaries bringing global safety standards. While smaller in overall size, these regions present significant long-term growth opportunities contingent on stable economic policies and continued regulatory enforcement modernization.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Sicherheits Absaugssystem Market.- Donaldson Company Inc.

- Camfil AB

- Nederman Holding AB

- AAF International (Daikin)

- Clarcor Inc. (Parker Hannifin)

- Sentry Air Systems Inc.

- Extrema Air Products Inc.

- Filtermist International Ltd.

- Plymovent AB

- Fumex Inc.

- KEMPER GmbH

- Absolent Group AB

- 3M Company

- Air Science LLC

- Votsch Industrietechnik GmbH

- Esco Global

- Rentschler Biopharma SE

- GEA Group Aktiengesellschaft

- Alfa Laval AB

- Munters Group AB

Frequently Asked Questions

Analyze common user questions about the Sicherheits Absaugssystem market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is a Sicherheits Absaugssystem and why is it essential for industrial operations?

A Sicherheits Absaugssystem (Safety Extraction System) is a comprehensive ventilation and filtration apparatus designed to capture and remove airborne contaminants like dust, fumes, vapors, and aerosols from a workplace. It is essential for protecting worker health, ensuring regulatory compliance (e.g., OSHA, EU directives), and preventing product or process contamination in sensitive environments like cleanrooms or pharmaceutical manufacturing.

How does the integration of IoT and AI benefit modern safety extraction systems?

IoT and AI integration transform traditional extraction units into smart systems by enabling real-time performance monitoring, automated compliance reporting, and predictive maintenance. AI algorithms analyze sensor data (pressure, flow rate) to anticipate component failure, optimize fan speed using Variable Air Volume (VAV) control for energy savings, and maximize filter lifespan through condition-based scheduling.

Which industrial sectors are the primary consumers of high-efficiency particulate air (HEPA) systems?

The primary consumers of HEPA and ULPA (Ultra-Low Penetration Air) systems are industries where containment and air purity are critical, notably the Pharmaceutical and Biotechnology sectors (for handling HPAPIs and sterile processes), Semiconductor and Electronics manufacturing (to prevent particulate contamination of microchips), and specialized research laboratories and cleanrooms.

What are the main drivers accelerating the growth of the Sicherheits Absaugssystem market?

The key drivers include increasingly strict global occupational health and safety regulations, the rising complexity and toxicity of materials used in modern manufacturing (e.g., nanomaterials), growing corporate focus on environmental, social, and governance (ESG) factors, and technological advancements leading to more efficient and adaptable modular extraction solutions.

What challenges do Small and Medium-sized Enterprises (SMEs) face in adopting advanced safety extraction systems?

SMEs primarily face challenges related to the high initial capital expenditure required for sophisticated, compliant systems, coupled with the ongoing operational costs associated with maintenance and filter replacements. Additionally, specialized technical expertise needed for custom system design and regulatory adherence can pose a significant barrier to entry for smaller organizations.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager