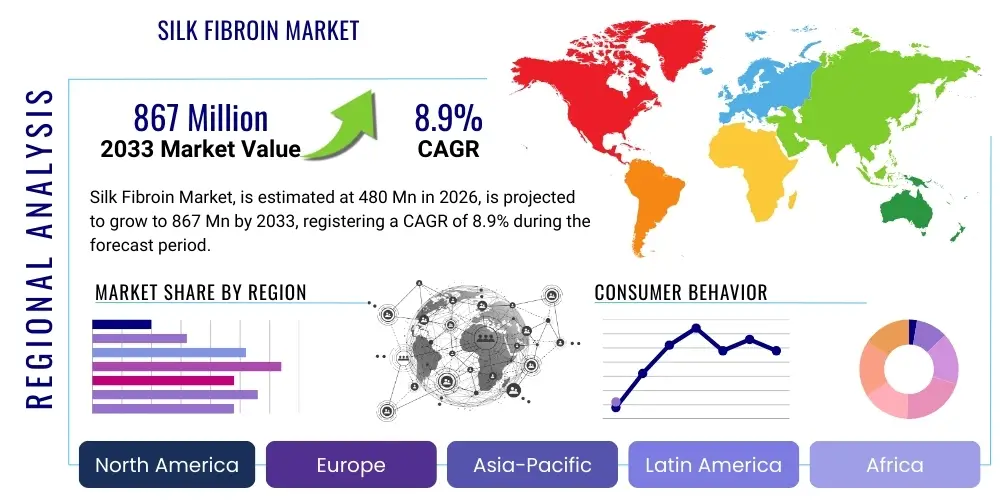

Silk Fibroin Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440925 | Date : Feb, 2026 | Pages : 257 | Region : Global | Publisher : MRU

Silk Fibroin Market Size

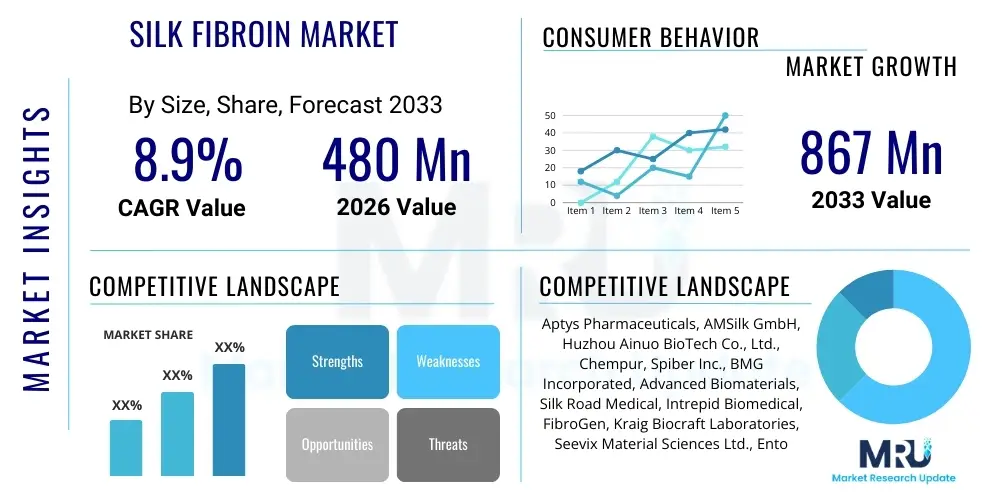

The Silk Fibroin Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.9% between 2026 and 2033. The market is estimated at USD 480 Million in 2026 and is projected to reach USD 867 Million by the end of the forecast period in 2033.

Silk Fibroin Market introduction

Silk fibroin, a natural protein derived primarily from the silkworm Bombyx mori, stands out as a highly versatile and biocompatible material critical in advanced biomedical and industrial applications. This protein is renowned for its exceptional mechanical strength, controllable biodegradability, and minimal immunogenicity, making it a superior alternative to many synthetic polymers. Its unique structural characteristics, particularly the ability to transition between alpha-helix and beta-sheet conformations, allow for precise control over material properties, enabling its use in complex structures ranging from hydrogels and films to scaffolds and microparticles.

The core applications of silk fibroin span several high-growth sectors, dominated by regenerative medicine and drug delivery systems. In the pharmaceutical and medical device industries, silk fibroin is utilized for creating tissue engineering scaffolds—mimicking native extracellular matrices for bone, cartilage, and skin regeneration—and as a stable, biocompatible coating for implantable devices. Furthermore, the material's capacity to stabilize sensitive therapeutic molecules, such as enzymes and vaccines, under harsh conditions has positioned it as a revolutionary tool in controlled drug release technologies, promising improved patient compliance and therapeutic efficacy.

Key driving factors accelerating the market include the rapidly expanding field of regenerative medicine, significant advancements in processing techniques (like electrospinning and 3D printing of silk constructs), and increasing consumer demand for natural, sustainable, and high-performance ingredients in cosmetics and functional materials. The inherent benefits of silk fibroin, such as its superb oxygen permeability and moisture retention capabilities, further solidify its indispensable role across diverse high-value commercial sectors globally.

Silk Fibroin Market Executive Summary

The Silk Fibroin Market is experiencing robust growth driven by its increasing adoption in high-value biomedical and pharmaceutical sectors, establishing it as a material platform essential for future innovations in tissue engineering and advanced drug delivery. Business trends indicate a heightened focus on scalable production methods, shifting from traditional extraction to more refined, quality-controlled aqueous processing techniques to meet stringent regulatory requirements for medical-grade materials. Collaboration between academic institutions and specialized biotech firms is fueling the development of proprietary silk fibroin formulations tailored for specific applications, such as high-definition bio-inks for 3D bioprinting and injectable hydrogels for minimally invasive procedures.

Regional trends highlight Asia Pacific (APAC) as the primary hub for both raw silk production and initial processing, while North America and Europe lead in research, development, and high-end consumption, particularly within the medical device and advanced cosmetics industries. Investment in manufacturing infrastructure in Western economies is aimed at mitigating supply chain risks associated with raw material sourcing, focusing on localized purification and derivatization capabilities. Segment trends show the Biomedical/Pharmaceutical application segment maintaining the largest market share, though the Cosmetics and Personal Care segment is demonstrating the highest growth velocity due to rising consumer preference for bio-based, active ingredients that offer superior skin barrier function and texture enhancement.

Overall, the market dynamic is characterized by intense innovation centered around molecular weight control, protein stabilization, and functionalization of the silk fibroin structure to improve cellular integration and mechanical tuning. The transition from bulk material usage to highly specialized, functionalized products dictates the market's trajectory, emphasizing quality, purity, and regulatory compliance as non-negotiable prerequisites for competitive success and sustained expansion.

AI Impact Analysis on Silk Fibroin Market

Users frequently inquire about how Artificial Intelligence (AI) and Machine Learning (ML) can optimize the complex production and application development phases of silk fibroin, particularly concerning material standardization and accelerated discovery. The key user themes revolve around leveraging AI to predict optimal dissolution parameters for consistent fibroin molecular weights, modeling complex scaffold degradation kinetics in biological environments, and accelerating the screening of functionalized silk constructs for enhanced cellular response in tissue engineering. Concerns center on the data requirements necessary to train accurate predictive models for such biologically intricate processes, and the integration of AI tools within existing biomanufacturing workflows, suggesting high expectations for AI to drive efficiency, reduce batch-to-batch variability, and dramatically speed up the development cycle for silk fibroin-based medical devices and therapies.

- AI optimizes large-scale raw material sourcing and quality control by identifying anomalies in raw silk batches, ensuring consistent protein purity.

- Machine Learning algorithms predict the precise processing parameters (temperature, solvent concentration, sonication time) required to achieve targeted silk fibroin molecular weights and crystallinity, reducing variability.

- AI-driven simulation models accelerate the design of complex 3D printed silk scaffolds, predicting mechanical properties and degradation rates in vivo before physical prototyping.

- Predictive analytics analyze cellular compatibility data, rapidly identifying optimal surface modifications (functionalization) of silk fibroin for specific tissue integration goals (e.g., neural or vascular).

- Robotics and AI are integrated into high-throughput screening of drug-loaded silk fibroin microparticles, assessing encapsulation efficiency and controlled release kinetics automatically.

DRO & Impact Forces Of Silk Fibroin Market

The Silk Fibroin Market is propelled by significant technological advancements in biomaterials science (Drivers) while facing hurdles related to standardization and high production costs (Restraints); however, the escalating demand in chronic disease management and regenerative medicine offers vast commercial opportunities (Opportunities). The primary impact forces influencing market dynamics include the rapidly changing regulatory landscape governing medical devices and biologics, intense competitive pressure from synthetic and other natural polymers, and the critical need for sustainable, scalable sourcing of high-purity raw materials. The interplay between these factors determines investment focus, market entry strategies, and the ultimate commercial viability of novel silk fibroin products, emphasizing innovation in both processing and end-use applications.

The primary driver remains the unmatched performance profile of silk fibroin, specifically its superior mechanical performance combined with excellent biocompatibility and controlled biodegradability, positioning it as a foundational material for the next generation of implantable devices and tissue grafts. Market expansion is further supported by governmental and private investment into regenerative medicine research globally, focusing on areas like orthopedic repair, wound healing, and advanced drug delivery mechanisms utilizing silk fibroin's stabilization properties. The cosmetic industry’s shift toward bio-based, high-efficacy ingredients also provides a continuous demand uplift for purified silk peptides and derivatives.

Restraints largely center on the challenges associated with upscaling production from laboratory to industrial levels while maintaining clinical-grade purity and consistency—a requirement often complicated by the biological variability inherent in natural materials. High manufacturing costs, particularly related to the complex, multi-step aqueous purification and processing required to remove sericin and other impurities, pose a competitive disadvantage against cheaper, mass-produced synthetic polymers. Opportunities are most pronounced in the development of functionalized silk fibroin platforms (e.g., genetically engineered silk or chemical conjugation) that can actively signal cells or release multiple therapeutics simultaneously, opening avenues in personalized medicine and complex disease treatment protocols.

Drivers:

- Accelerated R&D in Regenerative Medicine and Tissue Engineering: High demand for biocompatible scaffolds in areas like bone, cartilage, and nerve repair.

- Superior Biocompatibility and Mechanical Tunability: Unique properties allowing customization of degradation rates and mechanical strength for specific biological environments.

- Growth in Drug Delivery Systems: Silk fibroin's ability to stabilize sensitive pharmaceuticals (vaccines, proteins) and facilitate controlled, sustained release profiles.

- Increasing Consumer Preference for Natural and Sustainable Biomaterials: Demand across cosmetics, functional textiles, and food industries for bio-derived, non-toxic components.

Restraints:

- High Cost and Complexity of Industrial-Scale Purification: Maintaining clinical-grade purity and consistency across large batches is technically challenging and expensive.

- Standardization and Regulatory Hurdles: Lack of universally accepted standards for measuring and reporting molecular weight, crystallinity, and immunogenicity of diverse silk fibroin products.

- Competition from Synthetic Polymers: Established markets for synthetic alternatives (e.g., PLGA, PCL) that often offer lower production costs and more predictable material properties.

Opportunities:

- Development of Functionalized and Genetically Engineered Silk: Creating designer silk proteins with enhanced bioactivity or targeted therapeutic functions.

- Expansion into Advanced Bio-Inks and 3D Bioprinting: Using silk fibroin formulations for complex, patient-specific anatomical structures.

- Novel Applications in Electronics and Optics: Utilizing silk fibroin's optical transparency and thermal stability in bio-integrated electronics and flexible substrates.

- Penetration of the Nutraceutical and Functional Food Market: Utilizing silk peptides for bioactive supplements and food coatings.

Segmentation Analysis

The Silk Fibroin Market is meticulously segmented based on product type, application, and source, reflecting the diverse forms and end-uses of this versatile biopolymer. Segmentation by product type reveals the criticality of highly purified solutions and powders, which serve as foundational inputs for subsequent advanced manufacturing processes such as electrospinning and casting, dominating the revenue landscape due to their widespread use in research and pharmaceutical formulation. Conversely, segmentation by application highlights the strong revenue stream generated by the Biomedical and Pharmaceutical sector, which consistently demands the highest quality and most technologically advanced fibroin constructs, overshadowing other industrial applications.

Analysis by source indicates that Mulberry silk fibroin remains the commercial standard, owing to its standardized availability, established processing methods, and superior mechanical characteristics. However, non-Mulberry sources, including wild silks like Tussah and Antheraea, are gaining traction, driven by research efforts to capitalize on their unique properties, such as enhanced resilience or specific degradation profiles, expanding the potential material library for specialized applications where conventional Bombyx mori fibroin might be suboptimal. Understanding these segment dynamics is crucial for strategic investment, enabling companies to focus R&D resources on high-growth areas like functionalized films and scaffolds tailored for specific medical needs.

The rapidly evolving nature of silk fibroin technologies necessitates continuous evaluation of these segments, particularly as new processing technologies enable the creation of novel formats, such as highly stable nanoparticles for precision drug delivery or sophisticated aerogels for environmental filtration. This segmented approach ensures that market participants can accurately forecast demand, optimize production capacities, and tailor their product offerings to specific regulatory and end-user requirements within distinct sub-markets, such as the stringent demands of implantable medical devices versus the volume requirements of the textile industry.

- By Product Type:

- Solution (Aqueous, Organic)

- Powder/Lyophilized

- Film/Membrane

- Hydrogel/Gel

- Scaffold/Sponge

- By Application:

- Biomedical and Pharmaceutical (Tissue Engineering, Regenerative Medicine, Drug Delivery, Medical Devices)

- Cosmetics and Personal Care (Skin Care, Hair Care, Wound Healing Dressings)

- Textiles and Functional Materials (High-Performance Fibers, Coatings)

- Food and Beverages (Coatings, Edible Films, Nutraceuticals)

- Other Industrial Applications (Optics, Electronics, Filtration)

- By Source:

- Mulberry Silk (Bombyx mori)

- Non-Mulberry Silk (Tussah, Spider Silk Analogs)

Value Chain Analysis For Silk Fibroin Market

The silk fibroin value chain begins with the upstream sourcing and preparation of raw silk cocoons, which requires meticulous control over silkworm rearing conditions to ensure consistent raw protein quality. This is followed by the crucial degumming and aqueous dissolution processes, transforming raw silk into purified fibroin solutions or powders. Upstream success hinges entirely on achieving high purity—the complete removal of sericin—to minimize immunogenicity, a process that is capital-intensive and dictates the material's suitability for clinical applications. Suppliers specializing in high-quality raw silk and efficient, large-scale purification techniques hold significant leverage in this initial phase.

The midstream phase focuses on advanced processing and formulation, where purified fibroin is converted into specific end-user formats such as electrospun nanofibers, injectable hydrogels, or 3D bioprintable bio-inks. This stage involves significant R&D investment and technological expertise, differentiating market players based on their ability to precisely control the material's tertiary structure and mechanical properties. Direct distribution channels are predominantly used for specialized, high-value products like tissue engineering scaffolds, where direct engagement with research labs, hospitals, and specialized biopharma companies ensures specific product requirements and technical support are met efficiently.

Downstream analysis reveals that the largest consumers are the Biomedical, Pharmaceutical, and Advanced Cosmetics industries. Indirect distribution plays a crucial role for bulk materials and standardized cosmetic ingredients, often involving specialized chemical distributors or ingredient brokers who manage logistics and regional compliance. The final consumption stage is characterized by rigorous quality assessment and application-specific formulation, driven by end-user needs for controlled degradation, cellular integration, and sustained therapeutic effect, ultimately completing the high-value trajectory of silk fibroin from raw cocoon to advanced biomaterial.

Silk Fibroin Market Potential Customers

The primary customers for high-purity silk fibroin are entities deeply involved in the development and manufacture of advanced medical technologies and therapeutic solutions, requiring materials with unparalleled biocompatibility and customization potential. Major pharmaceutical and biotechnology companies utilize silk fibroin for encapsulating and stabilizing complex protein drugs, vaccines, and cell therapies, capitalizing on its superior preservation capabilities under various storage conditions. Research institutions and university labs constitute another critical segment, purchasing specialized fibroin formats for pioneering work in regenerative medicine, investigating novel scaffold designs, and advancing in vitro disease modeling platforms, often seeking customized, small-batch quantities tailored to specific experimental protocols.

The second major customer group includes manufacturers of high-end cosmetic and personal care products, specifically targeting premium skin and hair care lines. These companies utilize silk fibroin peptides and powders as active ingredients, valued for their proven abilities to enhance moisture retention, improve skin elasticity, and create protective, breathable films, appealing directly to the discerning consumer market focused on natural and highly effective ingredients. Furthermore, manufacturers of implantable medical devices, such as surgical meshes, temporary stents, and specialized wound dressings, are key institutional buyers, demanding clinical-grade material compliance and reliable mechanical properties for critical, long-term applications within the human body.

Emerging customer segments include firms developing functional textiles and advanced materials, looking to leverage silk fibroin’s thermal stability and flexibility for specialized clothing or bio-integrated electronics, and companies within the functional food and nutraceutical sector seeking edible coatings and bioavailability enhancers. This diverse customer base, ranging from large-scale manufacturers to specialized research centers, underscores the material's versatility, but all share a fundamental requirement for high-purity, standardized silk fibroin products accompanied by robust technical documentation and regulatory support.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 480 Million |

| Market Forecast in 2033 | USD 867 Million |

| Growth Rate | CAGR 8.9% |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Aptys Pharmaceuticals, AMSilk GmbH, Huzhou Ainuo BioTech Co., Ltd., Chempur, Spiber Inc., BMG Incorporated, Advanced Biomaterials, Silk Road Medical, Intrepid Biomedical, FibroGen, Kraig Biocraft Laboratories, Seevix Material Sciences Ltd., EntoGenex Industries, Resverlogix Corp., Serica Technologies, DSM Biomedical. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Silk Fibroin Market Key Technology Landscape

The technological landscape of the Silk Fibroin Market is defined by advanced processing methods aimed at achieving precise control over the material's molecular structure and resulting macroscopic properties, crucial for its high-performance applications. The foundation of the technology relies on the aqueous dissolution method, which involves careful degumming to remove the immunogenic sericin layer, followed by dissolution in specific solvents (often highly concentrated salt solutions) and subsequent dialysis to regenerate pure silk fibroin in a stable aqueous solution. This crucial technological step dictates the material's purity and is the starting point for nearly all subsequent formulation technologies, requiring stringent control over pH, temperature, and ionic strength to prevent premature aggregation and maintain target molecular weight distribution necessary for clinical grades.

Beyond dissolution, sophisticated fabrication techniques transform the liquid fibroin into functional forms. Electrospinning is a prominent technology utilized to create ultrafine nanofibers, mimicking the native extracellular matrix structure, ideal for tissue engineering scaffolds and advanced wound dressings due to their high surface-area-to-volume ratio and interconnected porosity. Furthermore, 3D bioprinting technologies heavily utilize silk fibroin as a bio-ink component due to its shear-thinning properties and ability to rapidly solidify post-printing (often induced by methanol or ethanol treatment), allowing for the creation of complex, patient-specific anatomical structures. The integration of 3D bioprinting is accelerating product commercialization by enabling customized medical device manufacturing on demand, revolutionizing personalized regenerative therapies.

Another rapidly developing area is the functionalization and genetic engineering of silk. Researchers are employing molecular biology techniques to integrate active biological motifs (such as cell-adhesion sequences like RGD) directly into the silk protein structure via genetic modification of silkworms or microbes, creating "designer silks" with enhanced bioactivity. Chemical modifications, including conjugation with polyethylene glycol (PEGylation) or other polymers, are also employed to tune immunogenicity, increase solubility, and precisely control the degradation kinetics, thereby optimizing the performance of silk fibroin in demanding applications like long-term implantable materials and sophisticated drug reservoirs.

Regional Highlights

- North America: North America holds a dominant market share in terms of value, primarily driven by massive investment in advanced regenerative medicine, sophisticated drug delivery research, and a highly established ecosystem of specialized biotech firms and medical device manufacturers. The region, particularly the US, is a leader in utilizing silk fibroin for high-end clinical trials and sophisticated biomedical devices, supported by strong funding from both government agencies (like the NIH) and private venture capital. Consumer uptake of silk-derived products in premium cosmetics is also high, fueling the demand for ultra-pure ingredients.

- Europe: Europe represents a mature market characterized by stringent regulatory environments (e.g., EMA) which necessitate high standards for material quality and documentation. Countries like Germany, Switzerland, and the UK are major research hubs for biomaterials science and tissue engineering, utilizing silk fibroin extensively in academic research and collaborative industrial projects focused on orthopedic and cardiovascular applications. The presence of specialized textile and cosmetic manufacturers also ensures steady demand for functionalized silk materials and peptides.

- Asia Pacific (APAC): APAC is projected to exhibit the highest Compound Annual Growth Rate (CAGR) due to its dual role as the global primary source of raw silk (China, India) and a rapidly expanding consumer market for biomedical and cosmetic products. While raw material production dominates the upstream sector, countries like South Korea and Japan are heavily investing in advanced downstream manufacturing, focusing on silk fibroin applications in functional foods, pharmaceuticals, and high-tech electronics, leveraging domestic expertise in material science and bioengineering.

- Latin America (LATAM): The LATAM region represents an emerging market, currently showing slow but steady adoption of silk fibroin, mainly concentrated in the cosmetic sector and basic medical dressings. Growth potential is high, contingent on increased regional R&D spending, infrastructure development for high-purity processing, and improved regulatory harmonization to facilitate the import and local manufacture of advanced biomaterials.

- Middle East and Africa (MEA): The MEA market for silk fibroin is nascent and focused predominantly on imported finished products, particularly specialized wound care and high-end cosmetics. Market penetration relies heavily on international partnerships and the development of local healthcare infrastructure capable of utilizing advanced biomaterials in surgical and regenerative procedures.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Silk Fibroin Market.- Aptys Pharmaceuticals

- AMSilk GmbH

- Huzhou Ainuo BioTech Co., Ltd.

- Chempur

- Spiber Inc.

- BMG Incorporated

- Advanced Biomaterials

- Silk Road Medical

- Intrepid Biomedical

- FibroGen

- Kraig Biocraft Laboratories

- Seevix Material Sciences Ltd.

- EntoGenex Industries

- Resverlogix Corp.

- Serica Technologies

- DSM Biomedical

- Tsinghua Tongfang Artificial Organ Co.

- Vornia Biomaterials

- Celgene (now part of Bristol Myers Squibb)

- 3M Company (Biomaterials Division)

Frequently Asked Questions

Analyze common user questions about the Silk Fibroin market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary commercial advantage of using silk fibroin over synthetic polymers in biomedical applications?

The primary advantage is silk fibroin's unique combination of high mechanical strength, excellent biocompatibility, and controlled, tunable biodegradability, which allows it to naturally degrade into harmless components, unlike many synthetic polymers that may generate toxic breakdown products.

In which medical application does silk fibroin currently hold the largest market share?

Silk fibroin holds the largest market share in the Biomedical and Pharmaceutical application segment, specifically within Tissue Engineering and Regenerative Medicine, where it is extensively used to create complex scaffolds for soft and hard tissue repair due to its similarity to the native extracellular matrix.

What are the key technical challenges facing the mass production of clinical-grade silk fibroin?

The main technical challenges involve achieving high purity and batch-to-batch consistency during the degumming and aqueous processing stages to eliminate trace sericin (a highly immunogenic protein), which is critical for meeting stringent medical device regulatory standards and scalability.

How is genetic engineering impacting the development of new silk fibroin materials?

Genetic engineering allows researchers to create 'designer silks' by incorporating specific bioactive peptides or functional domains directly into the protein sequence. This enables the fabrication of customized materials with enhanced cell-signaling capabilities, better targeted drug delivery, or altered mechanical properties far surpassing natural silk.

Which geographical region is expected to demonstrate the highest growth rate for the silk fibroin market?

The Asia Pacific (APAC) region is expected to demonstrate the highest growth rate, driven by its established position as the primary source of raw silk and increasing regional investment in advanced downstream manufacturing, bio-innovation hubs, and rapidly expanding pharmaceutical and cosmetic consumer markets.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager