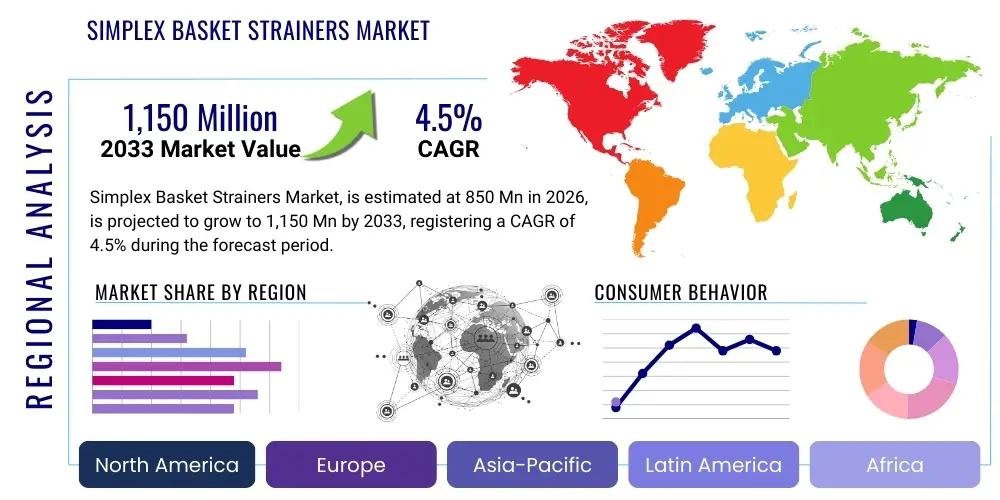

Simplex Basket Strainers Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 442194 | Date : Feb, 2026 | Pages : 246 | Region : Global | Publisher : MRU

Simplex Basket Strainers Market Size

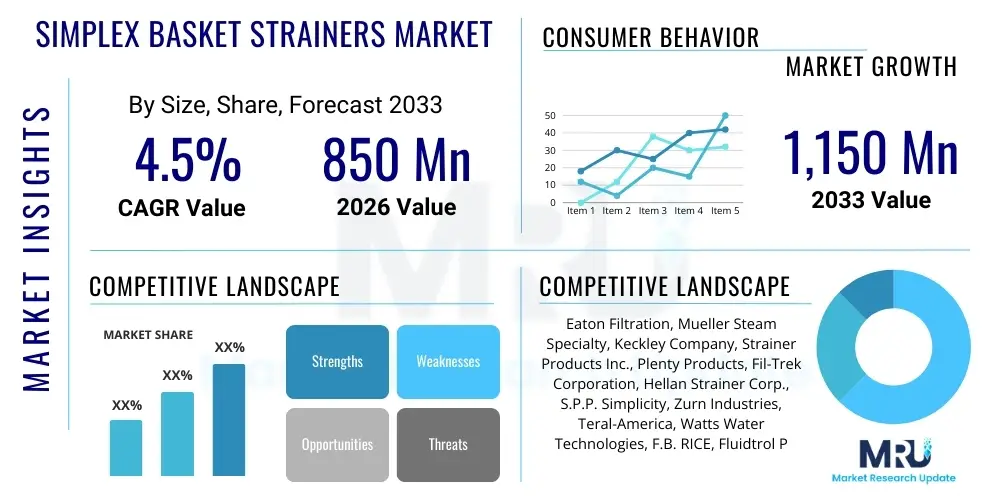

The Simplex Basket Strainers Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 4.5% between 2026 and 2033. The market is estimated at USD 850 Million in 2026 and is projected to reach USD 1,150 Million by the end of the forecast period in 2033. This consistent expansion is predominantly driven by increasing infrastructure development globally, particularly in emerging economies where reliable fluid handling systems are critical for industrial processes, alongside stringent regulatory requirements demanding higher purity levels in water and chemical processing.

Simplex Basket Strainers Market introduction

The Simplex Basket Strainers Market encompasses the manufacturing, distribution, and utilization of single-chamber filtration devices designed to remove particulate matter from fluid flow lines. Simplex strainers, characterized by their ease of use and ability to handle intermittent fluid flows, utilize a removable basket element to capture solids, thereby protecting sensitive downstream equipment such as pumps, valves, heat exchangers, and instrumentation. These devices are essential components in maintaining system integrity and operational efficiency across a vast array of industrial sectors, ensuring continuous pipeline operation during normal processes by preventing blockages and abrasive damage.

The core function of these strainers is crucial in environments where debris—such as rust, scale, or welding slag—is expected, yet continuous operation is not required during cleaning cycles. Simplex units require the line to be shut down for basket cleaning or replacement, making them ideal for systems with standby capacity or processes that can tolerate periodic interruptions. The primary materials used in manufacturing include cast iron, carbon steel, stainless steel (304, 316L), and various high-performance alloys, selected based on fluid compatibility, pressure ratings, and temperature requirements specific to the application.

Major applications of Simplex Basket Strainers span diverse industries, including water and wastewater treatment, where they protect disinfection systems and distribution networks; oil and gas, for pre-filtration in refineries and petrochemical plants; chemical processing, ensuring the purity of reagents and end products; and HVAC systems, safeguarding cooling tower loops and chillers. The benefits derived from deploying these strainers include significant reduction in maintenance costs for protected machinery, enhanced operational reliability, and compliance with increasingly demanding industrial standards for fluid cleanliness. Key driving factors underpinning market growth include rapid industrialization in Asia-Pacific, escalating demand for clean water infrastructure, and the continuous need to upgrade aging pipeline infrastructure across developed regions.

Simplex Basket Strainers Market Executive Summary

The Simplex Basket Strainers Market is witnessing robust expansion, largely fueled by sustained global investment in industrial fluid handling systems and crucial infrastructure upgrades. Current business trends indicate a definitive shift towards specialized materials, notably duplex and super duplex stainless steels, designed to withstand extremely corrosive environments prevalent in marine, offshore, and high-purity chemical processing industries. Furthermore, manufacturers are focusing on integrating advanced quick-opening covers and specialized coatings to reduce maintenance downtime and enhance the lifespan of the strainers, addressing operational efficiency demands from end-users. The competition remains fragmented, with large industrial valve and filtration specialists dominating the high-specification sectors, while regional manufacturers cater efficiently to standard, high-volume applications like general utilities and municipal water systems. Pricing sensitivity remains a challenge, particularly in commodity-grade segments, compelling innovation in manufacturing efficiency and supply chain optimization.

Regionally, the Asia Pacific (APAC) stands out as the primary growth engine, spurred by massive industrial output expansion, rapid urbanization, and extensive government initiatives in water infrastructure and energy generation projects, particularly in countries like China and India. North America and Europe maintain a mature yet stable market presence, characterized by high adoption rates of sophisticated, high-pressure, and high-temperature simplex strainers for regulatory compliance and safety enhancements in existing petrochemical and power generation facilities. Latin America and the Middle East & Africa (MEA) offer substantial opportunities, driven by ongoing investments in crude oil extraction, refining capacity expansion, and mining sector development, which inherently require robust primary filtration solutions to protect capital-intensive processing equipment.

Segment trends demonstrate strong demand for strainers defined by high pressure classes (ANSI 300 and 600) and those manufactured from corrosion-resistant alloys, reflecting the complexity and criticality of modern industrial fluid streams. While standard Y-strainers remain dominant for general utility purposes, the market for large-diameter basket strainers used in cooling water intake and municipal raw water systems is experiencing above-average growth. Furthermore, the increasing incorporation of smart accessories, such as differential pressure transmitters and remote monitoring systems, even on fundamentally passive simplex units, signals a broader industry trend toward digitalization and predictive maintenance protocols across all filtration equipment, enhancing the overall value proposition of these essential pipeline components.

AI Impact Analysis on Simplex Basket Strainers Market

Users frequently inquire about how AI and digitalization can impact traditional, mechanically simple components like Simplex Basket Strainers. Common user questions revolve around predictive maintenance schedules, optimizing filter replacement frequency, and automating the monitoring of differential pressure (DP) across the strainer to prevent system bottlenecks. Users seek assurance that investing in passive hardware is still worthwhile when sophisticated smart filtration systems are emerging. The analysis reveals that while AI does not directly alter the fundamental mechanism of the simplex strainer itself, it profoundly influences its operational context and supply chain efficiency. Key themes include leveraging machine learning algorithms to analyze flow rate variability, particulate load history, and DP sensor data to precisely forecast when a basket requires manual cleaning, shifting the maintenance paradigm from time-based schedules to condition-based intervention. This predictive capability minimizes costly shutdowns and maximizes the operational lifespan of the basket element, satisfying user demands for increased efficiency and reliability in filtration assets.

The implementation of Industrial Internet of Things (IIoT) sensors, combined with cloud-based AI platforms, allows for real-time aggregation and analysis of performance data from numerous filtration points across a plant or a network. For Simplex strainers, this translates into AI-driven inventory management, optimizing the stocking levels of replacement baskets and spare parts based on predicted usage patterns and regional demand fluctuations. This shift is particularly critical for facilities handling hazardous or high-temperature fluids, where minimizing unnecessary human intervention is paramount. Furthermore, AI contributes to design optimization by processing large datasets on failure modes and material performance under various stress conditions, leading to the development of better corrosion-resistant alloys and more ergonomically designed strainer housing and cover mechanisms that simplify the manual maintenance process, reducing mean time to repair (MTTR).

Ultimately, the impact of AI on the Simplex Basket Strainers market is less about revolutionizing the device and more about optimizing its integration within the broader industrial ecosystem. It transforms the strainer from a passive component into a smart data source, contributing valuable operational intelligence. This enhancement allows plant operators to achieve unprecedented levels of process stability and resource efficiency, making the overall filtration infrastructure more responsive and reliable. The long-term expectation is that standardization bodies will incorporate AI/ML compatibility requirements into future industrial filtration specifications, pushing manufacturers to ensure all new strainers are compatible with differential pressure and vibration sensors necessary for smart monitoring.

- AI-driven Predictive Maintenance: Optimizing manual cleaning schedules based on real-time differential pressure (DP) and historical flow data.

- Supply Chain Optimization: Machine learning models forecasting demand for specific basket sizes and materials, improving spare parts inventory management.

- Process Anomaly Detection: Identifying unusual pressure drops or flow fluctuations indicative of system health issues beyond simple basket clogging.

- Enhanced Safety Protocols: Using AI to flag critical maintenance needs in high-risk fluid applications, minimizing manual inspection exposure.

- Design Feedback Loop: Utilizing operational performance data to iteratively improve material selection, internal geometry, and ease of access for maintenance operations.

DRO & Impact Forces Of Simplex Basket Strainers Market

The Simplex Basket Strainers Market is shaped by a confluence of driving factors, restrictive elements, and expansive opportunities, all converging to determine the pace and direction of growth. Key drivers include stringent regulatory mandates, particularly those governing water quality and environmental discharge standards, which necessitate effective primary filtration across municipal and industrial sectors. The rapid industrial expansion, especially the establishment of new petrochemical facilities, power plants (conventional and nuclear), and pharmaceutical manufacturing units in developing nations, significantly boosts the demand for high-reliability strainers to protect critical, expensive processing machinery. Furthermore, the global trend of replacing older, inefficient infrastructure with modern, higher-pressure-rated, and more corrosion-resistant simplex units contributes substantially to market momentum.

Restraints primarily revolve around the inherent limitations of the simplex design, notably the necessity of shutting down the pipeline for manual cleaning or basket replacement, which is operationally prohibitive for continuous flow processes. This constraint often favors the adoption of more complex, higher-cost duplex or automatic self-cleaning strainers in critical, 24/7 operations, thereby diverting a portion of potential market share. Moreover, fluctuations in the price of raw materials, particularly nickel and chromium used in stainless steel and specialized alloys, introduce volatility into manufacturing costs, affecting final pricing and potentially slowing procurement cycles, especially for large capital projects. The presence of low-cost, substandard products from smaller regional players also creates pricing pressure and market confusion regarding quality and compliance standards, which can erode profit margins for premium manufacturers.

Opportunities in the market are substantial and primarily center on penetrating niche applications requiring high purity and specific material construction, such as cryogenic service, specialized chemical mixing, and biotechnology. The retrofit market, driven by the requirement to meet updated safety and environmental codes in aging industrial facilities across North America and Europe, presents continuous sales avenues. Additionally, the increasing integration of IIoT devices onto existing simplex installations—specifically differential pressure sensors that enable predictive maintenance—offers a significant aftermarket opportunity for accessory sales and service contracts. Technological advancement focuses on improving quick-opening closures (QOCs) and lightweight, high-strength composite materials for specific non-metallic applications, aiming to reduce maintenance time and lifecycle costs, thereby bolstering the competitive advantage of simplex units against more expensive duplex alternatives.

Segmentation Analysis

The Simplex Basket Strainers Market is segmented across multiple dimensions, reflecting the diverse industrial requirements for fluid filtration and protection. Key segmentation criteria include the type of material utilized for construction, which determines compatibility with corrosive fluids and tolerance to high pressures; the size and connection type, crucial for fitting into various pipeline dimensions and systems; the pressure rating, essential for safety and compliance in demanding industrial applications; and critically, the end-use industry, which dictates volume demand and required performance specifications. This multifaceted segmentation allows manufacturers to tailor products precisely to specific operational environments, ensuring optimal performance and compliance with industry-specific standards, such as ASME, API, and various national pressure vessel codes. The overall market landscape is defined by the varying complexity and price points across these segments, ranging from standardized cast iron strainers for water utilities to highly specialized, custom-fabricated stainless steel units for pharmaceutical or nuclear applications.

- By Material Type:

- Cast Iron

- Carbon Steel

- Stainless Steel (304, 316L)

- Duplex/Super Duplex Steel

- Non-metallic/Polymer

- By Connection Type:

- Flanged (ANSI, DIN, JIS)

- Threaded (NPT, BSP)

- Socket Weld

- By Size (Nominal Pipe Size - NPS):

- Below 2 inches

- 2 to 8 inches

- Above 8 inches

- By Pressure Class:

- Class 150

- Class 300

- Class 600 and Above

- By End-Use Industry:

- Oil & Gas (Upstream, Midstream, Downstream)

- Chemical and Petrochemical

- Power Generation (Thermal, Nuclear, Renewables)

- Water and Wastewater Treatment

- Pharmaceutical and Food & Beverage

- HVAC and Utilities

Value Chain Analysis For Simplex Basket Strainers Market

The value chain for Simplex Basket Strainers begins with the upstream procurement of raw materials, primarily specialized metallic alloys such as various grades of stainless steel (316, 3304, Duplex), carbon steel, and cast iron, along with non-metallic components like gaskets and seals (e.g., PTFE, Viton, EPDM). This phase is heavily influenced by global commodity markets and involves securing high-quality, traceable materials to meet stringent industrial specifications regarding pressure rating and corrosion resistance. Strategic partnerships with key metal suppliers and foundries are essential for maintaining stable costs and consistent quality in the casting and forging processes. Fluctuations in raw material prices directly impact the profitability of the mid-stream fabrication segment, necessitating effective hedging strategies and long-term supply contracts.

The midstream phase, focused on fabrication, involves specialized manufacturing processes, including precision casting, machining of flange faces and internal components, welding (for fabricated strainers), and assembly of the basket element within the housing. Quality control, including non-destructive testing (NDT) and hydrotesting, is critical at this stage to ensure compliance with standards such as ASME Boiler and Pressure Vessel Codes. Manufacturers must maintain certifications (e.g., ISO 9001, PED) to demonstrate competence and ensure product reliability. Downstream activities involve distribution and final installation, where products are channeled to end-users primarily through both direct and indirect routes. Direct sales are common for large, complex, custom-engineered strainers sold to major EPC (Engineering, Procurement, and Construction) firms or international oil companies requiring extensive technical support and large volume orders.

The indirect channel, which dominates the sales of standardized, off-the-shelf units, relies heavily on a network of specialized industrial distributors, MRO (Maintenance, Repair, and Operations) suppliers, and local representatives who provide logistical support and regional inventory. These indirect partners add value by offering localized installation expertise, rapid response for spare parts, and immediate product availability. Crucially, the after-sales service segment, including the supply of replacement baskets, seals, and maintenance training, contributes significantly to lifetime revenue and customer retention. Optimization of the value chain focuses on reducing lead times in fabrication, enhancing material traceability, and strengthening distributor relationships to efficiently reach diverse global end-markets while minimizing supply chain friction.

Simplex Basket Strainers Market Potential Customers

Potential customers for Simplex Basket Strainers span a wide spectrum of industrial and municipal entities whose operations critically depend on the protection of sensitive equipment from solid contaminants within fluid streams. Primary end-users are concentrated in sectors characterized by high flow rates, moderate contaminant levels, and operational flexibility that allows for periodic system shutdown for cleaning. The Power Generation sector, encompassing thermal, hydroelectric, and nuclear plants, represents a significant consumer, utilizing these strainers extensively in cooling water intake lines, condensate return systems, and lubrication oil circuits to protect heat exchangers and circulating pumps from debris ingestion, which could lead to catastrophic failure.

The Petrochemical and Chemical Processing industries are also core buyers, leveraging simplex strainers for the initial filtration of raw feedstocks, protection of metering pumps and expensive catalysts, and ensuring the purity of intermediate chemical products. In these volatile environments, the material selection—often demanding stainless steel or exotic alloys—is paramount, leading to higher average unit values. Further substantial demand originates from the Water and Wastewater Treatment sector, where municipal utilities use large-diameter strainers to screen raw water sourced from rivers or lakes before it enters treatment plants, protecting fine filters, membranes, and expensive pumps from gravel, silt, and vegetative matter that could severely impair purification processes and distribution efficiency.

Other vital customer segments include the Food & Beverage industry, where strainers ensure product quality and hygiene compliance, particularly in processing liquids like syrups, juices, and brewing components, often requiring polished internal surfaces and FDA-approved materials. The HVAC market utilizes them in large-scale commercial and industrial air conditioning and heating systems to prevent pipe scaling and debris accumulation in chiller barrels and boilers. These diverse customer bases share the common need for robust, low-maintenance filtration solutions that offer reliable protection and contribute to reduced operational expenditure over the long life cycle of the protected equipment. Procurement decisions are typically centralized by engineering departments and influenced heavily by system specifications, regulatory mandates, and total cost of ownership (TCO) assessments.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 850 Million |

| Market Forecast in 2033 | USD 1,150 Million |

| Growth Rate | 4.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Eaton Filtration, Mueller Steam Specialty, Keckley Company, Strainer Products Inc., Plenty Products, Fil-Trek Corporation, Hellan Strainer Corp., S.P.P. Simplicity, Zurn Industries, Teral-America, Watts Water Technologies, F.B. RICE, Fluidtrol Process Technologies, WESSELS Company, Pentair plc, Clark-Reliance Corporation, Ludemann, Spectro Alloys. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Simplex Basket Strainers Market Key Technology Landscape

The technology landscape in the Simplex Basket Strainers market, while fundamentally mature, is seeing significant evolutionary advancements focused primarily on materials science, ease of maintenance, and integration capabilities. A critical technological focus is the development and adoption of advanced corrosion-resistant alloys, such as high-nickel alloys and duplex stainless steels. These materials are essential for strainers deployed in challenging environments like sour gas processing, seawater desalination plants, and specific chemical reactors, offering superior longevity and reduced lifecycle replacement costs compared to traditional materials. Innovations in specialized internal and external coatings (e.g., epoxy, ceramic liners) also contribute to extending operational life and preventing micro-corrosion, which is crucial for maintaining the integrity of the pressure vessel over decades of service.

A second key technological area involves mechanical enhancements designed to significantly reduce the time required for cleaning and maintenance, which is the primary operational drawback of simplex units. Quick-Opening Closures (QOCs) have evolved from simple hinged bolts to complex, engineered locking mechanisms that ensure safe, pressure-locked opening capabilities while minimizing labor intensity. Modern QOC designs often feature ergonomic handles, visual pressure indicators, and fail-safe interlocks, enhancing worker safety and streamlining maintenance cycles. Furthermore, the standardization of housing design allows for greater interchangeability of basket elements, simplifying inventory management for end-users operating multiple types or brands of strainers across their facilities.

Finally, technology is driving the integration of the simplex strainer into smart plant environments through sensor technology. Although the strainer itself lacks complex mechanics, the incorporation of highly sensitive differential pressure (DP) transmitters is a major technological trend. These transmitters, utilizing piezoelectric or capacitance sensing technology, monitor the pressure differential across the basket in real-time, sending data back to a centralized control system. This enables precise, condition-based monitoring, alerting operators immediately when the basket is nearing its clogging limit. This smart integration effectively bridges the gap between traditional mechanical components and the requirements of Industry 4.0, transforming the simple strainer into a crucial data point for overall process health and predictive maintenance protocols, thereby optimizing labor allocation and minimizing unexpected system interruptions.

Regional Highlights

The market dynamics for Simplex Basket Strainers vary significantly across global regions, reflecting disparate industrialization rates, regulatory environments, and infrastructure investment priorities. North America represents a mature market characterized by a strong emphasis on regulatory compliance, safety standards, and replacing legacy infrastructure. Demand here is dominated by high-specification strainers required for the stringent environments of the oil and gas midstream and downstream sectors, as well as the nuclear power industry. The region, particularly the United States and Canada, shows a sustained demand for premium stainless steel and alloy strainers, often coupled with advanced monitoring technology, driven by ongoing modernization projects and high labor costs that necessitate minimizing maintenance frequency.

Europe’s market is defined by rigorous environmental protection standards and a focus on efficiency in manufacturing and water management. Countries in Western Europe drive demand for specialized, environmentally compliant filtration units, often utilizing non-metallic components in specific chemical processes or prioritizing strainers designed for high energy efficiency and low pressure drop. The ongoing necessity to upgrade aging industrial facilities and comply with updated EU directives concerning potable water and industrial emissions ensures a steady, albeit moderate, replacement and retrofit market. Eastern Europe presents faster growth potential due to continued industrial transition and infrastructure development projects in energy transmission and general manufacturing.

Asia Pacific (APAC) is the undisputed powerhouse for market growth, underpinned by unprecedented industrial expansion, rapid urbanization, and massive government investment in water and energy infrastructure across China, India, and Southeast Asia. The demand in APAC is characterized by high volume, particularly for cast iron and carbon steel strainers in general utility and municipal water applications. Furthermore, the region is becoming a major center for chemical processing and refining, creating significant demand for specialized alloy strainers. Economic growth and the establishment of new greenfield manufacturing facilities ensure that APAC will contribute the largest incremental revenue to the Simplex Basket Strainers market over the forecast period.

Latin America (LATAM) and the Middle East & Africa (MEA) offer high growth potential linked primarily to resource extraction and energy projects. In MEA, massive ongoing investments in desalination plants, oil refining capacity, and pipeline networks drive the procurement of large-diameter, high-pressure, corrosion-resistant strainers, specifically designed for harsh desert and offshore environments. LATAM’s market is influenced by large-scale mining operations and petrochemical developments in Brazil, Mexico, and Argentina, creating specific demand for highly robust units capable of handling high solid loads and abrasive fluids. These regions prioritize durability and operational reliability under challenging conditions, often necessitating highly customized filtration solutions.

- Asia Pacific (APAC): Dominant growth region fueled by infrastructure spending, urbanization, and expansion of petrochemical and power generation industries, particularly China and India.

- North America: Mature market focused on replacement, modernization, and high-specification units for oil & gas and regulatory compliance in established industries.

- Europe: Stable demand driven by environmental regulations, efficiency requirements, and continuous industrial retrofit projects, with strong demand for certified quality.

- Middle East & Africa (MEA): High growth potential linked to large-scale desalination projects, extensive oil and gas production expansion, and related infrastructure development.

- Latin America (LATAM): Growth spurred by mining sector investment, petrochemical industry expansion, and general utility improvements across key developing nations.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Simplex Basket Strainers Market.- Eaton Filtration

- Mueller Steam Specialty

- Keckley Company

- Strainer Products Inc.

- Plenty Products

- Fil-Trek Corporation

- Hellan Strainer Corp.

- S.P.P. Simplicity

- Zurn Industries

- Teral-America

- Watts Water Technologies

- F.B. RICE

- Fluidtrol Process Technologies

- WESSELS Company

- Pentair plc

- Clark-Reliance Corporation

- Ludemann

- Spectro Alloys

- Titan Flow Control

- Metraflex Company

Frequently Asked Questions

Analyze common user questions about the Simplex Basket Strainers market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary advantage of using a Simplex Basket Strainer over other filtration types?

The primary advantage of the Simplex Basket Strainer is its cost-effectiveness, simple design, and high debris holding capacity relative to its size, making it ideal for non-continuous processes or systems with standby equipment. It offers robust protection for pumps and instrumentation at a lower capital expenditure compared to automated or duplex filtration units.

In which industries are Simplex Basket Strainers most commonly utilized?

Simplex Basket Strainers are essential across numerous heavy industries, predominantly the Water and Wastewater Treatment sector, Chemical and Petrochemical processing, Power Generation facilities (for cooling water and lubricating systems), and general utilities and HVAC systems where intermittent cleaning cycles are permissible.

What are the key material considerations when selecting a Simplex Basket Strainer?

Key material considerations are the fluid corrosivity, operating temperature, and system pressure. Common materials include cast iron for basic water services, carbon steel for high pressure/temperature hydrocarbon applications, and stainless steel (316L, Duplex) for chemical resistance, high purity processes, and enhanced mechanical strength.

How does the integration of IIoT technology affect the usage of traditional Simplex Strainers?

IIoT technology, primarily through differential pressure (DP) sensors, transforms the Simplex Strainer into a 'smart' component. This integration enables predictive, condition-based maintenance scheduling, optimizing manual cleaning intervals and reducing unexpected downtime, thereby enhancing the overall operational reliability of the entire fluid system.

What is the projected growth trajectory for the Simplex Basket Strainers Market in the Asia Pacific region?

The Asia Pacific region is anticipated to demonstrate the highest Compound Annual Growth Rate (CAGR) due to extensive government investment in public infrastructure, rapid industrialization, and expansion of refining and chemical manufacturing capacity, creating sustained high-volume demand for reliable primary filtration equipment.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager