Single Vertical Balancing Machine Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440766 | Date : Feb, 2026 | Pages : 246 | Region : Global | Publisher : MRU

Single Vertical Balancing Machine Market Size

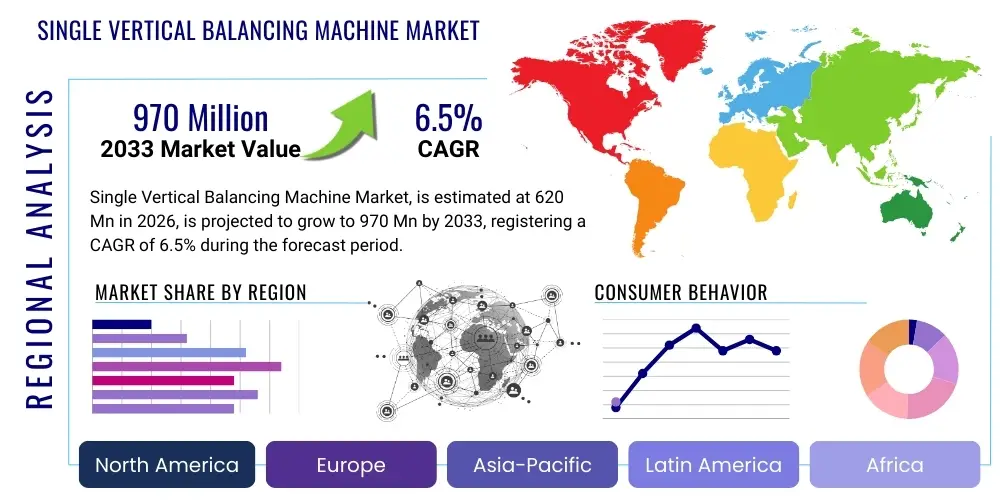

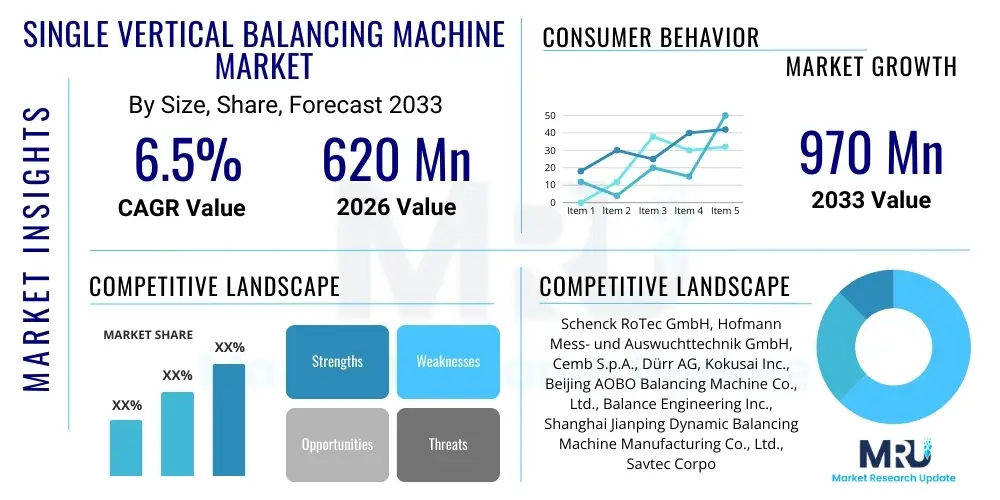

The Single Vertical Balancing Machine Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5% between 2026 and 2033. The market is estimated at USD 620 million in 2026 and is projected to reach USD 970 million by the end of the forecast period in 2033. This growth trajectory is underpinned by increasing global demand for precision manufacturing, stringent quality control standards across various industries, and the continuous push towards enhanced operational efficiency and product longevity in rotary components. The market’s expansion is primarily driven by the automotive, aerospace, and electronics sectors, which rely heavily on high-accuracy balancing to prevent vibration, reduce wear, and improve the overall performance and safety of their products.

Single Vertical Balancing Machine Market introduction

Single vertical balancing machines are specialized industrial equipment designed to measure and correct unbalance in disc-shaped or short-shaft components that require balancing in a single plane. These machines operate on the principle of rotational dynamics, identifying the exact location and magnitude of unbalance by spinning the workpiece and analyzing the resulting centrifugal forces. Key components typically include a robust machine base, a precision spindle, unbalance measuring instrumentation, a display unit, and often an integrated correction unit. The primary applications span across a wide array of industries, including the automotive sector for balancing brake discs, flywheels, and clutches; the aerospace industry for turbine discs and fan components; the electric motor industry for rotors; and general machinery manufacturing for impellers, grinding wheels, and pulleys. The fundamental benefit of utilizing these machines lies in the significant improvement of product quality and operational reliability. By minimizing vibrations, extending the lifespan of machinery, reducing noise levels, and ensuring compliance with stringent industry standards, these machines contribute directly to enhanced safety, performance, and overall customer satisfaction.

The market is experiencing robust growth driven by several critical factors. The surging global demand for high-performance and durable rotating machinery across industrial sectors necessitates precise balancing, pushing manufacturers to invest in advanced balancing solutions. Moreover, the increasing adoption of automation and Industry 4.0 principles in manufacturing processes is leading to a greater integration of automated balancing systems, which include single vertical balancing machines, to streamline production lines and reduce human intervention. Stringent quality regulations and safety standards, particularly in automotive and aerospace industries, mandate exact balancing of components, further accelerating market demand. The ongoing trend towards lightweighting of components to improve energy efficiency and performance, particularly in electric vehicles and aircraft, makes precise balancing even more critical. Finally, the growing manufacturing prowess in emerging economies, coupled with increased infrastructure development, is creating new avenues for the deployment of these essential precision tools.

Single Vertical Balancing Machine Market Executive Summary

The Single Vertical Balancing Machine Market is characterized by dynamic business trends reflecting an ongoing evolution in manufacturing demands and technological capabilities. Key trends include a heightened focus on customization and modularity, allowing manufacturers to tailor balancing solutions to specific component geometries and production volumes. There is also a notable shift towards integrated balancing solutions that combine measurement and correction processes within a single machine or a seamless production line, enhancing efficiency and reducing handling time. Furthermore, the market is observing a push for user-friendly interfaces and advanced diagnostic capabilities, making these complex machines more accessible and easier to operate for a broader range of technicians. Strategic collaborations between balancing machine manufacturers and industrial automation providers are becoming more common, aiming to offer comprehensive, turn-key solutions that cater to the sophisticated needs of modern smart factories. The emphasis on energy efficiency and reduced operational footprint in new machine designs also represents a significant business trend, aligning with global sustainability goals and lowering overall total cost of ownership for end-users.

Regionally, the market exhibits varied growth patterns. Asia Pacific stands out as a dominant and rapidly expanding market, primarily fueled by robust industrialization, significant investments in manufacturing infrastructure, and the burgeoning automotive and electronics sectors in countries like China, India, Japan, and South Korea. Europe remains a mature yet innovative market, driven by advanced manufacturing practices, stringent quality standards, and continuous technological advancements in Germany's automotive and machinery industries. North America, too, represents a substantial market, with strong demand from aerospace and automotive manufacturing, along coupled with a focus on adopting high-precision and automated balancing solutions. Emerging economies in Latin America and the Middle East & Africa are showing promising growth, albeit from a smaller base, as industrial diversification and infrastructure development projects create new opportunities for balancing machine deployment. Each region's growth is intricately linked to its industrial landscape, regulatory environment, and technological adoption rates.

Segment-wise, the market is seeing a clear preference for automatic and semi-automatic single vertical balancing machines, largely due to their ability to integrate seamlessly into automated production lines, offering higher throughput and reduced manual intervention compared to manual variants. The automotive application segment continues to hold the largest share, driven by the sheer volume of rotating components requiring precise balancing for vehicle safety and performance. However, significant growth is also observed in the aerospace and defense sector, where uncompromising precision is paramount for critical components like turbine blades and discs. The electric motor and generator segment is another strong performer, propelled by the global shift towards electrification and the increasing demand for high-efficiency motors. Custom-built solutions tailored for specific industrial applications, such as large impellers or specialized grinding wheels, also represent a growing niche, reflecting the market's responsiveness to diverse and evolving customer needs. The ongoing evolution of materials and component designs further influences segment trends, pushing for more adaptable and precise balancing technologies.

AI Impact Analysis on Single Vertical Balancing Machine Market

The integration of Artificial Intelligence (AI) is poised to revolutionize the Single Vertical Balancing Machine market by introducing unprecedented levels of precision, efficiency, and predictive capabilities. Users are increasingly questioning how AI can enhance existing balancing processes, particularly in terms of reducing setup times, optimizing correction cycles, and enabling proactive maintenance. Key themes emerging from user inquiries include the potential for AI-driven algorithms to learn from vast datasets of balancing operations, identifying complex patterns that human operators might miss, and thereby achieving more accurate and faster unbalance correction. Concerns often revolve around the initial investment costs, the complexity of AI integration with legacy systems, and the need for skilled personnel to manage and interpret AI outputs. Nevertheless, the overarching expectation is that AI will transform balancing machines from mere measurement tools into intelligent, self-optimizing systems that significantly contribute to overall manufacturing efficiency and quality control.

AI's influence extends beyond just efficiency. Users are also keen on understanding how AI can facilitate predictive quality control, ensuring that components remain balanced throughout their operational life, and how AI can improve the machine's ability to handle variations in material properties or component geometry without extensive manual recalibration. The demand for AI-powered diagnostics that can preemptively identify potential machine faults or calibration drift is growing, promising to minimize downtime and extend the service life of balancing equipment. Furthermore, there is considerable interest in how AI can enable adaptive balancing processes, where the machine automatically adjusts its parameters based on real-time feedback and historical data, leading to a more robust and consistent balancing performance. The ability of AI to interpret sensor data from multiple points, integrating it with machine vision and acoustic analysis, represents another area of high expectation, offering a more holistic view of component health and balancing requirements.

The long-term expectations for AI in this market include the development of fully autonomous balancing cells, where components are fed, measured, corrected, and inspected with minimal human intervention, all orchestrated by intelligent AI systems. This vision aligns perfectly with the Industry 4.0 paradigm, where machines communicate, learn, and optimize their processes in a connected environment. The data generated by AI-powered balancing machines will also provide invaluable insights into manufacturing deviations, material inconsistencies, and process improvements upstream, transforming balancing from a final quality check into a critical data-generating hub for continuous process optimization. Ultimately, AI is expected to elevate the role of single vertical balancing machines from essential equipment to intelligent agents that drive higher levels of manufacturing excellence and competitive advantage.

- AI-driven predictive maintenance: Algorithms analyze operational data to forecast machine failures, reducing downtime and maintenance costs.

- Optimized balancing algorithms: AI learns from historical data to achieve faster, more precise unbalance correction, minimizing cycle times.

- Enhanced quality control: AI identifies subtle patterns indicative of quality issues, ensuring consistent component balance and reducing defects.

- Adaptive process control: Machines adjust parameters dynamically based on real-time feedback, improving adaptability to variations in components.

- Automated fault detection: AI monitors machine health and component anomalies, alerting operators to potential issues before they escalate.

- Data analytics and insights: AI processes large datasets to provide actionable insights for process improvement and manufacturing optimization.

- Integration with smart factory ecosystems: AI enables seamless communication and collaboration with other automated systems in an Industry 4.0 environment.

- Reduced setup and calibration times: AI systems quickly configure machine parameters for new component types, increasing operational flexibility.

DRO & Impact Forces Of Single Vertical Balancing Machine Market

The Single Vertical Balancing Machine Market is primarily driven by the escalating demand for precision and reliability in rotating components across diverse industries. The automotive sector, particularly with the rise of electric vehicles requiring high-precision motor components, remains a significant driver. Furthermore, the stringent quality standards and safety regulations in aerospace, defense, and power generation industries necessitate the use of advanced balancing machines to ensure optimal performance and prevent catastrophic failures. The ongoing trend of industrial automation and the widespread adoption of Industry 4.0 principles also fuel market growth, as manufacturers seek integrated, automated solutions to enhance productivity, reduce labor costs, and improve overall manufacturing efficiency. Additionally, the increasing complexity of component designs and the use of new materials that demand highly accurate balancing contribute to market expansion, pushing innovation in balancing technology. These drivers collectively create a robust demand environment for high-quality single vertical balancing machines, emphasizing their critical role in modern manufacturing.

Despite the strong drivers, the market faces several notable restraints. The high initial capital investment required for purchasing advanced single vertical balancing machines can be a significant barrier for small and medium-sized enterprises (SMEs), limiting market penetration in certain segments. The technical complexity associated with operating and maintaining these sophisticated machines often requires highly skilled personnel, and a shortage of such expertise can hinder adoption, particularly in developing regions. Furthermore, the market for conventional balancing machines in developed regions might experience some saturation, leading to increased competition and pricing pressures. Economic downturns and geopolitical uncertainties can also impact industrial investments, causing delays or reductions in capital expenditure for new machinery. Lastly, the rapid pace of technological change necessitates continuous R&D investment, which can be challenging for some market players, potentially leading to a disparity in technological offerings and competitive advantage.

Opportunities within the Single Vertical Balancing Machine Market are abundant, especially in emerging economies undergoing rapid industrialization and infrastructure development, which present untapped potential for new installations. The growing trend of customized manufacturing and the increasing demand for specialized balancing solutions for unique component geometries offer avenues for innovation and market differentiation. Furthermore, the integration of advanced technologies such as Artificial intelligence (AI), machine learning, and advanced sensor technology into balancing machines represents a significant opportunity for enhancing precision, automation, and predictive capabilities. The aftermarket segment, including services, spare parts, and retrofits for older machines, also provides a stable revenue stream and growth opportunities. Strategic partnerships and collaborations with automation companies and software providers can lead to the development of integrated, smart factory solutions, further expanding market reach and utility. These opportunities highlight the potential for sustained growth and evolution within the market, driven by technological advancements and expanding industrial applications.

The collective impact of these drivers, restraints, and opportunities shapes the trajectory of the Single Vertical Balancing Machine Market. Drivers provide the fundamental impetus for growth, creating a baseline demand for these essential tools in precision manufacturing. Restraints act as limiting forces, potentially slowing down adoption rates or impacting profit margins, necessitating strategic navigation by market players. Opportunities, on the other hand, represent avenues for innovation, market expansion, and competitive differentiation, offering paths for sustained development even in the face of challenges. The interplay of these forces dictates market dynamics, influencing investment decisions, technological development, and the competitive landscape. Companies that effectively leverage drivers and opportunities while mitigating restraints are best positioned for long-term success, adapting to evolving industrial needs and technological advancements.

Segmentation Analysis

The Single Vertical Balancing Machine Market is comprehensively segmented based on various critical parameters including machine type, end-user application, and geographical region, providing a granular understanding of its dynamics. This segmentation is crucial for identifying distinct market niches, understanding specific customer needs, and developing targeted strategies. Each segment exhibits unique growth drivers and competitive landscapes, reflecting the diverse requirements of industries ranging from automotive to aerospace. Analyzing these segments helps in forecasting demand patterns, identifying high-growth areas, and assessing the competitive intensity within the market, allowing stakeholders to make informed investment and strategic decisions. The market’s segmentation highlights its versatility and the specific technological adaptations required to meet varied industrial demands, from manual operations to fully automated, high-precision manufacturing environments.

- By Type:

- Manual Single Vertical Balancing Machines: Characterized by operator-driven component loading, measurement initiation, and manual unbalance correction. Typically used for low-volume production or specialized applications.

- Semi-Automatic Single Vertical Balancing Machines: Feature automated measurement cycles and often integrated correction units, but still require manual loading/unloading of components. Offer a balance between automation and operator control.

- Automatic Single Vertical Balancing Machines: Fully automated systems for component handling, measurement, and unbalance correction. Designed for high-volume production lines requiring minimal human intervention.

- By Application:

- Automotive Components: Brake discs, flywheels, clutches, torque converters, pulleys, impellers, and electric vehicle motor components.

- Electric Motors and Generators: Rotors, armatures, and other rotating parts for various types of electric motors and power generators.

- Turbomachinery: Fans, blowers, impellers, turbochargers, and small turbine discs used in HVAC, power generation, and aerospace.

- Aerospace Components: Turbine discs, fan components, impellers, and other critical rotating parts demanding extremely high precision and reliability.

- Grinding Wheels and Cutting Tools: Balancing of abrasive wheels and precision cutting tools to ensure accuracy and prolong tool life.

- Others: Components for textile machinery, medical devices, pumps, agricultural machinery, and various general industrial applications.

- By End-User Industry:

- Automotive Industry: Manufacturers of passenger cars, commercial vehicles, electric vehicles, and automotive component suppliers.

- Aerospace and Defense Industry: Manufacturers of aircraft, spacecraft, defense systems, and their component suppliers.

- Electronics and Electrical Industry: Producers of electric motors, generators, electronic components requiring precision balancing.

- Machinery Manufacturing: Manufacturers of various industrial machinery, machine tools, and process equipment.

- Power Generation: Companies involved in the production of power plants, turbines, and generators.

- Precision Engineering: Industries requiring exceptionally high dimensional accuracy and rotational balance.

- Others: Industries such as medical, textile, agricultural, and general manufacturing.

- By Capacity/Component Weight:

- Light Weight (Up to 5 kg)

- Medium Weight (5 kg to 50 kg)

- Heavy Weight (Above 50 kg)

Value Chain Analysis For Single Vertical Balancing Machine Market

The value chain for the Single Vertical Balancing Machine Market encompasses a series of interconnected activities, beginning with upstream raw material and component suppliers, extending through manufacturing and assembly, and culminating in distribution and post-sales support to end-users. Upstream analysis highlights the critical role of specialized suppliers providing high-precision sensors, advanced control systems (PLCs, CNCs), sophisticated software for unbalance measurement and correction algorithms, high-quality steel and aluminum alloys for machine construction, and precision mechanical components such as spindles, bearings, and linear guides. The reliability and performance of the balancing machine are intrinsically linked to the quality and innovation provided by these upstream suppliers. Strong relationships with these suppliers are essential for ensuring a consistent supply of high-grade inputs, managing costs, and incorporating the latest technological advancements into the final product. Any disruptions or quality issues at this stage can significantly impact the final product's performance and market competitiveness.

Further along the value chain, the manufacturing and assembly phase involves the integration of these components into a functional balancing machine. This includes precision machining of the machine base, assembly of mechanical and electrical subsystems, installation of instrumentation, and rigorous testing and calibration to meet specified accuracy and performance standards. Downstream analysis focuses on how these machines reach the end-user. Distribution channels are varied, including direct sales from the manufacturer, which allows for closer customer relationships and customized solutions, particularly for complex or high-value systems. Indirect channels involve a network of distributors, agents, and resellers who provide market access, localized support, and integration services, especially in geographically dispersed or emerging markets. These intermediaries play a crucial role in market penetration, particularly for standardized or semi-automatic models, by providing sales, technical support, and after-sales services. The choice of distribution channel often depends on the target market, product complexity, and the manufacturer's strategic objectives, balancing reach with control.

The value chain extends beyond the initial sale to encompass comprehensive after-sales support, including installation, commissioning, training, maintenance, calibration services, and the provision of spare parts. This downstream activity is vital for ensuring customer satisfaction, maximizing machine uptime, and building long-term relationships. Effective after-sales support can differentiate a manufacturer in a competitive market and contribute significantly to overall revenue through service contracts and parts sales. Furthermore, the feedback loop from end-users and service technicians provides invaluable insights for product improvement and innovation, influencing future design and development. The efficiency and robustness of the entire value chain, from raw material procurement to post-purchase service, are critical determinants of a manufacturer's ability to deliver high-quality, competitive products to the market and maintain a strong brand reputation in the precision machinery sector.

Single Vertical Balancing Machine Market Potential Customers

The potential customers for Single Vertical Balancing Machines represent a broad spectrum of industries that rely on rotating components requiring precise balance to ensure optimal performance, extended lifespan, and adherence to stringent quality and safety standards. At the forefront are original equipment manufacturers (OEMs) and their suppliers within the automotive industry, which require these machines for balancing critical components such as brake discs, flywheels, clutches, crankshafts, and increasingly, electric motor rotors and driveline components for electric vehicles. The demand stems from the necessity to mitigate vibrations, enhance ride comfort, and improve the overall safety and fuel efficiency of vehicles. Similarly, the aerospace and defense sector constitutes a significant customer base, where the balancing of turbine discs, impellers, fan components, and other high-speed rotating parts is paramount for flight safety, engine efficiency, and compliance with rigorous aviation standards. The uncompromising precision demanded by aerospace applications often drives innovation in balancing machine technology.

Beyond these major sectors, the electric motor and generator manufacturing industry is a vital end-user segment. Companies producing a wide range of electric motors, from small industrial motors to large power generation units, rely on vertical balancing machines to ensure the smooth operation, efficiency, and longevity of their rotors and armatures. The global push towards electrification across various applications, coupled with the increasing demand for high-efficiency and quiet motors, further solidifies this customer base. Machinery manufacturers, particularly those involved in producing pumps, compressors, fans, blowers, and various machine tools, also represent a substantial customer segment. These industries require their rotating components to be precisely balanced to prevent premature wear, reduce noise, and ensure the reliable operation of their final products. Any imbalance in these components can lead to operational inefficiencies, increased maintenance costs, and potential equipment failure, making vertical balancing machines indispensable.

Furthermore, the precision engineering sector, which includes manufacturers of grinding wheels, cutting tools, optical components, and various high-precision instruments, is another key demographic. For these customers, even minute unbalance can significantly affect product quality, surface finish, and operational accuracy. Service and repair shops specializing in industrial equipment, as well as maintenance departments within large manufacturing plants, also represent potential buyers, seeking to re-balance components during overhaul or repair processes. The growth of specialized industries such as medical device manufacturing, where micro-rotors or miniature impellers require extremely fine balancing, is also expanding the customer landscape. In essence, any industry involved in the production, assembly, or maintenance of rotating components that operate at moderate to high speeds and require high levels of precision will likely be a potential customer for single vertical balancing machines, driven by the universal need to reduce vibration, enhance product quality, and extend operational life.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 620 Million |

| Market Forecast in 2033 | USD 970 Million |

| Growth Rate | 6.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Schenck RoTec GmbH, Hofmann Mess- und Auswuchttechnik GmbH, Cemb S.p.A., Dürr AG, Kokusai Inc., Beijing AOBO Balancing Machine Co., Ltd., Balance Engineering Inc., Shanghai Jianping Dynamic Balancing Machine Manufacturing Co., Ltd., Savtec Corporation, Tinius Olsen Testing Machine Company, BTI - Balancing Technologies, Inc., Haimer GmbH, Rontgen Balancing Machines Pvt. Ltd., FIE - Fuel Instruments & Engineers Pvt. Ltd., Ningbo Three-Star Balancing Machine Co., Ltd., Universal Balancing, CEMB Hofmann UK, American Hofmann Corporation, TEC Balancing, Hardinge Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Single Vertical Balancing Machine Market Key Technology Landscape

The Single Vertical Balancing Machine Market is continually evolving, driven by advancements in precision engineering, automation, and digital technologies. At the core of these machines are highly sensitive sensor technologies, predominantly piezoelectric or eddy current sensors, which are crucial for accurately detecting minute vibrations and unbalance forces. These sensors are integrated with sophisticated digital signal processing units that filter noise and extract precise unbalance measurements. Control systems have advanced from basic PLCs (Programmable Logic Controllers) to advanced CNC (Computer Numerical Control) systems, offering greater flexibility, precision, and the ability to execute complex balancing routines automatically. The user interface has also seen significant improvements, with modern machines featuring intuitive Human Machine Interfaces (HMIs) that incorporate touchscreens, graphical displays, and real-time data visualization, simplifying operation and diagnostics for technicians. Software plays an increasingly critical role, providing advanced algorithms for unbalance calculation, data acquisition, statistical process control, and comprehensive reporting, often with connectivity options for enterprise resource planning (ERP) systems.

Further technological advancements include the widespread adoption of automation and robotics for component handling, allowing for seamless integration into fully automated production lines. Robotic loaders and unloaders, coupled with automatic unbalance correction units (e.g., drilling, milling, or grinding stations), significantly reduce cycle times and minimize manual labor. Industry 4.0 integration is a paramount trend, enabling these machines to become "smart" devices within a connected manufacturing ecosystem. This involves the use of IoT (Internet of Things) sensors for real-time monitoring of machine health and performance, cloud connectivity for data storage and analysis, and remote diagnostic capabilities. Such integration facilitates predictive maintenance, optimizes production schedules, and allows for data-driven decision-making, moving beyond simple balancing to contribute to overall operational intelligence. Laser balancing, while more specialized, is also emerging for extremely precise applications, particularly for miniature or high-speed components, offering non-contact material removal with sub-micron accuracy.

Moreover, the incorporation of advanced materials and design methodologies is enhancing the structural integrity and vibration damping capabilities of the balancing machines themselves, leading to more stable and accurate measurements. Features like automatic tool compensation in correction units and adaptive balancing algorithms that learn from previous cycles further improve efficiency and precision. The advent of augmented reality (AR) and virtual reality (VR) is beginning to find applications in training and remote maintenance support, providing immersive experiences for troubleshooting and operational guidance. The synergy of these technologies—from advanced sensors and intelligent control systems to automation, Industry 4.0 connectivity, and AI-driven analytics—is transforming single vertical balancing machines into highly sophisticated, indispensable tools for modern manufacturing, capable of delivering unparalleled precision, efficiency, and reliability in dynamic balancing operations.

Regional Highlights

- North America: A mature market characterized by high adoption rates of advanced balancing technologies, particularly in the aerospace, defense, and automotive sectors. The region benefits from significant R&D investments, strong demand for high-precision components, and a growing emphasis on smart manufacturing and automation. The presence of leading technology providers and a robust industrial infrastructure contribute to its market stability and innovation.

- Europe: A key hub for automotive and machinery manufacturing, driving consistent demand for single vertical balancing machines. Countries like Germany and Italy are at the forefront of technological innovation and have stringent quality standards, necessitating advanced balancing solutions. The region also benefits from a strong focus on industrial automation and Industry 4.0 initiatives, fostering the integration of intelligent balancing systems.

- Asia Pacific (APAC): The largest and fastest-growing market, primarily due to rapid industrialization, burgeoning manufacturing sectors in China, India, Japan, and South Korea, and increasing investments in automotive, electronics, and general machinery production. The expanding middle class and rising disposable incomes contribute to increased demand for manufactured goods, subsequently driving the need for precision balancing equipment.

- Latin America: An emerging market with growing industrialization and infrastructure development, particularly in countries like Brazil and Mexico. The automotive manufacturing sector plays a significant role in market demand, although economic volatility and slower adoption of advanced technologies present challenges. Opportunities lie in increasing foreign direct investment and localized manufacturing initiatives.

- Middle East and Africa (MEA): This region is experiencing nascent growth driven by diversification away from oil economies, leading to investments in manufacturing, automotive assembly, and infrastructure projects. While currently a smaller market, government initiatives to promote industrial development and technological advancement are expected to boost demand for precision manufacturing equipment, including balancing machines, in the long term.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Single Vertical Balancing Machine Market.- Schenck RoTec GmbH

- Hofmann Mess- und Auswuchttechnik GmbH

- Cemb S.p.A.

- Dürr AG

- Kokusai Inc.

- Beijing AOBO Balancing Machine Co., Ltd.

- Balance Engineering Inc.

- Shanghai Jianping Dynamic Balancing Machine Manufacturing Co., Ltd.

- Savtec Corporation

- Tinius Olsen Testing Machine Company

- BTI - Balancing Technologies, Inc.

- Haimer GmbH

- Rontgen Balancing Machines Pvt. Ltd.

- FIE - Fuel Instruments & Engineers Pvt. Ltd.

- Ningbo Three-Star Balancing Machine Co., Ltd.

- Universal Balancing

- CEMB Hofmann UK

- American Hofmann Corporation

- TEC Balancing

- Hardinge Inc.

Frequently Asked Questions

Analyze common user questions about the Single Vertical Balancing Machine market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is a single vertical balancing machine and why is it essential?

A single vertical balancing machine measures and corrects unbalance in disc-shaped or short-shaft components in a single plane. It is essential for enhancing product quality, extending equipment lifespan, reducing vibrations and noise, and ensuring safety in rotating machinery across industries like automotive, aerospace, and electric motors.

What industries are the primary users of single vertical balancing machines?

Primary users include the automotive industry for components like brake discs and flywheels, aerospace for turbine parts, electric motor manufacturing for rotors, and general machinery producers for impellers and fans. Any sector with high-speed rotating components demanding precision benefits from these machines.

How do technological advancements, like AI, impact this market?

Technological advancements, particularly AI, are transforming the market by enabling predictive maintenance, optimizing balancing algorithms for faster and more precise corrections, enhancing quality control, and facilitating seamless integration into Industry 4.0 smart factories for data-driven insights and automated operations.

What are the key factors driving the growth of the single vertical balancing machine market?

Key growth drivers include increasing global demand for precision manufacturing, the push towards industrial automation and Industry 4.0, stringent quality and safety regulations, and the rising production of complex and high-performance rotating components in sectors like electric vehicles and aerospace.

What are the main challenges faced by manufacturers and buyers in this market?

Manufacturers and buyers face challenges such as high initial capital investment costs, the technical complexity of operating and maintaining advanced machines, a shortage of skilled labor, and the need for continuous technological upgrades to remain competitive in a rapidly evolving industrial landscape.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager