Slider Zipper Pouch Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 443186 | Date : Feb, 2026 | Pages : 258 | Region : Global | Publisher : MRU

Slider Zipper Pouch Market Size

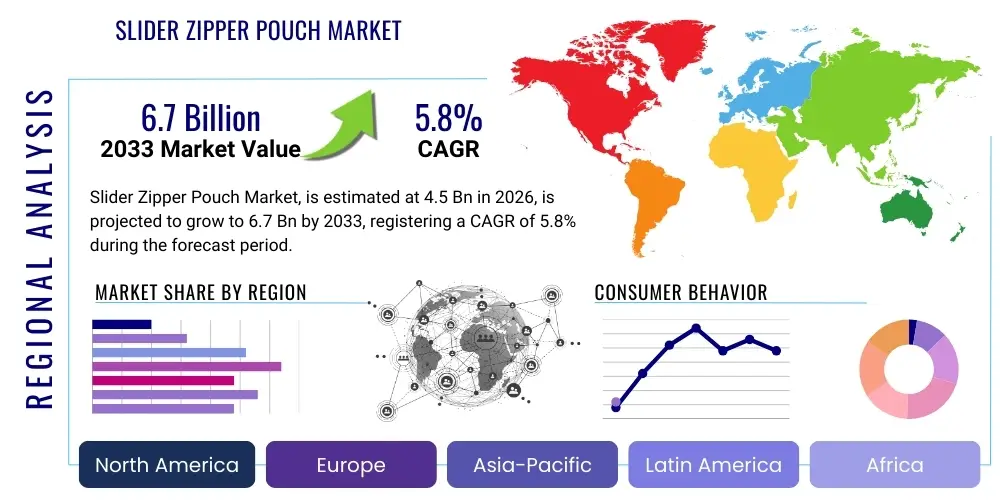

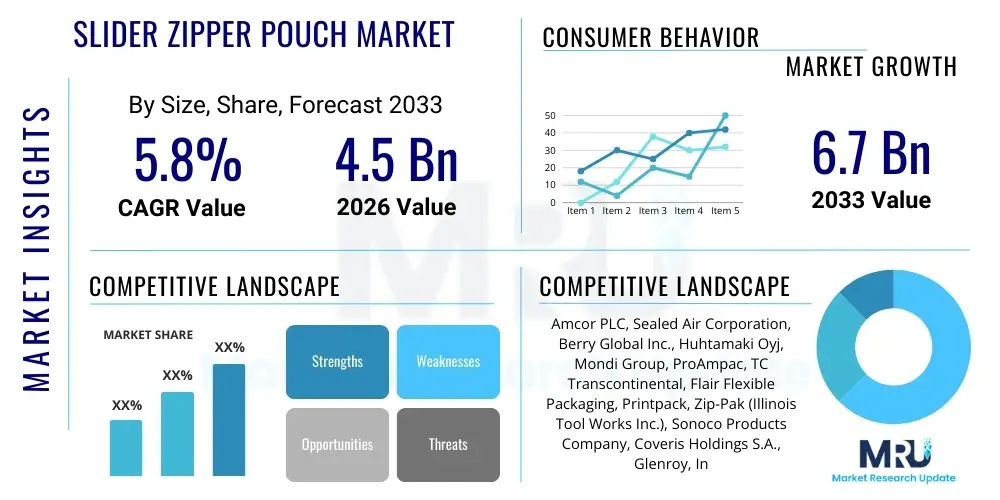

The Slider Zipper Pouch Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 4.5 Billion in 2026 and is projected to reach USD 6.7 Billion by the end of the forecast period in 2033.

Slider Zipper Pouch Market introduction

The Slider Zipper Pouch Market encompasses the manufacturing, distribution, and sale of flexible packaging solutions featuring a plastic slider mechanism integrated with a zipper profile. This design offers superior resealability and user convenience compared to traditional press-to-close zippers, enhancing product preservation and consumer experience across various industries. These pouches are fundamentally composed of multi-layer flexible films, predominantly polyethylene (PE), polypropylene (PP), or combinations involving barrier materials like aluminum foil or EVOH (Ethylene-Vinyl Alcohol), tailored to meet specific requirements for moisture, oxygen, and light protection. The sophistication of the slider mechanism allows for easier opening and robust closure, making them particularly favored in consumer packaged goods (CPG) sectors where frequent access to the contents is necessary, such as frozen foods, snacks, pet foods, and various household items. The global transition towards flexible packaging over rigid containers, driven by lower material costs, reduced transportation expenses, and enhanced shelf appeal, is fundamentally fueling the expansion of this specialized segment within the broader packaging industry.

Major applications of slider zipper pouches span food and beverage preservation, pharmaceuticals, personal care products, and industrial components. In the food sector, they are crucial for maintaining the freshness of perishable goods, including cheese, fresh produce, coffee, and dried fruits, providing consumers with extended shelf life and minimizing food waste. The key benefits driving adoption include superior barrier properties, which maintain product integrity; enhanced consumer convenience due to the ergonomic slider design, making them accessible to a wider demographic, including the elderly or those with dexterity issues; and sustainable appeal, as flexible pouches require significantly less material volume than equivalent rigid packaging, leading to a smaller carbon footprint throughout the supply chain. Furthermore, the large surface area of these pouches offers ample space for high-quality printing and branding, essential for competitive retail environments, enabling brand owners to differentiate their products effectively on crowded store shelves.

Driving factors for the market expansion include the exponential growth of the frozen food sector globally, which relies heavily on high-barrier resealable packaging; the increasing consumer preference for convenience foods and portion-controlled packaging; and significant technological advancements in film material science and high-speed pouch converting machinery. Manufacturers are continually innovating to integrate sustainable materials, such as bio-based or post-consumer recycled (PCR) content, into their slider zipper pouch designs to meet stringent environmental regulations and mounting consumer demand for eco-friendly solutions. This innovation cycle, coupled with robust population growth and increasing disposable incomes in emerging economies, particularly in the Asia Pacific region, solidifies the market trajectory toward sustained and substantial growth over the forecast period, emphasizing convenience and material efficiency as core tenets of future development.

Slider Zipper Pouch Market Executive Summary

The Slider Zipper Pouch Market is experiencing robust acceleration, primarily driven by the escalating demand for convenient, on-the-go packaging solutions and the global shift toward flexible formats that optimize material usage and reduce logistical costs. Current business trends indicate a strong focus on customization and barrier enhancement, with key players investing heavily in sophisticated multilayer films that protect oxygen and moisture-sensitive products, thereby expanding the applicability of these pouches beyond traditional dry goods into complex categories like specialized chemicals and high-end perishables. Furthermore, the imperative for sustainability is shaping corporate strategy, leading to a significant increase in the development of mono-material pouches, designed for easier recyclability, and the integration of certified PCR resins. Mergers, acquisitions, and strategic partnerships are becoming common as companies seek to consolidate market share, access proprietary barrier technologies, and expand their geographical footprint, particularly in high-growth regions like Southeast Asia and Latin America, where organized retail infrastructure is rapidly developing.

Regional trends highlight the dominance of North America and Europe in terms of technological adoption and market maturity, characterized by sophisticated consumer demands for premium and sustainable packaging options. These regions exhibit high per capita consumption of packaged foods and beverages, pushing innovation in specialized closure systems and advanced printing techniques. Conversely, the Asia Pacific (APAC) region is projected to register the highest growth rate, fueled by rapid urbanization, increasing middle-class populations, and the subsequent expansion of the food processing and retail sectors. Countries like China, India, and Japan are pivotal markets due to their large consumer bases and the increasing adoption of Western-style convenience packaging. The Middle East and Africa (MEA) and Latin America are emerging markets showing steady growth, primarily driven by foreign direct investment in food manufacturing and improvements in domestic supply chain logistics, adopting slider zipper pouches as a cost-effective alternative to rigid containers.

Segmentation trends reveal that the food application segment, particularly frozen food and snacks, maintains the largest market share due to the intrinsic value proposition of resealability for these categories. However, non-food applications, notably pet food and pharmaceuticals, are demonstrating accelerated growth as manufacturers in these sectors recognize the superior barrier protection and consumer appeal of slider zipper formats. By material, polyethylene (PE) remains the preferred choice due to its flexibility, cost-effectiveness, and compatibility with the slider mechanism, although specialized high-barrier films are gaining prominence. The increasing focus on child-resistant and tamper-evident features is driving innovation within the closure segment, meeting stringent regulatory requirements, particularly in cannabis and pharmaceutical packaging, thereby ensuring market diversity and sustained growth across multiple end-use industries.

AI Impact Analysis on Slider Zipper Pouch Market

User queries regarding the impact of Artificial Intelligence (AI) on the Slider Zipper Pouch Market predominantly revolve around three critical themes: optimizing manufacturing efficiency, enhancing quality control for complex barrier films, and driving personalization in packaging design and supply chain management. Consumers and industry stakeholders frequently ask how AI can reduce material waste during the highly precise pouch forming and filling processes, improve the reliability of the integrated slider mechanism, and predict demand fluctuations accurately to minimize inventory holding costs. Key concerns center on the initial investment required for AI implementation in legacy manufacturing facilities and ensuring data privacy across the interconnected supply chain. Expectations are high regarding AI's ability to create more sustainable packaging solutions by simulating material performance under varying conditions, thus optimizing film thickness and composition while guaranteeing functional integrity, ultimately lowering the total cost of ownership for brand owners.

AI's primary influence is manifesting in the advanced stages of production and quality assurance. Machine learning algorithms are being deployed to analyze real-time sensor data from converting machines, allowing for predictive maintenance that significantly reduces unplanned downtime and ensures consistent sealing temperatures and pressures essential for high-integrity barriers. In quality control, computer vision systems powered by AI are rapidly identifying microscopic flaws in film layers or misalignments in the zipper and slider application, far surpassing human inspection capabilities. This precision is critical for maintaining the guaranteed shelf life of sensitive products, such as infant formula or specialized nutritional supplements. By analyzing historical failure data and operational parameters, AI models optimize machine settings automatically, leading to higher throughput and reduced waste material, directly addressing sustainability mandates and improving operational profitability for pouch manufacturers.

Furthermore, AI is transforming upstream material procurement and downstream market responsiveness. Predictive analytics models use vast datasets—including consumer purchasing patterns, geographical sales trends, and external factors like weather—to forecast demand for specific pouch sizes, barrier levels, and aesthetic finishes with unprecedented accuracy. This enables manufacturers to optimize raw material inventories, particularly specialized barrier resins, and accelerate production cycles. In design, generative AI tools are assisting packaging engineers in creating novel pouch shapes and structural designs that maximize shelf appeal while adhering to material performance constraints and automated filling line requirements, thus integrating advanced analytics seamlessly into the creative and operational workflow of the flexible packaging industry.

- AI optimizes machine parameters for precise heat sealing and slider application, reducing production defects.

- Computer vision systems use AI to conduct high-speed, automated quality checks for film integrity and zipper alignment.

- Predictive maintenance schedules are generated by machine learning, minimizing costly unplanned downtime on converting lines.

- AI-driven demand forecasting improves inventory management of specialized barrier materials and finished pouches.

- Generative AI assists in designing sustainable, material-optimized pouch structures for improved recyclability.

- Automated defect detection reduces material waste, enhancing the environmental footprint of manufacturing processes.

DRO & Impact Forces Of Slider Zipper Pouch Market

The Slider Zipper Pouch Market is shaped by a confluence of powerful drivers, structural restraints, and emerging opportunities, which collectively determine its growth trajectory and competitive landscape. The primary driver is the pervasive consumer demand for convenience and resealability, particularly in fast-paced urban lifestyles where single-serving and portion-controlled packaging is highly valued. This is augmented by the robust expansion of the global food processing industry, especially in snacks, frozen fruits and vegetables, and ready-to-eat meals, where resealable barrier pouches are essential for preserving freshness and reducing food waste. Furthermore, the inherent cost and environmental benefits of flexible packaging over rigid alternatives—such as reduced material weight, lower shipping costs, and improved cube utilization—continue to motivate brand owners across diverse industries to transition their product lines into slider zipper formats. Technological advancements in material science, particularly the development of high-performance, recyclable films and robust slider systems, further solidify the market's positive momentum, enabling applications in previously inaccessible segments like high-pressure pasteurization (HPP) foods and sensitive medical devices, driving fundamental market expansion.

However, the market faces significant restraints, primarily centered around environmental pressures and the technical complexity of recycling multi-layer barrier films. Although mono-material solutions are emerging, the majority of high-barrier slider pouches utilize complex film structures (e.g., PET/Aluminum/PE) which are challenging and often economically unviable to recycle through existing infrastructure, leading to end-of-life concerns and negative public perception. Operational restraints include the relatively higher initial cost of specialized converting machinery required to precisely integrate the slider mechanism onto the pouch compared to basic stand-up pouches, which creates a barrier to entry for smaller manufacturers. Furthermore, ensuring the flawless functionality and leak-proof nature of the slider mechanism throughout the product lifecycle requires extremely tight tolerances during manufacturing; a failure in the closure system directly impacts product integrity and consumer trust, posing a continuous quality control challenge that necessitates substantial investment in advanced QA technologies.

Opportunities for expansion are abundant, particularly in integrating advanced features such as child resistance, anti-tamper systems, and smart packaging technologies like QR codes or NFC tags for enhanced consumer interaction and supply chain visibility. The pharmaceutical and healthcare sectors represent a burgeoning vertical, demanding precise barrier properties and reliable resealability for medical devices, diagnostic kits, and unit-dose medicines. Geographically, significant opportunities lie in penetrating untapped or rapidly industrializing economies in APAC and MEA, where the retail infrastructure is modernizing rapidly and the adoption of Western packaging standards is accelerating. Furthermore, the development and commercial scaling of certified compostable and truly recyclable high-barrier slider materials—addressing the market’s primary sustainability restraint—presents the single largest long-term growth opportunity, positioning manufacturers who pioneer these solutions for significant competitive advantage and long-term market dominance by aligning packaging with global circular economy goals, ultimately maximizing the positive impact forces and mitigating the restrictive ones.

- Drivers: Growing consumer preference for convenience and resealability; expansion of the frozen and snack food industries; cost and logistical advantages of flexible packaging; advancements in high-barrier film technologies.

- Restraints: Technical challenges and economic viability of recycling multi-layer barrier materials; higher initial capital investment for specialized slider application machinery; stringent quality requirements for closure functionality and leak prevention.

- Opportunity: Integration of smart packaging features (NFC, QR codes); penetration of high-value non-food sectors like pharmaceuticals and medical devices; development of fully recyclable or compostable mono-material slider pouches; rapid market expansion in emerging economies (APAC, MEA).

- Impact Forces: High (driven by convenience and sustainability mandates)

Segmentation Analysis

The Slider Zipper Pouch Market is comprehensively segmented based on material type, application, closure type, and regional distribution, allowing for granular analysis of demand patterns and strategic planning. Segmentation by material is critical, differentiating between standard polymers like Polyethylene (PE) and Polypropylene (PP), which dominate due to cost efficiency and flexibility, and advanced materials such as Ethylene-Vinyl Alcohol (EVOH) and Aluminum Foil, used to achieve superior oxygen and moisture barrier properties necessary for sensitive food products. The application segmentation delineates the end-use sectors, with Food & Beverage holding the largest share, followed by Pet Food, Pharmaceuticals, and Household Products, each requiring specific packaging attributes regarding durability, barrier protection, and size standardization. Understanding these segment dynamics is crucial for manufacturers to tailor product specifications—from film thickness to zipper strength—to meet the distinct functional and regulatory requirements of diverse customer verticals.

Further analysis focuses on closure type, which primarily differentiates between the standard press-to-close zipper systems and the more sophisticated, ergonomic slider zipper mechanism, which is the core focus of this market study. Within the slider category, variations exist, including child-resistant sliders mandated by certain regulatory bodies (e.g., cannabis packaging) and specialized tamper-evident features, adding complexity and value. Geographical segmentation provides insight into regional market maturity and growth potential, with developed economies driving innovation in sustainability and premiumization, while developing regions drive volume growth through expanding middle-class consumption and retail modernization. This multidimensional segmentation reveals that future growth is highly dependent on innovation within the material segment, specifically the successful commercialization of high-performance recyclable solutions that satisfy the increasing sustainability expectations of the dominant food and beverage application segment.

The interaction between these segments highlights key market trends: the rapid growth of premium pet food requires high-barrier slider pouches with large volume capacity; the increase in pharmaceutical and nutraceutical applications necessitates precise moisture barrier control and child-resistant closures; and the general food sector continually demands cost-optimized, high-throughput packaging solutions. Strategic success in the Slider Zipper Pouch Market hinges on the ability of packaging providers to offer flexible manufacturing platforms capable of switching efficiently between mono-material, standard barrier, and ultra-high barrier formats, while integrating the diverse range of closure and value-added features required by the diverse end-user base. This comprehensive segmentation framework aids in identifying niche markets, assessing competitive intensity within specific product categories, and forecasting regional shifts in demand for advanced flexible resealable solutions.

- By Material:

- Polyethylene (PE)

- Polypropylene (PP)

- BOPP (Biaxially Oriented Polypropylene)

- PET (Polyethylene Terephthalate)

- EVOH (Ethylene-Vinyl Alcohol)

- Aluminum Foil

- Others (Bio-plastics, PLA)

- By Application:

- Food & Beverage (Frozen Foods, Snacks, Dry Goods, Pet Food)

- Pharmaceutical & Nutraceuticals

- Household & Personal Care Products (Detergents, Soaps, Cosmetics)

- Industrial & Others (Agricultural chemicals, Components)

- By Closure Type:

- Standard Slider Zipper

- Child-Resistant Slider Zipper

- Tamper-Evident Slider Zipper

- By Pouch Type:

- Stand-up Pouch (SUP)

- Lay-Flat Pouch

- Gusseted Pouch

Value Chain Analysis For Slider Zipper Pouch Market

The Value Chain of the Slider Zipper Pouch Market begins with the upstream suppliers responsible for producing raw materials, including polymer resins (PE, PP, PET), specialized barrier materials (EVOH, Aluminum), and the components for the slider mechanism itself. This phase is highly centralized and subject to commodity price fluctuations and capacity constraints in the petrochemical industry, significantly influencing the final cost of the pouch. Following material production, the primary manufacturers utilize advanced film extrusion and lamination processes to create the multilayer barrier films, which are then supplied to pouch converters. The converter stage involves specialized machinery for forming the pouch structure, integrating the sophisticated slider zipper mechanism, and applying high-quality graphic printing. The performance and quality of the final product are highly dependent on the precision and technical expertise at the converting stage, especially regarding the integrity of the heat seals and the consistent functionality of the slider.

Downstream activities involve the distribution of finished pouches to diverse end-user industries, predominantly large-scale Food & Beverage producers, pharmaceutical companies, and CPG manufacturers. Distribution channels are varied, including direct sales from converters to major brand owners, especially for highly customized, large-volume contracts. Alternatively, indirect channels utilize packaging distributors and wholesalers who manage inventory and supply smaller to medium-sized end-users across multiple geographies. The choice between direct and indirect distribution often depends on the complexity of the order, the required lead time, and the geographical reach of the converter. The efficiency of the distribution network is crucial, as pouches are relatively voluminous when empty and require specialized logistics to minimize transportation damage and optimize storage before they reach the brand owner's filling lines. Effective management of the distribution channel ensures timely supply and maintains the competitive positioning of the converting entity within the market ecosystem.

The final element of the value chain involves the end-user utilizing the pouches on high-speed filling and sealing lines, followed by retail distribution and consumer usage. Key considerations at this stage include the pouch's compatibility with automated filling machinery, its shelf presence (stand-up capability), and its performance in the hands of the consumer (ease of opening, reliable resealability). The feedback loop from the end-user (CPG companies) and the consumer back to the converters drives innovation in material science and mechanical design, especially regarding sustainability features and ergonomic improvements. Thus, the value chain is characterized by high technical specialization in upstream processes and a strong emphasis on service, logistics, and customization in the downstream distribution and end-use phases, making collaborative relationships between converters and brand owners essential for successful market navigation and product development.

Slider Zipper Pouch Market Potential Customers

The primary customers for Slider Zipper Pouch products are large, multinational Consumer Packaged Goods (CPG) companies and mid-sized regional food and non-food manufacturers who prioritize product freshness, shelf appeal, and consumer convenience. Within the Food and Beverage sector, key buyers include major processors of frozen foods (e.g., vegetables, poultry, prepared meals), snack manufacturers (chips, nuts, pretzels), and producers of dry bulk goods (cereal, coffee, sugar substitutes), where the resealable feature offers immense value by preventing spoilage and maintaining crispness after initial opening. These customers require high volumes of customized pouches with specific barrier properties tailored to the shelf-life requirements of their contents, emphasizing reliable performance on high-speed vertical form-fill-seal (VFFS) and horizontal form-fill-seal (HFFS) packaging lines to ensure operational efficiency and minimal production halts.

Beyond the traditional food sector, significant growth in demand originates from specialized industries such as Pet Food manufacturing, particularly premium dry kibble and treats, where the large pouch format and robust resealability are critical for maintaining nutritional integrity and managing bulk quantities over time. The Pharmaceutical and Nutraceutical industries also constitute a high-value customer base, demanding pouches with superior moisture and oxygen barriers, often paired with specialized features like child-resistant sliders and tamper-evident seals to meet stringent regulatory mandates for safety and compliance, particularly for sensitive medicines, medical devices, and high-potency vitamins. These buyers often require detailed documentation and compliance certifications, making reliability and quality assurance paramount selection criteria over mere cost considerations.

Furthermore, household and personal care product manufacturers, including those producing laundry detergents, cleaning wipes, and powdered chemicals, are increasingly adopting slider zipper pouches as an environmentally superior and logistically efficient alternative to rigid plastic bottles or cartons. These customers value the durability of the pouches, their space-saving nature in storage and transport, and the ability to utilize high-definition graphics for powerful in-store branding. The common thread among all potential customers is the need for a packaging solution that reliably extends product life, enhances the end-user experience, and aligns with corporate sustainability goals, positioning the slider zipper pouch as a premium, functional, and forward-looking choice across diverse retail categories.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 4.5 Billion |

| Market Forecast in 2033 | USD 6.7 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Amcor PLC, Sealed Air Corporation, Berry Global Inc., Huhtamaki Oyj, Mondi Group, ProAmpac, TC Transcontinental, Flair Flexible Packaging, Printpack, Zip-Pak (Illinois Tool Works Inc.), Sonoco Products Company, Coveris Holdings S.A., Glenroy, Inc., Interflex Group, C-P Flexible Packaging, Scholle IPN, Constantia Flexibles Group GmbH, Charter NEX Films, Inc., Wipf AG, Smurfit Kappa Group. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Slider Zipper Pouch Market Key Technology Landscape

The technological landscape of the Slider Zipper Pouch Market is characterized by continuous advancements in three core areas: advanced material science for sustainable barrier films, high-precision converting and sealing machinery, and the integration of digital and smart packaging features. In material science, the industry is transitioning away from non-recyclable multi-material laminates towards mono-material structures (e.g., all-PE or all-PP) that incorporate high-performance coatings or nano-layering technologies (such as Plasma Enhanced Chemical Vapor Deposition - PECVD) to achieve necessary barrier properties while maintaining compatibility with standard mechanical recycling streams. This focus is directly driven by extended producer responsibility (EPR) schemes and regulatory pressure in developed markets, necessitating packaging that is 'designed for recycling' without compromising product shelf life. The innovation also extends to bio-based and compostable polymers, though these are currently limited to lower-barrier applications due to cost and performance constraints, representing a niche but rapidly evolving area.

Machinery technology is seeing significant evolution, specifically in optimizing the speed and accuracy of integrating the slider mechanism and ensuring the hermetic seal of the pouch structure. Modern converting lines utilize sophisticated ultrasonic welding and highly sensitive temperature control systems to attach the slider profile precisely without damaging the thin film structure, especially crucial for heat-sensitive sustainable films. Servo motor-driven systems offer enhanced precision and rapid changeovers between different pouch sizes and film types, dramatically improving operational flexibility and reducing material waste during setup. Furthermore, inline quality assurance systems, often integrating AI-powered vision technology, scan for seal defects, misalignments, or foreign bodies at extremely high speeds, guaranteeing product safety and functional integrity, which are paramount for the slider system's reliability and consumer satisfaction.

Finally, the rise of smart packaging technology is beginning to reshape the functionality of the slider pouch beyond mere containment and resealability. This includes integrating printed electronics, NFC (Near Field Communication) tags, or enhanced QR codes directly onto the pouch surface during printing. These technologies facilitate enhanced supply chain traceability, verify product authenticity (anti-counterfeiting), and enable interactive consumer engagement post-purchase, such as providing usage instructions or recycling information via a smartphone scan. While these features add to the complexity and cost, they provide significant value-added differentiation, allowing brand owners to leverage packaging as a direct communication tool and a key component of their circular economy strategy, thereby future-proofing the slider zipper pouch format against emerging competition and enhancing its overall technological relevance in a digitally connected marketplace.

Regional Highlights

- North America: Characterized by high market maturity, technological leadership, and stringent consumer demands for premium and sustainable packaging. The U.S. and Canada are major consumers of frozen foods, snacks, and pet food packaged in slider zipper pouches. Innovation here is focused on advanced recycling technologies, mono-material structures, and the adoption of child-resistant closures, particularly in the cannabis and pharmaceutical sectors. Regulatory adherence, especially concerning food contact safety and material composition, drives continuous investment in R&D.

- Europe: This region is a global leader in sustainability mandates, with the European Union (EU) driving initiatives like the Circular Economy Action Plan, heavily favoring recyclable and compostable packaging solutions. Growth is robust, driven by the shift from rigid plastic tubs to flexible pouches for household items and dairy products. Germany, the UK, and France are key markets, focusing intensely on achieving high material performance through mono-material designs that support the rigorous resealability demanded by the slider zipper format, balancing functionality with environmental responsibility.

- Asia Pacific (APAC): Expected to exhibit the highest CAGR due to rapid economic development, urbanization, and the expanding middle class, particularly in China, India, and Southeast Asian nations. The region is seeing massive growth in organized retail and food service industries, leading to increased demand for convenient, hygienically sealed, and cost-effective flexible packaging. While cost remains a significant factor, environmental awareness is growing, pushing local manufacturers to invest in modern converting technologies and basic barrier solutions to serve the massive domestic consumer base effectively.

- Latin America (LATAM): Showing steady, moderate growth, primarily centered in large economies like Brazil and Mexico. The market is driven by increasing consumption of processed foods and the modernization of distribution chains. Local manufacturers are expanding capacity, often through joint ventures with global players, to meet domestic demand. The market generally prioritizes value and functional performance, with sustainability considerations gradually gaining traction but trailing North America and Europe.

- Middle East and Africa (MEA): An emerging market with fragmented demand, but demonstrating high growth potential, especially in the Gulf Cooperation Council (GCC) countries, due to infrastructure investment and increasing reliance on imported and packaged foods. The adoption of slider zipper pouches is accelerating in premium segments, particularly pet food and specialty dry goods, driven by rising disposable incomes and changing dietary habits, though overall market size remains smaller compared to established regions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Slider Zipper Pouch Market.- Amcor PLC

- Sealed Air Corporation

- Berry Global Inc.

- Huhtamaki Oyj

- Mondi Group

- ProAmpac

- TC Transcontinental

- Flair Flexible Packaging

- Printpack

- Zip-Pak (Illinois Tool Works Inc.)

- Sonoco Products Company

- Coveris Holdings S.A.

- Glenroy, Inc.

- Interflex Group

- C-P Flexible Packaging

- Scholle IPN

- Constantia Flexibles Group GmbH

- Charter NEX Films, Inc.

- Wipf AG

- Smurfit Kappa Group

Frequently Asked Questions

Analyze common user questions about the Slider Zipper Pouch market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary driving force behind the growth of the Slider Zipper Pouch Market?

The primary driver is the accelerating global demand for consumer convenience, particularly the need for reliable resealability to maintain product freshness and minimize food waste, coupled with the logistical and cost advantages of flexible packaging over rigid alternatives.

How does the Slider Zipper Pouch Market address critical sustainability concerns?

The market is addressing sustainability by aggressively developing mono-material film structures (e.g., all-PE) that are designed for standard recycling streams, replacing traditional multi-layer, non-recyclable laminates, and integrating increasing amounts of certified Post-Consumer Recycled (PCR) content.

Which application segment holds the largest market share for slider zipper pouches?

The Food & Beverage application segment, especially the frozen food, snack food, and dry goods categories, maintains the largest market share due to the essential role of resealability in extending the shelf life and enhancing the consumption experience for these perishable or frequently accessed products.

What technological advancements are impacting the manufacturing of these pouches?

Key technological advancements include the use of AI-powered vision systems for quality control of seals and slider alignment, high-precision servo motor-driven converting machinery for faster production, and advanced coating technologies (like PECVD) to create high-barrier properties in simplified, recyclable mono-films.

Which geographical region is expected to register the highest growth rate during the forecast period?

The Asia Pacific (APAC) region is projected to register the highest growth rate, fueled by rapid economic expansion, increasing urbanization, the growth of the middle class, and the consequential modernization and standardization of the food processing and retail industries.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager