Sliding Vane Air Motor Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 443406 | Date : Feb, 2026 | Pages : 258 | Region : Global | Publisher : MRU

Sliding Vane Air Motor Market Size

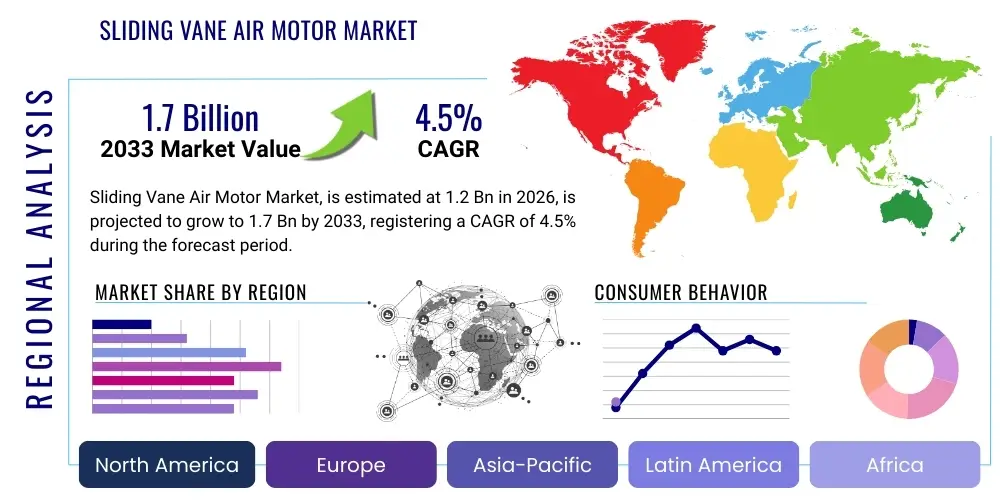

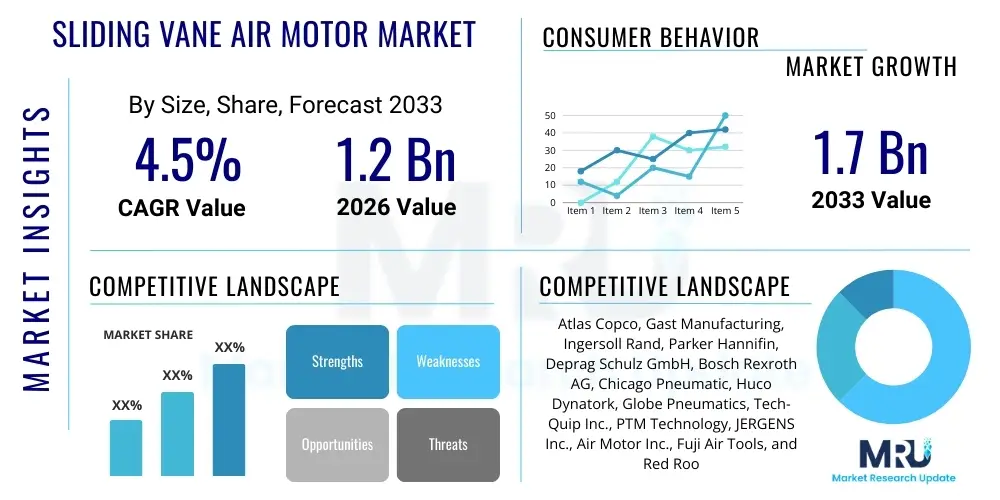

The Sliding Vane Air Motor Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 4.5% between 2026 and 2033. The market is estimated at $1.2 Billion in 2026 and is projected to reach $1.7 Billion by the end of the forecast period in 2033. This consistent expansion is fundamentally driven by the increasing need for reliable, explosion-proof, and compact power solutions across various heavy industries, coupled with stringent safety regulations that favor pneumatic drive systems over traditional electric motors in hazardous locations (HazLoc).

The valuation reflects sustained investments in industrial automation, particularly within the chemical processing, mining, and food and beverage sectors, where the inherent safety features of air motors provide a critical operational advantage. Although electric motors dominate general industrial applications, sliding vane air motors maintain a strong, irreplaceable niche in environments characterized by high dust levels, volatile chemicals, or extreme temperature fluctuations, guaranteeing continued market relevance and steady revenue growth throughout the forecast period.

Sliding Vane Air Motor Market introduction

The Sliding Vane Air Motor Market encompasses specialized rotary pneumatic actuators that convert compressed air energy into mechanical work. These devices operate on a simple principle: compressed air is introduced into a housing where it pushes against vanes sliding radially within a rotor, generating rotational motion. Known for their high power-to-weight ratio, instantaneous starting torque, and stall-proof capabilities, sliding vane air motors are indispensable components in industrial machinery requiring robust, variable-speed operation in challenging environments. Unlike electric motors, they are inherently explosion-proof and cannot overheat, making them the preferred choice for processes involving flammable gases or combustible dust.

Major applications for these motors span material handling (hoists, winches), mixing equipment in chemical and pharmaceutical plants, driving pumps, and various tools used in mining and construction. The core benefits driving their adoption include operational safety in hazardous atmospheres (ATEX/IECEx compliance), durability, and ease of maintenance due to their simpler mechanical structure compared to complex electrical systems. Furthermore, their ability to operate reliably at varying speeds and stall without damage provides significant operational flexibility in automated and semi-automated production lines.

Key factors propelling market growth include the rising global emphasis on workplace safety standards, particularly in emerging economies undergoing rapid industrialization, and continuous technological advancements aimed at improving energy efficiency and reducing noise levels. The need for precise torque control in complex assembly processes, coupled with the miniaturization trend in robotics and automation, further solidifies the market position of sliding vane air motors as a crucial power source where safety cannot be compromised. The intrinsic characteristics of these motors ensure their sustained utilization despite competition from alternative drive technologies.

Sliding Vane Air Motor Market Executive Summary

The Sliding Vane Air Motor Market is experiencing stable growth, marked by distinct business trends focused on optimizing motor efficiency and expanding application scope into precision assembly and medical devices. Key market players are concentrating on developing lightweight motors using advanced composite materials for vanes and housing, which not only improves performance but also adheres to sustainability goals by reducing compressed air consumption. Furthermore, the trend toward customization is prominent, allowing manufacturers to tailor torque, speed, and material specifications precisely to end-user needs in highly specialized industrial niches, thereby commanding premium pricing and strengthening customer loyalty.

Regionally, the Asia Pacific (APAC) stands out as the primary growth engine, fueled by massive infrastructure projects, burgeoning manufacturing sectors in China and India, and increasing adherence to international safety standards in oil and gas and chemical processing industries. While North America and Europe remain mature markets, demand here is steady, primarily driven by replacement cycles, modernization of existing facilities, and compliance with increasingly strict environmental and safety regulations (e.g., ATEX directives). The demand across all regions is consolidated by the non-sparking nature of air motors, which provides an unparalleled safety advantage.

Segment trends reveal that the high-power rating segment (above 5 kW) is gaining traction, largely due to the increased use of heavy-duty mixing and lifting equipment in mining and maritime industries. Concurrently, the low-speed, high-torque segment is essential for demanding material handling applications. The food and beverage segment shows significant adoption, driven by the need for motors that can withstand frequent wash-downs and aggressive sterilization processes, favoring stainless steel variants of sliding vane technology. These combined trends underscore a dynamic market that values both robust performance and adherence to sector-specific operational criteria.

AI Impact Analysis on Sliding Vane Air Motor Market

User inquiries regarding the impact of Artificial Intelligence (AI) on the Sliding Vane Air Motor Market primarily center on how AI can mitigate the traditional drawbacks of pneumatic systems—namely, energy inefficiency and predictive maintenance challenges. Users seek clarity on whether AI-driven compressor optimization and intelligent flow control systems can close the energy efficiency gap between air motors and electric motors. Key concerns also revolve around utilizing Machine Learning (ML) algorithms to predict vane wear and identify optimal replacement intervals, thus reducing unscheduled downtime and improving overall equipment effectiveness (OEE). The consensus expectation is that AI will transform the maintenance paradigm from reactive to highly predictive, extending the lifespan and reliability of these critical components within complex industrial ecosystems.

The application of AI is primarily indirect but profoundly influential, focusing on the peripheral systems that govern air motor performance and operational cost. For instance, sophisticated AI platforms are now used to analyze real-time air flow rates, pressure drops, and temperature signatures to dynamically adjust compressor output, ensuring the air motor receives only the necessary energy, significantly cutting down on wasted compressed air. Furthermore, the integration of smart sensors with ML models facilitates continuous condition monitoring, allowing operators to understand the exact wear progression of internal vanes and bearings, transforming a historically high-maintenance component into a highly manageable asset.

This integration of AI and IoT (Internet of Things) leads to the development of 'smart pneumatic systems' that are self-diagnosing and self-optimizing. While the core mechanical principle of the sliding vane air motor remains unchanged, its integration into the Industry 4.0 ecosystem elevates its competitive standing, especially in critical applications. AI-powered failure prediction enhances the value proposition of air motors by reducing their total cost of ownership (TCO) through optimized energy usage and minimizing operational interruptions, thereby addressing key historical restraints of the technology.

- AI-driven Predictive Maintenance: Optimizing maintenance schedules by analyzing vibration and thermal signatures to anticipate vane and bearing failures.

- Compressor Energy Optimization: Utilizing machine learning algorithms to reduce compressed air generation waste, thereby lowering the operating cost of pneumatic systems.

- Supply Chain Resilience: Employing AI to forecast component demand, ensuring timely availability of replacement parts (e.g., vanes and rotors).

- Enhanced Manufacturing Quality: Using computer vision and AI in the manufacturing process for precise quality control of critical motor components, ensuring tighter tolerances.

- System Integration Optimization: Developing AI models to select the most energy-efficient air motor for specific duty cycles, minimizing power usage.

DRO & Impact Forces Of Sliding Vane Air Motor Market

The dynamics of the Sliding Vane Air Motor Market are influenced by a complex interplay of inherent product strengths, external economic pressures, and stringent regulatory demands, collectively summarized by the Drivers, Restraints, and Opportunities (DRO) framework. Key drivers include the mandatory requirements for non-electrical equipment in hazardous environments (HazLoc), particularly in the chemical, mining, and oil and gas sectors, where the intrinsic safety of air motors is unmatched by electric counterparts. Opportunities arise from technological advancements focusing on composite materials for enhanced motor efficiency and durability, allowing manufacturers to penetrate niche markets requiring lightweight and specialized equipment. These positive forces are partially tempered by significant restraints, primarily the relatively low energy efficiency of compressed air compared to direct electric drive systems, and the intensive maintenance requirements associated with vane wear and air quality management.

Impact forces acting on this market are primarily technological and regulatory. The rapid evolution of Industry 4.0 necessitates that air motor systems integrate seamlessly with digital control platforms, pushing manufacturers toward incorporating advanced sensors and connectivity solutions. Simultaneously, global regulatory bodies continue to tighten standards for safety, noise emissions, and energy consumption. For example, increasingly strict European ATEX and North American NEC standards solidify the necessity of air motors in volatile atmospheres, yet simultaneous global pressures for carbon footprint reduction compel manufacturers to invest heavily in efficiency improvements to remain competitive against highly efficient electric motors.

Furthermore, economic volatility, particularly fluctuations in raw material prices (metals and polymers) and energy costs (which directly affect the cost of compressed air generation), significantly impact the market structure. The inherent simplicity and robustness of the sliding vane mechanism offer resilience against minor economic downturns, as capital expenditure on these motors is often necessary for safety compliance rather than being purely discretionary. Strategic market positioning, focusing on the motor’s core value proposition—unparalleled safety and operational reliability in extreme conditions—is critical for sustained growth against the backdrop of fluctuating macroeconomic conditions and competing drive technologies.

Segmentation Analysis

The Sliding Vane Air Motor Market is intricately segmented based on core operational characteristics, power delivery capabilities, material composition, and the specific application environments they serve. Analyzing these segments provides a clear delineation of demand patterns and strategic areas for product development. Segmentation by power output, ranging from fractional horsepower (under 0.5 kW) utilized in small tools and precision robotics to heavy-duty industrial motors (above 5 kW) used for winches and heavy mixers, is crucial for understanding target end-user needs. Furthermore, the market is differentiated by material type, specifically aluminum, cast iron, and increasingly, specialized stainless steel or composite plastic housings, tailored to resist corrosion or comply with strict hygiene standards, such as those in the food and pharmaceutical industries.

End-use industry segmentation provides the most critical insight into market drivers, highlighting the chemical and petrochemical sectors as dominant consumers due to inherent explosion risks, followed closely by the mining and construction industries where robust, high-torque performance is non-negotiable. Geographic segmentation reveals diverging maturity levels and growth rates, with mature markets focusing on replacement and customization, while developing regions prioritize initial installation and standardization. This layered approach to segmentation allows market participants to tailor their marketing and distribution strategies effectively, focusing resources on the most lucrative and rapidly evolving demand clusters globally.

- By Power Output:

- Below 0.5 kW (Fractional HP)

- 0.5 kW to 2 kW (Low Power)

- 2 kW to 5 kW (Medium Power)

- Above 5 kW (High Power)

- By Operating Speed:

- Low Speed (Under 500 RPM, High Torque)

- Medium Speed (500 to 5,000 RPM)

- High Speed (Above 5,000 RPM)

- By End-Use Industry:

- Oil & Gas and Petrochemical

- Mining and Construction

- Chemical and Pharmaceutical

- Food and Beverage

- General Industrial Automation

- Aerospace and Defense

- By Motor Type/Configuration:

- Reversible

- Non-Reversible

Value Chain Analysis For Sliding Vane Air Motor Market

The value chain for the Sliding Vane Air Motor Market begins with robust upstream analysis focusing on the procurement of critical raw materials, primarily high-grade steels for shafts and rotors, specialized polymers or composite materials for sliding vanes (which determine efficiency and lifespan), and corrosion-resistant metals like aluminum or stainless steel for the motor housing. Strategic sourcing of these materials, particularly those offering high wear resistance and low friction coefficient, is essential for maintaining product quality and managing production costs. Strong, reliable supplier relationships for pneumatic components and specialized seals are paramount, as the quality of these upstream inputs directly dictates the motor's operational lifespan and compliance with safety standards such as ATEX.

The midstream phase involves complex manufacturing processes, including precision machining, specialized heat treatments, and stringent assembly procedures to achieve the necessary tight tolerances for efficient operation and leakage prevention. Manufacturers must invest significantly in automated assembly lines and comprehensive quality control testing to ensure motors meet specified torque and speed characteristics under variable pressure conditions. This stage is highly proprietary, with key manufacturers often possessing unique patented designs for vane geometry, air flow paths, and sealing mechanisms that provide a competitive edge in efficiency and performance reliability, representing a high value-add point in the chain.

Downstream analysis covers distribution channels and post-sales services. The distribution of air motors is typically bifurcated into direct sales to large OEM clients (e.g., equipment manufacturers in mining or petrochemicals) and indirect sales through a network of specialized industrial distributors, MRO (Maintenance, Repair, and Operations) providers, and system integrators. The indirect channel relies heavily on the technical expertise of distributors to provide localized technical support, custom installation, and rapid supply of replacement parts (like vane kits). Effective service and maintenance contracts form a crucial component of the downstream revenue stream, especially given the operational criticality of these motors in high-risk environments.

Sliding Vane Air Motor Market Potential Customers

Potential customers for the Sliding Vane Air Motor Market are overwhelmingly concentrated in industries characterized by highly volatile, explosive, or corrosive operational environments where standard electric motors pose unacceptable safety risks. These end-users, frequently referred to as buyers of intrinsically safe equipment, include chemical processing plants, which utilize the motors for operating mixers, pumps, and agitators handling flammable solvents; petroleum refineries and offshore drilling platforms, where air motors drive crucial winches and valves; and mining operations (coal, gold, etc.) that rely on pneumatic systems for material conveyance and drilling in dust-laden or methane-rich atmospheres.

Beyond the high-hazard industries, a significant customer base exists in sectors requiring extreme durability, variable speed control, and hygiene. The food and beverage industry, particularly dairies and breweries, utilizes stainless steel air motors for blending and packaging operations due to their resistance to aggressive cleaning agents and sterilization cycles. Similarly, the pharmaceutical industry relies on these motors for precision mixing and conveying systems within cleanroom environments where minimizing sparking risks is critical to process integrity and regulatory compliance. These buyers prioritize motors with specific material certifications and wash-down capabilities.

Furthermore, general manufacturing and assembly lines constitute a consistent buyer segment, especially for material handling applications such as hoists, conveyor drives, and specialized automation equipment where immediate stop/start capabilities and stall resistance are beneficial. System integrators and original equipment manufacturers (OEMs) who build machinery for the aforementioned end-user industries represent a crucial secondary customer group, purchasing motors in bulk for integration into larger industrial systems, seeking customized specifications regarding flange mountings, shaft configurations, and specific torque profiles to meet complex machine design requirements.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $1.2 Billion |

| Market Forecast in 2033 | $1.7 Billion |

| Growth Rate | 4.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Atlas Copco, Gast Manufacturing, Ingersoll Rand, Parker Hannifin, Deprag Schulz GmbH, Bosch Rexroth AG, Chicago Pneumatic, Huco Dynatork, Globe Pneumatics, Tech-Quip Inc., PTM Technology, JERGENS Inc., Air Motor Inc., Fuji Air Tools, and Red Rooster Industrial. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Sliding Vane Air Motor Market Key Technology Landscape

The technology landscape for sliding vane air motors is primarily focused on incremental innovations aimed at enhancing efficiency, longevity, and operational characteristics, rather than fundamental changes to the core pneumatic principle. A critical area of development involves advanced materials science, specifically the utilization of high-performance composite polymers and specialized carbon-based materials for the construction of sliding vanes. These modern vanes exhibit superior self-lubricating properties, reducing friction, minimizing air leakage, and dramatically extending the motor's operational lifespan while simultaneously allowing for oil-less operation in sensitive applications like food processing or medical device manufacturing. This move away from traditional metal or plastic vanes addresses the historical drawback of frequent replacement and high maintenance costs.

Another significant technological advancement centers on improving air flow dynamics and motor sealing to maximize energy utilization. Manufacturers are employing Computational Fluid Dynamics (CFD) analysis during the design phase to optimize the internal porting and vane geometry, ensuring more efficient expansion of compressed air and reduced turbulence. Coupled with precision machining and improved sealing technologies (e.g., advanced O-rings and specialized shaft seals), these optimizations contribute directly to a measurable increase in the motor's horsepower-per-cubic-foot-of-air-consumed ratio, making pneumatic systems more economically viable compared to electric alternatives for certain duty cycles. Noise reduction technology, often involving specialized mufflers and housing dampening materials, is also gaining prominence, driven by increasing workplace safety and noise pollution regulations.

Furthermore, the integration of smart technology is redefining the peripheral landscape. Although the motor itself remains mechanical, the adoption of IoT-enabled sensors (pressure, temperature, and vibration) is becoming standard practice. These sensors facilitate real-time performance monitoring and integrate the air motor into broader industrial control systems. This connectivity enables advanced diagnostics, facilitates remote monitoring, and, when combined with AI analysis, supports highly precise predictive maintenance programs. This technological evolution ensures that the sliding vane air motor remains a relevant, high-reliability solution in the rapidly digitizing industrial environment, shifting its value proposition beyond mere safety into optimized operational effectiveness.

Regional Highlights

Geographically, the Sliding Vane Air Motor Market exhibits diverse growth trajectories and maturity levels across major global regions, reflecting variances in industrial safety regulations, energy costs, and the pace of industrialization.

- North America: This region represents a mature and highly stable market, characterized by stringent safety regulations (OSHA, NEC standards) which mandate the use of intrinsically safe equipment in HazLoc areas, especially in the US oil and gas, chemical processing, and aerospace industries. Demand is primarily driven by replacement cycles, facility upgrades, and a high concentration of sophisticated manufacturing requiring precision pneumatic tools. The market favors high-quality, durable motors, and customization options are highly sought after by established industrial clients.

- Europe: Europe is defined by equally strict and internationally influential regulations, particularly the ATEX directive, making it a critical hub for pneumatic technology adoption in hazardous environments. The demand here is sophisticated, with a strong emphasis on energy efficiency, noise reduction (driven by occupational health regulations), and high standards for material quality (e.g., stainless steel for wash-down applications in pharma and food industries). Western European countries lead in technological adoption and specialized applications.

- Asia Pacific (APAC): APAC is projected to be the fastest-growing market globally, driven by massive investments in infrastructure development, rapid expansion of the manufacturing base (especially in China, India, and Southeast Asia), and increasing awareness and enforcement of industrial safety standards. While price sensitivity exists, the sheer scale of new industrial projects in sectors like mining, automotive, and chemicals ensures robust demand for cost-effective and reliable air motor solutions. This region offers the highest potential for new market entry and volume growth.

- Latin America (LATAM): This region shows steady growth, primarily concentrated in resource-extraction industries (mining in Chile and Peru, oil and gas in Brazil and Mexico). Market expansion is closely tied to commodity price volatility and investments in industrial modernization. Buyers often seek proven, robust, and low-maintenance solutions capable of withstanding harsh, remote operational conditions.

- Middle East and Africa (MEA): Growth in MEA is dominated by the massive oil and gas and petrochemical sectors, particularly in the GCC countries. The high reliance on explosion-proof equipment in drilling, refining, and transportation drives significant, high-value demand for high-power air motors. Market growth is sensitive to global oil prices and regional geopolitical stability, but the fundamental safety requirements ensure a continuous baseline demand.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Sliding Vane Air Motor Market.- Atlas Copco

- Gast Manufacturing

- Ingersoll Rand

- Parker Hannifin

- Deprag Schulz GmbH

- Bosch Rexroth AG

- Chicago Pneumatic

- Huco Dynatork

- Globe Pneumatics

- Tech-Quip Inc.

- PTM Technology

- JERGENS Inc.

- Air Motor Inc.

- Fuji Air Tools

- Red Rooster Industrial

- Aro (Ingersoll Rand Subsidiary)

- SATA GmbH & Co. KG

- Desoutter Tools

- Zoro Tools

- Jergens Inc.

Frequently Asked Questions

Analyze common user questions about the Sliding Vane Air Motor market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary advantage of a sliding vane air motor over an electric motor in industrial settings?

The primary advantage is inherent safety; sliding vane air motors are intrinsically explosion-proof (non-sparking) and cannot overheat, making them the mandatory choice for operating equipment in hazardous atmospheres (HazLoc) containing flammable gases, dust, or volatile chemicals, thereby ensuring regulatory compliance and operational security.

How does the energy efficiency of sliding vane air motors compare to electric motors?

Sliding vane air motors generally exhibit lower energy efficiency compared to modern electric motors, largely due to energy losses in the compressed air generation and delivery system. However, recent technological advancements focusing on optimized vane materials and air flow dynamics are gradually improving the power output per unit of compressed air consumed, enhancing overall system viability.

Which industrial sectors are the largest consumers of sliding vane air motors?

The largest consumer sectors are those with critical safety requirements, including Oil & Gas (drilling, pumping), Chemical and Petrochemical processing (mixing, agitation), and Mining (material handling, drilling). The Food & Beverage and Pharmaceutical industries also form a significant segment, demanding corrosion-resistant, sterile-compatible air motors.

What are the key maintenance challenges associated with sliding vane technology?

The main maintenance challenges involve the scheduled replacement of the sliding vanes, which are subject to wear, and ensuring high-quality, dry, and filtered compressed air to prevent internal corrosion and premature failure. Implementing AI-driven predictive maintenance systems is becoming crucial to manage these challenges effectively and minimize unscheduled downtime.

What is the projected Compound Annual Growth Rate (CAGR) for the Sliding Vane Air Motor Market?

The Sliding Vane Air Motor Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 4.5% between 2026 and 2033, driven by increasing industrial safety mandates and the rapid industrialization occurring within the Asia Pacific region.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager