Small Hull Cleaning Robot Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440988 | Date : Feb, 2026 | Pages : 243 | Region : Global | Publisher : MRU

Small Hull Cleaning Robot Market Size

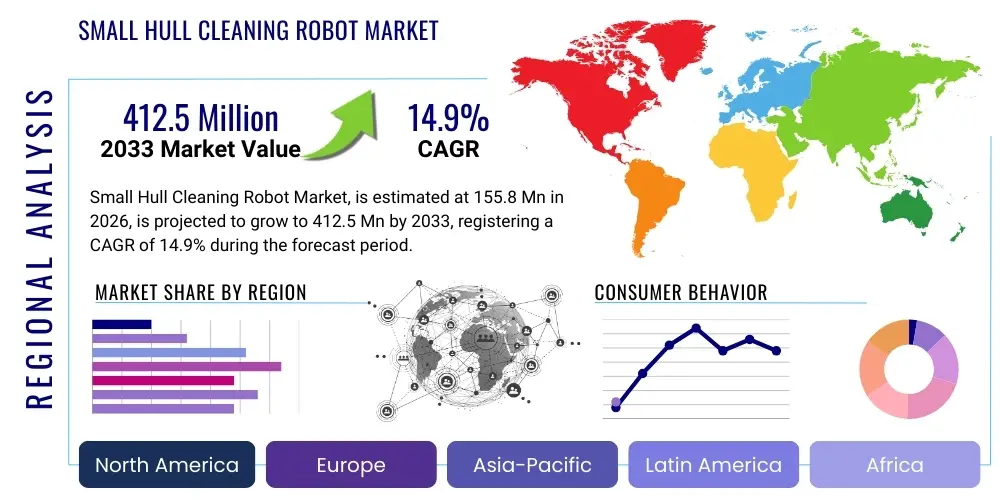

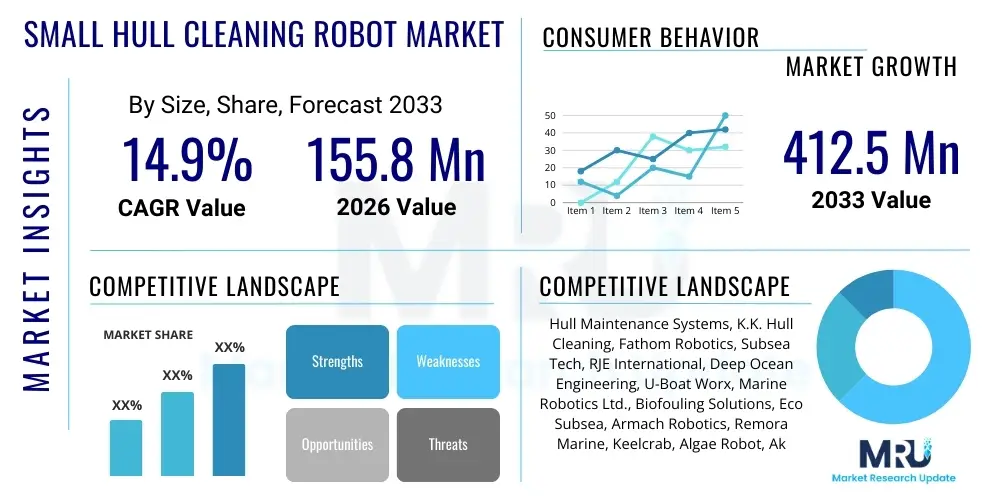

The Small Hull Cleaning Robot Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 14.9% between 2026 and 2033. The market is estimated at $155.8 Million USD in 2026 and is projected to reach $412.5 Million USD by the end of the forecast period in 2033.

Small Hull Cleaning Robot Market introduction

The Small Hull Cleaning Robot Market is defined by the development, manufacturing, and deployment of compact, specialized robotic systems designed for the submerged maintenance of vessels typically under 50 meters in length, encompassing recreational yachts, light commercial vessels, fishing boats, and ancillary maritime infrastructure. These highly engineered systems represent a paradigm shift in marine maintenance, moving away from resource-intensive manual diving or disruptive dry-docking procedures towards continuous, in-water grooming that minimizes operational downtime. The core objective of these robots is the proactive removal of marine biofouling—the accumulation of microorganisms, plants, and small animals on submerged surfaces. This biofouling significantly compromises the vessel's hydrodynamic performance, necessitating up to a 40% increase in power to maintain speed in severely fouled conditions. Consequently, the adoption of robotic solutions is a direct response to global pressures concerning fuel efficiency, operational expenditure reduction, and compliance with increasingly rigorous environmental standards aimed at mitigating the transfer of Invasive Aquatic Species (IAS).

Product sophistication within this market is characterized by a fusion of advanced engineering disciplines. Modern small hull cleaning robots integrate high-precision magnetic or suction-based adhesion systems to ensure stable movement across complex, curved hull geometries, regardless of the water depth or current. The cleaning modules themselves utilize a variety of mechanisms—ranging from soft polymer brushes optimized for delicate antifouling paints to controlled low-pressure water jets—all governed by sophisticated onboard processors. Furthermore, these platforms serve a dual function, often incorporating high-resolution cameras and advanced Non-Destructive Testing (NDT) sensors, such as ultrasonic thickness gauges, transforming the cleaning process into a comprehensive hull condition monitoring routine. Key features driving product description include ease of deployment by a single operator, minimal training requirements, and connectivity to cloud platforms for data logging and remote diagnostics. Major applications span the high-end recreational sector, where aesthetic and performance maintenance is crucial, and the small commercial sector, where guaranteed uptime and predictable fuel consumption are absolute necessities for profitability in competitive logistics and transport operations.

The principal benefits derived from the widespread adoption of these autonomous platforms include dramatic reductions in fuel consumption, extended life cycle of expensive antifouling coatings, and enhanced safety by eliminating the need for human divers in potentially hazardous underwater environments. The primary driving factors propelling the market forward include the sustained volatility in global marine fuel prices, making even marginal efficiency gains economically compelling, and the growing legislative pressure from bodies like the International Maritime Organization (IMO). These factors compel vessel owners to seek cost-effective, environmentally compliant, and scalable solutions for biofouling management. Furthermore, continuous technological breakthroughs in battery energy density, sensor miniaturization, and AI-driven path planning capabilities are overcoming earlier limitations related to mission endurance and operational precision. The convergence of these economic, regulatory, and technological drivers positions the small hull cleaning robot market for sustained, exponential growth throughout the forecast period, transitioning hull maintenance from an intermittent necessary evil to a highly optimized, data-driven operational routine integrated within the broader marine IoT framework.

Small Hull Cleaning Robot Market Executive Summary

The global Small Hull Cleaning Robot Market is currently undergoing rapid commercialization, underpinned by significant advancements in robotics and a compelling market need for sustainable maritime operations. Current business trends indicate a decisive move away from outright sales towards flexible Robotics-as-a-Service (RaaS) models, particularly favored by small fleet operators and marinas. This shift lowers the barrier to entry, transfers maintenance and upgrade burdens to the service provider, and guarantees consistent, high-quality cleaning outcomes. Key manufacturers are differentiating themselves not solely through hardware capability but through the intelligence of their proprietary software platforms, which manage scheduling, track historical hull performance data, and provide predictive maintenance alerts. Strategic consolidation and collaborative ventures between technology developers and established marine maintenance contractors are key trends, allowing innovative startups to leverage existing service infrastructures for expanded geographical reach and immediate customer trust. The competition landscape is intensifying, rewarding firms that can demonstrate high compliance with global biofouling waste disposal regulations.

Regional dynamics highlight a maturing market in developed maritime economies and rapid acceleration in emerging regions. North America and Europe maintain leading market shares due to high vessel density, early technological adoption spurred by high labor costs, and mature regulatory environments that favor automated, eco-friendly cleaning. However, the Asia Pacific (APAC) region is forecasted to achieve the highest growth rate, primarily driven by explosive growth in aquaculture—where automated cleaning of nets and pen infrastructure is non-negotiable for operational hygiene and output maximization—and substantial government investments in domestic commercial fleet renewal. This regional growth is characterized by demand for highly durable, low-cost systems optimized for tropical waters where biofouling growth rates are significantly higher. Conversely, adoption in Latin America and the Middle East remains focused on critical infrastructure maintenance and specialized port operations, highly influenced by public sector tenders and national economic diversification strategies focused on maritime logistics.

Segmentation trends reveal strong momentum in the hybrid adhesion segment, which provides the versatility required to service diverse customer fleets comprising steel, aluminum, and composite hulls. The demand for Autonomous Underwater Vehicles (AUVs) is steadily overtaking that of tethered Remotely Operated Vehicles (ROVs), driven by the requirement for systems capable of unsupervised, complex missions, particularly for vessels anchored or moored away from dedicated port infrastructure. Crucially, the market value is migrating towards data and intelligence: hull integrity monitoring, predictive corrosion assessment, and detailed coating wear reports are now essential deliverables packaged alongside the cleaning service. The successful commercial platforms are those that seamlessly integrate cleaning efficiency with actionable data analytics, establishing long-term recurring revenue streams that solidify market presence. Regulatory harmonization, particularly regarding acceptable biofouling collection and disposal standards across major international ports, remains a critical factor that will shape the profitability and growth trajectory of all operational segments in the medium term.

AI Impact Analysis on Small Hull Cleaning Robot Market

Common user inquiries regarding the application of Artificial Intelligence (AI) and Machine Learning (ML) in the Small Hull Cleaning Robot Market center on three critical performance areas: enhanced autonomy, improved cleaning efficacy, and predictive capabilities. Users frequently ask about the reliability of completely untethered navigation, specifically how robots handle GPS signal loss underwater and maintain precise location awareness on geometrically complex surfaces, like bulbous bows or propeller shafts. There is high expectation that AI will solve the perennial challenge of differentiating between various types of fouling (e.g., soft slime, hard barnacles) and adjusting the cleaning force instantaneously to maximize removal while crucially avoiding damage to advanced, delicate antifouling paints. Furthermore, commercial fleet operators are intensely interested in the data synthesis capabilities of AI, expecting sophisticated algorithms to analyze historical cleaning efficacy, operational metrics, and environmental parameters (water temperature, salinity) to generate optimized, highly personalized proactive cleaning schedules, thereby minimizing human decision-making and guaranteeing peak hydrodynamic efficiency across their entire fleet.

The implementation of AI, particularly utilizing sophisticated Convolutional Neural Networks (CNNs) trained on vast datasets of submerged hull imagery, is transforming the robot’s perception capabilities. These AI-driven systems provide superior, real-time situational awareness by fusing data from multiple sensors—including acoustic sonar, inertial measurement units (IMUs), and vision cameras—to achieve robust Simultaneous Localization and Mapping (SLAM). This allows the robot to build a dynamic, accurate 3D model of its operational environment and the hull structure, enabling superior path planning that ensures comprehensive surface coverage while instinctively avoiding sensitive hull appendages like sacrificial anodes and specialized transducers. AI also empowers true adaptive cleaning: the system continuously monitors the optical feedback and acoustic signature during the cleaning process and dynamically modulates brush pressure, rotation speed, or water jet intensity. This level of granular, non-linear control is impossible for human operators and is the cornerstone for delivering environmentally sound cleaning that protects the hull coating investment, extending its useful life and enhancing the value proposition for the end-user.

Beyond operational control, AI is the foundational layer for transforming robotic cleaning into a data intelligence service. Machine Learning models process petabytes of operational data, identifying subtle correlations between cleaning cycles, vessel performance metrics (reported fuel consumption), and regional environmental conditions. This holistic analysis allows manufacturers and service providers to shift from simply cleaning vessels to providing a powerful predictive maintenance protocol. AI algorithms can forecast when biofouling will reach a critical threshold for efficiency loss, triggering an autonomous cleaning mission precisely when needed, rather than relying on arbitrary, calendar-based schedules. Furthermore, Generative AI models are utilized in the design phase, simulating millions of mission scenarios to optimize robot hardware design, battery usage, and control system responsiveness prior to physical prototyping. This comprehensive AI integration not only boosts the robot’s intelligence and efficiency but significantly enhances the reliability and profitability of the RaaS deployment model, positioning AI as the central differentiator in the competitive market landscape.

- AI-driven SLAM for precision navigation and dynamic obstacle avoidance on complex hull surfaces.

- Machine Vision using CNNs for granular, real-time classification of biofouling type and density.

- Adaptive Cleaning Algorithms that modulate brush force or water pressure to protect specialized antifouling coatings.

- Predictive Maintenance Protocols generated by ML analysis of hull performance data and environmental factors.

- Optimized Energy Management systems for maximizing mission endurance based on predicted cleaning workload.

- Automated Anomaly Detection for identifying early signs of hull coating failure, corrosion, or structural damage during cleaning cycles.

- Simulation and Digital Twin creation for rapid deployment planning and operator training in varying marine conditions.

DRO & Impact Forces Of Small Hull Cleaning Robot Market

The Small Hull Cleaning Robot Market is propelled by powerful economic drivers and inescapable regulatory compliance obligations, forming a dynamic landscape characterized by high innovation but equally high technical demands. The foremost driver is the economic incentive derived from minimizing operational expenditures; fuel consumption, which represents a massive portion of maritime operating costs, is directly correlated with hull roughness caused by biofouling. A marginal 5-10% reduction in drag achieved through automated, routine cleaning translates into millions in annual savings for commercial fleet operators, creating an overwhelming commercial imperative for adoption. Coupled with this is the escalating global regulatory framework, most notably the IMO’s focus on energy efficiency and the Ballast Water Management Convention, indirectly compelling owners to adopt best practices for hull husbandry to prevent the vessel surface from becoming a vector for Invasive Aquatic Species (IAS). The continuously improving technological maturity, marked by lighter, more powerful, and cheaper sensor systems, further lowers the total cost of ownership (TCO) and enhances system reliability, reinforcing the market growth trajectory.

Despite these accelerators, the market faces several structural and technical restraints that impede wider, faster adoption. The primary technical hurdle remains the current limitation of underwater power systems; achieving prolonged autonomy (mission times exceeding 8 hours) while powering energy-intensive systems like suction mechanisms, high-torque thrusters, and advanced sensors presents significant engineering challenges, often necessitating tethered solutions or frequent battery swaps. Financially, the high initial capital outlay for purchasing sophisticated robotic systems, compared to the perceived low short-term cost of manual diving services, remains a significant psychological barrier for small operators. Furthermore, the regulatory environment is characterized by regional heterogeneity: differing local port authority rules regarding the disposal of biofouling waste (In-Water Cleaning protocols, or IWC) create operational friction and regulatory compliance risks for systems operating globally. A lack of standardized certification and performance metrics for robotic cleaning efficacy also contributes to uncertainty among potential buyers, delaying large-scale fleet integration decisions.

The market opportunities are substantial, concentrated in areas of strategic maritime growth and technological convergence. The RaaS model presents an immense opportunity to democratize access to high-end technology, transitioning the market towards predictable, annuity-based revenue streams. The explosive growth of the global aquaculture sector offers a specialized, high-demand vertical for robust anti-fouling and infrastructure maintenance robots. Furthermore, the integration of these robots into comprehensive marine IoT platforms allows manufacturers to leverage their devices as data collection nodes, selling valuable hull condition intelligence that far exceeds the value of the cleaning service alone, moving them into the lucrative predictive maintenance software domain. The key impact forces driving transformational market change are the unstoppable momentum of global shipping decarbonization efforts, which mandate operational efficiency improvements, and the increasing reliance on robotics across all industrial sectors, establishing automation as the preferred solution for hazardous, repetitive tasks. Successful players will navigate the regulatory patchwork by providing certified, waste-capture solutions while continuously innovating in power efficiency and autonomous intelligence.

Segmentation Analysis

Segmentation analysis of the Small Hull Cleaning Robot Market reveals a complex interplay of functional requirements dictated by vessel design, operational environment, and end-user budgetary constraints. The market is fundamentally segmented by the type of hull material—steel, aluminum, or composite/fiberglass—which directly dictates the necessary adhesion and cleaning technologies. Steel hulls primarily utilize magnetic systems, demanding powerful, reliable electromagnetic or permanent magnet arrays, whereas non-ferrous hulls necessitate robust suction or negative buoyancy mechanisms, often requiring complex pump systems and advanced pressure regulation to maintain consistent wall contact. This material-based segmentation is critical, as a one-size-fits-all approach often leads to sub-optimal performance or potential hull damage, driving manufacturers toward highly specialized, material-specific robot designs and associated commercialization strategies tailored to dominant regional fleet compositions (e.g., high fiberglass yacht populations in the Mediterranean).

Further delineation occurs based on the Cleaning Mechanism and the Operation Mode. Cleaning mechanism segments include mechanical (brushing), hydrodynamic (water jet/cavitation), and hybrid approaches. The brush segment, while effective for heavier fouling, faces pressure to utilize compliant, variable-stiffness polymers to protect high-performance coatings, a necessity in the luxury yacht segment. Conversely, water jet systems, though safer for paint, require significantly higher power inputs, challenging mission endurance. In terms of Operation Mode, the split between Remotely Operated Vehicles (ROVs) and Autonomous Underwater Vehicles (AUVs) is a key determinant of operational cost and scalability. ROVs offer high reliability and real-time human intervention but incur ongoing labor costs. AUVs promise true autonomy and scalability for large fleet management but require highly sophisticated AI and robust sensor fusion to operate reliably in dynamic, unpredictable marine environments, making them the technology focus for long-term commercial dominance.

The application-based segmentation is perhaps the most defining characteristic of demand. The Recreational Boating segment emphasizes ease of use, aesthetics, and low noise, often accepting higher unit costs for compact, highly integrated systems. The Small Commercial Fleet segment demands ruggedness, durability, and a demonstrable Return on Investment (ROI) linked directly to fuel savings and extended operational cycles. The fastest-growing segment, Aquaculture, requires specialized systems for flexible, submerged netting, demanding unique non-abrasive cleaning methodologies and bio-secure operational protocols. Understanding these distinct end-user needs—ranging from the individual yacht owner prioritizing aesthetics to the large commercial operator prioritizing fuel burn reduction—is vital for successful market penetration. Manufacturers must develop modular platforms that allow easy customization of cleaning tools and control interfaces to address these varied, often conflicting, demands across the global maritime landscape, ensuring regulatory compliance is maintained across all operational verticals.

- By Hull Material

- Steel Hulls (Commercial and Patrol Vessels)

- Fiberglass/Composite Hulls (Recreational Yachts, Trawlers)

- Aluminum Hulls (Fast Patrol Boats, Catamarans)

- By Adhesion Mechanism

- Magnetic Adhesion Robots (Dominate steel applications)

- Suction/Vortex Adhesion Robots (Essential for non-ferrous hulls)

- Hybrid (Magnetic & Suction/Buoyancy) Robots (Focus on versatility and transition efficiency)

- By Cleaning Mechanism

- Brush and Mechanical Cleaning (Highest removal efficiency for mature fouling)

- Water Jet and Cavitation Cleaning (Non-contact, safest for sensitive coatings)

- Hybrid Cleaning Systems (Combining mechanical scrubbing with water assistance)

- By Operation Mode

- Remotely Operated Vehicles (ROV) (Used for inspection and complex cleaning)

- Autonomous Underwater Vehicles (AUV) (Growing rapidly for scheduled, unsupervised grooming)

- By Application

- Recreational Boating Maintenance (Focus on convenience and aesthetics)

- Small Commercial Fleet Management (Tugboats, Ferries, Supply Vessels) (Focus on ROI and uptime)

- Aquaculture and Net Cleaning (Specialized systems for bio-secure infrastructure maintenance)

- Naval and Maritime Security Vessels (High-security, rapid deployment requirements)

Value Chain Analysis For Small Hull Cleaning Robot Market

The upstream segment of the Small Hull Cleaning Robot value chain is characterized by a high reliance on specialized, high-technology component suppliers. This phase involves the procurement of highly sensitive and durable components capable of operating reliably under continuous pressure and exposure to corrosive saltwater environments. Critical components include high-energy-density battery packs (often requiring specialized pressure housings), powerful and precise miniaturized thrusters (BLDC motors optimized for marine use), and advanced sensor arrays, including multibeam sonar, acoustic Doppler current profilers (ADCPs), and inertial measurement units (IMUs). The supply chain for rare-earth magnets, necessary for high-performance magnetic adhesion systems, presents a significant geopolitical and logistical challenge, often dictating production scalability and cost structures. Furthermore, the reliance on specialized microprocessors and computing hardware capable of running complex AI algorithms (SLAM, image processing) underwater necessitates rigorous component selection and secure sourcing from specialized industrial electronics manufacturers, ensuring long-term reliability and compliance with stringent operational specifications.

Midstream activities involve the sophisticated assembly, calibration, and rigorous testing of the robotic platforms. Given the harsh operating environment, precision engineering is non-negotiable; complex processes like hermetic sealing, pressure compensation testing, and anti-corrosion treatments are integral to the manufacturing process. Value accretion in this stage is heavily influenced by proprietary intellectual property (IP) related to software, specifically the control algorithms governing adhesion reliability, path optimization, and adaptive cleaning protocols. Manufacturers often invest heavily in developing modular robot architectures to facilitate easier maintenance and component replacement, a necessity given the high wear and tear associated with constant submerged operations. The integration of robust telemetry and diagnostic tools during assembly ensures that post-deployment data can be reliably logged and used for continuous product improvement, establishing a closed feedback loop that enhances both product quality and service efficiency in the long run.

Downstream activities center on distribution, service delivery, and the monetization of operational data. Distribution channels are varied: direct sales dominate the commercial and governmental sectors, allowing manufacturers to provide bespoke integration and training. Indirect channels, utilizing specialized marine equipment dealers, marinas, and third-party maintenance contractors, are crucial for accessing the fragmented recreational market. The service delivery model is rapidly transitioning to RaaS, where the service provider retains ownership of the hardware but charges subscription or usage fees, often incorporating sophisticated data analytics packages. This allows for continuous value capture through maintenance contracts, software upgrades, and the provision of actionable hull condition reports (data monetization). A vital, non-negotiable component of the downstream value chain is compliance with environmental regulations—requiring certified protocols for collecting, handling, and disposing of removed biofouling waste—a service often provided as a high-value add-on that significantly differentiates leading service providers.

Small Hull Cleaning Robot Market Potential Customers

The Small Hull Cleaning Robot Market targets a highly stratified customer base, spanning individual high-net-worth consumers to large-scale government and commercial fleet managers, each possessing distinct procurement criteria. The segment encompassing Recreational and Luxury Yacht owners represents a significant revenue stream. These buyers are motivated primarily by maintaining peak performance for racing, preserving the aesthetic integrity of high-value hulls, and the convenience of automated, discreet maintenance that minimizes disruption to their recreational use. They demand highly polished user interfaces, compact storage, and systems capable of very gentle cleaning on sensitive, advanced antifouling coatings. The purchasing decision often prioritizes ease of use and the provision of localized, rapid-response service support, often leading to the adoption of smaller, highly autonomous systems available through marina-based service contracts or direct sales channels emphasizing premium branding and technological sophistication.

The second, and perhaps largest, volume consumer is the Small Commercial Fleet operator, including operators of coastal ferries, tugboats, offshore supply vessels, and specialized port service boats. For this critical demographic, the purchasing rationale is purely economic and operational. Small hull cleaning robots are viewed as essential tools for maximizing fuel efficiency and guaranteeing continuous operational readiness. Downtime for dry-docking is prohibitively expensive, making in-water automated maintenance the only viable, cost-effective option for proactive biofouling management. These customers require robust, industrial-grade reliability, compatibility with steel and frequently complex aluminum hulls, and detailed reporting capabilities to prove fuel savings and regulatory compliance. They favor scalable fleet solutions, long-term leasing agreements, and RaaS models that offer predictable fixed operational costs, transferring the technology risk to the service provider, often procured through central fleet management departments.

The final crucial customer groups include the rapidly expanding Global Aquaculture sector and Governmental/Naval Agencies. Aquaculture farms, particularly those involved in high-density fish farming, are major consumers, requiring robots optimized for flexible net cleaning to ensure adequate water flow and prevent disease proliferation, emphasizing specialized non-abrasive tools and bio-security protocols. Naval and Coast Guard entities require these robots for ensuring the operational readiness and stealth of their patrol fleets. Their requirements are characterized by a demand for rapid deployment, high-security features (data encryption, physical security), and systems capable of deployment in remote or high-security anchorages where manual diving is restricted or prohibitively dangerous. These institutional buyers prioritize proven reliability, adherence to military or governmental specifications, and the long-term support capabilities of the robot manufacturer, often utilizing complex public tendering processes for procurement that emphasize technical compliance over immediate cost efficiency.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $155.8 Million USD |

| Market Forecast in 2033 | $412.5 Million USD |

| Growth Rate | 14.9% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Hull Maintenance Systems, K.K. Hull Cleaning, Fathom Robotics, Subsea Tech, RJE International, Deep Ocean Engineering, U-Boat Worx, Marine Robotics Ltd., Biofouling Solutions, Eco Subsea, Armach Robotics, Remora Marine, Keelcrab, Algae Robot, AkzoNobel (Underwater Solutions), Jotun (Robotic Partnerships), Saab Seaeye, IKM Subsea, Oceaneering International, Greensea Systems, Deep Trekker. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Small Hull Cleaning Robot Market Key Technology Landscape

The technological sophistication driving the Small Hull Cleaning Robot Market is centered on achieving reliable, autonomous operation and minimizing ecological impact under demanding marine conditions. Core technological development focuses heavily on optimizing energy storage and propulsion efficiency. High-density lithium-polymer battery packs, often utilizing specialized pressure-compensating oils and advanced thermal management systems, are essential for extending untethered mission times. Propulsion systems typically employ multi-axis vectored thrusters or highly articulated tracked mechanisms to counteract unpredictable underwater currents and ensure consistent wall contact. A critical breakthrough involves sensor fusion technology: integrating high-frequency acoustic transducers (micro-sonar) with optical sensors and high-precision Inertial Measurement Units (IMUs) allows for robust, centimeter-level localization and mapping without external referencing, which is vital for the execution of complex, comprehensive cleaning patterns on curved three-dimensional surfaces.

Adhesion technology continues to be a central area of innovation, balancing grip reliability with energy consumption. For magnetic systems, the focus is on developing lightweight, highly efficient permanent magnet arrays supplemented by controllable electromagnets, allowing for precise adjustment of holding force during transit and cleaning. For non-ferrous hulls, cavitation-resistant pump technology and smart sealing techniques are necessary to generate reliable suction forces under high hydrostatic pressure, often utilizing sophisticated closed-loop control systems to dynamically regulate internal vacuum levels based on the robot's orientation and motion dynamics. Furthermore, the cleaning tools themselves are evolving; there is a distinct move towards engineered polymer brush materials and soft composite scrapers that ensure effective removal of early-stage biofouling while demonstrably reducing the stress and abrasion inflicted upon high-value silicone and ceramic antifouling coatings, thereby protecting the longevity and performance of the expensive paint system.

The most transformative technologies are rooted in data and control architecture. Autonomous operation relies on advanced, real-time computational capability, typically utilizing dedicated System-on-Chip (SoC) solutions designed for low power consumption. These onboard computers run proprietary AI algorithms for mission planning, obstacle classification (e.g., distinguishing between a valuable transducer and a minor hull irregularity), and automated data capture. Post-mission, secure, high-bandwidth data transfer systems (often via acoustic modems followed by Wi-Fi or 5G upon surfacing) enable the fleet management software to ingest operational metrics, hull inspection videos, and condition reports. The ability to seamlessly integrate these proprietary data streams into major maritime enterprise resource planning (ERP) systems, alongside robust cybersecurity protocols to protect sensitive vessel information, defines the commercial viability of the next generation of robotic hull management solutions. Continuous firmware and software updates delivered wirelessly allow manufacturers to rapidly iterate on cleaning performance and introduce new inspection functionalities.

Regional Highlights

- North America: This region dominates the high-value segment, driven by the massive concentration of recreational vessels along the Atlantic and Pacific coasts, coupled with some of the world's most restrictive In-Water Cleaning (IWC) regulations, particularly in major ports. Adoption is strongly supported by high disposable incomes and a pervasive culture of early technological adoption. Key market activity is centered on R&D for AI-powered autonomous systems and the aggressive deployment of Robotics-as-a-Service (RaaS) models targeting marinas and high-end yacht management companies, often commanding premium prices due to stringent biofouling control requirements and high labor costs.

- Europe: Characterized by a highly competitive landscape and strong regulatory enforcement, particularly in the Baltic and North Seas concerning environmental protection and decarbonization (EEDI/EEXI compliance). The European market sees strong demand from small commercial vessel operators (fishing, coastal transport) benefiting from governmental efficiency incentives. Innovation is focused on waste capture and containment systems, driven by strict regional laws governing the disposal of removed biofouling mass, making certified, environmentally compliant solutions a critical competitive differentiator across the continent.

- Asia Pacific (APAC): Positioned as the highest growth market, APAC's expansion is fundamentally linked to the region's burgeoning aquaculture sector and the massive expansion and modernization of its maritime infrastructure, especially in rapidly developing coastal economies. While regulatory enforcement varies, the economic imperative for efficiency in tropical waters, which experience extremely aggressive biofouling growth rates, necessitates frequent, automated cleaning. This region favors robust, scalable, and cost-effective solutions, attracting significant foreign investment and local manufacturing initiatives focused on high-volume production.

- Latin America: This emerging market shows concentrated growth in strategically important areas like the Panama Canal and major container ports. Adoption is often linked to infrastructure investment projects and the modernization of governmental patrol fleets. Challenges include overcoming high import tariffs and establishing adequate local technical support networks. Initial sales are typically government or large corporate tenders focused on pilot programs, emphasizing ROV systems for inspection and targeted cleaning tasks over full AUV autonomy due to cost sensitivities.

- Middle East and Africa (MEA): Growth in the MEA is primarily confined to key economic hubs like the UAE, Saudi Arabia, and South Africa, driven by investments in modern naval assets and the maintenance of high-value oil and gas support vessels in warm waters. The extreme biofouling risk due to high temperatures makes proactive robotic maintenance a necessity for operational readiness. The market demands highly robust, corrosion-resistant systems capable of withstanding high-salinity and high-temperature operating conditions, often supplied via direct sales to government and large state-owned enterprises.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Small Hull Cleaning Robot Market.- Armach Robotics

- Keelcrab

- Hull Maintenance Systems

- Fathom Robotics

- Subsea Tech

- RJE International

- Deep Ocean Engineering

- Marine Robotics Ltd.

- Biofouling Solutions

- Eco Subsea

- Remora Marine

- Algae Robot

- U-Boat Worx

- Saab Seaeye

- IKM Subsea

- Oceaneering International

- AkzoNobel (Underwater Solutions)

- Jotun (Robotic Partnerships)

- Greensea Systems

- Deep Trekker

Frequently Asked Questions

Analyze common user questions about the Small Hull Cleaning Robot market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary economic benefit of using small hull cleaning robots?

The primary economic benefit is substantial fuel savings, achieved by mitigating marine biofouling which increases hydrodynamic drag. Routine robotic grooming can reduce drag significantly, translating directly into lower fuel consumption, reduced operational costs, and fewer required dry-dockings over the vessel's lifespan, providing a rapid return on investment (ROI).

Are these robots effective on all types of hull materials and coatings?

Modern small hull cleaning robots are designed with variable adhesion mechanisms (magnetic for steel, suction for composites/aluminum) and adjustable cleaning intensity (soft brushes or water jets) to effectively and safely clean virtually all hull materials, including specialized thin-film antifouling coatings, minimizing paint abrasion and maximizing efficacy.

How do small hull cleaning robots comply with strict environmental regulations regarding biofouling?

To ensure compliance, leading robotic systems are designed to operate proactively, removing only soft, early-stage biofouling. Crucially, they often incorporate filtration or collection systems that capture the removed fouling biomass and its associated biocides, preventing their release into sensitive port or coastal waters, thus meeting stringent In-Water Cleaning (IWC) regulatory standards.

Is the market trending towards Autonomous Underwater Vehicles (AUVs) or Remotely Operated Vehicles (ROVs)?

While tethered ROVs remain dominant for real-time control and high power needs, the market is rapidly trending towards untethered AUVs, especially for fleet management and routine grooming tasks. AUVs, powered by AI for navigation and path planning, offer scalability, reduced labor dependency, and the capacity for truly autonomous, scheduled cleaning missions.

What role does Artificial Intelligence (AI) play in the latest generation of small hull cleaning robots?

AI is fundamental for advanced robotics, enabling autonomous path planning via SLAM, real-time classification of biofouling severity, and adaptive adjustment of cleaning parameters to protect hull coatings. AI also powers predictive maintenance platforms, advising operators on optimal cleaning schedules based on historical performance and environmental data, moving maintenance from reactive to proactive.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager