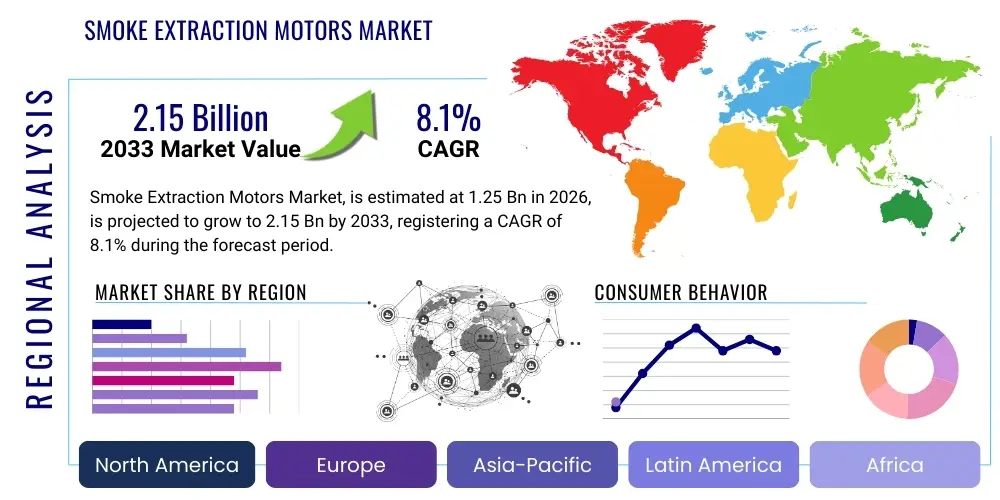

Smoke Extraction Motors Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 441288 | Date : Feb, 2026 | Pages : 241 | Region : Global | Publisher : MRU

Smoke Extraction Motors Market Size

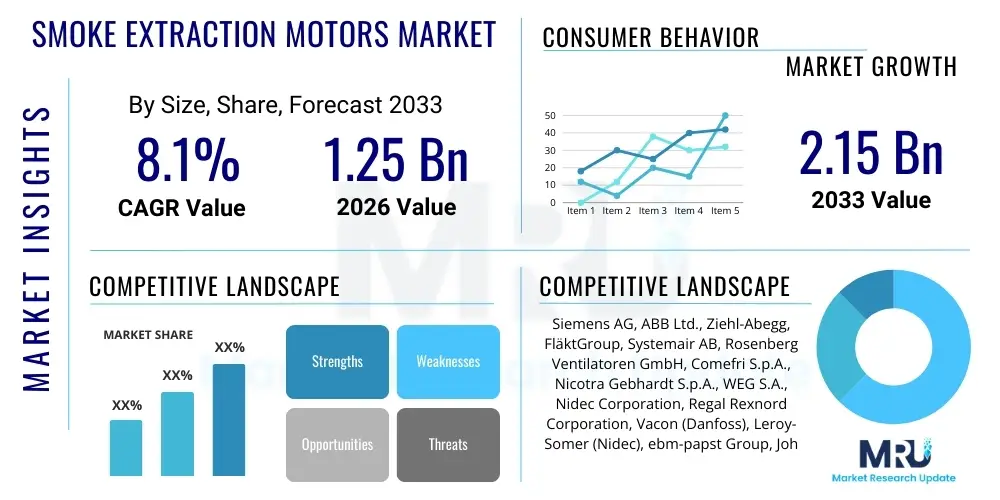

The Smoke Extraction Motors Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.05% between 2026 and 2033. The market is estimated at USD 1.25 Billion in 2026 and is projected to reach USD 2.15 Billion by the end of the forecast period in 2033.

Smoke Extraction Motors Market introduction

The Smoke Extraction Motors Market encompasses specialized electric motors designed to operate reliably under extreme thermal stress, typically reaching temperatures of 300°C to 400°C for defined durations, often 60 to 120 minutes, as mandated by stringent global fire safety standards such as EN 12101-3. These motors are integral components of powered smoke and heat exhaust ventilation systems (SHEVS), which are critical for maintaining clear escape routes, facilitating access for emergency services, and limiting structural damage in commercial, industrial, and infrastructural environments. The primary function of these systems is to extract hot smoke and combustion gases from enclosed spaces during a fire event, thereby preventing smoke logging and reducing the risk of flashovers, which is vital for occupant safety and regulatory compliance.

Smoke extraction motors are typically deployed in conjunction with axial or centrifugal fans, forming robust ventilation units specifically engineered for high-temperature resilience. Key product characteristics include advanced insulation materials, heat-resistant bearings and lubricants, and specialized winding designs to ensure continuous operation when standard motors would fail due to thermal overload. Major applications span a wide range, including large commercial centers, high-rise residential buildings, complex underground infrastructure like metro stations and road tunnels, and industrial plants where hazardous materials or processes increase fire risk. The increasing complexity and density of urban architecture, coupled with stricter enforcement of building safety codes worldwide, are substantially accelerating the adoption rate of these high-specification motor systems.

The core benefit delivered by these motors is enhanced life safety and asset protection. By ensuring the effective removal of smoke, they prevent the rapid spread of toxic gases, which are the leading cause of fire-related fatalities, and maintain temperature stability within the structural limits of the building. Driving factors for market growth include mandatory safety legislation upgrades, rapid urbanization leading to increased construction of large, enclosed spaces, and a growing emphasis on smart building technologies that integrate fire safety systems with broader building management platforms. Furthermore, technological advancements, particularly in highly efficient EC (Electronically Commutated) motors capable of meeting energy efficiency goals while providing high-temperature performance, are shaping product development and market dynamics.

Smoke Extraction Motors Market Executive Summary

The Smoke Extraction Motors Market is undergoing robust expansion, fundamentally driven by stringent governmental mandates on fire safety across major global economies, coupled with significant growth in non-residential construction, particularly in Asia Pacific and the Middle East. Business trends indicate a strong shift towards Electronically Commutated (EC) motors, which offer superior energy efficiency and variable speed control compared to traditional AC induction counterparts, positioning them as the preferred choice for sophisticated, energy-conscious building designs. Manufacturers are heavily investing in modular solutions and integrated fan-motor assemblies, reducing installation complexity and improving system reliability, while the growing demand for retrofit applications in older infrastructure provides a sustainable revenue stream beyond new construction projects. Competitive intensity is characterized by specialized motor manufacturers focusing on achieving high thermal ratings (F400 being increasingly standard) and optimizing motor control algorithms for seamless integration into advanced fire detection and Building Management Systems (BMS).

Regionally, Asia Pacific stands out as the fastest-growing market, propelled by rapid urbanization, substantial investment in large-scale infrastructure projects (e.g., tunnels, high-speed rail networks), and the introduction of stricter local fire safety codes harmonizing with international standards. Europe maintains a mature, dominant market share, characterized by high regulatory adherence and a focus on premium, energy-efficient products, notably driven by the Energy Performance of Buildings Directive (EPBD) requirements. North America demonstrates stable growth, primarily focused on upgrading existing commercial properties and deploying certified systems that meet specific UL and NFPA standards. The trend across all regions emphasizes reliability, longevity, and adherence to specific temperature performance classes, pushing R&D towards superior material science in motor construction.

Segment trends highlight the dominance of the commercial and industrial segments, which necessitate powerful, certified smoke extraction systems for large volumes of air. Within the Motor Type segment, AC induction motors currently hold a substantial share due to their established reliability and lower upfront cost, but EC motors are rapidly gaining traction due to lifecycle cost advantages derived from lower energy consumption and better performance flexibility. Furthermore, the segmentation by thermal rating shows a clear migration towards F400 (400°C for 120 minutes) as developers seek maximum safety margins and future-proofing, especially in deep tunnels and complex, high-occupancy structures. The aftermarket segment is becoming increasingly vital, providing opportunities for service providers specializing in mandatory inspection, maintenance, and replacement of motors within installed fire safety infrastructure.

AI Impact Analysis on Smoke Extraction Motors Market

Common user questions regarding AI’s influence on the Smoke Extraction Motors market typically revolve around predictive maintenance capabilities, optimization of system response during a fire event, and the potential for AI-driven energy management in ventilation systems. Users frequently ask how AI can enhance the reliability of motors operating under extreme conditions and if AI integration will be mandated by future safety standards. The analysis reveals that the primary user interest lies in using AI/Machine Learning (ML) algorithms to process real-time sensor data from motor vibrations, temperature fluctuations, and current consumption. This allows for early detection of potential failures (e.g., bearing degradation, insulation breakdown) before a fire even occurs, thereby maximizing motor readiness. Furthermore, AI is expected to optimize the motor's operational profile during an actual fire event by dynamically adjusting fan speed and direction based on smoke propagation modeling, ensuring optimal evacuation pathways and maximizing extraction efficiency, addressing key safety and operational concerns.

- AI-driven Predictive Maintenance: Utilizing ML models to analyze motor performance data (vibration, temperature, current) to forecast component failure, significantly improving uptime and reliability crucial for safety-critical systems.

- Dynamic Smoke Control Optimization: Implementing AI algorithms to integrate with fire detection systems and BMS, dynamically adjusting motor speed and fan operation based on real-time smoke density and airflow simulation to enhance extraction efficiency.

- Energy Efficiency Management: Using AI to optimize the routine, non-emergency operational schedules of ventilation systems when they function as standard exhaust fans, minimizing energy consumption without compromising emergency readiness.

- Enhanced Fault Detection and Diagnostics: Advanced pattern recognition systems powered by AI that can quickly isolate minor operational anomalies, distinguishing them from normal high-temperature stress responses.

- Virtual Testing and Certification: Application of AI/ML in simulating extreme thermal and operational scenarios, potentially speeding up the stringent certification process required for new motor designs (F300/F400 ratings).

DRO & Impact Forces Of Smoke Extraction Motors Market

The Smoke Extraction Motors Market is primarily driven by escalating global mandates for fire and life safety in complex urban structures, making high-performance extraction systems non-negotiable regulatory requirements in most developed and rapidly developing nations. Restraints primarily involve the high upfront cost associated with specialized, certified motors and the complexity of integrating these robust systems into existing infrastructure, particularly in older buildings where space and power supply limitations pose technical challenges. Opportunities are significantly concentrated in the retrofit market, particularly in densely populated cities requiring infrastructure modernization, and through the development of highly efficient, standardized motor solutions, such as EC technology, which addresses growing energy consumption concerns. Impact forces are predominantly regulatory pressure from bodies like the CEN (European Committee for Standardization) and NFPA (National Fire Protection Association), coupled with technological advancements focusing on thermal resistance and smart connectivity, forcing market participants to continuously innovate materials science and control electronics to maintain competitive relevance and compliance.

The mandatory adoption of specific thermal ratings (e.g., F400) for public transport systems and high-rise commercial buildings is a fundamental market driver. Developers recognize that failure to comply results in significant legal and financial repercussions, cementing the demand floor for certified motors. Furthermore, the increasing architectural complexity, particularly the construction of 'mega-structures' and deep subterranean infrastructure, inherently demands more powerful, reliable, and durable smoke extraction capabilities. These large projects often require multi-stage ventilation systems where the motor must maintain performance continuity under the most adverse conditions. This systemic requirement for resilience ensures sustained investment in premium motor technology, regardless of short-term economic fluctuations.

Despite strong regulatory tailwinds, the market faces headwinds from volatility in raw material prices, particularly copper and specialized insulation polymers, which directly impact manufacturing costs and pricing strategies. Furthermore, the market is characterized by a high barrier to entry due to the necessity of rigorous, time-consuming third-party certification processes (e.g., meeting EN 12101-3 standards), limiting competition and potentially slowing down the adoption of newer technologies. However, the long-term opportunity lies in leveraging digitalization—specifically, the integration of Industrial Internet of Things (IIoT) sensors into motor systems—to provide real-time diagnostics and condition monitoring. This not only enhances maintenance schedules but also supports the transition to performance-based fire safety designs, which evaluate the entire system's effectiveness rather than just component compliance.

Segmentation Analysis

The Smoke Extraction Motors Market is segmented based on critical technical and application parameters, providing a detailed view of market demand characteristics. Key segments include Motor Type (AC Induction, EC Motors, DC Motors), Thermal Rating (F200, F300, F400), Application (Commercial, Industrial, Infrastructure, Residential), and Sales Channel (OEM and Aftermarket). This structure allows stakeholders to analyze product performance requirements against specific end-user demands and regulatory environments. The application segmentation reveals that infrastructure (tunnels, metro systems) and commercial buildings (malls, high-rises) represent the largest and most demanding segments, requiring the highest thermal ratings and robust performance specifications.

- Motor Type:

- AC Induction Motors

- Electronically Commutated (EC) Motors

- DC Motors

- Thermal Rating:

- F200 (200°C for 120 minutes)

- F300 (300°C for 60 minutes)

- F400 (400°C for 120 minutes)

- Others (Higher or specialized ratings)

- Application:

- Commercial Buildings (Office Complexes, Retail Centers, Hospitals)

- Industrial Facilities (Manufacturing Plants, Warehouses)

- Infrastructure (Tunnels, Metro Stations, Airports)

- Residential Complexes (High-Rise Apartments)

- Sales Channel:

- Original Equipment Manufacturer (OEM)

- Aftermarket (Replacement and Maintenance)

Value Chain Analysis For Smoke Extraction Motors Market

The value chain for smoke extraction motors starts with the upstream suppliers of critical raw materials, including specialized heat-resistant alloys, high-temperature copper windings, insulation materials (such as mica and polyimide films), and advanced lubricants and bearings capable of surviving extreme thermal cycles. Due to the high-reliability requirement, material procurement is often highly specialized and subject to strict quality control, which adds to the product’s complexity and cost. Motor manufacturers then engage in highly specialized design and production, focusing heavily on thermal modeling, insulation techniques, and achieving compliance with standards like EN 12101-3. This stage includes meticulous testing and third-party certification, representing a significant value-add step.

Midstream activities involve the integration of the smoke extraction motor into fan systems. Major fan manufacturers (OEMs) often purchase the certified motors and integrate them into complete fan units (e.g., axial or centrifugal fans), which are then sold as certified smoke extraction systems. Distribution channels are complex, involving both direct sales to major infrastructure developers and indirect channels through specialized Heating, Ventilation, and Air Conditioning (HVAC) distributors, fire safety contractors, and system integrators. The selection of the channel often depends on the project size; large infrastructure projects typically utilize direct sales and close collaboration between the motor manufacturer and the principal contractor.

Downstream analysis focuses on installation, commissioning, and continuous maintenance. Installation is performed by certified fire safety and mechanical contractors who ensure the system operates correctly within the broader BMS. The aftermarket segment is crucial, providing value through routine inspection, mandatory performance testing, and eventual motor replacement as dictated by system lifespan or regulatory updates. Direct channels are vital for large-scale, long-term maintenance contracts, ensuring specialized knowledge is applied, while indirect channels serve smaller commercial retrofits. The integrity of the entire system, not just the motor, dictates end-user value, emphasizing the importance of certified installation and timely servicing.

Smoke Extraction Motors Market Potential Customers

Potential customers for smoke extraction motors are primarily entities responsible for designing, constructing, and maintaining high-occupancy or critical infrastructure environments where fire safety mandates are non-negotiable. The largest buyer segments include construction firms and mechanical contractors specializing in commercial development, particularly those building skyscrapers, expansive shopping centers, and large-scale data centers where rapid smoke removal is essential for business continuity and life safety. Government bodies and public transport authorities represent major customers, especially those managing critical infrastructure like road tunnels, railway networks, and subterranean public transport stations, demanding the highest thermal resistance ratings (F400 or higher) due to the complexity of evacuation in enclosed spaces.

Furthermore, industrial facilities, especially those dealing with hazardous materials or processes that generate high heat, such as petrochemical plants and large manufacturing complexes, are key end-users. These environments require bespoke, often explosion-proof or chemically resistant, smoke extraction systems integrated with the motor technology. Institutional clients, including large hospital networks and university campuses, also constitute a stable customer base, driven by compliance and the need to protect vulnerable occupants. The purchasing decision often involves collaboration among fire safety consultants, system integrators, and mechanical engineers, prioritizing certified performance, proven reliability, and total cost of ownership (TCO) over basic component cost.

The aftermarket customer base, equally crucial for market stability, consists of facility managers, property management companies, and specialized fire safety maintenance providers who regularly procure replacement motors and associated parts. Due to the stringent regulatory requirements for system checks, replacement cycles for smoke extraction motors, even if preventative, are predictable and non-deferrable. Consequently, maintaining robust relationships with authorized service partners and offering comprehensive service contracts is critical for manufacturers to capture recurring revenue from this essential customer segment.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.25 Billion |

| Market Forecast in 2033 | USD 2.15 Billion |

| Growth Rate | 8.05% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Siemens AG, ABB Ltd., Ziehl-Abegg, FläktGroup, Systemair AB, Rosenberg Ventilatoren GmbH, Comefri S.p.A., Nicotra Gebhardt S.p.A., WEG S.A., Nidec Corporation, Regal Rexnord Corporation, Vacon (Danfoss), Leroy-Somer (Nidec), ebm-papst Group, Johnson Electric, Teco Electric & Machinery Co., Ltd., Brook Crompton, Mitsubishi Electric Corporation, Crompton Greaves Consumer Electricals Limited, Fime S.p.A. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Smoke Extraction Motors Market Key Technology Landscape

The technological landscape of the Smoke Extraction Motors Market is defined by the critical need to balance extreme thermal resilience with superior energy efficiency and digital connectivity. Traditionally, standard AC induction motors dominated the market due to their ruggedness and simplicity. However, current innovation centers around the advancement of insulation materials, specifically utilizing advanced thermal classes (H and R insulation systems) combined with specialized high-temperature bearings and lubricants that prevent seizure or degradation under sustained heat loads (400°C for 120 minutes). Materials science is pivotal, focusing on copper wire coatings and magnetic steel laminations designed to maintain electromagnetic integrity despite severe ambient temperature increases. The goal is to ensure the motor provides full torque and specified revolutions per minute (RPM) throughout the entire duration of the required fire event scenario.

A major technological paradigm shift is the rising adoption of Electronically Commutated (EC) motors. EC technology, fundamentally a brushless DC motor design, incorporates integrated electronics and permanent magnets, offering substantial advantages in terms of energy consumption (often 20-30% more efficient than AC counterparts) and precise speed control. This variability is crucial for modern fire safety strategies, allowing the system to modulate air flow based on dynamic fire conditions detected by sensors. While the integration of sensitive electronics presents challenges in maintaining thermal integrity, manufacturers are successfully encapsulating and cooling the necessary control boards to withstand specified fire temperatures, making EC motors increasingly viable and demanded in the premium and energy-conscious segments of the market, aligning motor technology with broader sustainability goals.

Furthermore, digitalization and the integration of smart features are rapidly becoming standard. Key motors are now frequently equipped with embedded sensors for monitoring vibration, winding temperature, and electrical load. This integration facilitates condition monitoring and predictive maintenance capabilities, leveraging IIoT platforms to transmit data to the Building Management System (BMS) for diagnostics. These technological advances not only ensure the motor is operational when needed (enhanced reliability) but also optimize routine ventilation operations. The focus is shifting from simple compliance to intelligent, digitally managed safety systems, where the motor acts as a smart node within the broader fire safety infrastructure, requiring seamless communication protocols and robust data security.

Regional Highlights

- Europe: This region holds a leading market share, driven by stringent, well-established standards (primarily EN 12101-3) and a high level of regulatory compliance maturity. Countries like Germany, the UK, and France are characterized by advanced construction practices and a strong emphasis on energy efficiency, leading to a high penetration rate of certified F400 motors and EC motor technology, particularly in tunnel ventilation systems and large commercial buildings. The strong presence of key global manufacturers and system integrators reinforces this dominance.

- Asia Pacific (APAC): APAC is projected to exhibit the highest growth rate during the forecast period. Rapid urbanization, massive infrastructure development (new metro lines, airports, high-rise residential towers) in countries such as China, India, and Southeast Asian nations, and the gradual adoption of international fire safety standards fuel this expansion. While cost remains a factor, the increasing severity of fire events and government commitments to modernization are pushing demand for F300 and F400 rated motors for public safety applications.

- North America: The market here is robust and mature, governed by rigorous local standards set by organizations like the NFPA (National Fire Protection Association) and requiring specific UL certifications. Growth is stable, driven primarily by the modernization and retrofitting of aging commercial infrastructure and the continuous development of large-scale industrial complexes. The focus is often on reliability and meeting specific local code requirements for high-hazard areas, though adoption of highly efficient EC motors is accelerating.

- Middle East and Africa (MEA): This region shows significant growth potential, largely attributable to monumental construction projects in the GCC countries (UAE, Saudi Arabia, Qatar) related to economic diversification and major events. These projects, often involving iconic, high-rise buildings and complex rail networks, adhere to the highest international standards, demanding F400 systems. The demand is heavily focused on premium, integrated solutions designed for high-heat environments.

- Latin America: This region represents an emerging market, where growth is highly dependent on national economic stability and the varying pace of regulatory enforcement. Brazil and Mexico are leading the adoption curve, driven by increasing foreign investment in commercial real estate and industrial warehousing. The market often seeks a balance between cost-effectiveness and meeting international certification requirements, gradually shifting from basic systems to certified F300 solutions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Smoke Extraction Motors Market.- Siemens AG

- ABB Ltd.

- Ziehl-Abegg

- FläktGroup

- Systemair AB

- Rosenberg Ventilatoren GmbH

- Comefri S.p.A.

- Nicotra Gebhardt S.p.A.

- WEG S.A.

- Nidec Corporation

- Regal Rexnord Corporation

- Vacon (Danfoss)

- Leroy-Somer (Nidec)

- ebm-papst Group

- Johnson Electric

- Teco Electric & Machinery Co., Ltd.

- Brook Crompton

- Mitsubishi Electric Corporation

- Crompton Greaves Consumer Electricals Limited

- Fime S.p.A.

Frequently Asked Questions

Analyze common user questions about the Smoke Extraction Motors market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary difference between a standard motor and a smoke extraction motor?

The primary difference is the certified thermal resistance and operational duration. Smoke extraction motors are specifically designed and certified (e.g., F400) to operate reliably at extremely high temperatures (up to 400°C) for a mandated duration (typically 120 minutes) during a fire event, ensuring continuous smoke removal where standard industrial motors would fail due to insulation or bearing breakdown.

Which thermal rating (F-class) is most commonly required for underground infrastructure?

The F400 rating (400°C for 120 minutes) is most commonly required for critical underground infrastructure, such as road tunnels, metro stations, and large rail networks. This high rating ensures maximum system resilience and adequate time for emergency response and full evacuation in complex, enclosed environments where smoke clearance is highly challenging.

How do Electronically Commutated (EC) motors benefit the smoke extraction market?

EC motors benefit the market by offering superior energy efficiency, precise variable speed control, and lower lifecycle costs compared to traditional AC motors. Their integration allows for dynamic airflow adjustments based on fire conditions, enhancing the overall performance and energy management of the ventilation system during both routine operation and emergency use.

Is predictive maintenance technology being integrated into smoke extraction motors?

Yes, predictive maintenance is a key technological trend. Manufacturers are increasingly integrating IoT sensors into motors to monitor key operational parameters like vibration and temperature. This data is analyzed by AI/ML algorithms to predict potential component failures, thereby ensuring the motor is always in optimum working condition for a fire emergency.

What are the main regulatory standards governing the global market for these motors?

The main regulatory standard, especially prevalent in Europe and influential globally, is EN 12101-3, which specifies the performance requirements, including thermal resistance ratings (F200, F300, F400), for powered smoke and heat control ventilation systems. In North America, requirements are dictated by UL standards and NFPA codes.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager