Solder Fume Extraction Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 443627 | Date : Feb, 2026 | Pages : 258 | Region : Global | Publisher : MRU

Solder Fume Extraction Market Size

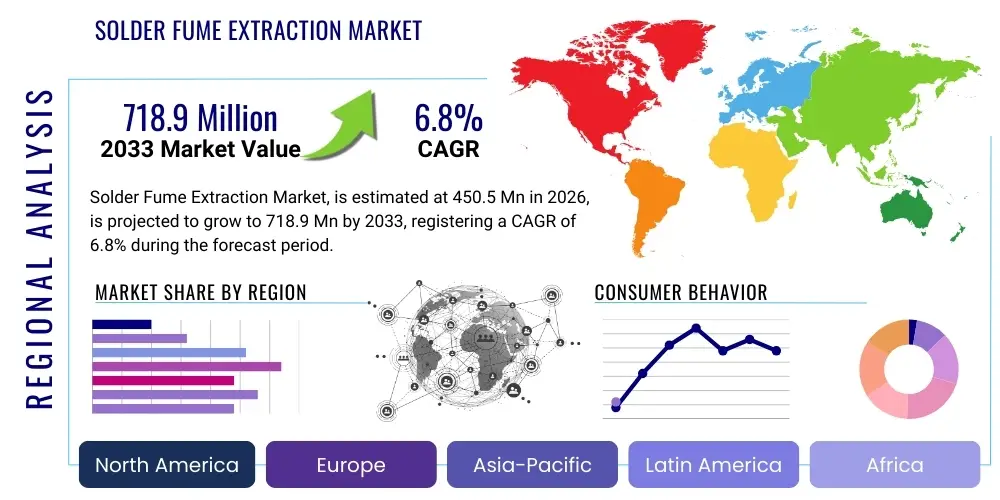

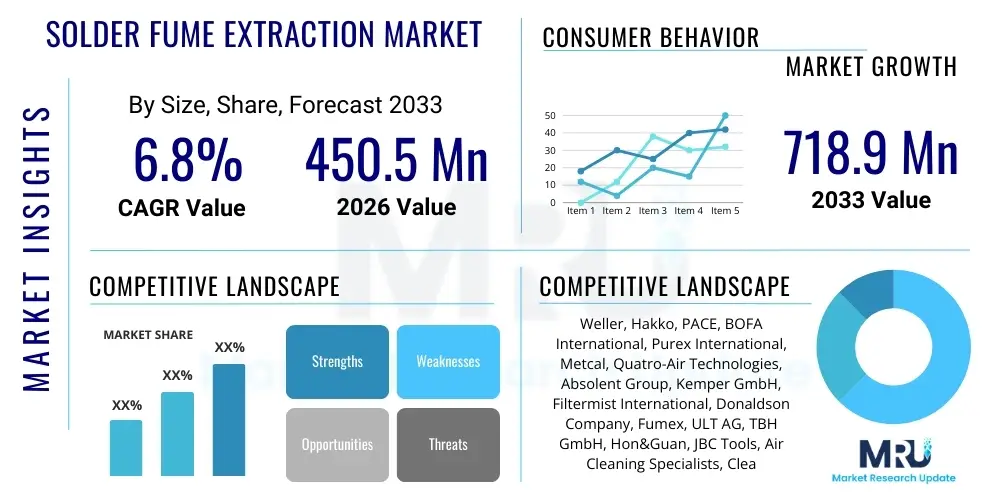

The Solder Fume Extraction Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 450.5 Million in 2026 and is projected to reach USD 718.9 Million by the end of the forecast period in 2033.

Solder Fume Extraction Market introduction

The Solder Fume Extraction Market encompasses equipment designed to remove hazardous fumes and particulate matter generated during soldering processes in electronics manufacturing, assembly, and repair operations. These systems are crucial for maintaining worker safety and adhering to stringent occupational health regulations worldwide. The primary function of these extractors is to capture airborne contaminants, including rosin-based fluxes, volatile organic compounds (VOCs), and solder alloy particles, preventing their inhalation by operators and mitigating environmental contamination.

Key products within this market include benchtop units, portable extraction systems, and centralized filtration infrastructures, categorized based on their application scale and mobility. Major applications span across the electronics industry, particularly printed circuit board (PCB) assembly, automotive electronics, aerospace, medical device manufacturing, and repair workshops. These systems often utilize multi-stage filtration technologies, typically involving pre-filters for large particulates, main filters (such as HEPA or absolute filters) for fine particles, and chemical filters (like activated carbon) to absorb gases and odors.

The market growth is fundamentally driven by the escalating global production of sophisticated electronic devices, miniaturization trends requiring precise soldering, and, most importantly, increasing governmental and organizational focus on worker respiratory protection. Benefits of implementing high-efficiency solder fume extraction include reduced occupational illnesses, improved product quality through cleaner working environments, and compliance with standards set by organizations like OSHA (Occupational Safety and Health Administration) and similar regulatory bodies across Europe and Asia Pacific.

Solder Fume Extraction Market Executive Summary

The Solder Fume Extraction Market is poised for stable and consistent growth, primarily fueled by regulatory strictness regarding air quality in industrial settings and the relentless expansion of the global electronics manufacturing base, particularly in Asia Pacific. Business trends indicate a shift toward intelligent, IoT-enabled fume extraction units that offer real-time monitoring of filter saturation and airflow performance, optimizing maintenance schedules and ensuring continuous compliance. Leading manufacturers are focusing on developing high-efficiency particulate air (HEPA) and activated carbon filter solutions capable of handling the increasingly complex chemical compositions of modern, lead-free solder fluxes.

Regionally, Asia Pacific dominates the market due driven by its status as the world’s major electronics manufacturing hub, hosting vast semiconductor and PCB assembly operations in countries like China, South Korea, Taiwan, and Vietnam. However, North America and Europe continue to represent high-value markets, characterized by rapid adoption of premium, centralized extraction systems and strict adherence to occupational safety standards. Emerging markets in Latin America and MEA are beginning to mandate higher safety standards, presenting significant opportunities for portable and entry-level benchtop units.

Segment trends highlight the dominance of benchtop and portable extraction systems due to their flexibility and ease of integration into existing assembly lines, though centralized systems remain critical for large-scale operations. From an end-user perspective, the electronics and telecommunications segment remains the largest consumer, while the automotive electronics sector is exhibiting the highest CAGR, propelled by the proliferation of electric vehicles (EVs) and advanced driver-assistance systems (ADAS), both demanding high-quality, high-volume soldering processes under strict environmental controls.

AI Impact Analysis on Solder Fume Extraction Market

User queries regarding AI's influence in the Solder Fume Extraction Market frequently center on how machine learning can improve operational efficiency, predictive maintenance, and real-time regulatory compliance. Users are keenly interested in whether AI algorithms can analyze airborne pollutant data captured by sensors to dynamically adjust extraction rates, thereby saving energy while maintaining optimal safety margins. Key themes include the integration of AI for predictive filter replacement schedules, reducing downtime and maintenance costs, and using computer vision systems integrated with extraction hoods to detect instances of poor soldering practices or inadequate fume capture at the source. There is also an expectation that AI can contribute to better process optimization by linking fume generation rates directly to specific soldering profiles or machinery settings.

The application of Artificial Intelligence (AI) and Machine Learning (ML) is moving the Solder Fume Extraction market beyond traditional passive filtration toward sophisticated, proactive air management systems. AI algorithms can process vast amounts of sensor data related to airflow volume, particulate concentration, and VOC levels to create highly optimized operational models. This capability allows extraction systems to modulate suction power based on the intensity and location of soldering activity, leading to substantial energy savings compared to constantly running systems at maximum capacity. Furthermore, AI-driven diagnostics enable system self-monitoring, flagging subtle performance degradations long before they lead to noticeable dips in air quality or system failure.

The integration of AI-powered analytics also supports regulatory documentation and audit trails. By maintaining continuous, verifiable records of environmental conditions and system performance, manufacturers can demonstrate robust compliance effortlessly. For instance, ML can analyze historical usage patterns and filter data to predict the precise remaining useful life (RUL) of different filter stages, enabling just-in-time procurement and replacement, minimizing inventory costs, and maximizing effective filtration time. This shift towards smart extraction aligns perfectly with the broader trend of Industry 4.0 adoption in the electronics manufacturing sector.

- AI-driven Predictive Maintenance: Analyzing filter usage and particulate load to forecast optimal replacement times, reducing system downtime and unnecessary maintenance costs.

- Dynamic Flow Control: Utilizing ML algorithms to adjust fan speed and extraction rate in real-time based on actual fume generation, optimizing energy consumption while ensuring safety standards are met.

- Compliance Monitoring Automation: Generating automated, verifiable compliance reports based on continuous monitoring of air quality parameters (e.g., VOC, particulate matter).

- Process Optimization: Linking fume generation data back to specific soldering station parameters (e.g., temperature, flux type) to provide insights for improving manufacturing processes and reducing source emissions.

- Fault Detection: Real-time anomaly detection in airflow or sensor readings, allowing for immediate intervention before hazardous conditions develop.

DRO & Impact Forces Of Solder Fume Extraction Market

The market dynamics are defined by stringent health and safety regulations mandating clean air environments (Drivers), the substantial initial capital investment required for centralized systems (Restraints), and the massive potential presented by the proliferation of smart electronics and Industry 4.0 integration (Opportunities). These forces collectively shape the competitive landscape and strategic direction of the Solder Fume Extraction Market. The primary impact force accelerating adoption is the global consensus on occupational safety, pushing even small-to-medium enterprises (SMEs) to invest in compliant extraction technology.

Key drivers include the global expansion of electronics manufacturing, particularly in fast-growing sectors like 5G infrastructure, IoT devices, and electric vehicle components, all requiring precise and contamination-free soldering processes. Furthermore, the mandatory transition to lead-free solders, which require higher processing temperatures and often generate higher volumes of potentially harmful flux fumes and aerosols, necessitates more robust and efficient extraction solutions. Regulatory bodies globally are tightening exposure limits for airborne contaminants, directly compelling industries to upgrade or implement new extraction systems.

Restraints primarily revolve around high procurement costs, particularly for advanced, multi-stage filtration units and sophisticated centralized systems. Operational restraints include the recurring cost of replacement filters, which can be substantial and constitute a major factor in the total cost of ownership (TCO). In smaller companies or developing regions, lack of awareness or resistance to mandated safety expenditures can also slightly impede market penetration, although regulatory enforcement is mitigating this issue over time. Opportunities lie significantly in developing energy-efficient and connected systems that appeal to modern manufacturing objectives, along with expansion into emerging markets where industrialization is accelerating.

The impact forces are predominantly positive, favoring market expansion. Regulatory pull and technological push (e.g., advanced sensor integration and variable speed drives) are strong accelerators. The critical force shaping future product development is the need for highly effective filtration of ultra-fine particles (UFPs) and specific VOCs generated by next-generation fluxes, driving innovation in filter media and system design. Environmental accountability is also becoming a critical force, pushing manufacturers to design systems that are easier to recycle and have lower energy footprints.

Segmentation Analysis

The Solder Fume Extraction Market is comprehensively segmented based on product type, operator requirement, application, and filter technology, allowing for targeted analysis of diverse end-user needs. This segmentation reveals distinct growth trajectories within the market, with high-efficiency filtration systems and those targeting multi-operator workstations showing particular momentum. Understanding these segments is vital for manufacturers positioning their products, whether they focus on the high-volume electronics assembly sector requiring complex centralized solutions or specialized repair facilities utilizing flexible benchtop units.

The segmentation by product type—benchtop, portable, and fixed (centralized)—defines the primary purchasing behaviors, heavily influenced by facility size and production throughput. Benchtop units cater to localized, lower-volume operations, while centralized systems are the backbone of large, automated production lines. Filter technology segmentation, particularly the focus on HEPA and activated carbon, reflects the need to address both particulate matter and gaseous contaminants simultaneously. The end-user segment reveals the concentration of demand, confirming that electronics manufacturing remains the largest, but sectors like aerospace and medical devices drive demand for the highest precision and regulatory compliance standards.

- By Product Type:

- Benchtop Fume Extractors

- Portable Fume Extractors

- Fixed/Centralized Fume Extraction Systems

- By Operator Requirement:

- Single Operator Systems

- Multi-Operator Systems

- By Filter Technology:

- HEPA Filters (High-Efficiency Particulate Air)

- Activated Carbon Filters

- Combined/Multi-Stage Filtration Systems

- By Application/End-User:

- Electronics Manufacturing (PCB Assembly, Semiconductor)

- Automotive Electronics

- Aerospace and Defense

- Medical Device Manufacturing

- Repair and Rework Stations

- Jewelry and Hobbyist Applications

Value Chain Analysis For Solder Fume Extraction Market

The value chain for the Solder Fume Extraction Market begins with upstream activities involving the sourcing of raw materials, particularly metals for housing, advanced polymers, fan and motor components, and specialized filter media such as borosilicate fibers for HEPA and high-grade activated carbon. Key challenges in the upstream sector include maintaining a stable supply of high-purity filter materials and managing volatile metal prices. Suppliers of high-quality sensor technology and variable speed drives are also critical, particularly for smart extraction systems. Manufacturers focus on R&D for aerodynamics, filtration efficiency, and noise reduction, translating these raw components into finished extraction units—benchtop, portable, and centralized systems.

The downstream activities involve distribution, marketing, installation, and post-sales servicing. Distribution channels are typically a mix of direct sales to large corporations and original equipment manufacturers (OEMs), and indirect sales through specialized industrial safety distributors and electronics equipment resellers. Specialized distributors often provide value-added services such as system sizing, installation oversight, and training, which are essential due to the technical nature of centralized systems. Indirect channels dominate the distribution of portable and benchtop units, leveraging broad market reach and established logistics networks.

Direct engagement is crucial for customized centralized installations in major automotive or aerospace facilities, ensuring tailored solutions meet strict regulatory requirements. Indirect channels, including e-commerce platforms and local safety equipment vendors, are increasingly important for reaching smaller repair shops and educational institutions. The service phase, encompassing routine maintenance, filter replacement contracts, and system validation, represents a significant and stable revenue stream for both the manufacturers and specialized service providers, cementing the long-term relationship with end-users and ensuring optimal system performance throughout the equipment lifecycle.

Solder Fume Extraction Market Potential Customers

The primary consumers (End-Users/Buyers) of solder fume extraction equipment are concentrated within the high-technology and precision manufacturing sectors where soldering is a mandatory process for connectivity and component attachment. The largest single customer segment is the electronics manufacturing industry, including global Contract Manufacturing (CMs) and Electronic Manufacturing Services (EMS) providers responsible for producing consumer electronics, computing hardware, and networking equipment. These entities require high-throughput, centralized systems capable of servicing vast assembly lines, complemented by smaller units for rework and specialized stations.

Beyond traditional electronics, significant potential lies within specialized industries that operate under extremely high quality and safety standards. Automotive electronics manufacturers, particularly those focusing on power electronics for EVs and ADAS modules, are mandatory buyers due to stringent quality control requirements and high production volumes. Similarly, the aerospace and defense sector represents a key customer base, demanding systems that can meet military-grade specifications for air purity and reliability, often preferring customized, fixed installations with robust validation protocols.

Secondary, yet rapidly expanding, customer segments include medical device manufacturers, where clean room environments and avoidance of contamination are paramount, and vocational training centers or technical schools that need to comply with educational safety mandates. Rework and repair service providers, ranging from authorized repair centers to independent shops, rely heavily on flexible, high-performance benchtop and portable extractors to manage lower volume, high-variability soldering tasks while protecting technicians.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450.5 Million |

| Market Forecast in 2033 | USD 718.9 Million |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Weller, Hakko, PACE, BOFA International, Purex International, Metcal, Quatro-Air Technologies, Absolent Group, Kemper GmbH, Filtermist International, Donaldson Company, Fumex, ULT AG, TBH GmbH, Hon&Guan, JBC Tools, Air Cleaning Specialists, Clean Air Solutions, Nederman Holding, Lincoln Electric. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Solder Fume Extraction Market Key Technology Landscape

The Solder Fume Extraction market is characterized by continuous technological refinement focused on increasing filtration efficiency, enhancing energy usage, and improving system connectivity. The core technology revolves around multi-stage filtration, typically involving a sequence starting with coarse pre-filters to capture larger particles, progressing to high-efficiency particulate filters (HEPA or ULPA) capable of capturing 99.97% or more of particles down to 0.3 microns, and concluding with chemical filters, predominantly based on high-surface-area activated carbon or specialized treated media, to neutralize gases and Volatile Organic Compounds (VOCs).

Recent advancements are heavily focused on smart system integration, aligning with Industry 4.0 paradigms. This includes the incorporation of Internet of Things (IoT) sensors for real-time monitoring of filter status (e.g., pressure drop across the filter media), airflow velocity, and ambient air quality. These connected features allow for proactive maintenance alerts and remote diagnostics, moving away from time-based maintenance schedules toward condition-based servicing. Furthermore, brushless motors and variable frequency drives (VFDs) are becoming standard, enabling dynamic adjustment of fan speed, which significantly reduces energy consumption while maintaining the required capture velocity.

Another crucial technological development is the improvement in capture methodologies. Manufacturers are developing more ergonomically designed fume extraction nozzles and arms that optimize source capture efficiency, minimizing the risk of fumes escaping into the operator's breathing zone. Specialized filter media are also emerging to handle the unique chemical signatures of increasingly complex, flux-heavy lead-free soldering pastes, ensuring complete neutralization of potentially carcinogenic aldehydes and other noxious gases generated during high-temperature processing.

Regional Highlights

- Asia Pacific (APAC): Dominates the global market volume due to the concentration of the global electronics supply chain, including major PCB assembly, semiconductor fabrication, and consumer electronics manufacturing centers in China, Taiwan, South Korea, and Southeast Asia. Regulatory environments, particularly in emerging economies, are steadily becoming stricter, accelerating the adoption of professional-grade extraction systems beyond mandatory requirements. High investment in 5G infrastructure and EV manufacturing further solidifies APAC's leading position.

- North America: Characterized by a high adoption rate of advanced, centralized extraction systems and a strong focus on compliance with stringent OSHA standards. The market here is value-driven, favoring premium brands offering IoT integration, predictive maintenance features, and robust validation documentation, particularly within the aerospace, defense, and high-reliability medical device sectors.

- Europe: A mature market driven by rigorous regulatory standards set by bodies such as the European Agency for Safety and Health at Work (EU-OSHA). Western Europe sees high demand for energy-efficient, environmentally friendly systems (AEO optimization focus), emphasizing low noise levels and sustainable filter disposal. Germany and the UK are key markets, heavily influenced by automotive and industrial electronics sectors.

- Latin America: An emerging market showing steady growth, primarily focused on localized or benchtop units for electronics repair and smaller assembly operations. Market growth is spurred by increasing foreign investment in regional manufacturing hubs (e.g., Mexico and Brazil) and the subsequent requirement to adhere to international safety standards.

- Middle East and Africa (MEA): Currently represents the smallest market share, but growth is notable in regions like the UAE and Saudi Arabia, driven by diversification efforts into high-tech manufacturing, defense electronics, and local assembly operations that necessitate baseline safety infrastructure.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Solder Fume Extraction Market.- Weller

- Hakko Corporation

- PACE Worldwide

- BOFA International

- Purex International Ltd.

- Metcal (OK International)

- Quatro-Air Technologies Inc.

- Absolent Group AB

- Kemper GmbH

- Filtermist International Limited

- Donaldson Company, Inc.

- Fumex, Inc.

- ULT AG

- TBH GmbH

- Hon&Guan

- JBC Tools

- Air Cleaning Specialists, Inc.

- Clean Air Solutions

- Nederman Holding AB

- Lincoln Electric (Clear-Pak Division)

Frequently Asked Questions

Analyze common user questions about the Solder Fume Extraction market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary regulatory standards governing solder fume extraction?

The Solder Fume Extraction Market is largely governed by Occupational Safety and Health Administration (OSHA) standards in the US, COSHH (Control of Substances Hazardous to Health) regulations in the UK and similar EU directives, and national health and safety mandates across APAC. These standards define permissible exposure limits (PELs) for airborne contaminants, necessitating high-efficiency filtration systems.

How do lead-free solders affect fume extraction requirements?

Lead-free solders require higher processing temperatures, which typically result in greater volatilization of flux components and generate finer particulate matter. This mandates the use of more robust extraction systems with superior thermal resistance, higher airflow capacity, and advanced multi-stage filtration, specifically including activated carbon to handle increased VOC load.

What is the difference between benchtop, portable, and centralized extraction systems?

Benchtop units are small, localized extractors designed for 1-2 operators directly at the source. Portable units offer flexibility to be moved between workstations. Centralized (Fixed) systems are large, ducted installations designed to service entire production lines, offering high capacity and integrating into facility HVAC systems, suitable for high-volume manufacturing.

What factors determine the total cost of ownership (TCO) for a fume extraction unit?

TCO is determined by three main factors: the initial capital expenditure (purchase price), energy consumption (operating costs, influenced by motor efficiency and duty cycle), and, most significantly, the recurring cost and frequency of replacement filters. Advanced systems often have a higher initial cost but lower long-term filter and energy expenses due to efficiency gains.

How is Industry 4.0 technology influencing modern fume extraction equipment?

Industry 4.0 integration involves incorporating IoT sensors and AI-driven monitoring into extraction systems. This allows for real-time filter status checks, predictive maintenance scheduling, automated data logging for compliance audits, and dynamic adjustment of fan speed for energy optimization, enhancing both safety and operational efficiency.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager