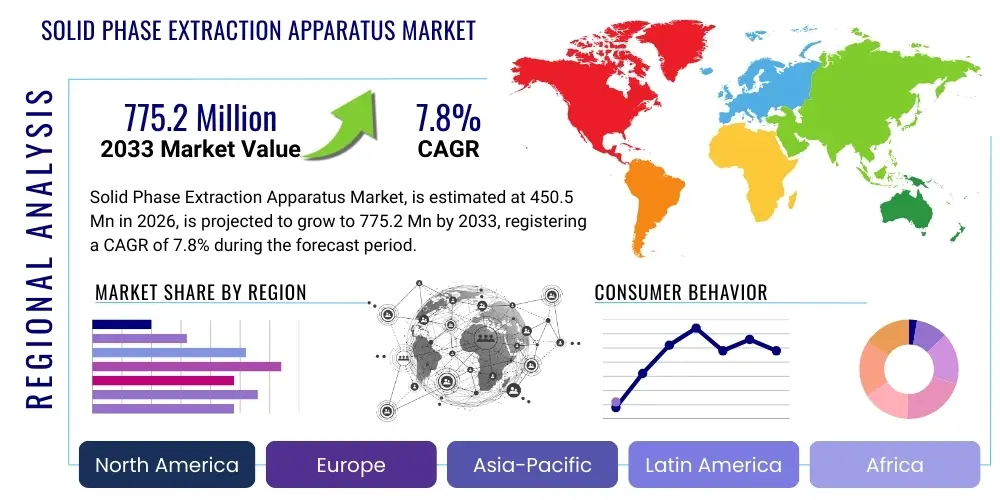

Solid Phase Extraction Apparatus Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 442536 | Date : Feb, 2026 | Pages : 258 | Region : Global | Publisher : MRU

Solid Phase Extraction Apparatus Market Size

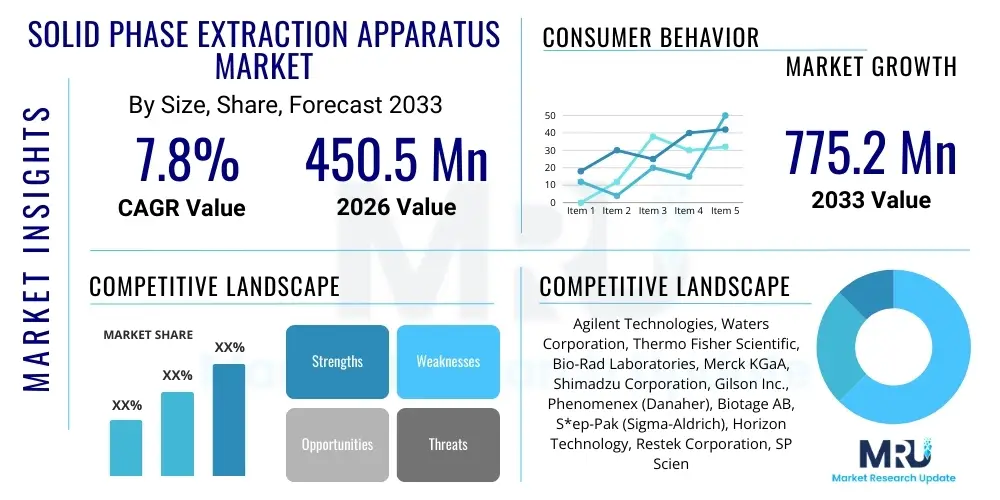

The Solid Phase Extraction Apparatus Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.8% between 2026 and 2033. The market is estimated at USD 450.5 Million in 2026 and is projected to reach USD 775.2 Million by the end of the forecast period in 2033. This growth trajectory is fundamentally driven by the escalating demand for highly sensitive and selective sample preparation techniques across critical analytical disciplines, including pharmaceutical drug discovery, environmental monitoring, and clinical toxicology.

Solid Phase Extraction Apparatus Market introduction

The Solid Phase Extraction (SPE) Apparatus Market encompasses a range of instrumentation and related consumables designed to prepare liquid samples for subsequent high-performance analytical techniques, such as High-Performance Liquid Chromatography (HPLC) or Gas Chromatography (GC)-Mass Spectrometry (MS). SPE is a critical preparatory step used to concentrate trace analytes, isolate specific compounds, and remove interfering matrix components from complex samples. Product offerings span from basic vacuum manifolds, which enable manual processing of individual SPE cartridges, to sophisticated, fully automated SPE workstations capable of processing dozens of samples simultaneously with high precision and minimal human intervention.

Major applications for SPE apparatus are concentrated heavily within regulated sectors. In the pharmaceutical industry, SPE is indispensable for bioanalysis, enabling the extraction of drug metabolites from biological fluids for pharmacokinetic studies, and ensuring quality control by purifying Active Pharmaceutical Ingredients (APIs). Environmental laboratories utilize SPE extensively for water quality testing, pesticide residue analysis, and emerging contaminant detection (e.g., PFAS), where samples often require massive concentration factors. Furthermore, clinical laboratories rely on SPE for therapeutic drug monitoring and forensic toxicology, demanding reliability and high throughput to handle large volumes of patient or evidence samples.

The primary benefits of utilizing modern SPE systems include superior sample cleanliness, which significantly extends the lifespan of expensive analytical columns, enhances detector sensitivity, and minimizes system downtime caused by matrix fouling. Key driving factors underpinning market expansion include stringent global regulatory standards demanding lower detection limits for contaminants, the increasing complexity of sample matrices (particularly in clinical and food safety testing), and the shift towards fully automated workflow solutions that improve laboratory efficiency, reproducibility, and compliance with Good Laboratory Practice (GLP) standards.

Solid Phase Extraction Apparatus Market Executive Summary

The Solid Phase Extraction Apparatus Market demonstrates robust growth, propelled primarily by technological advancements facilitating higher throughput and greater automation in sample preparation. Business trends indicate a strong industry preference for online SPE systems integrated directly with chromatographic equipment, reducing manual steps and improving analytical precision. Key manufacturers are focusing on developing novel sorbent chemistries, particularly specialized phases like mixed-mode and restricted-access media (RAM), to handle increasingly challenging biological and environmental matrices. Additionally, there is a pronounced trend toward miniaturization, utilizing micro-SPE and tip-based systems, which conserve valuable sample volume and reduce solvent consumption, aligning with green chemistry initiatives and lowering operational costs across industrial and academic research settings.

Regionally, North America and Europe currently dominate the market due to their mature pharmaceutical and biotechnology sectors, coupled with stringent environmental regulations necessitating consistent and advanced sample preparation. However, the Asia Pacific (APAC) region is projected to register the fastest growth rate, fueled by substantial investments in public health infrastructure, the rapid establishment of pharmaceutical manufacturing hubs in countries like China and India, and increasing governmental focus on food safety monitoring and pollution control. Latin America and the Middle East & Africa (MEA) are emerging as significant opportunity areas, primarily driven by international aid for disease monitoring and the modernization of governmental research laboratories.

Segment trends reveal that the Automated SPE Systems segment is experiencing the highest revenue growth, reflecting the industry-wide move away from labor-intensive manual methods toward high-throughput, reproducible solutions necessary for large-scale bioanalytical and clinical applications. By application, the pharmaceutical and biotechnology segment maintains the largest market share, driven by complex drug metabolism studies and quality assurance requirements. Conversely, the environmental testing application segment is witnessing accelerating demand due to rising concerns over microplastics, pharmaceutical waste in water bodies, and complex contaminant analysis requiring highly selective SPE methods for robust matrix cleanup before sensitive mass spectrometry analysis.

AI Impact Analysis on Solid Phase Extraction Apparatus Market

User queries regarding AI's influence on the SPE apparatus market often revolve around efficiency gains, predictive method development, and quality control automation. Users frequently ask: "Can AI optimize SPE parameters automatically?", "How does machine learning improve reproducibility?", and "Will smart systems predict column failure or matrix interference?" These common questions highlight user expectations concerning AI's capability to transform SPE from a largely empirical and iterative process into a data-driven, predictive workflow. Users anticipate AI integrating complex data generated during method optimization—such as solvent compatibility, flow rates, and sorbent selection—to arrive at validated, robust SPE protocols faster than traditional trial-and-error approaches, minimizing both development time and reagent waste, while also seeking AI-driven diagnostics to ensure instrument uptime.

The practical application of Artificial Intelligence and Machine Learning (ML) in the Solid Phase Extraction domain is focused predominantly on optimizing the entire sample preparation workflow. AI algorithms can process vast datasets related to compound properties (log P, pKa), sample matrix complexity, and historical extraction efficiencies to rapidly suggest optimal sorbent chemistry and elution parameters. This drastically reduces the time and cost associated with method development, a notoriously bottlenecked step in analytical chemistry. Furthermore, integrated AI platforms monitor real-time pressure, flow rate, and historical performance metrics of the SPE system components, enabling predictive maintenance schedules, automated troubleshooting, and proactive warning systems for potential system failures or inconsistencies.

By leveraging computational power, AI enhances the quality and reliability of sample preparation, which directly impacts the accuracy of subsequent quantitative analyses. Machine learning models can be trained to recognize patterns associated with matrix effects or poor recovery, suggesting dynamic adjustments during the extraction process itself. This level of smart automation ensures higher consistency across batches, meeting the stringent reproducibility requirements of regulated environments like clinical diagnostics and pharmaceutical Good Manufacturing Practice (GMP). Ultimately, AI integration transforms SPE apparatus from simple hardware into intelligent, self-optimizing sample handlers, significantly lowering the skill barrier for laboratory technicians and maximizing laboratory efficiency.

- AI optimizes sorbent selection and elution conditions based on analyte physicochemical properties and sample matrix composition.

- Machine learning facilitates predictive method development, reducing empirical optimization cycles and accelerating time-to-result validation.

- Integrated algorithms enable real-time monitoring of system pressure and flow, supporting predictive maintenance and minimizing operational downtime.

- AI enhances quality control by automatically detecting and correcting anomalies related to extraction inconsistency or matrix effects.

- Smart automation improves reproducibility across different operators and instruments, crucial for regulatory compliance (e.g., FDA/EMA submissions).

DRO & Impact Forces Of Solid Phase Extraction Apparatus Market

The Solid Phase Extraction Apparatus Market is shaped by a confluence of accelerating drivers (D), persistent restraints (R), emerging opportunities (O), and significant impact forces derived from these elements. Key drivers include the global expansion of pharmaceutical research activities, the introduction of increasingly complex drug molecules requiring advanced cleanup, and rising public and regulatory demands for ultra-trace analysis in food and environmental safety, pushing detection limits lower. Restraints largely center on the high initial capital investment required for fully automated SPE workstations, the dependency on consumables (cartridges/plates), and the necessity for skilled personnel to develop and validate complex extraction methods tailored to specific matrices. Opportunities lie in the proliferation of miniaturized SPE formats (e.g., Sorbent-Tip SPE, micro-elution plates), expanding applications in forensic and clinical toxicology, and geographical expansion into burgeoning APAC and LATAM markets where laboratory modernization is a priority.

The primary impact force driving current market dynamics is the unyielding pressure for laboratory efficiency and high-throughput analysis. As the volume of samples processed globally increases, particularly in contract research organizations (CROs) and large-scale diagnostic labs, manual SPE techniques become unsustainable. This compels laboratories to invest in automated SPE systems (a driver), despite the high initial cost (a restraint), leading to a strategic market push towards vendors offering fully integrated, walk-away solutions. This force disproportionately benefits manufacturers specializing in robotics and high-density 96-well plate formats, optimizing workflow and labor utilization.

A secondary, yet potent, impact force stems from evolving regulatory scrutiny, particularly concerning environmental contamination (e.g., trace pharmaceuticals, pesticides, and industrial chemicals like PFAS). These regulations mandate methodologies that can reliably achieve extremely low limits of quantification (LOQ) in complex matrices such as wastewater, soil extracts, or food products. This necessity elevates the demand for advanced SPE sorbents (mixed-mode, polymeric) and automated apparatus that minimize cross-contamination and ensure maximum analyte recovery, validating the investment in sophisticated sample preparation tools as a cost of regulatory compliance rather than an optional enhancement.

Segmentation Analysis

The Solid Phase Extraction Apparatus market is systematically segmented based on Product Type, Consumables Type, Application, and End-User, providing a granular view of market dynamics and adoption trends. Product segmentation differentiates between manual systems, which remain popular in low-throughput or academic settings due to their simplicity and low cost, and highly automated systems, which dominate high-throughput regulated industries. Consumables segmentation is crucial as it represents the recurring revenue stream for manufacturers, focusing on material types like silica-based, polymeric, and specialty sorbents (e.g., ion exchange, immunoaffinity). Application segmentation highlights the dominance of pharmaceuticals and environmental testing, while End-User segmentation provides insight into purchasing power and laboratory requirements across CROs, academic research institutions, and governmental agencies. This comprehensive segmentation allows market participants to tailor their innovation and marketing strategies to specific, high-growth niches within the overall analytical workflow landscape.

- By Product Type:

- Automated SPE Systems (Online and Offline)

- Vacuum Manifolds and Accessories

- Positive Pressure Manifolds

- Gravity-Flow SPE Systems

- By Consumables Type:

- SPE Cartridges (Silica-based, Polymeric, Mixed-mode, Ion Exchange)

- SPE Plates (96-well and 48-well format)

- Dispersive SPE (QuEChERS)

- SPE Tips (Micro-SPE)

- By Application:

- Pharmaceutical and Biotechnology (Drug Discovery, Bioanalysis, QC)

- Environmental Testing (Water, Soil, Air Analysis)

- Food and Beverage Analysis (Pesticide Residue, Toxin Screening)

- Clinical and Forensic Toxicology

- Chemical and Petrochemical Analysis

- By End-User:

- Contract Research Organizations (CROs)

- Pharmaceutical and Biotechnology Companies

- Academic and Research Institutions

- Governmental and Environmental Agencies

- Hospitals and Clinical Laboratories

Value Chain Analysis For Solid Phase Extraction Apparatus Market

The value chain for the Solid Phase Extraction Apparatus market begins with upstream activities involving the sourcing of highly specialized raw materials, primarily high-purity silica gels, specific polymers (like polystyrenedivinylbenzene or specialized methacrylate), and sophisticated plastics for housing cartridges and plates. Suppliers in this segment must meet stringent quality control standards to ensure batch-to-batch consistency in sorbent particle size and pore structure, which is vital for reproducible extraction performance. Manufacturers of SPE apparatus then focus on R&D, designing robust mechanical systems (for automated platforms) and implementing advanced bonding chemistry for the sorbent materials. Intellectual property related to novel sorbent chemistries represents a significant competitive advantage in this upstream phase.

The distribution channel plays a critical role in moving finished products to end-users globally. This involves a mix of direct and indirect channels. Direct sales are typically employed for high-value automated SPE systems and large volume contracts with major pharmaceutical companies or high-throughput CROs, where installation, validation (IQ/OQ/PQ), and technical support are paramount. Indirect channels, utilizing specialized analytical and laboratory equipment distributors, are common for standard cartridges, vacuum manifolds, and accessory sales, providing broad geographical reach and local inventory management, particularly in smaller markets or emerging economies.

Downstream activities center on the end-user’s integration of the SPE apparatus into their complex analytical workflows. This requires ongoing support, application method development assistance, and training provided by the manufacturers or distributors. The final stage involves the post-sale lifecycle management, including maintenance contracts for automated systems and the recurrent sale of high-volume consumables. The efficiency of the downstream support directly impacts customer loyalty and repeat business, particularly given the specialized nature of analytical chemistry and the high cost associated with system downtime in regulated laboratory environments.

Solid Phase Extraction Apparatus Market Potential Customers

The primary customers for Solid Phase Extraction Apparatus are organizations and entities operating highly regulated or research-intensive analytical laboratories that require reliable, high-purity sample preparation before final analysis. Contract Research Organizations (CROs) constitute a major consumer base, particularly those focusing on bioanalysis for pharmacokinetic and toxicological studies, where the massive throughput of biological samples necessitates fully automated SPE systems to ensure speed and regulatory compliance. Pharmaceutical and biotechnology companies, specifically within their drug metabolism and quality control departments, are also core buyers, relying on SPE for purifying active ingredients and isolating metabolites from complex matrices.

Governmental and environmental agencies, including EPA laboratories and national food safety organizations, represent another critical segment. These agencies frequently analyze vast numbers of environmental water, soil, and food samples for trace contaminants, requiring robust, validated SPE methods capable of achieving ultra-low detection limits. The increasing stringency of global environmental and food safety standards continuously drives the need for more sophisticated and efficient SPE technology in this sector. Furthermore, clinical laboratories involved in therapeutic drug monitoring, newborn screening, and forensic toxicology units rely heavily on SPE to clean up complex human fluid samples, where precision and rapid turnaround time are crucial.

Academic and institutional research laboratories also constitute significant, albeit budget-sensitive, customers. While they may utilize more manual or semi-automated systems for smaller research projects, their continuous exploration into novel biomarkers, metabolomics, and new analytical methodologies provides an important avenue for adopting specialized SPE chemistries and new apparatus formats, such as micro-SPE and automated benchtop units, often supported by research grants and institutional modernization initiatives.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450.5 Million |

| Market Forecast in 2033 | USD 775.2 Million |

| Growth Rate | 7.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Agilent Technologies, Waters Corporation, Thermo Fisher Scientific, Bio-Rad Laboratories, Merck KGaA, Shimadzu Corporation, Gilson Inc., Phenomenex (Danaher), Biotage AB, S*ep-Pak (Sigma-Aldrich), Horizon Technology, Restek Corporation, SP Scientific, Tecan Group, Hamilton Company, PerkinElmer Inc., ANKOM Technology, Tosoh Bioscience, Orochem Technologies, CEM Corporation. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Solid Phase Extraction Apparatus Market Key Technology Landscape

The technology landscape within the Solid Phase Extraction Apparatus market is characterized by a strong focus on automation, integration, and the refinement of sorbent chemistry to tackle increasingly challenging separation problems. Automated SPE systems currently represent the technological vanguard, moving beyond simple liquid handling robotics to incorporate sophisticated pressure control, precise solvent dispensing, and seamless integration with analytical instrumentation, creating "online SPE-LC/MS" systems. This integration minimizes sample handling errors, eliminates transfer steps, and enables faster analysis times, crucial for high-throughput environments like pharmaceutical bioanalysis. Key technological trends include the development of positive pressure manifolds, which offer more consistent flow rates compared to traditional vacuum manifolds, leading to improved method reproducibility and recovery rates, especially for viscous samples.

A significant area of innovation involves miniaturization and alternative extraction techniques. Micro-SPE (µSPE) and SPE pipette tips (e.g., C18 functionalized tips) are gaining traction as they require minute sample volumes and significantly reduce solvent consumption, aligning with principles of green chemistry and catering to applications where sample availability is limited, such as neonatal screening or single-cell analysis. Furthermore, the prominence of QuEChERS (Quick, Easy, Cheap, Effective, Rugged, Safe) for food and agricultural residue analysis has led to the development of specialized dispersive SPE accessories and methods that enhance the cleanup phase specific to these matrices, offering a faster and simpler alternative to traditional column SPE for certain applications.

Sorbent technology remains the core driver of separation efficiency. Manufacturers are continuously introducing novel sorbent materials, including highly selective restricted-access media (RAM) designed to filter out proteins while allowing small analytes to pass, which is essential for direct injection of biological fluids. Mixed-mode sorbents, which utilize both hydrophobic (reversed-phase) and ionic (ion-exchange) retention mechanisms simultaneously, are becoming standard for complex extractions, providing unparalleled selectivity and the ability to isolate analytes from highly contaminated or complex matrices in a single, streamlined step. The competition is intensely focused on proprietary sorbent formulations that offer superior stability, higher capacity, and better water wettability characteristics.

Regional Highlights

- North America: This region holds the largest market share, driven by a well-established and highly sophisticated pharmaceutical and biotechnology industry, coupled with stringent regulatory frameworks established by the FDA and EPA. The U.S. is the epicenter of innovation, characterized by high adoption rates of fully automated SPE systems and integrated online solutions in Contract Research Organizations (CROs) for bioanalysis and drug metabolism studies. Robust governmental spending on advanced environmental monitoring and forensic toxicology further solidifies the demand for high-end SPE apparatus and specialized consumables. The maturity of the academic research ecosystem also ensures sustained technological uptake.

- Europe: The European market is the second largest, characterized by high quality standards and demanding environmental directives (e.g., REACH, Water Framework Directive), which necessitate the deployment of reliable and efficient SPE technology for compliance testing. Countries such as Germany, the UK, and Switzerland house major analytical instrument manufacturers and pharmaceutical firms, driving innovation and early adoption. The region is seeing a rapid shift towards green chemistry principles, accelerating the adoption of miniaturized SPE techniques that reduce solvent consumption and waste generation, making µSPE and automated high-efficiency platforms particularly attractive.

- Asia Pacific (APAC): APAC is projected to be the fastest-growing region, primarily due to expanding healthcare infrastructure, rising industrial pollution requiring intensive environmental monitoring, and significant foreign direct investment into the pharmaceutical and clinical sectors of China and India. Government initiatives focused on modernizing analytical laboratories and enhancing food safety standards are major market accelerators. While initial adoption often leans towards cost-effective manual manifolds, the increasing volume of samples handled by newly established CROs and modernized public health labs is rapidly shifting demand toward semi-automated and automated platforms, especially in high-volume testing centers.

- Latin America: This region presents significant growth potential, although hampered by diverse economic conditions. Brazil and Mexico are the largest contributors, driven by growing pharmaceutical production, local regulatory requirements for product quality, and the necessity to manage complex agricultural and environmental samples. Market growth is largely dependent on the availability of affordable, robust instrumentation and robust local distribution and service networks, often preferring systems that offer a balance between automation capabilities and operational cost efficiency.

- Middle East and Africa (MEA): Growth in MEA is primarily localized in the GCC countries (Saudi Arabia, UAE) and South Africa, driven by increased investment in petrochemical analysis, water treatment facilities, and clinical diagnostics modernization. The demand is often project-based, linked to large-scale governmental or industrial modernization projects. The market requires high-durability apparatus capable of handling demanding matrices, such as heavily saline water or complex crude oil extracts, making specialized sorbent chemistries essential for reliable operation in challenging environments.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Solid Phase Extraction Apparatus Market.- Agilent Technologies

- Waters Corporation

- Thermo Fisher Scientific

- Biotage AB

- Merck KGaA

- Bio-Rad Laboratories

- Shimadzu Corporation

- Gilson Inc.

- Phenomenex (Danaher)

- Restek Corporation

- Horizon Technology

- SP Scientific

- Tecan Group

- Hamilton Company

- PerkinElmer Inc.

- Orochem Technologies

- S*ep-Pak (Sigma-Aldrich)

- ANTHUS Corporation

- CEM Corporation

- Tosoh Bioscience

Frequently Asked Questions

Analyze common user questions about the Solid Phase Extraction Apparatus market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the key advantage of automated Solid Phase Extraction (SPE) systems over manual methods?

Automated SPE systems significantly enhance laboratory efficiency, offering superior sample-to-sample reproducibility, minimized risk of human error, and the capability to handle high sample throughput (e.g., 96-well plate format) required for pharmacokinetic studies and large-scale regulatory monitoring, thereby ensuring better data quality and compliance.

How are changing regulatory standards impacting the demand for SPE apparatus?

Stricter regulations, particularly in environmental and food safety sectors (e.g., lower limits for PFAS or pesticide residues), necessitate sample preparation techniques that achieve high concentration factors and excellent matrix cleanup. This drives demand for advanced, highly selective SPE sorbents and reliable, validated automated apparatus that can consistently meet required low detection limits (LODs) and quantification limits (LOQs).

Which application segment holds the largest market share for SPE apparatus?

The Pharmaceutical and Biotechnology application segment dominates the market share. SPE is indispensable in this sector for bioanalysis, drug metabolism studies, and quality control (QC) testing of both drug substances and finished products, requiring robust, high-throughput extraction methods for complex biological matrices and purified compounds.

What are the primary factors restraining the growth of the automated SPE market?

The main restraining factors include the high initial capital investment required for purchasing sophisticated, fully automated workstations and the ongoing need for highly skilled technical personnel capable of developing, validating, and maintaining complex extraction methods specific to new analytes and sample matrices.

What recent technological advancements are prominent in SPE consumables?

Key advancements include the proliferation of mixed-mode sorbents, which combine multiple retention mechanisms for enhanced selectivity, and the increased adoption of micro-SPE (µSPE) or pipette tip SPE formats, which drastically reduce solvent usage and enable efficient analysis of minimal sample volumes, aligning with green chemistry principles.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Solid Phase Extraction Apparatus Market Statistics 2025 Analysis By Application (Pharma, Academia, Hospital & Clinical, Environmental), By Type (Small Volume, Large Volume), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Solid Phase Extraction Apparatus Market Size, Share, Trends, & Covid-19 Impact Analysis By Type (Large Volume Solid Phase Extraction Apparatus, Small Volume Solid Phase Extraction Apparatus, Others), By Application (Hospital & Clinical, Academia, Pharma), By Region - North America, Latin America, Europe, Asia Pacific, Middle East, and Africa | In-depth Analysis of all factors and Forecast 2023-2030

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager