Sport Goods Zipper Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 443258 | Date : Feb, 2026 | Pages : 246 | Region : Global | Publisher : MRU

Sport Goods Zipper Market Size

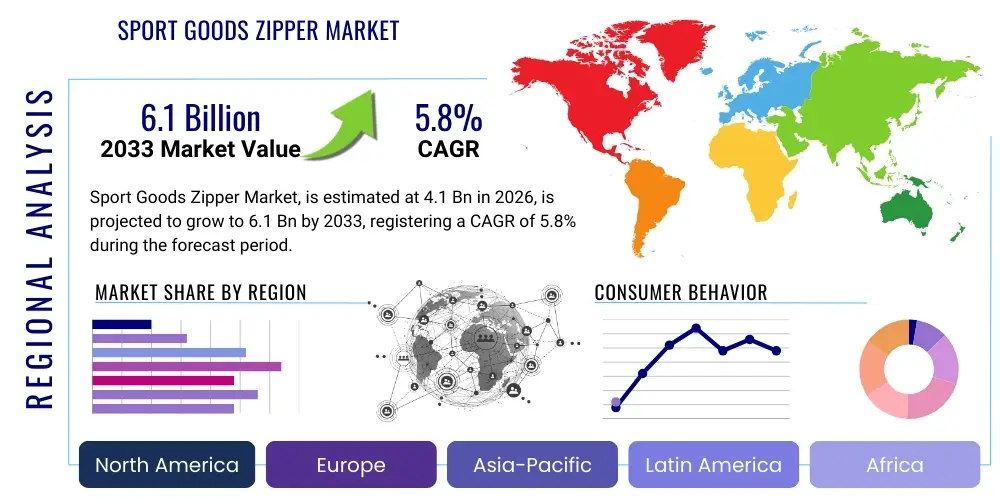

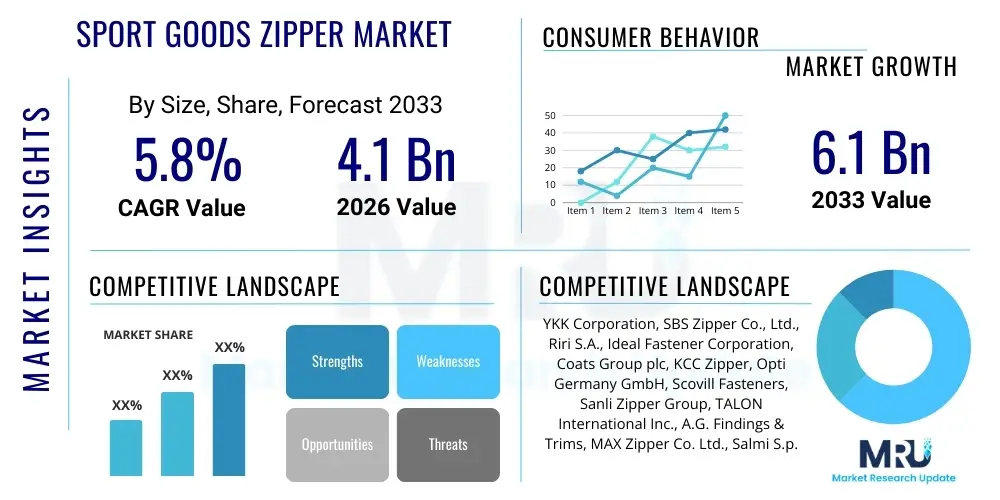

The Sport Goods Zipper Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 4.1 Billion in 2026 and is projected to reach USD 6.1 Billion by the end of the forecast period in 2033.

Sport Goods Zipper Market introduction

The Sport Goods Zipper Market encompasses the specialized segment of fastener solutions designed and manufactured explicitly for athletic apparel, outdoor gear, footwear, and equipment such as tents, bags, and protective padding. These zippers are distinct from general-purpose fasteners due to stringent requirements regarding durability, weather resistance, weight optimization, ergonomic operation, and aesthetic integration with high-performance fabrics. Key product categories include plastic coil zippers, metal zippers (often brass or aluminum for heavy-duty applications), and specialized waterproof or water-repellent zippers, which are essential for snow sports and marine activities. The fundamental driving force for market growth is the sustained global increase in consumer participation in recreational and professional sports, coupled with technological advancements in textile materials that necessitate equally advanced fastening solutions.

Major applications for sport goods zippers span across high-end technical outerwear, including skiing jackets and climbing gear, requiring high-abrasion resistance and secure closure against extreme elements, to everyday athletic wear like tracksuits and training bags, prioritizing smooth operation and lightweight construction. The increasing globalization of major sporting events and the subsequent focus on premium performance apparel further solidifies the demand. Furthermore, the rising awareness among athletes regarding the importance of specialized features such as self-locking mechanisms, anti-snag designs, and enhanced puller ergonomics contributes significantly to market maturation.

The primary benefits derived from specialized sport goods zippers include improved garment functionality, extended product lifespan under rigorous use, enhanced comfort for the end-user due to lightweight and flexible designs, and compliance with specific safety and regulatory standards pertinent to protective sporting equipment. Driving factors for the market include rapid urbanization leading to increased investment in fitness infrastructure, the burgeoning adventure tourism sector, and persistent innovation by leading apparel brands focused on differentiating their products through superior component quality and sustainability credentials, such as recycled plastic zippers.

Sport Goods Zipper Market Executive Summary

The Sport Goods Zipper Market is characterized by robust growth stemming from dynamic business trends centered on material innovation and supply chain resilience. Key business trends involve the shift toward sustainable and recycled zipper materials (e.g., zippers made from post-consumer plastic bottles) driven by corporate Environmental, Social, and Governance (ESG) mandates and strong consumer preference for eco-friendly products, particularly in North American and European markets. Furthermore, major zipper manufacturers are strategically partnering with top-tier sports apparel and footwear brands early in the design cycle to co-develop customized, highly technical fastening solutions, thereby securing long-term contracts and strengthening market positioning. This emphasis on customization and performance engineering is boosting Average Selling Prices (ASPs) for specialized sport zippers.

Regionally, the Asia Pacific (APAC) continues to dominate both in terms of manufacturing capacity and consumption growth, powered by expanding domestic markets in China and India, coupled with the region's established role as the global hub for textile and garment production. North America and Europe remain critical markets, distinguished by high adoption rates of premium, technical, and aesthetically sophisticated zippers used in high-value outdoor and performance wear. Regional trends also highlight infrastructure improvements in emerging markets, increasing disposable income, and rising participation in fitness and sports activities, which collectively drive volume growth, particularly for mid-range and budget sporting goods categories.

In terms of segmentation trends, the Nylon/Plastic Coil Zipper segment maintains the largest market share due to its versatility, low cost, and suitability for a wide range of apparel and bags, particularly where weight reduction is prioritized. However, the specialized Waterproof Zipper segment is exhibiting the highest Compound Annual Growth Rate (CAGR), reflecting the increasing demand for high-performance outdoor and marine sporting apparel capable of withstanding extreme environmental conditions. The end-user segments, particularly the Outerwear and Equipment/Bags segments, are experiencing significant expansion, driven by continuous innovation in design and functionality demanded by professional athletes and serious recreational users. These trends underscore a dual market structure: high-volume, cost-sensitive demand for general goods, and high-value, performance-driven demand for technical applications.

AI Impact Analysis on Sport Goods Zipper Market

User queries regarding the impact of Artificial Intelligence (AI) on the Sport Goods Zipper Market commonly revolve around themes of manufacturing efficiency, predictive demand forecasting, personalized product design, and supply chain optimization. Users are particularly interested in how AI can streamline complex production processes, such as automating quality control checks for microscopic tolerances in waterproof zippers or predicting specific color and size demands based on fashion trends and regional sporting participation data. Key concerns center on the investment cost required for implementing AI-driven machinery and the potential displacement of skilled labor in traditional manufacturing environments. Expectations are high regarding AI's capability to enhance precision in material usage, minimize waste, and accelerate the development cycle of novel zipper concepts, ultimately driving down costs while improving product reliability and customization for major apparel brands.

- Predictive Demand Forecasting: AI algorithms analyze historical sales data, regional sports participation rates, and social media trends to accurately predict future demand for specific zipper types (e.g., color, length, material) months in advance, optimizing inventory and reducing stockouts.

- Automated Quality Control (AQC): High-speed cameras and machine vision systems, powered by AI, detect minute flaws in zipper teeth alignment, puller mechanism integrity, and waterproofing layers far more effectively than human inspection, ensuring ultra-high product reliability.

- Generative Design for Components: AI assists engineers in optimizing the structural design of zipper sliders and pullers to maximize strength-to-weight ratio using minimal material, leading to lighter, more durable sport goods components.

- Supply Chain Optimization: AI models manage complex global supply chains, optimizing logistics for raw materials (plastics, metals) and finished goods distribution, mitigating risks associated with geopolitical shifts and transportation delays.

- Personalized Product Customization: AI-driven platforms enable sports apparel manufacturers to offer highly customizable zipper options (e.g., engraved pullers, unique coatings) with minimal impact on manufacturing lead times and costs.

DRO & Impact Forces Of Sport Goods Zipper Market

The market dynamics are governed by a complex interplay of Drivers, Restraints, and Opportunities, collectively forming the Impact Forces. A key driver is the relentless consumer demand for high-performance, aesthetically pleasing, and durable athletic wear, compelling manufacturers to integrate superior fastening technology. This is amplified by the expansion of niche sporting activities like trail running, extreme cycling, and specialized water sports, which require highly resistant and functional zippers. Conversely, a significant restraint is the high volatility of raw material prices, particularly for metals (brass, aluminum) and petrochemical derivatives used in plastic coils, which directly impacts production costs and profit margins for zipper manufacturers. The market also faces constraints related to the complexity of achieving truly sustainable, high-performance fastening systems that meet rigorous performance standards.

Opportunities in the market are abundant, primarily revolving around the implementation of circular economy principles, such as developing 100% biodegradable or infinitely recyclable zippers, which aligns with global sustainability goals. Furthermore, the technological convergence of smart textiles and traditional fasteners presents an avenue for developing ‘smart zippers’ with embedded sensors for performance tracking or heating elements, although these applications are still nascent. The emergence of specialized markets in adaptive sports and tactical sports gear also offers high-growth potential for manufacturers capable of producing ultra-robust and easily operable fasteners. The ability to navigate stringent environmental regulations in mature markets like the EU represents both a restraint (compliance cost) and an opportunity (competitive differentiation).

The primary impact forces shaping the competitive landscape include intensifying competition among global manufacturers leading to pricing pressures, the need for constant investment in advanced automation to maintain cost competitiveness, and the increasing influence of Intellectual Property (IP) protection surrounding specialized fastener mechanisms (e.g., waterproofing membranes, locking systems). Strategic partnerships between zipper suppliers and major sports brands exert significant impact, as these collaborations dictate design specifications and procurement volumes for several years. Successful market navigation requires a strategic balance between high-volume, cost-efficient production and specialized, high-margin innovation.

Segmentation Analysis

The Sport Goods Zipper Market is comprehensively segmented based on material, type, application, and end-user, providing granular insights into demand patterns and growth vectors across various industry verticals. Understanding these segments is critical for identifying high-growth niches and tailoring product development strategies. The material segmentation (Metal, Plastic Coil, Vislon/Molded) dictates the primary performance characteristics—metal zippers offer maximum strength for heavy-duty applications, while plastic coil zippers provide flexibility and weight reduction essential for apparel. The application segmentation delineates usage across Apparel, Footwear, and Equipment, recognizing the unique functional requirements for each category, such as the need for corrosion resistance in marine equipment versus lightweight flexibility in running apparel. Overall, market growth is increasingly driven by the premium performance and technical functionality segments, prioritizing features like watertight sealing and ease of repair in the field.

- By Material:

- Metal Zippers (Brass, Aluminum, Nickel)

- Nylon/Plastic Coil Zippers (Polyester, Nylon)

- Vislon/Molded Plastic Zippers (Polypropylene, Polyacetal)

- By Type:

- Invisible Zippers

- Separating Zippers (Open-End)

- Non-Separating Zippers (Closed-End)

- Two-Way Zippers

- Waterproof/Water-Repellent Zippers

- By Application:

- Apparel (Outerwear, Base Layers, Team Uniforms)

- Footwear (Boots, Athletic Shoes)

- Equipment & Bags (Backpacks, Tents, Protective Gear, Sleeping Bags)

- By End-User:

- Professional Sports Brands

- Recreational Sports Brands

- Specialty Outdoor Retailers

- By Sales Channel:

- Direct Sales (B2B to Manufacturers)

- Distributors/Wholesalers

Value Chain Analysis For Sport Goods Zipper Market

The value chain for the Sport Goods Zipper Market begins with upstream activities focusing on the procurement and processing of fundamental raw materials, primarily polymers (nylon, polyester, acetal resin) and metals (brass, zinc, aluminum). This stage is characterized by high capital intensity and reliance on global petrochemical and metal markets. Key upstream challenges include maintaining consistent quality control over raw polymer formulations to ensure specific performance criteria—such as UV resistance, colorfastness, and tensile strength—required for high-end sporting applications. Manufacturers often engage in strategic, long-term contracts with major material suppliers to ensure supply stability and hedge against price volatility, which is particularly critical given the narrow profit margins in volume-based zipper production.

The midstream phase involves core manufacturing, including tape weaving, element molding or stamping, slider assembly, and rigorous testing for functionality and durability. This stage has seen massive technological modernization, with significant investments in high-speed, precision machinery to achieve the micron-level tolerances required for premium zippers, especially the specialized waterproof variety that requires sophisticated lamination techniques. Distribution channels in this market are predominantly direct (B2B), where major zipper manufacturers sell components directly to large sports apparel and equipment Original Equipment Manufacturers (OEMs) like Nike, Adidas, and Patagonia. This direct relationship facilitates rapid customization and integration feedback necessary for new product lines.

Downstream activities focus on integration, branding, and final consumer sales. Indirect channels involve distributors or agents who serve smaller garment factories or regional manufacturers, providing standardized zipper stock. The ultimate value added downstream involves the seamless incorporation of the zipper into the final sports product, where its functionality, aesthetics, and reliability become integral to the brand's perceived quality. Effective inventory management and quick response manufacturing (QRM) capabilities are vital in the downstream segment to align zipper supply precisely with the apparel industry's highly seasonal and fast-changing fashion cycles. The strong preference of leading OEMs to work with only a few highly accredited global zipper suppliers (YKK, Riri, SBS) underscores the importance of quality assurance and reliable logistics throughout the entire value chain.

Sport Goods Zipper Market Potential Customers

The primary potential customers and end-users of specialized sport goods zippers are multinational corporations and regional enterprises engaged in the production of performance apparel, footwear, and technical outdoor gear. These customers require zippers that not only fulfill basic fastening requirements but also contribute actively to the garment's performance specifications, such as thermal regulation, moisture management, and extreme durability. Key decision-makers within these organizations—including product development managers, sourcing directors, and materials engineers—prioritize suppliers who can demonstrate proven expertise in high-stress applications, offer customized colors and finishes, and adhere to strict chemical safety standards (e.g., REACH compliance). The buying cycle is typically long-term, involving rigorous sample testing and supplier accreditation before volume orders are placed, emphasizing the need for robust supplier relationships and consistent product quality.

The segment of high-end outdoor equipment manufacturers represents an extremely valuable customer base, demanding fasteners for items like expedition backpacks, mountaineering tents, and specialized tactical gear where failure is unacceptable. For these customers, cost sensitivity is secondary to reliability and functionality, driving demand for premium materials like marine-grade brass or specialized water-tight zippers with sophisticated sealing mechanisms. Furthermore, the growing market for team sports uniforms and licensed merchandise requires zippers that can withstand frequent industrial laundering while maintaining aesthetic integrity and smooth operation, leading to steady bulk demand for standardized, high-quality plastic coil zippers.

Emerging potential customer segments include companies focusing on sustainable fashion and circular economy initiatives in sportswear. These buyers are actively seeking innovative zipper solutions, such as fully recycled mono-material zippers that simplify end-of-life recycling for apparel. Addressing the specific needs of smaller, artisanal brands that prioritize ethical sourcing and unique aesthetics—often requiring low-minimum order quantities (MOQs) and complex customization—presents a niche yet profitable customer segment, often serviced through specialized regional distributors rather than direct sales. The evolving landscape of athletic equipment, including smart vests and specialized recovery gear, also introduces new customer profiles requiring miniaturized, durable, and highly integrated fastening technology.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 4.1 Billion |

| Market Forecast in 2033 | USD 6.1 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | YKK Corporation, SBS Zipper Co., Ltd., Riri S.A., Ideal Fastener Corporation, Coats Group plc, KCC Zipper, Opti Germany GmbH, Scovill Fasteners, Sanli Zipper Group, TALON International Inc., A.G. Findings & Trims, MAX Zipper Co. Ltd., Salmi S.p.A., HHH Zipper, Wasa Group. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Sport Goods Zipper Market Key Technology Landscape

The technology landscape within the Sport Goods Zipper Market is rapidly evolving, driven primarily by the need for enhanced durability, weatherproofing, and operational smoothness under extreme conditions. A foundational technology is the development of specialized polymer formulations for plastic coil zippers that offer superior resistance to abrasion, UV degradation, and chemical exposure (such as chlorine or saltwater). Modern manufacturing utilizes precision injection molding and extrusion techniques to ensure flawless element symmetry and spacing, which is critical for consistent, snag-free performance required in fast-moving sporting activities. The continuous refinement of dyeing and finishing processes also plays a vital role, enabling perfect color matching with technical fabrics without compromising material integrity or contributing to fabric staining, which is a common requirement from high-end apparel brands.

A major focus area is the advancement in waterproofing technology, moving beyond traditional storm flaps. This involves sophisticated lamination and coating processes (often utilizing specialized polyurethane films) applied directly to the zipper tape and elements, creating truly water-tight seals. Innovations in slider mechanisms are also paramount; this includes the development of auto-lock sliders that prevent accidental unzipping during strenuous movement, and ergonomic pullers designed for easy operation while wearing gloves (common in winter sports). Furthermore, magnetic assist systems and quick-release mechanisms are gaining traction in specialized fields, such as safety gear or tactical wear, where immediate opening is sometimes necessary.

The ongoing push towards sustainability dictates significant technological investment in closed-loop manufacturing systems and material substitution. This includes scaling the production of zippers made entirely from recycled post-consumer plastic and ensuring that these materials meet the same stringent performance criteria as virgin polymers. Digital manufacturing techniques, including advanced robotics and sensor integration (IoT), are being adopted to increase production efficiency, reduce material waste, and facilitate real-time quality assurance throughout the molding and assembly phases. These technological advancements ensure that fasteners remain an integrated, high-performance component rather than a mere accessory, particularly as sports apparel continues to push the boundaries of fabric engineering.

Regional Highlights

The performance of the Sport Goods Zipper Market is segmented into five major geographic regions, each exhibiting unique consumption patterns and manufacturing strengths. These regional dynamics are pivotal in shaping global supply chain strategies and investment decisions for major market participants.

- Asia Pacific (APAC): Dominates the global market, both as the largest manufacturing base for apparel and textiles and as a rapidly expanding consumer market. Countries like China, Vietnam, and Indonesia host significant portions of the global garment production capacity, driving immense volume demand for zippers. Furthermore, rising disposable incomes and increasing interest in organized sports in India and Southeast Asia fuel local consumption growth. The regional focus is heavily split between high-volume, cost-competitive production and specialized manufacturing for export to Western markets.

- North America: Characterized by high demand for premium, performance-oriented zippers, particularly in the highly lucrative outdoor and winter sports segments (e.g., skiing, hiking, mountaineering). Consumer brand loyalty and a willingness to pay a premium for technologically advanced features (like lifetime guarantees and extreme weather resistance) ensure high Average Selling Prices (ASPs). Regulatory compliance, especially regarding chemical usage and sustainability standards, is a critical purchasing criterion.

- Europe: Similar to North America, Europe is a mature market focused on innovation, sustainability, and aesthetic design. Western European countries (Germany, France, UK) are leaders in adopting eco-friendly zippers and specialized functional fasteners for high-fashion sportswear and technical maritime gear. The stringent European Union (EU) environmental regulations drive manufacturers to invest heavily in sustainable material sourcing and non-toxic finishing processes.

- Latin America (LATAM): Represents an emerging market with significant growth potential, driven by expanding middle classes and rising investments in local sports infrastructure, particularly in Brazil and Mexico. Demand is generally focused on mid-range, durable zippers for team sports apparel and basic athletic wear, often sourced through regional distribution networks focusing on cost-effectiveness.

- Middle East and Africa (MEA): A diverse region showing gradual growth, particularly in the Gulf Cooperation Council (GCC) countries due to high discretionary spending on imported luxury sports brands and investment in mega-sports events. The market is smaller but requires specific product features related to extreme heat and dust resistance for outdoor gear and apparel used in arid environments.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Sport Goods Zipper Market.- YKK Corporation

- SBS Zipper Co., Ltd.

- Riri S.A.

- Ideal Fastener Corporation

- Coats Group plc

- KCC Zipper

- Opti Germany GmbH

- Scovill Fasteners

- Sanli Zipper Group

- TALON International Inc.

- A.G. Findings & Trims

- MAX Zipper Co. Ltd.

- Salmi S.p.A.

- HHH Zipper

- Wasa Group

- Ningbo MH Industry Co., Ltd.

- Texon International Group

- Shandong Kexing Zipper Co., Ltd.

- Zhejiang GMS Zipper Co., Ltd.

- Prym Fashion

Frequently Asked Questions

Analyze common user questions about the Sport Goods Zipper market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary factor driving demand for waterproof sport goods zippers?

The primary factor is the increasing consumer participation in high-performance outdoor and extreme weather sports, such as skiing, mountaineering, and marine activities, requiring apparel and equipment that guarantee absolute protection against moisture and environmental elements, making technical water-tight sealing indispensable.

How is sustainability impacting the selection of zipper materials in the sports industry?

Sustainability is profoundly impacting material selection, leading to a strong market shift towards fasteners manufactured from recycled materials, particularly post-consumer plastic and bio-based polymers. Major sports brands mandate that suppliers offer transparent sourcing and low-impact production methods to meet corporate ESG goals.

Which zipper type holds the largest market share in the sport goods segment?

Nylon or Plastic Coil Zippers hold the largest market share. Their versatility, high flexibility, lightweight nature, and cost-effectiveness make them ideal for the majority of athletic apparel, training wear, and general sports bags, offering an optimal balance of performance and efficiency.

What are the key technological advancements expected to shape the future of the sport goods zipper market?

Future developments are expected to focus on smart zipper integration (e.g., embedded sensors), advanced generative design to optimize component weight, and further sophistication in non-sewn, welded waterproofing techniques to seamlessly integrate fasteners with technical membrane fabrics, eliminating conventional stitching.

Which geographical region exhibits the fastest growth rate for the Sport Goods Zipper Market?

The Asia Pacific (APAC) region is projected to exhibit the fastest growth rate, fueled by its dominant position as the global manufacturing hub and the rapidly expanding domestic consumption market driven by rising youth population engagement in sports and increasing urbanization across countries like China, India, and Southeast Asia.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager