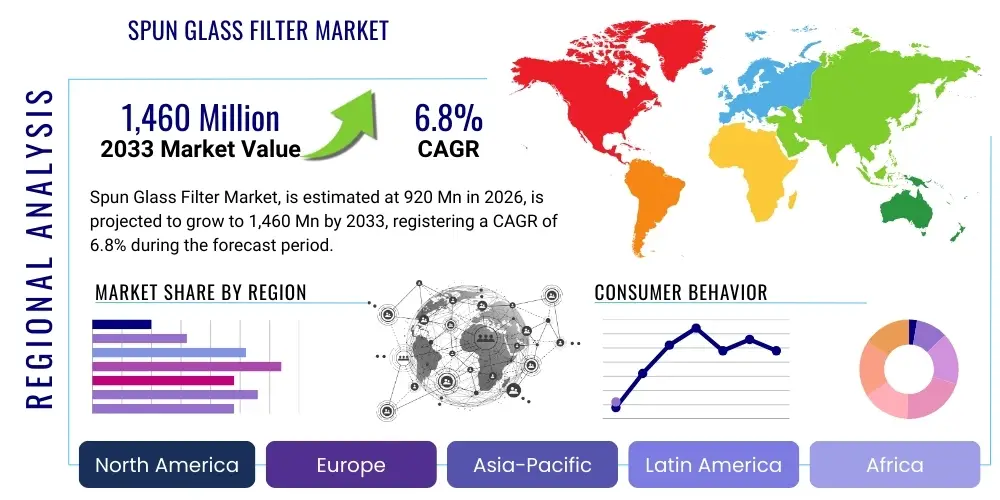

Spun Glass Filter Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440820 | Date : Feb, 2026 | Pages : 258 | Region : Global | Publisher : MRU

Spun Glass Filter Market Size

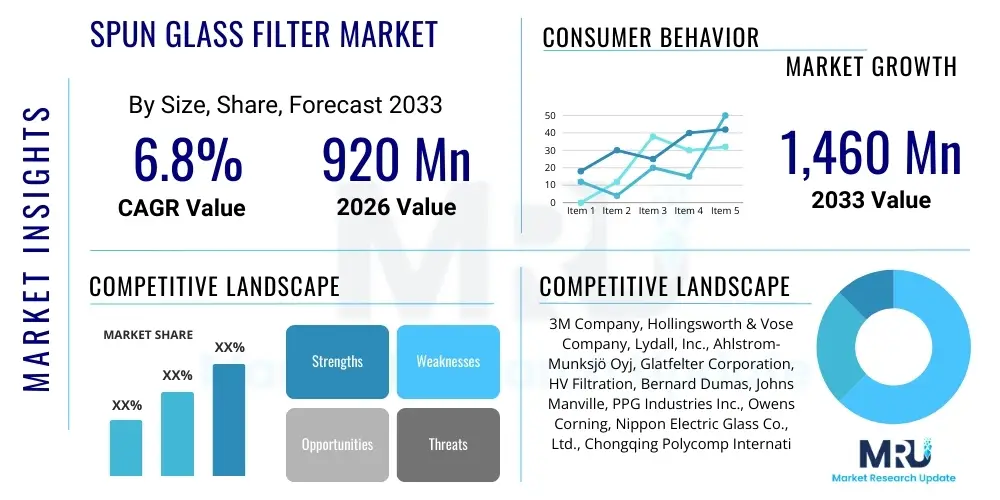

The Spun Glass Filter Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 920 million in 2026 and is projected to reach USD 1,460 million by the end of the forecast period in 2033. This growth is primarily fueled by increasing industrialization, stringent environmental regulations necessitating advanced filtration solutions, and a rising demand for high-efficiency air and liquid purification across diverse sectors globally. The inherent properties of spun glass filters, such as high-temperature resistance, chemical inertness, and superior filtration efficiency, position them as a preferred choice in demanding industrial applications.

Spun Glass Filter Market introduction

The Spun Glass Filter Market encompasses a wide range of filtration products made from meticulously engineered glass fibers, designed to capture particulate matter from air, gas, and liquid streams. These filters are manufactured by melting glass materials and then drawing them into extremely fine fibers through a specialized spinning process, which are subsequently formed into various media types like mats, felts, or papers. The intricate structure of these fibers creates a dense, tortuous path that effectively traps particles while allowing fluids to pass through with minimal pressure drop. This unique manufacturing process ensures consistent pore size distribution and mechanical strength, making spun glass filters highly effective across a myriad of applications demanding high-efficiency particulate air (HEPA) filtration, ultra-low penetration air (ULPA) filtration, or precise liquid clarification.

Major applications for spun glass filters span across critical industries including HVAC systems for commercial and residential buildings, automotive filtration for engine air intake and cabin air quality, industrial air purification in manufacturing facilities, pharmaceutical production where sterile environments are paramount, and food and beverage processing requiring ultra-clean liquids. Additionally, they are extensively utilized in chemical processing, oil and gas, and power generation sectors for demanding liquid and gas filtration tasks where thermal and chemical stability are non-negotiable. The product's versatility stems from its ability to be tailored for specific micron ratings, flow rates, and operational conditions, adapting to a broad spectrum of filtration challenges.

The core benefits of spun glass filters include exceptional filtration efficiency, often achieving efficiencies of 99.97% or higher for particles 0.3 microns and larger, superior chemical resistance to withstand corrosive environments, and excellent thermal stability, allowing them to operate effectively in high-temperature applications where other filter media would degrade. These characteristics, coupled with their relatively low-cost-to-performance ratio and long service life, contribute significantly to operational cost savings and enhanced process reliability. The driving factors behind market expansion are multifaceted, including increasingly stringent global air and water quality regulations, rapid industrial expansion in emerging economies, a growing emphasis on indoor air quality, and continuous innovation in filter media technology to meet evolving industry standards and specialized application requirements. The demand for cleaner production processes and safer working environments also substantially propels the adoption of these advanced filtration solutions.

Spun Glass Filter Market Executive Summary

The Spun Glass Filter Market is experiencing robust growth driven by a confluence of evolving business trends, distinct regional dynamics, and specialized segment-specific demands. Key business trends include a significant push towards developing more sustainable and energy-efficient filter solutions, often involving novel binder technologies and fiber arrangements that reduce environmental impact while enhancing performance. There is also a notable consolidation among major players, alongside increased investment in R&D to innovate new spun glass fiber chemistries and structural designs for advanced applications. The shift towards automation in manufacturing processes for spun glass filters is aimed at improving production efficiency and consistency, responding to the escalating global demand. Furthermore, the market is witnessing an emphasis on custom-engineered solutions, where filter manufacturers collaborate closely with end-users to design filters perfectly tailored to unique operational parameters and contaminant challenges, moving beyond standardized product offerings to value-added services.

Regional trends reveal a vibrant growth trajectory, particularly in the Asia-Pacific (APAC) region, fueled by rapid industrialization, burgeoning manufacturing sectors, and increasing concerns over air and water pollution, which necessitate the widespread adoption of effective filtration systems. Countries like China, India, and Southeast Asian nations are at the forefront of this growth, driven by infrastructure development and tightening environmental protection mandates. North America and Europe, while being mature markets, continue to demonstrate stable demand, primarily driven by strict regulatory frameworks for emissions and air quality, replacement cycles for existing HVAC and industrial filtration infrastructure, and continuous technological advancements in filter media. These regions are also leading in the adoption of premium, high-efficiency spun glass filters for specialized applications such as cleanrooms, pharmaceutical manufacturing, and advanced automotive systems, emphasizing compliance and performance over mere cost.

Segment trends underscore the diversified nature of the spun glass filter market. The air filtration segment, encompassing HVAC, industrial air purification, and automotive cabin air filters, remains the largest and fastest-growing due to universal concerns about air quality and public health. Within liquid filtration, the demand for spun glass filters is escalating in industries like pharmaceuticals, food and beverage, and chemical processing, where precise particle removal and chemical resistance are critical for product purity and safety. The increasing complexity of industrial processes and the need to meet rigorous product specifications are driving demand for finer filtration capabilities within these liquid applications. Moreover, emerging segments such as gas filtration for emission control and specialized applications in renewable energy and semiconductor manufacturing are presenting new avenues for growth, leveraging the unique properties of spun glass media to address highly technical and demanding filtration requirements. The emphasis on high-performance materials capable of operating in extreme conditions positions spun glass filters advantageously across these evolving industrial landscapes.

AI Impact Analysis on Spun Glass Filter Market

The integration of Artificial Intelligence (AI) into the spun glass filter market is poised to revolutionize various aspects, from design and manufacturing to operational deployment and maintenance. Common user questions often revolve around how AI can enhance filter performance, predict failure, optimize production, and contribute to the development of "smart" filtration systems. Users are concerned about the practicality of AI in improving efficiency, reducing costs, and enabling more proactive maintenance strategies. They seek to understand AI's role in real-time monitoring, ensuring optimal filtration parameters, and extending filter lifespan, while also questioning its potential to identify and implement novel material combinations or manufacturing techniques for next-generation filters. The overarching theme is the expectation that AI will drive greater intelligence and efficiency across the entire lifecycle of spun glass filter products, moving beyond traditional static systems to dynamic, self-optimizing solutions.

- Optimized Filter Design: AI algorithms can analyze vast datasets of performance characteristics, material properties, and fluid dynamics to rapidly prototype and optimize spun glass filter designs, improving filtration efficiency and lifespan while reducing material waste.

- Predictive Maintenance: AI-driven sensors embedded in filtration systems can monitor filter loading, pressure drop, and air/liquid quality in real-time, predicting filter clogging or failure before it occurs, thereby scheduling maintenance proactively and minimizing downtime.

- Enhanced Manufacturing Processes: Machine learning can optimize manufacturing parameters like fiber drawing speed, binder application, and curing temperatures, leading to more consistent product quality, reduced defects, and increased production efficiency.

- Supply Chain Optimization: AI can forecast demand, manage inventory, and optimize logistics for raw materials and finished spun glass filters, ensuring timely delivery and minimizing storage costs.

- Smart Filtration Systems: AI enables the development of intelligent filtration systems that can adapt to changing environmental conditions or process requirements, automatically adjusting flow rates or switching filter elements for optimal performance.

- Quality Control and Inspection: Computer vision and AI can perform automated, high-speed inspection of spun glass filter media for defects, ensuring superior product quality and reducing reliance on manual checks.

- Material Innovation: AI can accelerate the discovery and development of new glass fiber formulations and binder chemistries, leading to filters with enhanced properties such as greater durability, higher efficiency, or improved sustainability.

- Energy Efficiency: By continuously monitoring and optimizing system operation, AI can reduce the energy consumption associated with filtration processes, contributing to lower operating costs and a smaller carbon footprint.

DRO & Impact Forces Of Spun Glass Filter Market

The Spun Glass Filter Market is significantly shaped by a dynamic interplay of Drivers, Restraints, and Opportunities (DRO), which collectively form potent Impact Forces dictating its growth trajectory and competitive landscape. A primary driver is the global escalation of stringent air and water quality regulations, compelling industries to adopt advanced filtration solutions to comply with environmental standards and protect public health. This regulatory push, coupled with rapid industrialization and infrastructure development in emerging economies, particularly in Asia-Pacific, substantially increases the demand for effective filtration systems across manufacturing, HVAC, automotive, and processing industries. Furthermore, the inherent benefits of spun glass filters, such as high efficiency, thermal stability, and chemical resistance, make them indispensable for critical applications, further propelling their adoption and market expansion. The continuous evolution of HVAC systems, demanding higher indoor air quality, and the increasing electrification and sophistication of automotive vehicles also contribute significantly to the market's upward trend, emphasizing the need for robust and reliable filtration.

However, the market also faces notable restraints. The volatility of raw material prices, particularly for silica sand, borax, and various binders, directly impacts manufacturing costs and can fluctuate profit margins for filter producers, posing a challenge for long-term planning and pricing stability. Intense competition from alternative filter materials, such as synthetic polymers, ceramics, and activated carbon, which may offer specific advantages in niche applications or at lower price points, also limits market penetration for spun glass filters in certain sectors. Additionally, the challenges associated with the disposal and recycling of used spun glass filters, particularly those contaminated with hazardous substances, present environmental and logistical hurdles. High initial investment costs for specialized spun glass filtration systems in certain industrial applications can also deter smaller enterprises or those operating on tight capital expenditure budgets, slowing down market adoption in specific segments.

Despite these restraints, significant opportunities abound for the spun glass filter market. The burgeoning economies in Asia-Pacific and Latin America present vast untapped potential as industrial output and environmental awareness grow, driving demand for advanced filtration. The development of smart and sustainable filter solutions, integrating IoT sensors for real-time monitoring and exploring biodegradable or easily recyclable binder technologies, offers a pathway for innovation and market differentiation. There is a growing need for specialized spun glass filters in high-tech industries like semiconductor manufacturing, where ultra-clean environments are paramount, and in renewable energy sectors for critical process filtration. Moreover, the substantial market for retrofit and replacement demand in aging industrial and HVAC infrastructure globally provides a consistent revenue stream, as existing systems are upgraded to meet modern efficiency and regulatory standards. Strategic partnerships, technological advancements in fiber engineering, and a focus on expanding application specific product lines are key for unlocking these growth opportunities.

Segmentation Analysis

The Spun Glass Filter Market is meticulously segmented to provide a granular understanding of its diverse components, allowing for precise market analysis, strategic planning, and targeted product development. This comprehensive segmentation typically includes categorization by type of glass fiber, the specific application or end-use where the filters are deployed, and the various end-user industries that benefit from their unique filtration capabilities. Understanding these segments is crucial for identifying key growth areas, competitive dynamics, and the evolving needs of different customer bases. Each segment is driven by distinct factors, ranging from performance requirements and regulatory compliance to cost-efficiency and operational stability, contributing to the varied landscape of the overall market. This structured breakdown ensures that market participants can tailor their offerings to specific demands, optimizing both product innovation and market penetration strategies across the global filtration industry. The robust properties of spun glass make it adaptable across these varied demands.

- By Type

- Glass Wool Filters: Generally used for coarser filtration, often in pre-filtration stages or less demanding HVAC applications, characterized by lower density and good dust holding capacity.

- Fiberglass Mat Filters: Composed of non-woven fiberglass material, offering good rigidity and moderate to high efficiency, common in industrial air filtration and some automotive applications.

- Microfiber Glass Filters: Known for their extremely fine fibers, enabling very high filtration efficiencies (HEPA/ULPA grades), critical for cleanrooms, pharmaceuticals, and specialized industrial processes.

- Spunbond Glass Filters: Utilizing advanced non-woven techniques, these offer a balance of strength, efficiency, and flow characteristics, finding use in various air and liquid filtration contexts.

- By Application

- Air Filtration:

- HVAC Systems: Filters for commercial, residential, and industrial heating, ventilation, and air conditioning units, enhancing indoor air quality.

- Industrial Air Purification: Filters used in manufacturing plants, power generation, and other industrial settings to remove particulates, dust, and fumes from process or exhaust air.

- Automotive Cabin Air Filtration: Filters designed to purify the air entering vehicle cabins, protecting occupants from pollutants, pollen, and dust.

- Cleanrooms: Ultra-high efficiency filters essential for maintaining sterile and particulate-free environments in semiconductor, pharmaceutical, and biotechnology industries.

- Liquid Filtration:

- Industrial Process Water Filtration: Filters for treating water used in manufacturing processes, preventing contamination and protecting equipment.

- Chemicals & Solvents Filtration: Filters designed to handle corrosive or aggressive chemicals, ensuring purity and preventing contamination in various chemical processes.

- Oil & Gas Filtration: Filters used in upstream, midstream, and downstream oil and gas operations for purifying crude oil, natural gas, and refined products.

- Food & Beverage Filtration: Filters critical for ensuring product clarity, purity, and microbial stability in the production of food, beverages, and bottled water.

- Gas Filtration:

- Exhaust Gas Treatment: Filters for removing particulates from industrial exhaust streams, crucial for emissions control and regulatory compliance.

- Compressed Air Filtration: Filters used to remove oil, water, and particulate contaminants from compressed air lines, protecting pneumatic equipment and end products.

- Air Filtration:

- By End-Use Industry

- Manufacturing: Includes automotive, electronics, heavy industry, metal fabrication, and other general manufacturing processes requiring air and liquid purification.

- HVAC & Building Management: Filters for commercial buildings, data centers, hospitals, and residential complexes to maintain indoor air quality and protect HVAC equipment.

- Pharmaceuticals & Healthcare: Critical for cleanroom environments, sterile production, and filtration of medicinal liquids and gases, ensuring product integrity and patient safety.

- Food & Beverage: Essential for maintaining hygiene, purity, and quality control in the production of food products, beverages, and potable water.

- Oil & Gas: Used across exploration, production, refining, and petrochemical operations for various fluid and gas filtration applications.

- Power Generation: Filters for air intake systems, turbine lubrication, and water treatment processes in thermal, nuclear, and renewable energy power plants.

- Water & Wastewater Treatment: Filters used in municipal and industrial water treatment plants for particle removal and purification.

Value Chain Analysis For Spun Glass Filter Market

A comprehensive value chain analysis for the Spun Glass Filter Market reveals a sequential flow of activities, from raw material sourcing to the final end-user, highlighting the various stages where value is added and costs are incurred. The upstream segment of the value chain is dominated by raw material suppliers, primarily providing high-purity silica sand, borax, and other mineral additives essential for glass manufacturing. These suppliers are critical as the quality and consistency of their materials directly impact the performance and durability of the spun glass fibers. Energy providers, binder chemical manufacturers (e.g., phenolic resins, acrylics), and specialized equipment providers for glass melting and fiber spinning also constitute crucial upstream partners. The efficiency and cost-effectiveness of these initial stages significantly influence the competitiveness of the final filter product, making robust supplier relationships and quality control paramount.

The midstream segment involves the core manufacturing of spun glass fibers and their conversion into various filter media. This stage encompasses glass melting, fiber drawing, mat formation, pleating, and assembly into finished filter elements. Manufacturers often differentiate themselves through proprietary fiber formulations, advanced spinning technologies, and innovative filter designs that optimize filtration efficiency, dust holding capacity, and airflow characteristics. This segment also includes the integration of spun glass media into complete filtration solutions by filter manufacturers, who may also produce other components like frames, gaskets, and housings. Downstream activities involve the distribution and sales channels, where products move from manufacturers to end-users. This includes direct sales forces catering to large industrial clients or specialized OEMs, as well as indirect channels involving a network of distributors, wholesalers, and retailers that serve a broader market, including smaller businesses and the replacement market.

Distribution channels for spun glass filters are multi-faceted, encompassing both direct and indirect approaches. Direct channels involve manufacturers selling directly to original equipment manufacturers (OEMs) who integrate these filters into their machinery (e.g., HVAC units, automotive engines) or to large industrial end-users with high-volume, customized requirements. This approach allows for direct communication, technical support, and tailored solutions. Indirect channels, on the other hand, leverage a network of specialized industrial distributors, filtration solution providers, and MRO (Maintenance, Repair, and Operations) suppliers. These intermediaries play a crucial role in market penetration by providing regional accessibility, warehousing, logistics, and often installation or maintenance services. The choice of distribution strategy depends on the target market, product complexity, and desired market reach, with many companies employing a hybrid model to maximize their market footprint and cater to diverse customer needs effectively.

Spun Glass Filter Market Potential Customers

The Spun Glass Filter Market serves an incredibly diverse range of potential customers, primarily classified as end-users or buyers who require high-performance filtration solutions for air, gas, or liquid purification. These customers span across virtually every industrial sector and extend into commercial and even advanced residential applications where air quality is a premium concern. Industrial manufacturing plants, encompassing sectors such as automotive assembly, electronics production, heavy machinery fabrication, and metal processing, represent a significant customer base, relying on spun glass filters for industrial air purification, dust collection, and process liquid treatment to ensure product quality and worker safety. The precision and consistency offered by spun glass filters are critical in these environments to protect sensitive equipment from particulate damage and maintain compliance with occupational health standards, making them an indispensable part of their operational infrastructure.

Another major segment of potential customers includes the Pharmaceuticals and Healthcare industries, where the demand for ultra-clean environments and sterile processes is paramount. Hospitals, pharmaceutical manufacturing facilities, biotechnology laboratories, and research institutions extensively utilize HEPA and ULPA-grade spun glass filters in cleanrooms, laminar flow hoods, and HVAC systems to prevent contamination and ensure product integrity and patient safety. Similarly, the Food and Beverage sector, including dairies, breweries, bottling plants, and processed food manufacturers, relies on spun glass filters for critical liquid filtration applications to achieve product clarity, remove impurities, and meet stringent hygiene and quality standards. These applications often demand filters that are chemically inert and able to withstand sterilization processes, characteristics inherent to spun glass media, thus making it a preferred choice for ensuring consumer safety and product quality.

Furthermore, the Oil & Gas industry utilizes spun glass filters across its upstream, midstream, and downstream operations for applications such as purifying drilling fluids, separating oil from water, and filtering refined petroleum products and natural gas, where thermal and chemical resistance are crucial. Power generation facilities, including thermal power plants and nuclear facilities, depend on these filters for air intake systems, turbine lubrication, and water treatment, safeguarding critical machinery and ensuring operational efficiency. The widespread HVAC & Building Management sector, encompassing commercial buildings, data centers, and advanced residential systems, is a continuous and growing consumer, driven by increasing public awareness of indoor air quality and energy efficiency demands. Lastly, specialized high-tech industries like semiconductor manufacturing heavily rely on ultra-efficient spun glass filters to create contamination-free production environments, vital for producing microscopic electronic components. Each of these diverse customer groups seeks the reliability, efficiency, and specific performance attributes that spun glass filters uniquely provide, making them an essential component in their respective operations.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 920 Million |

| Market Forecast in 2033 | USD 1,460 Million |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | 3M Company, Hollingsworth & Vose Company, Lydall, Inc., Ahlstrom-Munksjö Oyj, Glatfelter Corporation, HV Filtration, Bernard Dumas, Johns Manville, PPG Industries Inc., Owens Corning, Nippon Electric Glass Co., Ltd., Chongqing Polycomp International Corp. (CPIC), Saint-Gobain Adfors, Sinoma Science & Technology Co., Ltd., Trelleborg AB, Donaldson Company, Inc., Freudenberg Filtration Technologies, Parker Hannifin Corporation, MANN+HUMMEL International GmbH & Co. KG, Clarcor Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Spun Glass Filter Market Key Technology Landscape

The key technology landscape of the Spun Glass Filter Market is characterized by continuous innovation aimed at enhancing filtration efficiency, durability, and sustainability, while also reducing manufacturing costs. Central to this landscape are advancements in the fiber spinning processes, which allow for the production of glass microfibers with increasingly consistent diameters and customized structural properties, leading to media with superior particle capture capabilities and lower pressure drop. Techniques such as rotary spinning, flame attenuation, and melt-blown processes are continually refined to optimize fiber characteristics for specific applications, ranging from high-efficiency particulate air (HEPA) filters to robust liquid filtration media. Innovations in binder technologies are also critical, moving towards more environmentally friendly, formaldehyde-free, and high-performance binders that maintain filter integrity under extreme thermal and chemical conditions, while also contributing to improved air quality during filter use and disposal. These binder advancements ensure that the spun glass media retains its shape and structural stability throughout its operational life, preventing fiber migration and maintaining consistent filtration performance.

Beyond the foundational fiber and binder technologies, significant technological strides are being made in filter media construction and manufacturing processes. This includes the development of multi-layered filtration media, where different densities or types of spun glass fibers are combined to achieve graded filtration, enhancing dust holding capacity and extending filter lifespan. Advanced pleating techniques are also crucial, maximizing the surface area of the filter media within a compact space, thereby improving airflow characteristics and efficiency without increasing the physical size of the filter element. Furthermore, the integration of nanofibers, often composed of synthetic polymers or sometimes hybrid glass-polymer composites, onto spun glass substrates represents a cutting-edge technological trend. This hybrid approach leverages the structural strength and thermal resistance of glass fibers while utilizing the ultra-fine filtration capabilities of nanofibers to achieve even higher particulate removal efficiencies, particularly for sub-micron particles, opening new possibilities for ultra-high-performance applications in sensitive industries.

The emergent trend of smart filter integration is profoundly influencing the technology landscape. This involves embedding or attaching sensors to spun glass filters to monitor real-time performance parameters such as pressure drop, differential pressure, flow rate, and even particulate loading. These sensors, often connected through IoT (Internet of Things) platforms, enable predictive maintenance, optimizing filter change-out schedules to prevent unexpected downtime and ensure continuous optimal operation. Data analytics and artificial intelligence are increasingly being employed to interpret the sensor data, providing insights into system performance, identifying potential issues, and suggesting operational adjustments for improved efficiency and energy savings. This shift towards intelligent, connected filtration systems allows for greater control, reduced manual intervention, and a more proactive approach to filtration management. Furthermore, the development of sustainable manufacturing practices, including energy-efficient production methods and exploration of recycled glass content in fiber production, is gaining traction, reflecting an industry-wide commitment to environmental responsibility alongside technological advancement.

Regional Highlights

- North America: This region represents a mature and significant market for spun glass filters, driven by stringent environmental regulations, a robust industrial base, and a high demand for indoor air quality solutions in residential and commercial sectors. The presence of key market players, technological advancements, and a strong replacement market for HVAC and automotive filters further solidify its position. High adoption rates in pharmaceutical and semiconductor industries underscore the demand for ultra-high efficiency filters.

- Europe: Similar to North America, Europe is a well-established market characterized by strict air quality standards, a strong focus on sustainable manufacturing, and continuous innovation in filtration technology. Countries like Germany, France, and the UK lead in industrial filtration, automotive applications, and cleanroom technologies. The emphasis on energy efficiency and green building initiatives also drives demand for high-performance spun glass filters.

- Asia Pacific (APAC): APAC is the fastest-growing market, propelled by rapid industrialization, booming manufacturing sectors, and increasing awareness of air and water pollution in developing economies such as China, India, and Southeast Asian countries. Massive infrastructure development projects, rising disposable incomes leading to greater adoption of HVAC systems, and evolving environmental regulations are significant drivers, creating immense opportunities for market expansion.

- Latin America: This region is experiencing steady growth in the spun glass filter market, primarily due to expanding industrial activities, particularly in Brazil and Mexico. Investments in manufacturing, automotive, and infrastructure sectors are increasing the demand for filtration solutions. Regulatory developments and growing environmental awareness are also gradually influencing market dynamics.

- Middle East and Africa (MEA): The MEA market for spun glass filters is growing, driven by large-scale infrastructure projects, expansion of the oil & gas industry, and increasing industrialization efforts in countries like Saudi Arabia and UAE. The rising concerns about air quality, especially in urban centers and industrial zones, coupled with investments in commercial and residential construction, contribute to the growing demand.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Spun Glass Filter Market.- 3M Company

- Hollingsworth & Vose Company

- Lydall, Inc.

- Ahlstrom-Munksjö Oyj

- Glatfelter Corporation

- HV Filtration

- Bernard Dumas

- Johns Manville

- PPG Industries Inc.

- Owens Corning

- Nippon Electric Glass Co., Ltd.

- Chongqing Polycomp International Corp. (CPIC)

- Saint-Gobain Adfors

- Sinoma Science & Technology Co., Ltd.

- Trelleborg AB

- Donaldson Company, Inc.

- Freudenberg Filtration Technologies

- Parker Hannifin Corporation

- MANN+HUMMEL International GmbH & Co. KG

- Clarcor Inc.

Frequently Asked Questions

What are spun glass filters primarily used for?

Spun glass filters are primarily used for high-efficiency air, gas, and liquid filtration across various industries. Their main applications include HVAC systems, industrial air purification, automotive filtration, cleanrooms, pharmaceutical manufacturing, food and beverage processing, and chemical filtration, where they effectively remove particulates and ensure purity.

What are the key advantages of using spun glass filters compared to other filter media?

Key advantages include exceptional filtration efficiency (often HEPA/ULPA grade), superior thermal stability allowing operation at high temperatures, excellent chemical resistance to corrosive substances, and a high dust holding capacity, contributing to longer service life and reduced operational costs in demanding environments.

How do stringent environmental regulations impact the spun glass filter market?

Stringent environmental regulations are a significant driver for the market, compelling industries to adopt advanced filtration solutions for air emissions and wastewater treatment. These regulations mandate higher filtration efficiencies and lower permissible contaminant levels, thereby increasing the demand for high-performance spun glass filters to ensure compliance and minimize environmental impact.

What role does Artificial Intelligence (AI) play in the future of spun glass filters?

AI is set to enhance spun glass filters by optimizing design and manufacturing processes, enabling predictive maintenance through real-time monitoring, and facilitating the development of smart filtration systems. AI integration promises to improve efficiency, reduce operational costs, and drive innovation in filter materials and applications.

Which geographical regions are expected to show the most significant growth in the spun glass filter market?

The Asia-Pacific (APAC) region is projected to exhibit the most significant growth due to rapid industrialization, increasing manufacturing activities, and growing concerns over air and water pollution in countries like China and India. This regional expansion is further supported by substantial infrastructure development and evolving environmental protection policies.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager