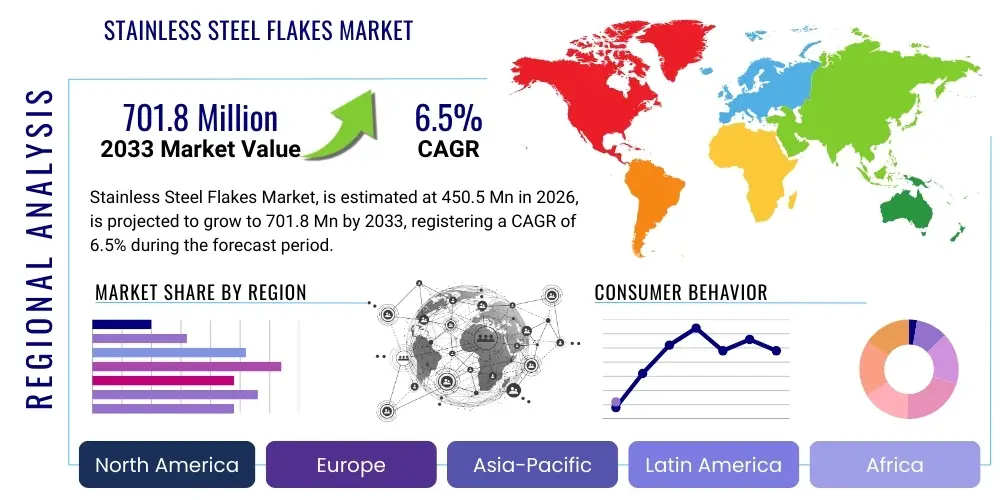

Stainless Steel Flakes Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 441714 | Date : Feb, 2026 | Pages : 242 | Region : Global | Publisher : MRU

Stainless Steel Flakes Market Size

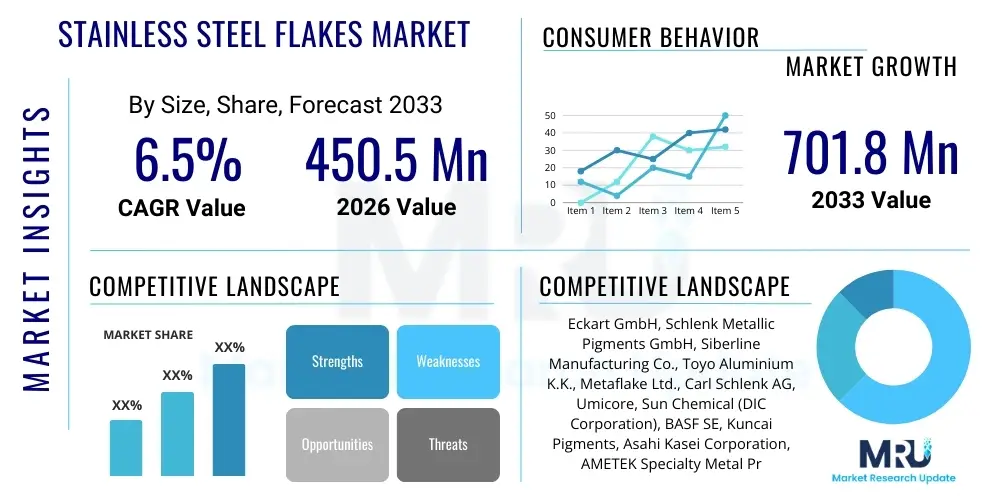

The Stainless Steel Flakes Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5% between 2026 and 2033. The market is estimated at USD 450.5 Million in 2026 and is projected to reach USD 701.8 Million by the end of the forecast period in 2033. This consistent growth trajectory is primarily fueled by increasing demand for high-performance corrosion-resistant coatings in the automotive, marine, and construction industries, where stainless steel flakes offer superior longevity and aesthetic properties compared to traditional metallic pigments.

Stainless Steel Flakes Market introduction

Stainless steel flakes are specialized metallic pigments derived from stainless steel powder through processes such as atomization followed by intensive milling or grinding. These flakes are characterized by their high aspect ratio, excellent chemical stability, outstanding resistance to corrosion, and superior thermal properties. They are produced in various grades, typically utilizing 300 series (austenitic) or 400 series (ferritic) stainless steel, depending on the specific application requirements regarding magnetic properties and corrosion resistance.

The primary applications of stainless steel flakes span across industrial coatings, conductive inks, electromagnetic interference (EMI) shielding materials, and specialized plastics and composites. In coatings, they provide a durable, metallic appearance while enhancing barrier protection against harsh environments. Their conductive nature makes them indispensable in creating pathways for electrical signals or dissipating static charge in complex electronic assemblies, crucial for maintaining device integrity and performance.

Driving factors for this market include the global expansion of the electronics manufacturing sector, particularly in Asia Pacific, which heavily relies on efficient EMI shielding solutions. Furthermore, stringent regulatory requirements in the automotive and aerospace industries demanding lightweight, durable, and fire-resistant materials accelerate the adoption of stainless steel flake-infused composites and coatings, cementing their position as a premium additive in high-specification manufacturing.

Stainless Steel Flakes Market Executive Summary

The Stainless Steel Flakes market is currently experiencing robust growth, propelled by significant business trends focusing on material innovation and sustainability. Manufacturers are increasingly investing in proprietary milling and surface treatment technologies to produce ultra-thin, high-aspect-ratio flakes that improve conductivity and pigment performance while reducing the required material load. Key business trends also involve strategic partnerships between flake producers and major coatings formulators and polymer compounders to develop application-specific products, especially tailored for harsh marine and chemical processing environments, ensuring enhanced performance and market penetration.

Regionally, Asia Pacific maintains the largest market share and exhibits the fastest growth due to the overwhelming presence of electronics manufacturing hubs and rapid urbanization driving infrastructure and automotive production. North America and Europe, while mature, show steady demand, particularly driven by high-specification industrial maintenance and the robust aerospace sector requiring sophisticated protective coatings and lightweight composite materials. The shift towards electric vehicles (EVs) globally is also fueling regional demand for stainless steel flakes in battery pack casings and thermal management systems for enhanced safety and durability.

In terms of segments, the 316L grade stainless steel flakes segment dominates due to its superior resistance to chlorides and pitting corrosion, making it preferred for marine and pharmaceutical applications. Application-wise, EMI/RFI shielding and protective coatings remain the leading segments. Future segment trends indicate significant potential in additive manufacturing (3D printing) and functional inks, where the precision and unique morphological characteristics of stainless steel micro-flakes are utilized to create complex, high-strength metallic structures and conductive pathways with unprecedented resolution and repeatability.

AI Impact Analysis on Stainless Steel Flakes Market

Common user questions regarding the impact of Artificial Intelligence (AI) on the Stainless Steel Flakes market often revolve around efficiency gains in manufacturing, predictive quality control, and the optimization of feedstock utilization. Users are concerned about how AI can mitigate the inherent variability in particle morphology produced by mechanical milling processes and how machine learning algorithms can predict the optimal milling time and energy input required to achieve a specific flake size and aspect ratio with minimal defect rates. Furthermore, questions frequently address AI’s role in supply chain resilience, specifically predicting demand fluctuations from key end-user industries (like automotive and electronics) and optimizing inventory levels for specialized grades, thereby minimizing waste and maximizing profitability. The key thematic expectation is that AI will transform stainless steel flake production from a process heavily reliant on empirical tuning to one driven by data-based predictive modeling, ensuring higher product consistency and lower operational expenditure.

- AI-driven optimization of high-energy ball milling parameters (speed, temperature, duration) to achieve desired aspect ratios and particle size distribution.

- Predictive maintenance analytics applied to critical production equipment, reducing unplanned downtime and enhancing overall equipment effectiveness (OEE).

- Machine learning algorithms utilized for advanced defect detection and quality control during the material classification and sorting phases.

- Enhanced supply chain management through AI forecasting of raw material prices (nickel, chromium, steel scrap) and predicting end-user demand patterns.

- Development of smart coatings and conductive formulations using AI to model the optimal dispersion and orientation of flakes for maximum performance (e.g., maximizing shielding effectiveness or gloss).

DRO & Impact Forces Of Stainless Steel Flakes Market

The Stainless Steel Flakes market is fundamentally shaped by a confluence of driving factors, critical restraints, and emerging opportunities, all impacting market dynamics and investment decisions. A major driver is the increasing regulatory focus on environmental protection and product longevity, necessitating the use of high-durability, corrosion-resistant coatings, especially in infrastructure and maritime applications. Furthermore, the relentless miniaturization and complexity of electronic devices drive the demand for superior Electromagnetic Interference (EMI) shielding solutions where stainless steel flakes excel due to their excellent conductivity and robustness under varying environmental conditions, particularly in 5G and IoT infrastructure deployments. The adoption of advanced stainless steel grades, such as duplex and super duplex, in flake form further expands applications into extremely corrosive environments.

However, the market faces significant restraints, primarily stemming from the high manufacturing costs associated with the production process. Transforming stainless steel powder into thin, high-aspect-ratio flakes requires energy-intensive mechanical milling processes, which adds considerably to the final product cost compared to cheaper alternatives like aluminum flakes or mica pigments. Additionally, the challenge of achieving stable dispersion of high-density stainless steel flakes within low-viscosity liquid matrices (like paints and inks) without sedimentation or agglomeration poses a technical barrier, requiring specialized formulation expertise and premium additives, thereby potentially slowing adoption in cost-sensitive markets.

Opportunities for growth are abundant, particularly within the nascent field of additive manufacturing (AM), where stainless steel micro-flakes can be used as feedstock in specialized binder jetting or fused deposition modeling (FDM) processes to create functional, high-strength components with controlled surface characteristics. Moreover, the shift toward sustainable and smart buildings globally creates an opportunity for specialized coatings utilizing stainless steel flakes for integrated conductive pathways or thermal regulation features. The development of surface-functionalized flakes, designed for superior adhesion and compatibility with various polymer matrices, presents a significant avenue for product differentiation and market expansion, overcoming traditional formulation challenges and expanding use in highly demanding composite materials.

Segmentation Analysis

The Stainless Steel Flakes Market is segmented across several critical parameters, including Grade, Application, Particle Size, and Region, allowing for precise market analysis and strategic targeting. Segmentation by Grade is vital, as it dictates the material's chemical resistance and thermal properties, with Grade 316L being essential for corrosive environments and Grade 304 frequently used in general industrial and decorative applications. The segmentation by Application highlights the varied functional requirements of end-users, ranging from highly aesthetic requirements in industrial paints to highly technical requirements in sensitive EMI shielding applications for telecommunications hardware.

Particle size is a distinguishing factor that profoundly affects both the aesthetic outcome (e.g., metallic brilliance or texture in coatings) and the functional performance (e.g., shielding effectiveness and conductivity). The market is typically categorized into micronized flakes and specialized sub-micron/nano-flakes, with smaller particles generally required for high-resolution printing or highly transparent coatings. The diversity in these segments reflects the highly specialized nature of the stainless steel flake market, driven by engineering specifications rather than simple commodity demand.

- By Grade:

- Grade 304 Stainless Steel Flakes

- Grade 316L Stainless Steel Flakes

- Grade 400 Series Stainless Steel Flakes

- Other Specialty Grades (e.g., Duplex Steel)

- By Particle Size:

- Micronized Flakes (gt;10 µm)

- Sub-Micron Flakes (1 µm – 10 µm)

- Nano-Flakes (lt;1 µm)

- By Application:

- Protective and Industrial Coatings (e.g., Marine, Chemical Plants, Infrastructure)

- Electromagnetic Interference (EMI) / Radio Frequency Interference (RFI) Shielding

- Plastics and Composites (e.g., Automotive Components, Housings)

- Conductive Inks and Pastes

- Additive Manufacturing

- By Region:

- North America

- Europe

- Asia Pacific (APAC)

- Latin America (LATAM)

- Middle East and Africa (MEA)

Value Chain Analysis For Stainless Steel Flakes Market

The value chain for the Stainless Steel Flakes market is complex, commencing with the upstream acquisition and processing of high-purity stainless steel feedstocks. Upstream analysis involves the procurement of stainless steel scrap, ferroalloys (chromium, nickel, molybdenum), and subsequent processing into high-quality stainless steel powder, primarily through atomization (gas or water). The quality and consistency of this starting powder are critical, as they directly influence the efficiency of the subsequent mechanical milling stage and the final morphology of the flakes. Key upstream players include major stainless steel producers and specialized metal powder manufacturers who supply the primary raw material for flake conversion.

The core midstream activity involves the transformation of spherical or irregular stainless steel powder into flat, high-aspect-ratio flakes using specialized high-energy ball milling, attrition milling, or specialized grinding techniques. This conversion step is technology-intensive and represents a significant value addition point, as expertise in controlling flake thickness, lateral dimension, and surface smoothness dictates the product's performance in end applications. Direct manufacturers often conduct proprietary surface treatments (e.g., silane coatings or polymeric encapsulation) to improve flake dispersion and compatibility with specific binder systems used in paints and polymers, further enhancing the midstream value proposition.

Downstream analysis focuses on distribution and integration into end-user products. Distribution channels are typically a mix of direct sales to large volume users (like major automotive OEM suppliers or global coatings manufacturers) and indirect sales through specialized chemical distributors and agents, particularly for smaller formulators. The final market integrators include paint and coatings companies, polymer compounders, and electronics manufacturers who formulate the flakes into functional end-products such as anti-corrosion primers, conductive plastics for consumer electronics housings, or specialized pastes for circuit board assembly. The effectiveness of the product hinges on close collaboration between flake manufacturers and downstream formulators to ensure optimal dispersion and application parameters are met.

Stainless Steel Flakes Market Potential Customers

Potential customers for stainless steel flakes are highly concentrated in industrial sectors requiring exceptional durability, corrosion resistance, and specific electromagnetic properties. The primary customer base includes global coatings formulators, particularly those serving the marine, petrochemical, and heavy infrastructure maintenance markets. These customers utilize large volumes of stainless steel flakes in highly aggressive primers and topcoats designed to protect valuable assets such as oil rigs, bridges, chemical storage tanks, and naval vessels from premature failure due to environmental degradation and harsh chemical exposure, demanding high purity and consistency, especially for Grade 316L flakes.

Another major segment of buyers includes electronics and telecommunications equipment manufacturers. These customers purchase stainless steel flakes for integration into injection molding plastics and conductive paints used in the manufacturing of casings, shields, and gaskets. With the proliferation of 5G, IoT devices, and complex server architecture, the necessity for robust Electromagnetic Interference (EMI) shielding has escalated significantly. Stainless steel flakes provide an effective, robust, and cost-efficient alternative to heavier or more expensive shielding materials, making electronics manufacturers key drivers of demand for sub-micron and fine-sized flakes.

Furthermore, automotive and aerospace component suppliers represent a growing customer base. In the automotive sector, customers seek materials for lightweight composite parts, specialized brake components, and coatings for internal combustion or battery components that require excellent thermal stability and fire resistance. The aerospace industry utilizes these flakes for specialized structural composites and high-performance primers applied to aircraft frames and engine components, where material failure due to corrosion or heat stress is unacceptable. These industries demand stringent quality control, robust supply chains, and certifications guaranteeing material performance under extreme conditions.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450.5 Million |

| Market Forecast in 2033 | USD 701.8 Million |

| Growth Rate | 6.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Eckart GmbH, Schlenk Metallic Pigments GmbH, Siberline Manufacturing Co., Toyo Aluminium K.K., Metaflake Ltd., Carl Schlenk AG, Umicore, Sun Chemical (DIC Corporation), BASF SE, Kuncai Pigments, Asahi Kasei Corporation, AMETEK Specialty Metal Products, Höganäs AB, Sandvik AB, Kennametal Inc., GKN Powder Metallurgy, Atlantic Equipment Engineers, Praxair Surface Technologies, Daikyo Nishikawa Corporation, JFE Steel Corporation |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Stainless Steel Flakes Market Key Technology Landscape

The technology landscape governing the production and application of stainless steel flakes is dominated by advancements in powder metallurgy and specialized surface engineering. The core manufacturing process relies heavily on sophisticated high-energy mechanical milling, such as ball milling or vibratory milling, which utilizes specialized grinding media and controlled inert atmospheres to transform pre-alloyed spherical powders into flattened flakes. Recent technological innovations focus on optimizing the geometry of the milling equipment and developing proprietary milling agents that minimize cold welding and fracture, thereby ensuring highly uniform particle size distribution and maximized aspect ratios, crucial for achieving superior coverage and conductivity in end-use applications.

A crucial technological area involves post-processing and surface modification techniques. Since bare stainless steel flakes can be challenging to disperse in organic solvents or polymer matrices, leading to sedimentation or poor adhesion, advanced surface coating technologies are being employed. These include chemical vapor deposition (CVD), silanization, and micro-encapsulation using organic polymers or specialized inorganic shells (e.g., silica). These coatings enhance compatibility, protect the flake surface from oxidation, and improve the durability and flexibility of the resulting coatings or composites, unlocking new applications in water-based systems and high-flexibility applications like flexible electronics.

Furthermore, the development of technologies enabling the commercial production of stainless steel nano-flakes is a transformative trend. These ultra-thin flakes, often produced using electro-deposition or advanced chemical exfoliation methods, offer unprecedented characteristics for use in transparent conductive films, high-resolution 3D printing, and complex medical device coatings where material economy and optical transparency are paramount. The ability to precisely classify and sort these nano-materials using advanced laser diffraction and sedimentation analysis represents a critical technological barrier being addressed by leading market players, ensuring consistency and purity vital for high-end electronic applications.

Regional Highlights

- Asia Pacific (APAC): APAC represents the largest and fastest-growing market for stainless steel flakes globally, primarily driven by the massive electronics manufacturing sector in countries like China, South Korea, and Taiwan, which requires high volumes of EMI shielding materials. Rapid urbanization and massive infrastructure projects across India and Southeast Asia fuel the demand for high-performance, long-lasting protective coatings for bridges, ports, and industrial facilities. Furthermore, the region is a global hub for automotive production, where stainless steel flakes are increasingly adopted in performance coatings and specialized plastic composites for both internal combustion engine (ICE) vehicles and electric vehicles (EVs), underscoring sustained and diverse industrial growth.

- North America: This region is characterized by high demand for specialized, high-grade flakes, particularly in the aerospace, defense, and oil and gas sectors, where material specifications are extremely rigorous. The robust presence of advanced research and development activities in materials science and additive manufacturing also drives innovation and consumption. Strict environmental regulations concerning volatile organic compounds (VOCs) encourage the adoption of stainless steel flakes in solvent-free and water-borne coating systems, maintaining steady demand for technologically advanced products.

- Europe: Europe is a mature market dominated by stringent quality standards in the automotive, industrial machinery, and high-end consumer goods sectors. Germany, in particular, leads the demand due to its strong automotive and chemical industries, utilizing stainless steel flakes for premium finishes and superior corrosion protection in exposed machinery and infrastructure. Regulatory frameworks like REACH influence the development of safer, non-toxic pigment alternatives, positioning stainless steel flakes advantageously over certain conventional heavy metal pigments, contributing to stable, quality-driven growth across the continent.

- Latin America (LATAM): LATAM exhibits moderate growth, largely influenced by infrastructure development and the expanding oil and gas sector, particularly in Brazil and Mexico. Demand is concentrated in protective coatings for pipelines, refining facilities, and marine applications. Market growth is sensitive to economic volatility and commodity price fluctuations, which can impact large-scale construction and industrial maintenance cycles.

- Middle East and Africa (MEA): Growth in the MEA region is heavily concentrated in the Gulf Cooperation Council (GCC) countries, fueled by massive investments in petrochemical complexes, desalination plants, and ambitious construction projects. The extremely high salinity and temperatures necessitate the use of premium, corrosion-resistant materials, making Grade 316L stainless steel flakes essential for ensuring the durability and longevity of critical industrial assets exposed to harsh desert and coastal environments.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Stainless Steel Flakes Market.- Eckart GmbH

- Schlenk Metallic Pigments GmbH

- Siberline Manufacturing Co.

- Toyo Aluminium K.K.

- Metaflake Ltd.

- Carl Schlenk AG

- Umicore

- Sun Chemical (DIC Corporation)

- BASF SE

- Kuncai Pigments

- Asahi Kasei Corporation

- AMETEK Specialty Metal Products

- Höganäs AB

- Sandvik AB

- Kennametal Inc.

- GKN Powder Metallurgy

- Atlantic Equipment Engineers

- Praxair Surface Technologies

- Daikyo Nishikawa Corporation

- JFE Steel Corporation

Frequently Asked Questions

Analyze common user questions about the Stainless Steel Flakes market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary functional benefits of using stainless steel flakes over aluminum flakes in coatings?

Stainless steel flakes offer significantly superior corrosion resistance, particularly against chlorides and chemical exposure, making them ideal for maritime and petrochemical environments. They also provide enhanced physical durability, better scratch resistance, and are non-flammable, unlike highly reactive aluminum pigments, thereby offering better safety and longevity in high-performance coatings.

Which stainless steel grade is most commonly used for high-corrosion environments like marine applications?

Grade 316L stainless steel flakes are the industry standard for high-corrosion applications. The presence of molybdenum in 316L provides exceptional resistance to pitting and crevice corrosion, making it indispensable for coatings used on offshore structures, pipelines, and equipment regularly exposed to saltwater.

How do stainless steel flakes contribute to Electromagnetic Interference (EMI) shielding?

Stainless steel flakes contribute to EMI shielding by forming a conductive network within the polymer matrix or coating layer. When a sufficient concentration is achieved, this network effectively reflects and absorbs electromagnetic radiation, thereby preventing interference in sensitive electronic equipment and meeting stringent regulatory compliance standards.

What is the key technological challenge in manufacturing high-quality stainless steel flakes?

The key technological challenge is achieving uniform morphology—specifically, a high aspect ratio (large diameter relative to thin thickness) and consistent particle size distribution—during the energy-intensive mechanical milling process. Inconsistency can lead to poor dispersion, reduced conductivity, and subpar aesthetic performance in the final application.

Is the Stainless Steel Flakes market seeing growth in sustainable or water-borne applications?

Yes, the market is shifting toward sustainable formulations. Manufacturers are developing surface-treated, functionalized stainless steel flakes that exhibit excellent compatibility and stability in low-VOC and water-borne coating systems, addressing increasing environmental regulations and fulfilling the growing demand for eco-friendly industrial products without compromising performance.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager