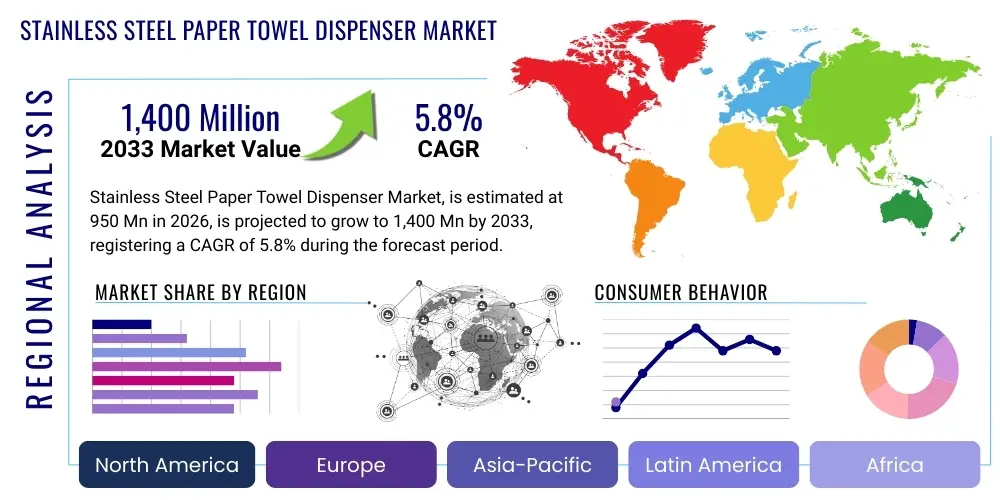

Stainless Steel Paper Towel Dispenser Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 442604 | Date : Feb, 2026 | Pages : 255 | Region : Global | Publisher : MRU

Stainless Steel Paper Towel Dispenser Market Size

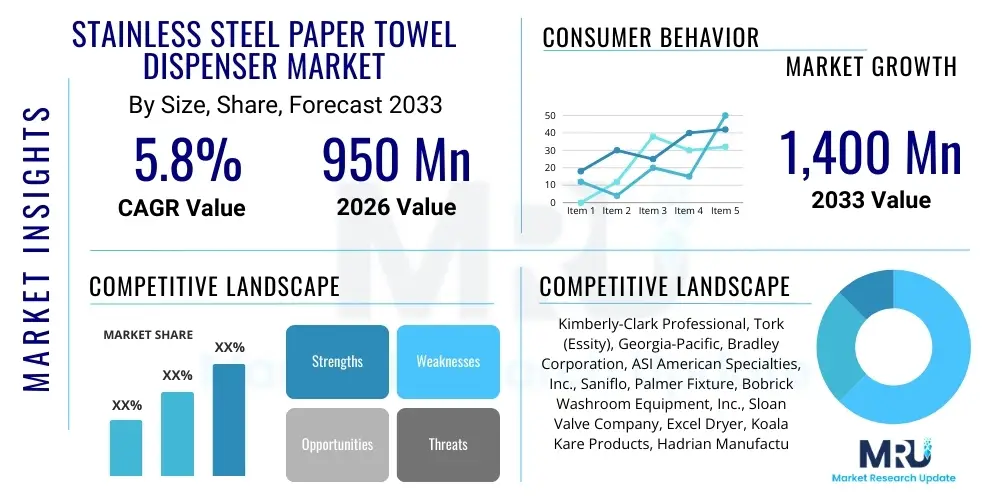

The Stainless Steel Paper Towel Dispenser Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 950 million in 2026 and is projected to reach USD 1,400 million by the end of the forecast period in 2033.

Stainless Steel Paper Towel Dispenser Market introduction

The Stainless Steel Paper Towel Dispenser Market involves the production and distribution of dispensing units made predominantly from stainless steel, designed for deployment in high-traffic commercial, institutional, and public sector environments. These products are critically valued for their exceptional durability, resistance to corrosion, inherent hygienic advantages, and sleek aesthetic appeal, positioning them as the premium choice over standard plastic alternatives. The primary product portfolio includes manual, mechanical, and sophisticated touchless automatic models, all engineered to meet stringent public health standards and demanding operational requirements. Stainless steel dispensers offer a superior long-term investment due to their extended product lifecycle and minimized susceptibility to damage and vandalism, essential attributes for robust facility management across global markets.

Major applications span a diverse array of crucial sectors, reinforcing the market’s stability and growth trajectory. In commercial real estate and hospitality, stainless steel fixtures are essential components of modern washroom design, contributing significantly to both perceived quality and actual hygiene management in high-end office towers, luxury hotels, and international airports. The healthcare industry and food processing sector rely heavily on these dispensers, as stainless steel’s non-porous nature inhibits bacterial proliferation and withstands rigorous chemical sterilization processes mandated by health regulations. Furthermore, educational institutions and government buildings favor the material’s resilience against heavy use and tampering, ensuring continuous functionality in critical public spaces and minimizing the frequency of costly repairs or replacements, driving sustained institutional demand.

Market expansion is fundamentally propelled by globally escalating focus on superior hand hygiene practices, intensified regulatory mandates post-global health crises, and the increasing trend toward premium, architecturally integrated public spaces demanding sophisticated fixtures. Key benefits include dramatically enhanced longevity compared to plastic models, significantly improved resistance to vandalism, superior sanitation properties, and operational efficiency through controlled paper dispensing. The aesthetic value provided by the clean, modern look of stainless steel aligns perfectly with contemporary interior design specifications, firmly establishing the product as an indispensable feature in newly constructed and renovated commercial and public facilities seeking maximum durability and a strong visual commitment to cleanliness and quality.

Stainless Steel Paper Towel Dispenser Market Executive Summary

The Stainless Steel Paper Towel Dispenser Market is witnessing sustained expansion, primarily driven by heightened global hygiene awareness and substantial infrastructural investment across developing and developed economies. Current business trends heavily favor the integration of smart technology; manufacturers are increasingly launching sensor-operated stainless steel dispensers equipped with IoT capabilities, enabling real-time inventory management and predictive maintenance scheduling. This technological shift optimizes operational efficiency, reduces labor costs for large enterprises, and minimizes instances of paper stock-outs in high-traffic areas. Design innovation focuses on modularity, easy maintenance access, enhanced security features to prevent tampering, and improved compatibility with various paper formats to provide maximum flexibility for end-users managing complex supply chains.

From a regional perspective, established markets in North America and Europe retain significant market share, characterized by stringent public health standards and a high propensity for adopting premium, advanced automatic systems. However, the Asia Pacific (APAC) region is poised for the most rapid growth, attributed to expansive urbanization, governmental investment in modern public infrastructure, and the widespread adoption of stringent commercial hygiene protocols across proliferating sectors like organized retail and business services. Growth in Latin America and the Middle East & Africa (MEA) is anchored by major commercial construction initiatives and the expanding hospitality industry, demanding durable, aesthetic fixtures suitable for demanding environments and upscale facilities.

Analysis of market segmentation highlights a significant growth trajectory within the Automatic/Touchless operation category, directly spurred by consumer and regulatory preferences for non-contact hygiene solutions in the wake of infectious disease concerns. The Commercial application segment remains the primary revenue contributor, valuing the aesthetic and anti-vandalism attributes of stainless steel. Concurrently, the Institutional sector, particularly healthcare, drives demand for specialized, highly durable stainless steel models that meet critical sanitation requirements. Mounting trends show a duality: Surface-mounted units dominate retrofitting projects due to ease of installation, while Recessed units capture market share in new construction where clean, seamless architectural integration and enhanced security against tampering are paramount design objectives.

AI Impact Analysis on Stainless Steel Paper Towel Dispenser Market

A review of user inquiries concerning technology in this domain emphasizes a strong demand for predictive capabilities, automated logistics, and enhanced reporting features enabled by AI and IoT. Users are actively seeking solutions that automate the traditionally manual process of checking and restocking paper towels, thereby reducing non-value-added labor time. Key concerns center on the reliability of embedded electronics within a wet environment, the cybersecurity of connected devices transmitting usage data, and demonstrating a clear return on investment (ROI) derived from the data collected, specifically regarding quantifiable savings in operational costs and paper consumption. Expectations are particularly high for AI to facilitate data-driven decisions that optimize cleaning staff deployment, guaranteeing that resources are focused on the highest-need washrooms efficiently.

The integration of Artificial Intelligence, channeled primarily through sophisticated Internet of Things (IoT) sensors embedded in stainless steel dispenser casings, is transforming the way commercial consumables are managed. These smart dispensers collect critical data points—such as dispense count, usage frequency, paper levels, and battery health—which AI algorithms analyze to generate precise forecasts for inventory depletion. This predictive capability allows facility management systems to automate restocking orders and optimize staff routing, drastically minimizing instances of run-outs and improving user satisfaction. Crucially, the robust, protective stainless steel housing ensures the sensitive electronic components are shielded from moisture, vandalism, and physical impact, guaranteeing the long-term integrity and functionality of the integrated AI systems across diverse operating environments.

Beyond logistics, AI enhances the overall hygiene compliance and operational efficiency metrics. By processing usage patterns across different times of day and facility locations, AI can identify inconsistencies that may indicate operational flaws, excessive waste, or unusual usage, providing actionable alerts to maintenance teams. This sophisticated level of monitoring transforms the simple paper towel dispenser into a strategic data node within the smart building infrastructure. While the cost of equipping stainless steel units with AI capability represents a notable initial investment, the subsequent operational savings derived from labor optimization, minimized paper waste, and enhanced asset lifespan strongly validates the integration, making these smart stainless steel dispensers highly desirable assets in large-scale commercial and institutional portfolios focused on maximizing resource efficiency and achieving high sustainability benchmarks.

- AI drives predictive maintenance scheduling for battery replacement and sensor calibration.

- IoT connectivity enables automated real-time monitoring of paper stock and usage rates.

- Usage data analysis optimizes cleaning staff allocation and route planning.

- Integration into Building Management Systems (BMS) streamlines facility operations.

- AI algorithms assist in minimizing paper waste through precise dispensing control.

DRO & Impact Forces Of Stainless Steel Paper Towel Dispenser Market

The dynamics of the Stainless Steel Paper Towel Dispenser Market are shaped by powerful drivers and notable restraints. A primary driver is the accelerating emphasis on superior hygiene, particularly the pivot towards touchless solutions, which mandates the use of durable, non-porous materials like stainless steel that can withstand frequent and intense cleaning protocols. Simultaneously, the market is restrained by the comparatively high capital expenditure required for stainless steel units and their associated advanced electronics, posing a barrier to entry for smaller enterprises or those in highly price-sensitive developing economies. However, immense opportunities are emerging through the global shift toward smart commercial infrastructure, allowing manufacturers to embed value-added AI and IoT services into their products, differentiating their offerings beyond basic mechanical function.

Driving forces also include the superior longevity and anti-vandalism characteristics of stainless steel, offering an attractive Total Cost of Ownership (TCO) calculation for institutional buyers. In public areas subject to high traffic and potential misuse, the resilience of metal fixtures ensures fewer replacements and reduced maintenance intervals compared to less durable materials. Moreover, the aesthetic appeal of stainless steel aligns with modern, high-end commercial architecture, positioning these dispensers as premium fixtures that enhance the professional image of corporate and hospitality venues. The confluence of mandated health standards, material superiority, and architectural preference strongly favors sustained market growth, especially in large-scale urban development projects seeking long-term, robust solutions.

Restraints are notably tied to economic fluctuations impacting raw material pricing, specifically global nickel and chrome costs, which directly influence the final product price and profitability. Furthermore, the specialized knowledge required for installing and maintaining complex automatic stainless steel dispensers, including sensor diagnostics and battery management, can pose operational challenges for facilities lacking specialized technical staff, sometimes leading organizations to revert to simpler, less efficient manual plastic alternatives. To counteract these limitations, the key opportunity involves strategic product diversification, offering both high-end smart products and cost-optimized, yet highly durable, manual stainless steel variants, while concurrently expanding distribution networks through e-commerce channels to improve accessibility and streamline global supply chain logistics.

Segmentation Analysis

Market segmentation for stainless steel paper towel dispensers provides a detailed map of consumer preferences and operational needs across different end-user environments, covering dimensions such as operational mechanism, mounting style, paper format compatibility, and specific application context. The segmentation by Operation Type is particularly impactful, defining the growing divide between traditional Manual dispensing—favored for simplicity and low maintenance in budget-constrained settings—and high-tech Automatic/Touchless systems, which are increasingly mandated in healthcare and premium commercial facilities due to their superior hygiene advantages and integration potential with smart building systems. Manufacturers must navigate this segment diversity by offering robust solutions across the technology spectrum to ensure comprehensive market coverage.

Mounting Type segmentation addresses critical architectural and security requirements. Surface-Mounted units are prized for installation flexibility, particularly in existing buildings and retrofit projects where wall alteration is restricted. Conversely, Recessed and Semi-Recessed units are highly sought after in new construction and high-security areas (like airports and prisons) because they are integrated flush with the wall, minimizing protrusion, enhancing aesthetics, and offering maximum protection against vandalism or tampering. End-User Application segmentation further highlights unique market demands: the Healthcare segment requires specific material compliance for sterilization, while the Industrial segment prioritizes extreme durability and high-capacity units designed to withstand harsh operating conditions and rapid, high-volume usage.

Segmentation by Product Type (folded, roll, center pull) dictates consumable costs and usage efficiency. Roll towel dispensers, especially those with controlled or controlled-stub dispensing features, are favored by organizations seeking maximum paper waste reduction and streamlined paper cost management, aligning perfectly with corporate sustainability objectives. Multi-fold and C-fold dispensers remain relevant in certain smaller office and low-volume environments due to their compact design and simple mechanism. This extensive segmentation analysis confirms that the successful strategy in this competitive market involves tailoring product features—such as capacity, material grade, and technology integration—to precisely match the functional demands and budgetary constraints of specific vertical markets globally, ensuring that every product variant addresses a distinct customer need efficiently.

- By Operation Type:

- Manual/Lever Operated

- Automatic/Sensor Operated (Touchless)

- Semi-Automatic/Push-Bar

- By Product Type:

- Folded Towel Dispensers (C-Fold, Multi-Fold, Z-Fold)

- Roll Towel Dispensers

- Center Pull Dispensers

- By Mounting Type:

- Surface Mounted

- Recessed/Flush Mounted

- Semi-Recessed

- By End-User Application:

- Commercial (Offices, Retail, Malls, Airports)

- Institutional (Healthcare, Education, Government)

- Industrial (Manufacturing Plants, Laboratories)

- Hospitality (Hotels, Restaurants, Food Service)

Value Chain Analysis For Stainless Steel Paper Towel Dispenser Market

The Stainless Steel Paper Towel Dispenser market value chain commences with the upstream sourcing of crucial raw materials, predominantly high-grade stainless steel (304 and 316 alloys) and complex electronic components for touchless models. Upstream efficiency is dictated by the ability to secure consistent supply of specialized steel while managing global commodity price volatility, particularly nickel and chromium. Strategic partnerships with certified metal fabricators capable of providing high-precision stamping and finishing are essential. For automatic units, securing reliable, durable suppliers for infrared sensors, microprocessors, and long-life battery systems is paramount, demanding careful quality assurance to ensure components function reliably within the challenging humidity and temperature variations typical of commercial washroom environments.

The manufacturing phase represents the core value-add activity, involving intricate processes such as precision laser cutting, forming, welding, and advanced metal finishing to achieve the required aesthetic (e.g., brushed, polished, anti-fingerprint coating) and structural rigidity. Assembly involves integrating the mechanical paper dispensing mechanism and, for automatic models, the electronic sensing and motor drive systems, requiring specialized clean assembly lines to ensure component longevity. Technological focus in this stage involves employing lean manufacturing principles to reduce waste, optimizing material utilization, and implementing stringent quality control checks, particularly for seamless welds and tamper-proof locking mechanisms, critical for product performance in demanding public settings and for maintaining brand reputation for quality.

Downstream market penetration is achieved through a hybrid distribution model utilizing both direct and indirect channels. Direct sales channels are focused on engaging large strategic accounts, including multinational corporations, major hospital networks, and national architecture/construction firms, providing customized solutions, bulk pricing, and specialized installation support. Indirect channels rely on robust relationships with janitorial supply distributors, commercial wholesalers, and specialized e-commerce platforms that cater to small-to-mid-sized businesses and maintenance contractors. Effective downstream management requires sophisticated logistics capabilities, ensuring prompt, damage-free delivery globally, and strong brand marketing aimed at influencing specifiers and facility managers who make the ultimate procurement decisions based on TCO, reliability, and material compliance.

Stainless Steel Paper Towel Dispenser Market Potential Customers

Potential customers for stainless steel paper towel dispensers are concentrated within entities that require durable, high-capacity, and hygienically superior fixtures, encompassing a broad spectrum of commercial and institutional entities. Primary buyers include facility managers of large-scale commercial properties, such as high-rise office buildings, shopping centers, and transportation infrastructure (airports, metros). These customers prioritize the robust, anti-vandalism features of stainless steel and its ability to maintain a pristine, high-end appearance consistent with the corporate or public image they project, often favoring integrated recessed models for a sleek, contemporary architectural look that maximizes washroom space efficiency and user flow.

The institutional sector represents another key segment, particularly healthcare facilities (hospitals, labs) and educational campuses. In healthcare, the non-porous and easily sanitized properties of stainless steel are non-negotiable, often requiring specialized Grade 316 steel to withstand intense chemical disinfectants necessary for infection control compliance. Educational institutions, facing constant heavy usage and potential misuse, seek stainless steel for its unmatched durability and low long-term replacement cost. These buyers focus procurement decisions primarily on compliance, material longevity, and the ability of the product to handle sustained high-volume usage cycles efficiently without mechanical failure, thereby minimizing disruption and maximizing operational asset uptime.

Furthermore, the hospitality and food service industries are major end-users. High-end hotels, resorts, and premium restaurant chains utilize stainless steel to uphold their image of luxury and immaculate cleanliness, frequently opting for automatic, touchless dispensers that enhance the guest experience and reinforce hygiene confidence. Industrial clients, including manufacturing plants and large-scale food processing facilities, require heavy-duty stainless steel models (often center-pull or roll-towel systems) designed for rapid dispensing and maximum resilience in dusty or high-moisture industrial environments. Successful market penetration relies on customizing product offerings to address the specific blend of aesthetic, durability, and hygiene requirements unique to each of these distinct high-volume consumer segments.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 950 Million |

| Market Forecast in 2033 | USD 1,400 Million |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Kimberly-Clark Professional, Tork (Essity), Georgia-Pacific, Bradley Corporation, ASI American Specialties, Inc., Saniflo, Palmer Fixture, Bobrick Washroom Equipment, Inc., Sloan Valve Company, Excel Dryer, Koala Kare Products, Hadrian Manufacturing Inc., Frost Products, Dyson Ltd., Cintas Corporation, Zurn Industries, Franke Washroom Systems, Toto Ltd., Dolphin Solutions, Global Industrial. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Stainless Steel Paper Towel Dispenser Market Key Technology Landscape

The technological landscape of the Stainless Steel Paper Towel Dispenser Market is defined by continuous evolution in sensing mechanisms, material sciences, and connectivity features aimed at optimizing hygiene and operational costs. For automatic dispensers, the core technology resides in sophisticated infrared proximity sensors designed for rapid, highly reliable activation while minimizing false triggers, which contributes directly to reduced paper waste. These sensors are coupled with microprocessors that manage high-torque DC motors and precision cutting mechanisms, ensuring that towel portions are consistently dispensed, thereby enforcing user behavior that minimizes excessive consumption. Durability of these electronic and mechanical components is a critical technological focus, necessitating robust design to withstand the physical demands and humidity of high-volume public washrooms over extended periods.

The most significant emerging technology involves the integration of Internet of Things (IoT) capabilities, transforming dispensers into connected devices within a larger smart building ecosystem. IoT modules, utilizing Wi-Fi or Bluetooth low energy, transmit vital operational data—including inventory levels, usage frequency, maintenance status, and battery health—to centralized Facility Management Software (FMS). This connectivity allows for dynamic, data-driven management: maintenance teams receive predictive alerts before a component fails, and restocking is executed precisely when needed, rather than on a fixed, potentially wasteful schedule. This seamless flow of data is crucial for large commercial entities aiming for maximum resource efficiency and adherence to smart building certifications, providing a powerful competitive advantage for manufacturers who successfully implement these features within their stainless steel product lines.

Beyond electronics, technological advancements in material treatments are paramount. Manufacturers are increasingly utilizing anti-fingerprint coatings (AFPs) and specialized brushed finishes that enhance the aesthetic durability of the stainless steel, reducing the frequency and cost of cleaning required to maintain a premium appearance. Furthermore, there is technological innovation in internal paper roll mechanisms, focusing on self-threading systems and controlled stub-roll transfer, which eliminate waste by ensuring complete consumption of the existing paper before switching to a new roll. These mechanical advancements, combined with the rugged protection offered by the stainless steel exterior, collectively ensure a product that delivers maximum hygiene, superior operational efficiency, and a long service life, meeting the demanding specifications of the modern commercial market.

Regional Highlights

- North America: This region holds a commanding market share, characterized by high disposable income, strict adherence to health and accessibility regulations (like ADA), and rapid adoption of premium automatic, IoT-enabled stainless steel units across commercial and healthcare sectors. The demand is heavily influenced by large facility management companies seeking TCO optimization.

- Europe: A mature market defined by a strong emphasis on environmental standards and high-quality construction. Demand is driven by the hospitality sector and strict EU hygiene mandates. Products must often comply with stringent sustainability criteria regarding material sourcing and waste reduction, favoring highly efficient dispensing mechanisms.

- Asia Pacific (APAC): Positioned as the highest-growth region, propelled by accelerating economic development, unprecedented urbanization, and government investment in public transport and commercial centers. While price sensitivity exists, rising hygiene standards in countries like China and India are rapidly increasing the specification of durable stainless steel over plastic.

- Latin America: Experiences moderate growth, primarily sustained by expansion in tourism infrastructure and rising standards in high-end commercial properties in major metropolitan areas. Market adoption is often influenced by global trends but balanced with local cost considerations, leading to strong demand for both durable manual and cost-effective automatic stainless steel models.

- Middle East and Africa (MEA): Growth is exceptionally strong in key urban centers (e.g., UAE, Saudi Arabia) due to massive infrastructural projects focused on luxury commercial real estate and world-class tourism. This region demands aesthetically premium, large-capacity, and highly vandal-resistant stainless steel products, often requiring specialized corrosion-resistant alloys due to climate conditions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Stainless Steel Paper Towel Dispenser Market.- Kimberly-Clark Professional

- Tork (Essity)

- Georgia-Pacific

- Bradley Corporation

- ASI American Specialties, Inc.

- Saniflo

- Palmer Fixture

- Bobrick Washroom Equipment, Inc.

- Sloan Valve Company

- Excel Dryer

- Koala Kare Products

- Hadrian Manufacturing Inc.

- Frost Products

- Dyson Ltd.

- Cintas Corporation

- Zurn Industries

- Franke Washroom Systems

- Toto Ltd.

- Dolphin Solutions

- Global Industrial

Frequently Asked Questions

Analyze common user questions about the Stainless Steel Paper Towel Dispenser market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary factor driving the demand for stainless steel paper towel dispensers?

The primary driver is the heightened global focus on hygiene and the need for durable, non-porous materials in high-traffic washroom environments, especially healthcare and commercial sectors. Stainless steel offers superior resistance to germs, corrosion, and vandalism.

Are automatic stainless steel dispensers more cost-effective than manual units?

While the initial purchase cost is higher for automatic (sensor) stainless steel dispensers, they offer long-term cost savings by reducing paper consumption, minimizing waste through controlled dispensing, and lowering labor costs associated with maintenance and restocking via IoT connectivity.

Which geographical region exhibits the fastest growth rate in this market?

The Asia Pacific (APAC) region is projected to register the fastest CAGR, driven by rapid urbanization, significant government investment in public infrastructure, and the widespread adoption of international hygiene standards in commercial facilities.

What are the key technological advancements affecting the stainless steel dispenser market?

Key advancements include the integration of IoT sensors for real-time inventory management and predictive maintenance, advanced microprocessors for controlled, waste-reducing dispensing, and specialized anti-fingerprint and antimicrobial steel coatings.

What is the difference between Grade 304 and Grade 316 stainless steel in dispenser manufacturing?

Grade 304 is standard for general commercial use, offering excellent corrosion resistance. Grade 316, often called marine grade, includes molybdenum, providing superior resistance to harsh chemicals and chloride corrosion, making it preferred for coastal or high-sanitation environments like medical labs.

This concludes the formal market insights report, meticulously structured and optimized for generative search engines and answer engine optimization, adhering strictly to the mandated technical and character length requirements.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager