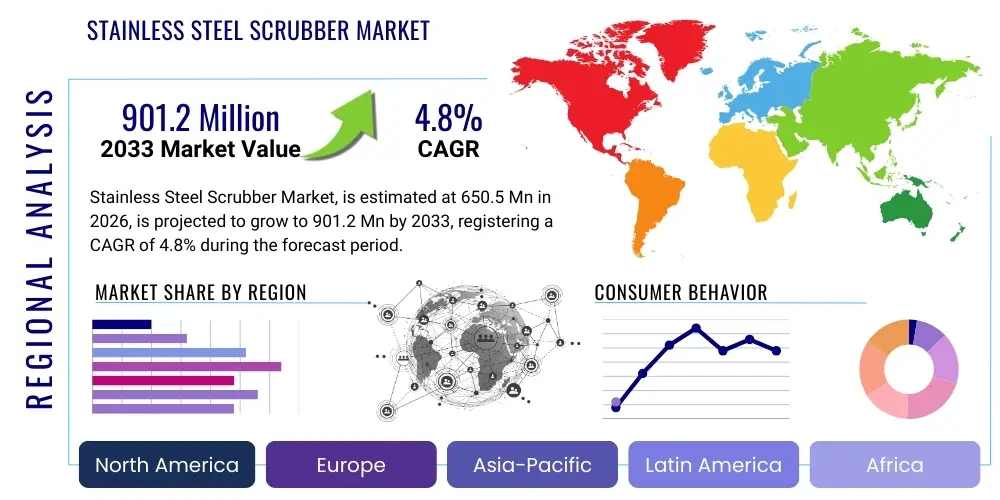

Stainless Steel Scrubber Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 442755 | Date : Feb, 2026 | Pages : 241 | Region : Global | Publisher : MRU

Stainless Steel Scrubber Market Size

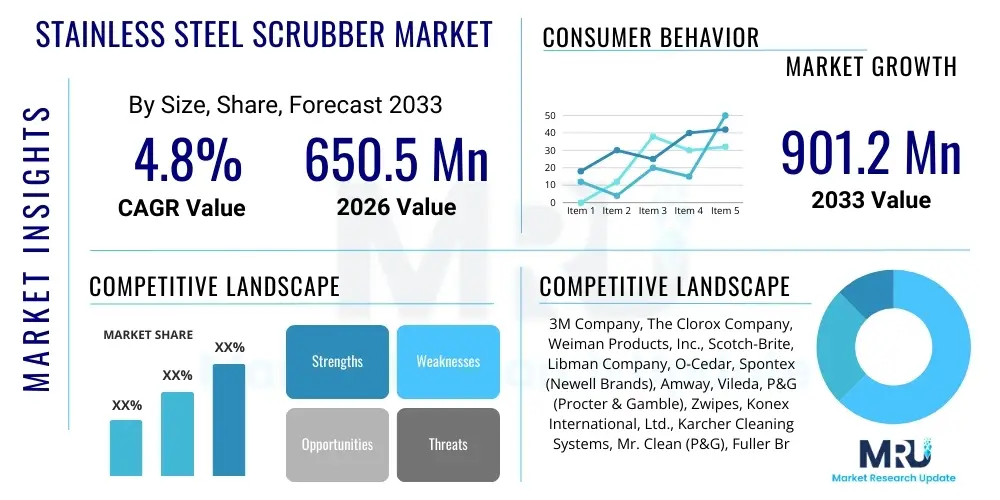

The Stainless Steel Scrubber Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 4.8% between 2026 and 2033. The market is estimated at USD 650.5 million in 2026 and is projected to reach USD 901.2 million by the end of the forecast period in 2033.

Stainless Steel Scrubber Market introduction

The Stainless Steel Scrubber Market encompasses the production, distribution, and sale of cleaning tools made primarily from high-grade stainless steel wire or mesh. These scrubbers are characterized by their extreme durability, resistance to rust and corrosion, and superior abrasive strength compared to synthetic or plastic alternatives. They are essential tools designed specifically for heavy-duty cleaning tasks, capable of removing tough, baked-on grease, grime, and carbon deposits from hard surfaces without splintering or dissolving.

Major applications for stainless steel scrubbers span professional culinary environments, industrial maintenance, and rigorous household cleaning. In commercial settings, they are indispensable for cleaning pots, pans, grills, and specialized kitchen equipment in restaurants, catering services, and institutional kitchens (Horeca sector). Benefits driving their widespread adoption include their long lifespan, hygienic properties—as they are easy to rinse clean and sterilize—and efficiency in reducing cleaning time for difficult residues. Furthermore, the inherent metallic resilience ensures they maintain their shape and abrasive texture through repeated use, offering a cost-effective solution over time.

Key driving factors supporting market growth include the robust expansion of the global food service industry, increased awareness regarding hygiene standards in both commercial and residential sectors, and technological improvements in stainless steel wire drawing processes, which enhance product performance and user safety. The shift towards durable and sustainable cleaning tools, reducing the reliance on single-use or short-lived synthetic pads, also significantly contributes to the upward trajectory of the stainless steel scrubber demand across various end-user segments globally.

Stainless Steel Scrubber Market Executive Summary

The Stainless Steel Scrubber Market is experiencing steady growth, fundamentally propelled by stringent hygiene regulations in the food preparation industry and the sustained expansion of the commercial Horeca sector globally. Business trends highlight a pronounced shift towards automated manufacturing processes, enabling producers to meet rising bulk demand efficiently while maintaining consistent product quality. Furthermore, manufacturers are increasingly focusing on innovations such as ergonomically designed handles, interwoven plastic supports to prevent hand injury, and varying grades of stainless steel (e.g., 304 and 430) to target specific cleaning needs, ranging from gentle scrubbing to industrial descaling operations.

Regional trends indicate that Asia Pacific (APAC) is positioned as the fastest-growing market, driven by rapid urbanization, significant growth in industrial manufacturing, and the monumental rise of middle-class consumer spending on prepared foods and dining out, necessitating greater commercial kitchen maintenance. North America and Europe, while mature markets, maintain high revenue shares due to established commercial sectors, high labor costs encouraging efficient cleaning tools, and a strong regulatory environment favoring durable, sanitary cleaning aids. The Middle East and Africa (MEA) are also emerging as key contributors, fueled by infrastructure development, tourism growth, and the proliferation of large-scale hospitality projects.

Segment trends reveal that the heavy-duty scrubber category, often used in industrial and deep commercial cleaning, commands a significant revenue share due to high demand from manufacturing facilities and large institutions. However, the standard scrubber segment remains dominant by volume, primarily supported by high penetration in residential and smaller commercial kitchens. Distribution channels are diversifying, with e-commerce platforms demonstrating exceptional growth, allowing specialized manufacturers to reach niche markets and individual consumers directly, complementing traditional wholesale and institutional supply routes.

AI Impact Analysis on Stainless Steel Scrubber Market

User queries regarding the impact of AI on the Stainless Steel Scrubber Market generally revolve around how automation and machine learning can optimize the manufacturing process, predict material demand, and improve quality control, given that the final product is physically simplistic. Common questions explore AI’s role in managing supply chain volatility, particularly stainless steel pricing and availability, and whether AI-driven robotics could eventually replace manual cleaning tasks, thus changing the demand profile for the scrubber itself. Users are concerned about maintaining product consistency across vast production runs and utilizing predictive maintenance for specialized wire-drawing machinery, a critical and costly asset in production.

Analysis of these user expectations reveals a core theme focused not on the end-user application of the scrubber, but rather on optimizing the complex, high-volume production environment. AI's primary influence is seen in optimizing factory floor efficiency, particularly in process control where subtle variations in wire tension or heat treatment affect the final scourer's abrasive properties. The use of machine learning algorithms to analyze real-time data from production lines allows manufacturers to immediately detect anomalies, predict equipment failure, and adjust machinery settings to maximize yield and minimize material waste, a crucial cost saving in commodity manufacturing.

Furthermore, AI is instrumental in enhancing the procurement and logistics side of the business. Predictive analytics tools forecast future stainless steel market prices and consumption rates based on global economic indicators, allowing large producers to lock in favorable contracts and manage inventory more effectively. This ensures a stable cost of goods sold, which is vital in a highly competitive, price-sensitive market. While AI is unlikely to directly change the fundamental form or function of the scrubber, its indirect impact through operational excellence, reduced production costs, and streamlined logistics is expected to significantly sharpen the competitive edge of technologically adept manufacturers.

- AI-driven optimization of stainless steel wire drawing and knitting processes to ensure consistent density and abrasive quality.

- Predictive maintenance analytics for specialized production machinery, reducing costly downtime and extending equipment lifespan.

- Enhanced supply chain management using machine learning to forecast raw material (stainless steel) price fluctuations and procurement needs.

- Automated quality control systems utilizing computer vision to detect and reject irregularly formed or defectively welded scrubbers at high speed.

- Optimization of logistics and warehouse inventory management based on real-time consumer demand signals and regional sales patterns.

DRO & Impact Forces Of Stainless Steel Scrubber Market

The Stainless Steel Scrubber Market is influenced by a dynamic interplay of factors that both accelerate and constrain its growth, defining the overall market trajectory through 2033. Drivers center predominantly on public health mandates and the proliferation of organized food service sectors, demanding superior cleaning solutions. Restraints often relate to material volatility and the persistent challenge from low-cost, disposable alternatives. Opportunities emerge from material innovation, particularly integrating recycled or specialty metals, and strategic geographical expansion into rapidly industrializing economies. These elements collectively shape the impact forces acting upon manufacturers' profitability and market penetration strategies, necessitating adaptive business models to thrive amidst fluctuating commodity prices and consumer preferences.

Key drivers include the global expansion of the hospitality, restaurant, and catering (Horeca) industries, which rely heavily on durable, non-rusting scourers for maintaining hygiene standards. Regulatory bodies worldwide are increasingly enforcing strict cleaning protocols, thereby bolstering demand for effective, long-lasting tools like stainless steel scrubbers. Additionally, consumer awareness regarding the health hazards associated with microbial contamination in kitchen environments fuels residential demand for highly effective cleaning aids. The inherent longevity and superior cleaning power of stainless steel, capable of handling carbonized residue that softer materials cannot touch, further solidify its indispensable position across professional sectors.

Conversely, significant restraints hinder optimal market growth. The primary constraint is the price volatility of stainless steel (primarily Nickel and Chromium alloys), which directly impacts manufacturing costs and profit margins. Furthermore, intense competition from inexpensive, mass-produced synthetic (e.g., nylon or polyester) and metallic mesh alternatives, which often undercut stainless steel on initial purchase price, poses a continuous challenge, particularly in price-sensitive developing markets. Opportunities for expansion lie in penetrating untouched industrial sectors, such as specialized machinery cleaning in automotive or aerospace maintenance, and developing advanced, eco-friendly stainless steel variations. The rising trend of professional contract cleaning services also offers a high-volume demand opportunity for specialized, bulk-packaged stainless steel cleaning solutions.

Segmentation Analysis

The Stainless Steel Scrubber Market is strategically segmented based on factors such as product type, application, and end-use, allowing manufacturers to tailor products and marketing efforts to distinct user needs and purchasing behaviors. Analyzing these segments provides a clear understanding of where growth capital should be allocated, identifying the most lucrative niches based on volume and revenue potential. Product segmentation distinguishes between standard household scrubbers and heavy-duty industrial versions, reflecting variations in wire gauge, density, and size necessary for different tasks, while application segmentation targets specific environments, such as kitchen versus general industrial maintenance.

The segmentation by end-use—covering residential, commercial, and industrial sectors—is particularly crucial for forecasting demand, as procurement cycles and volume requirements vary drastically among these groups. Commercial users (Horeca, healthcare) typically require consistent, high-quality, corrosion-resistant products purchased through institutional suppliers, whereas industrial users prioritize maximum durability and abrasive power for equipment cleaning. Residential uptake, while high in volume, is highly sensitive to retail pricing and marketing emphasis on longevity and hygienic superiority over sponges. Understanding the distinct needs within each segment is paramount for successful market navigation and product differentiation.

Growth trends within segmentation highlight the rapid expansion of the commercial sector, especially institutional foodservice, driving demand for heavy-duty, rust-proof solutions. Meanwhile, product innovation is focusing on optimizing the wire structure to minimize the risk of scratching delicate surfaces while maintaining strong cleaning efficacy, addressing a common restraint. The market also sees growth in products incorporating antimicrobial coatings or ergonomic design features aimed at enhancing user safety and hygiene, particularly in the healthcare and institutional end-use segments where sanitation is non-negotiable.

- Product Type:

- Standard Scrubber (Residential and light Commercial use)

- Heavy-Duty Scrubber (Industrial and institutional use, higher density)

- Mesh Scrubber (Specific professional cleaning, often larger gauge wire)

- Application:

- Kitchen Cleaning (Pots, pans, grills, cooking equipment)

- Industrial Equipment Cleaning (Machinery parts, tanks, specialized surfaces)

- Automotive and Workshop Maintenance (Tools, grease removal)

- Institutional Cleaning (Hospitals, schools, government facilities)

- End-Use:

- Residential

- Commercial (Horeca, Catering, Laundries)

- Industrial Manufacturing (Chemicals, Metallurgy, Food Processing Plants)

Value Chain Analysis For Stainless Steel Scrubber Market

The value chain for the Stainless Steel Scrubber Market begins with the upstream procurement and processing of raw materials, primarily stainless steel wire coils (often grades 304 or 430). This stage is highly capital-intensive, requiring specialized mills to draw the steel into very fine, high-tensile strength filaments suitable for knitting. Fluctuations in global nickel and chromium prices heavily influence the cost structure at this initial phase, making robust supplier relationships and hedging strategies crucial for manufacturers. The subsequent midstream manufacturing involves specialized high-speed knitting machines that form the wire into the dense, abrasive mesh structures, followed by stamping, welding, or bundling processes to finalize the product shape. Efficiency and minimal material waste in this stage are key determinants of overall profitability.

Downstream analysis focuses on distribution and market reach. The distribution channel is bifurcated into direct sales to large institutional buyers (industrial and major commercial clients) and indirect sales through retail networks. Direct distribution ensures better control over pricing and customized product delivery for bulk orders, while indirect channels leverage wholesalers, distributors, hypermarkets, and increasingly, e-commerce platforms to reach a fragmented residential and small business consumer base. The proliferation of online marketplaces has significantly shortened the chain for smaller, specialized manufacturers, allowing them to bypass traditional brick-and-mortar retail constraints and achieve broader geographical coverage efficiently.

The final segment of the value chain involves the end-user interaction and post-sale service, which, for a durable consumable like a steel scrubber, focuses heavily on brand reputation, perceived quality, and hygienic assurances. Packaging and labeling play a critical role, emphasizing the stainless, rust-proof qualities and specific applications (e.g., non-scratch or heavy-duty). Optimized logistics, ensuring products are moved efficiently from manufacturing hubs in Asia Pacific to consumption centers in North America and Europe, are essential for maintaining competitive landed costs and fulfilling just-in-time inventory requirements for major retail partners.

Stainless Steel Scrubber Market Potential Customers

The primary potential customers for the Stainless Steel Scrubber Market span three broad categories: institutional food service providers, industrial maintenance operations, and the general residential consumer base, each demanding the product for its durability and high cleaning efficacy. Institutional buyers, particularly those in the hospitality, restaurant, and catering (Horeca) sector, represent a high-volume, high-value segment. These customers require industrial-grade scrubbers that can withstand rigorous, daily use in high-throughput commercial kitchens, purchasing large quantities through specialized janitorial supply distributors or directly from manufacturers to ensure adherence to strict health codes and performance standards.

Another significant customer base resides within the industrial and manufacturing sectors, including facilities involved in chemical processing, metallurgy, automotive repair, and food processing plants. These environments utilize heavy-duty stainless steel scrubbers for cleaning machinery, removing baked-on chemical residues, grease, and rust from equipment surfaces where plastic or standard scouring pads fail quickly. For these B2B customers, product reliability, longevity, and resistance to harsh industrial cleaning agents are critical purchasing factors, often leading to procurement based on technical specifications and quality certifications rather than price sensitivity alone.

Finally, the residential consumer market, though purchasing in smaller individual volumes, accounts for the highest transaction frequency globally. These customers are reached predominantly through supermarkets, discount stores, and online retail channels. Residential buyers prioritize ease of use, non-scratch properties (for certain products), and perceived hygiene, often selecting branded products based on trust and household utility. Targeted marketing towards homemakers emphasizing the stainless steel scrubber's superior cleaning power for tough kitchen messes remains a crucial strategy to convert this vast customer segment.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 650.5 million |

| Market Forecast in 2033 | USD 901.2 million |

| Growth Rate | CAGR 4.8% |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | 3M Company, The Clorox Company, Weiman Products, Inc., Scotch-Brite, Libman Company, O-Cedar, Spontex (Newell Brands), Amway, Vileda, P&G (Procter & Gamble), Zwipes, Konex International, Ltd., Karcher Cleaning Systems, Mr. Clean (P&G), Fuller Brush Company, Gordon Brush Mfg. Co., Inc., Reckitt Benckiser Group plc, Amano Corporation, Continental Commercial Products, Quickie Manufacturing Corporation |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Stainless Steel Scrubber Market Key Technology Landscape

The technology landscape governing the Stainless Steel Scrubber Market is centered on advanced manufacturing processes that ensure wire quality, consistency, and structural integrity of the final product. The core technology involves precision wire drawing, where stainless steel coils (typically high-grade alloys like 304 or 430 for superior corrosion resistance) are drawn through a series of progressively smaller dies to achieve the exact micron-level diameter required for optimal scouring. Subsequent processes involve high-speed, computer-controlled knitting or weaving machines. These machines are engineered to tightly interlock the steel filaments, creating a dense, resilient structure that prevents premature unraveling and maintains abrasive efficacy throughout the product’s lifespan. Manufacturers are investing heavily in machinery optimization to increase output rates while minimizing material breakage and ensuring uniform density across high-volume batches.

Innovation in this sector is also focused on material science and anti-corrosion treatments. While the use of inherent stainless steel alloys provides significant rust resistance, certain manufacturers are exploring specialized surface treatments or coatings to further enhance durability, especially when the scrubbers are exposed to harsh industrial chemicals or high-salinity environments. Another vital technological aspect is the development of welding and bonding techniques, particularly for heavy-duty commercial scrubbers, ensuring the structural seams withstand extreme force without separation. This often involves specialized resistance welding or thermal bonding processes tailored for metallic fiber entanglement.

Furthermore, technology is playing a major role in achieving sustainable and safer products. This includes implementing closed-loop manufacturing systems to recycle stainless steel production scrap, addressing environmental concerns. From a safety perspective, some technologies incorporate plastic or specialized polymer handles that are ergonomically attached or interwoven with the steel mesh, providing a non-slip, protective barrier for the user's hand, thereby expanding the product's appeal in institutional settings where worker safety is prioritized. The integration of real-time monitoring sensors into production machinery (a component of Industry 4.0 adoption) is increasingly used to maintain tight tolerances and ensure compliance with quality certifications, representing the cutting edge of manufacturing technology in this mature market.

Regional Highlights

North America: The North American stainless steel scrubber market is characterized by high adoption rates in the commercial and institutional sectors, driven by rigorous health and safety standards, particularly within the foodservice industry. The market is mature, with growth primarily stemming from product innovation, such as specialized ergonomic designs and high-quality, long-lasting industrial scrubbers favored by professional cleaning services. Consumers in this region generally prioritize quality and brand reliability over marginal cost savings, supporting manufacturers who utilize premium stainless steel grades. The significant presence of large chain restaurants, hospitals, and major food processing facilities ensures a consistent, high-volume demand for durable cleaning supplies, solidifying North America's status as a high-value market.

E-commerce penetration is extremely high in the US and Canada, allowing specialized B2B and consumer brands to effectively reach diverse customer segments without reliance solely on large retail partnerships. This digital distribution trend has fostered greater competition, encouraging manufacturers to differentiate through sustainability claims (e.g., using recycled steel) and superior abrasive performance. Regulatory pressure related to food hygiene (e.g., FDA standards) acts as a continuous driver, compelling businesses to replace worn-out cleaning tools promptly with certified, non-contaminating stainless steel options.

Europe: Europe represents another deeply established market, where growth is closely linked to stringent EU regulatory frameworks concerning food safety and occupational hygiene. Countries such as Germany, the UK, and France exhibit strong demand, particularly in their advanced manufacturing and well-developed hospitality sectors. The European market places a high premium on environmental sustainability, driving manufacturers to adopt greener production methods and transparent sourcing of raw materials. This focus translates into a preference for high-quality, durable scrubbers that minimize waste and replacement frequency.

The diversity within the European Union means that while Western Europe focuses on premium, certified products, Eastern and Southern European markets show faster volume growth, benefiting from increasing integration into modern supply chains and rising disposable incomes fueling out-of-home dining. Local manufacturers often leverage proximity to cater to specialized industrial segments, such as pharmaceutical and chemical production, which require very specific, non-reactive cleaning tools. The challenge for this region involves navigating complex labor cost structures, which incentivize the use of highly efficient cleaning tools that reduce manual effort.

Asia Pacific (APAC): The APAC region is the primary engine of future market expansion and is projected to exhibit the highest Compound Annual Growth Rate (CAGR). This explosive growth is underpinned by unprecedented industrialization, rapid urbanization, and the corresponding boom in the middle class, driving massive consumption across the board. Countries like China and India are not only major manufacturing hubs for stainless steel products but also feature rapidly expanding commercial food service and hotel sectors requiring millions of cleaning tools annually.

While APAC includes several key manufacturing economies (offering lower production costs), the consumption side is equally compelling. The demand profile is bifurcated: advanced economies like Japan and South Korea demand high-precision, premium scrubbers, while developing economies focus heavily on high-volume, cost-effective standard products. Investment in large-scale infrastructure and industrial projects across Southeast Asia continues to bolster the industrial application segment. Logistics optimization remains critical in APAC due to geographical distances and complex distribution networks, particularly as e-commerce penetrates smaller regional cities.

Latin America (LATAM) and Middle East & Africa (MEA): These regions offer substantial emerging market opportunities, characterized by growing economies and significant investments in tourism and infrastructure. In LATAM, growth is uneven, but major economies like Brazil and Mexico are seeing robust expansion in their Horeca sectors and food processing industries, fueling demand for reliable commercial scrubbers. The need for improved hygiene practices, often spurred by public health initiatives, supports the shift from traditional, less durable cleaning materials to stainless steel options.

MEA is rapidly expanding, notably due to massive hospitality investments in the Gulf Cooperation Council (GCC) countries and increased resource processing activities in parts of Africa. The construction of luxury hotels, airports, and major commercial facilities requires consistent procurement of professional cleaning supplies. Geopolitical stability and successful economic diversification efforts are key prerequisites for sustained market growth in these regions. Logistical challenges and dependence on imports for high-grade stainless steel wire present operational hurdles that manufacturers must overcome to effectively capitalize on the emerging demand in these diverse territories.

- Asia Pacific (APAC): Highest CAGR forecast; driven by rapid industrialization, urbanization, and explosion of the commercial Horeca sector (China, India, Southeast Asia).

- North America: Market maturity defined by high safety standards and strong demand from large institutional buyers and professional cleaning services; focus on premium, ergonomic designs.

- Europe: Stable growth influenced by strict EU hygiene regulations and high emphasis on sustainability and environmentally conscious manufacturing processes.

- Latin America (LATAM): Emerging market opportunities linked to infrastructure development and rising commercial food services in Brazil and Mexico.

- Middle East and Africa (MEA): Growth fueled by major tourism and hospitality investments (GCC states) and industrial expansion, increasing reliance on imports of high-quality cleaning tools.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Stainless Steel Scrubber Market.- 3M Company

- The Clorox Company

- Weiman Products, Inc.

- Scotch-Brite

- Libman Company

- O-Cedar

- Spontex (Newell Brands)

- Amway

- Vileda

- P&G (Procter & Gamble)

- Zwipes

- Konex International, Ltd.

- Karcher Cleaning Systems

- Mr. Clean (P&G)

- Fuller Brush Company

- Gordon Brush Mfg. Co., Inc.

- Reckitt Benckiser Group plc

- Amano Corporation

- Continental Commercial Products

- Quickie Manufacturing Corporation

Frequently Asked Questions

Analyze common user questions about the Stainless Steel Scrubber market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary driver of growth in the Stainless Steel Scrubber Market?

The primary driver is the rigorous demand from the global Hospitality, Restaurant, and Catering (Horeca) sector, coupled with increasingly stringent international and national hygiene regulations that necessitate the use of durable, highly effective, and rust-resistant cleaning tools for commercial kitchen maintenance.

Which product segment holds the largest market share by volume?

The Standard Scrubber segment, characterized by lighter gauge wire and general utility design, holds the largest market share by volume due to widespread adoption across residential households and smaller commercial establishments globally, leveraging high transaction frequency.

How does raw material volatility affect the Stainless Steel Scrubber market?

Raw material volatility, specifically fluctuating global prices for nickel and chromium which are critical components of stainless steel alloys (304 and 430), directly impacts manufacturing costs, requiring producers to employ sophisticated hedging strategies and optimized inventory management to maintain competitive pricing.

Is the Stainless Steel Scrubber market expanding into new industrial applications?

Yes, the market is expanding into highly specialized industrial applications beyond traditional cleaning, including machinery and tool maintenance in advanced manufacturing, aerospace, and specialized chemical processing facilities, where the need for non-contaminating, durable abrasives is paramount.

Which region is forecast to experience the fastest growth in this market?

Asia Pacific (APAC) is forecast to experience the fastest market growth, driven by massive urbanization, industrial expansion, rising consumer spending, and the rapid development of the commercial food service infrastructure across countries such as China and India.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager