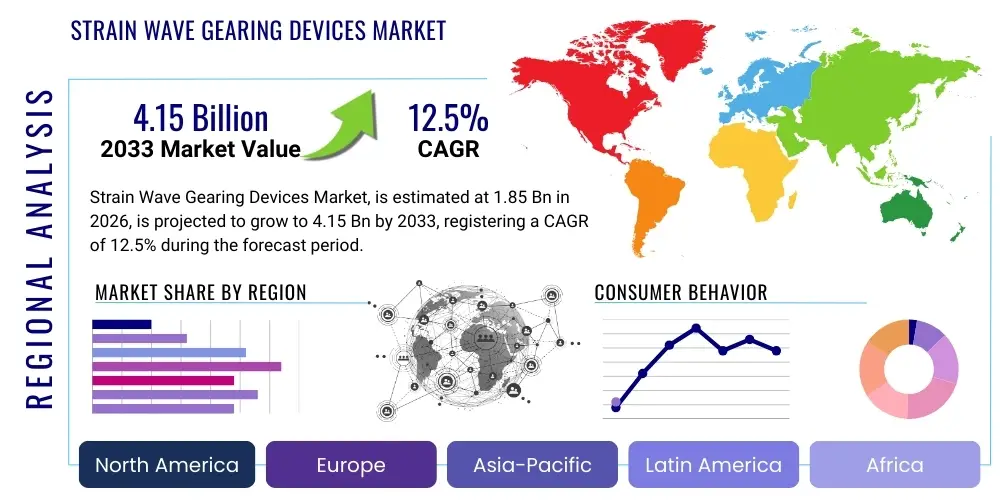

Strain Wave Gearing Devices Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 442481 | Date : Feb, 2026 | Pages : 258 | Region : Global | Publisher : MRU

Strain Wave Gearing Devices Market Size

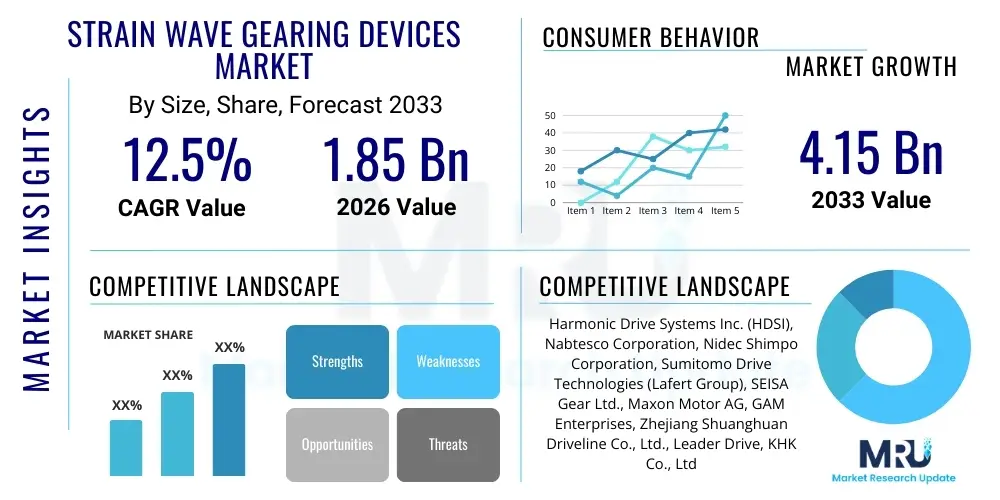

The Strain Wave Gearing Devices Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 12.5% between 2026 and 2033. The market is estimated at USD 1.85 Billion in 2026 and is projected to reach USD 4.15 Billion by the end of the forecast period in 2033. This substantial expansion is fundamentally driven by the accelerating demand for high-precision, zero-backlash motion control solutions essential across sophisticated industrial automation sectors, particularly robotics and high-fidelity manufacturing equipment. The unique kinematic properties of strain wave gears, offering exceptional torque density and compact design, position them as indispensable components in next-generation machinery, thereby ensuring robust market capitalization expansion.

Strain Wave Gearing Devices Market introduction

The Strain Wave Gearing Devices Market encompasses highly specialized mechanical systems utilized for power transmission and motion control, characterized by their unique construction involving a flexible component (flexspline), a rigid circular spline, and a wave generator. These devices, often referred to as harmonic drives, are defined by their capability to achieve extremely high gear ratios within a minimal volume, delivering unparalleled positional accuracy, zero backlash, and high torque density. This technological prowess makes them critical components in demanding applications where precision and reliability are paramount, such as collaborative robotics (cobots), surgical robotics, aerospace mechanisms, and precision optical equipment.

The key driving factors propelling the market expansion include the global surge in industrial automation adoption, especially in high-wage economies seeking productivity enhancements and labor cost mitigation. Furthermore, the rapid advancements in articulated and humanoid robotics necessitate lightweight, compact gearing solutions capable of handling significant loads while maintaining sub-arc-minute precision, which strain wave gears inherently provide. The benefits of using these devices—including reduced footprint, enhanced system stiffness, and prolonged operational lifespan—are leading to their increased integration over traditional gearboxes in specialized machinery, solidifying their market position as foundational technology for Industry 4.0 infrastructure.

Major applications span diverse high-tech industries. In robotics, they are deployed in articulated joints, wrist mechanisms, and end-effectors due to their superior repeatability. The medical sector leverages them for precise movement in MRI machines and complex surgical robots, where failure is not permissible. Additionally, semiconductor manufacturing equipment, telescope positioning systems, and specialized defense actuation systems rely heavily on the accuracy and reliability offered by strain wave gearing. This versatility across mission-critical applications is a primary catalyst for sustained market demand and technological innovation within the segment.

Strain Wave Gearing Devices Market Executive Summary

The Strain Wave Gearing Devices Market is exhibiting a strong growth trajectory, underpinned by transformative business trends focusing on miniaturization, enhanced torque density, and integration with advanced digital control systems. Leading manufacturers are investing heavily in material science—specifically, high-strength alloys and advanced composite materials for the flexspline—to increase gear life and efficiency without compromising size. The competitive landscape is characterized by strategic partnerships between gear manufacturers and robotic integrators, aiming to co-develop optimized drive systems tailored for specific robotic payloads and operational environments. Furthermore, a major trend involves developing modular strain wave gear units that can be easily adapted and scaled for diverse automation tasks, accelerating time-to-market for end-product manufacturers.

Regionally, the Asia Pacific (APAC) stands as the dominant and fastest-growing market, primarily fueled by massive government investments in smart manufacturing initiatives in China, South Korea, and Japan, which are global leaders in industrial and service robotics deployment. North America and Europe maintain robust demand, driven by stringent quality requirements in aerospace, defense, and medical device manufacturing, sectors that prioritize precision and reliability over initial cost. Emerging markets in Latin America and MEA are showing nascent growth, stimulated by increasing foreign direct investment in localized automation infrastructure and light manufacturing assembly lines, though adoption remains focused on lower-precision applications compared to mature regions.

Segmentation trends highlight the increasing prominence of products categorized by bore size and gear ratio. Small-bore gears (below 50 mm) are experiencing rapid adoption due to the proliferation of compact collaborative robots and miniaturized medical devices. Similarly, high-ratio systems are preferred in applications demanding powerful, slow-speed rotation with maximum precision, such as high-resolution antenna positioning systems. The adoption of component sets (as opposed to cased units) is rising, allowing system integrators greater flexibility in design and direct integration into custom machinery components, reflecting a shift towards highly tailored motion solutions in specialized industrial segments.

AI Impact Analysis on Strain Wave Gearing Devices Market

The integration of Artificial Intelligence (AI) and Machine Learning (ML) is fundamentally altering the lifecycle and performance optimization of Strain Wave Gearing Devices, leading to common user queries centering on predictive maintenance, design optimization, and autonomous operational control. Users frequently inquire about how AI algorithms can predict flexspline fatigue life based on real-time operational telemetry, minimizing unscheduled downtime in critical applications like surgical robotics. Another key theme revolves around AI-driven design iteration, asking whether generative design based on ML feedback loops can rapidly optimize gear tooth profiles for better efficiency and reduced thermal losses. Expectations are high regarding the use of AI in closed-loop control systems to dynamically adjust motor torque and current, compensating instantly for temperature variations and minor manufacturing eccentricities, thereby ensuring the gear maintains sub-arc-minute precision throughout its service life.

- AI-driven Predictive Maintenance: Utilizing sensor data (vibration, temperature, current draw) to forecast gear component failure, maximizing uptime and optimizing service schedules.

- Generative Design Optimization: Employing ML to rapidly simulate and iterate on flexspline geometry and tooth profiles for enhanced torque density and reduced weight.

- Closed-Loop Positional Control: AI algorithms refine servo control parameters in real-time to compensate for external disturbances or internal wear, maintaining superior positional accuracy and repeatability.

- Automated Quality Inspection: Vision AI systems enhance manufacturing quality control by detecting microscopic surface defects and geometric anomalies in gear components during production.

- Robot Teaching and Path Planning: Strain wave gear performance data feeds into AI systems for optimized robot path planning, minimizing stress on the drive train and extending operational life.

DRO & Impact Forces Of Strain Wave Gearing Devices Market

The dynamics of the Strain Wave Gearing Devices Market are shaped by powerful Drivers (D), Restraints (R), Opportunities (O), and associated Impact Forces. The primary drivers are the exponential growth of the global robotics industry, encompassing both industrial automation and service robotics, coupled with the critical need for ultra-high-precision components in aerospace and medical technology. These forces compel manufacturers to seek out gear mechanisms that offer high reduction ratios in a lightweight, compact form factor. However, the market faces significant restraints, chiefly the relatively high manufacturing cost associated with producing the specialized, thin-walled flexspline and the stringent material requirements necessary to achieve zero-backlash performance and long operational lifespan. The intricate manufacturing processes demand high capital investment, creating significant barriers to entry for new players, thus concentrating market power among a few established specialists.

Key opportunities arise from the proliferation of collaborative robots (cobots), which necessitate smaller, quieter, and safer motion control devices suitable for human-centric environments. Furthermore, the burgeoning field of surgical and rehabilitation robotics represents a high-margin opportunity, demanding customized, sterilized, and highly reliable strain wave gearing solutions. Technological advancements in additive manufacturing (3D printing) of complex metallic components offer the potential to overcome some existing manufacturing cost and complexity restraints, potentially opening pathways for more rapid prototyping and localized production of specialized gear components. The ongoing digitalization of manufacturing also creates opportunities for integrating smart sensors directly into the gear units, enabling sophisticated condition monitoring and predictive maintenance services.

The impact forces influencing this market are predominantly technological and competitive. The competitive intensity is moderate to high, centered around patented designs and long-standing relationships with major robotics and aerospace OEMs. Technological impact is profound; any breakthrough in achieving similar precision with significantly lower manufacturing complexity (e.g., advanced cycloidal drives or magneto-rheological fluid systems) could disrupt the current dominance of strain wave technology. Economically, the cost-benefit analysis favors strain wave gears only in high-precision, high-value applications, meaning general industrial machinery remains largely outside their scope. The stringent quality standards in critical sectors (medical, aerospace) act as an amplifying regulatory impact force, mandating rigorous testing and certification, thus reinforcing the reliability reputation of established strain wave gear manufacturers.

Summary of DRO & Impact Forces:

- Drivers: Rapid adoption of industrial and collaborative robotics; increasing demand for high-precision motion control in defense and medical devices; need for high torque density and zero backlash in compact assemblies.

- Restraints: High initial manufacturing complexity and cost of components (especially flexspline); requirement for specialized assembly and maintenance expertise; limited availability of specialized materials.

- Opportunities: Exponential growth in cobots and surgical robotics; advancements in material science and additive manufacturing for customized geometries; potential for smart, sensor-integrated gear units (IIoT integration).

- Impact Forces: Technological obsolescence risk from alternative high-precision drive systems; strong influence of intellectual property and patents; stringent regulatory requirements in mission-critical applications reinforcing market reliability standards.

Segmentation Analysis

The Strain Wave Gearing Devices Market is comprehensively segmented based on product type, component, reduction ratio, torque capacity, and end-use application. This segmentation provides a granular view of market dynamics, revealing differential growth rates and adoption patterns across various industrial sectors. Product type segmentation typically differentiates between component sets, which are integrated directly into the surrounding machinery structure, and cased gear units, which are sealed and self-contained modules. Component sets are increasingly preferred by advanced robotic manufacturers seeking maximum space efficiency and system integration, while cased units offer easier installation and maintenance for retrofit and lower-volume applications. Understanding these structural preferences is crucial for suppliers aiming to align their product portfolio with evolving OEM requirements.

Reduction ratio is another critical dimension, separating low-ratio, medium-ratio, and high-ratio gears. High-ratio gears (typically exceeding 80:1 up to 320:1) command a significant market share due to their necessity in achieving precise, slow rotational speeds and high output torque, vital for tasks like robotic welding, cleanroom automation, and satellite antenna adjustments. Torque capacity segmentation ensures products are appropriately matched to application loads, distinguishing between light-duty (cobots, medical) and heavy-duty (large industrial robots, heavy machinery). This detailed analysis helps in pinpointing niche requirements, such as those for specialized lightweight aerospace actuators, which demand extremely high torque-to-weight ratios.

- By Product Type:

- Component Set (Zero-backlash, high integration potential)

- Cased Gear Unit (Easier installation, higher standardization)

- By Reduction Ratio:

- Low Ratio (Below 50:1)

- Medium Ratio (50:1 to 100:1)

- High Ratio (Above 100:1)

- By Bore Size:

- Small Bore (Under 50 mm)

- Medium Bore (50 mm to 100 mm)

- Large Bore (Above 100 mm)

- By Torque Capacity:

- Low Torque (For cobots and small actuators)

- Medium Torque (Standard industrial robots)

- High Torque (Heavy manipulation and machining centers)

- By End-Use Application:

- Industrial Robotics and Automation (Largest segment)

- Aerospace and Defense (Actuators, gimbals, control surfaces)

- Medical and Healthcare (Surgical robots, rehabilitation devices, diagnostic imaging)

- Semiconductor and Flat Panel Display Manufacturing

- Precision Instruments and Optics (Telescopes, radar systems)

Value Chain Analysis For Strain Wave Gearing Devices Market

The value chain for Strain Wave Gearing Devices is highly specialized and knowledge-intensive, beginning with the sourcing of exotic materials required for the flexspline and circular spline components. Upstream activities involve specialized metal suppliers providing high-strength, fatigue-resistant steel alloys and sometimes titanium, followed by precision machining companies that handle the intricate shaping of the wave generator and the gear components. The quality and purity of these raw materials directly dictate the final gear performance, lifespan, and zero-backlash capabilities, emphasizing the critical nature of these foundational stages. Suppliers must adhere to stringent quality control standards, especially those serving the aerospace and medical device end-users, where material traceability and certification are mandatory requirements.

Midstream processing is dominated by the core manufacturing process, which includes highly specialized grinding, heat treatment, and surface finishing techniques necessary to achieve the sub-micrometer tolerances required for strain wave action. Assembly and rigorous testing follow, where manufacturers precisely match and integrate the flexspline, circular spline, and wave generator into either component sets or cased units. Intellectual property surrounding the patented gear tooth profiles and manufacturing methodologies grants significant leverage to key market players at this stage. Distribution channels primarily involve a direct sales model to large Original Equipment Manufacturers (OEMs) in robotics and specialized automation, given the technical complexity and high cost of integration. Indirect distribution, leveraging specialized industrial distributors, handles smaller clients and aftermarket services.

Downstream analysis focuses on end-use integration and aftermarket services. OEMs integrate these gears into multi-axis robots, surgical arms, or satellite positioning systems. The subsequent value generated is substantial, as the gear's precision enables high-value tasks such as micro-assembly or complex surgery. Aftermarket services, including maintenance, repair, and replacement (MR&R) of flexsplines, represent a steady revenue stream due to the long operational life and high cost of replacement components. The direct channel ensures deep technical engagement with OEMs, facilitating custom design work and rapid iteration, which is essential for capturing market share in fast-evolving sectors like collaborative robotics, where integration depth is key.

Strain Wave Gearing Devices Market Potential Customers

Potential customers for Strain Wave Gearing Devices are predominantly entities requiring high-reliability, high-precision motion control in constrained spaces. The largest segment of buyers comprises industrial robot manufacturers, including articulated arm robot producers and SCARA robot builders, who utilize these gears in nearly every major joint to ensure repeatability and load-bearing capacity. These companies, such as FANUC, Yaskawa, ABB, and KUKA, are the cornerstone demand generators, often requiring large volumes of standardized component sets tailored to specific robot payloads and axes. The relationship between gear supplier and robotics OEM is often long-term and consultative, driven by co-design and stringent supply chain assurance requirements.

Beyond traditional industrial automation, the medical technology sector represents an increasingly critical buyer base. Customers here include manufacturers of surgical robots (like Intuitive Surgical competitors), diagnostic imaging equipment, and advanced prosthetics. These buyers prioritize zero-backlash and smooth motion profiles, along with compliance to strict regulatory standards regarding biocompatibility and sterilization, often requiring specialized coatings and materials. The aerospace and defense sector constitutes another premium customer segment, purchasing strain wave gears for satellite deployment mechanisms, high-altitude surveillance gimbals, missile fin actuators, and precision radar systems, where weight reduction and reliability in extreme temperatures are non-negotiable purchasing criteria.

Furthermore, specialized industrial customers in semiconductor fabrication (e.g., equipment for lithography and wafer handling), precision measuring machinery, and high-end printing presses are significant purchasers. These end-users demand gearing that ensures near-perfect parallelism and positional stability over long operational cycles to maintain nanometer-level accuracy in their processes. The purchasing decision for all these customer segments is heavily weighted toward component lifespan, torque density, tested reliability data, and technical support availability, rather than simply minimizing upfront procurement costs, reflecting the mission-critical nature of the applications.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.85 Billion |

| Market Forecast in 2033 | USD 4.15 Billion |

| Growth Rate | 12.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Harmonic Drive Systems Inc. (HDSI), Nabtesco Corporation, Nidec Shimpo Corporation, Sumitomo Drive Technologies (Lafert Group), SEISA Gear Ltd., Maxon Motor AG, GAM Enterprises, Zhejiang Shuanghuan Driveline Co., Ltd., Leader Drive, KHK Co., Ltd., Beijing CTKM Harmonic Drive Co., Ltd., Cone Drive Operations Inc., Electromate Inc., SST Drive Systems, Schaeffler AG, WITTENSTEIN SE, ZF Friedrichshafen AG, THK Co., Ltd., Tsubakimoto Chain Co., Renishaw plc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Strain Wave Gearing Devices Market Key Technology Landscape

The technological landscape of the Strain Wave Gearing Devices Market is characterized by continuous refinement aimed at improving efficiency, reducing weight, and increasing component longevity. A core focus area involves advanced material science, particularly the development of new, high-fatigue-strength steels and specialized lightweight alloys for the flexspline, which is the most highly stressed component. Innovations in surface treatment, such as low-friction coatings and specialized heat treatments (e.g., carburizing and nitriding), are being adopted to minimize wear and improve the overall efficiency of the gear sets. Manufacturers are also exploring the potential of composite materials in the wave generator to further reduce inertial mass, thereby enhancing dynamic performance in high-speed robotic applications where minimizing mass is critical for energy consumption and cycle time.

Precision manufacturing techniques remain paramount. The industry is increasingly relying on ultra-precision CNC grinding and lapping processes to achieve the exacting tooth profiles and geometric tolerances required to ensure zero backlash and high positional accuracy. Deviation allowances are measured in microns, necessitating stringent environmental control during production. Furthermore, the design phase is heavily supported by sophisticated computer-aided engineering (CAE) simulations, including Finite Element Analysis (FEA), which allows engineers to model stress distribution, predict fatigue life, and optimize the gear geometry for specific load conditions before physical prototyping, significantly accelerating the product development cycle and ensuring maximum torque density is achieved within constrained envelopes.

An emerging technological shift involves the integration of smart features. Modern strain wave gears are being designed to accommodate micro-sensors for condition monitoring. These integrated sensors track parameters such as temperature, vibration, and torsional strain, feeding real-time data into predictive maintenance systems, often utilizing AI and machine learning platforms. This sensor integration, coupled with miniaturized control electronics, transforms the gear unit from a passive mechanical component into an active, intelligent drive system capable of self-diagnosis and communication within an Industrial Internet of Things (IIoT) framework. This convergence of mechanical precision with digital intelligence is defining the next generation of high-performance motion components.

Regional Highlights

The global distribution of the Strain Wave Gearing Devices Market showcases significant regional variation driven by manufacturing maturity, technological investment, and adoption rates of advanced automation. Asia Pacific (APAC) holds the dominant market share and is projected to exhibit the highest CAGR throughout the forecast period. This leadership is largely attributable to China, Japan, and South Korea, which are global hubs for industrial and consumer electronics manufacturing, driving immense demand for precision automation equipment. China’s "Made in China 2025" initiative heavily promotes indigenous robotics development, leading to massive procurement of strain wave gears. Japan, home to major robotics and harmonic drive manufacturers, continues to lead in technological innovation and high-quality, high-reliability production for global export. The dense semiconductor manufacturing sector in South Korea and Taiwan further cements APAC's critical role.

North America maintains a strong position, particularly due to substantial demand from high-reliability sectors such as aerospace and defense (A&D) and specialized medical device manufacturing. The United States is a key consumer, where strain wave gears are extensively used in advanced military actuation systems, NASA programs, and the rapidly growing field of surgical robotics. These applications prioritize quality and certification over cost, ensuring high average selling prices for units sold in the region. Furthermore, the presence of major technology and research institutions drives significant innovation in advanced manufacturing, encouraging the rapid adoption of next-generation cobots and automated logistics systems requiring high-precision drives.

Europe represents a mature and technologically sophisticated market, driven by Germany’s robust mechanical engineering and industrial automation sector, as well as significant defense expenditures in the UK and France. European manufacturers focus heavily on energy efficiency and system integration standards, leading to a strong demand for cased, modular gear units. The region's aging industrial workforce also accelerates the adoption of collaborative robotics in SMEs, widening the application base for smaller, integrated strain wave drives. Latin America and the Middle East & Africa (MEA) currently represent smaller markets, though investments in localized automotive assembly plants and oil & gas exploration automation are expected to generate moderate growth, particularly for medium-torque, standard industrial applications, although precision requirements remain generally lower than in the Triad regions.

- Asia Pacific (APAC): Dominates market share due to massive industrial robotics deployment in China, Japan, and South Korea; strong governmental support for automation initiatives; leading producer and consumer of semiconductor manufacturing equipment.

- North America: High-value market driven by critical sectors like Aerospace & Defense, and Medical Robotics; focus on R&D and integrating smart gear technologies; stringent quality requirements ensure premium pricing.

- Europe: Mature market characterized by advanced manufacturing bases (Germany, Italy); strong demand for precise, energy-efficient automation solutions and specialized machinery for complex tasks.

- Latin America: Emerging market with growth tied to foreign investment in automotive and consumer goods manufacturing; primary focus on standard industrial automation applications.

- Middle East & Africa (MEA): Nascent market, expansion driven by automation investments in the oil & gas sector and infrastructure projects; slower adoption of ultra-high precision systems compared to global leaders.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Strain Wave Gearing Devices Market.- Harmonic Drive Systems Inc. (HDSI)

- Nabtesco Corporation

- Nidec Shimpo Corporation

- Sumitomo Drive Technologies (Lafert Group)

- SEISA Gear Ltd.

- Maxon Motor AG

- GAM Enterprises

- Zhejiang Shuanghuan Driveline Co., Ltd.

- Leader Drive

- KHK Co., Ltd.

- Beijing CTKM Harmonic Drive Co., Ltd.

- Cone Drive Operations Inc.

- Electromate Inc.

- SST Drive Systems

- Schaeffler AG

- WITTENSTEIN SE

- ZF Friedrichshafen AG

- THK Co., Ltd.

- Tsubakimoto Chain Co.

- Renishaw plc.

Frequently Asked Questions

Analyze common user questions about the Strain Wave Gearing Devices market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary benefit of using strain wave gearing over traditional gearboxes in robotics?

The primary benefit is achieving exceptionally high torque density and high reduction ratios in a lightweight, compact form factor, coupled with zero-backlash operation and superior positional accuracy, which is critical for robotic repeatability and precision motion control.

Which applications are driving the highest demand for strain wave gearing devices globally?

Industrial robotics, especially articulated robots and collaborative robots (cobots), constitute the largest demand segment, followed by high-precision applications in aerospace actuation systems, and sophisticated medical devices like surgical robots.

What are the main technical challenges associated with strain wave gear manufacturing?

The main challenges include achieving the micron-level precision required for the specialized gear teeth, manufacturing the highly flexible yet durable thin-walled flexspline component, and managing the high material costs associated with high-fatigue-strength alloys.

How is AI impacting the design and maintenance of strain wave gearing devices?

AI is primarily used to enhance predictive maintenance by analyzing sensor data (vibration, temperature) to forecast potential failures, and in generative design processes to optimize the complex geometry of the gear components for efficiency and lifespan.

Which geographical region exhibits the fastest growth rate in the Strain Wave Gearing Market?

Asia Pacific (APAC), particularly driven by industrial automation initiatives and massive robotics adoption in nations like China and South Korea, is projected to register the highest Compound Annual Growth Rate (CAGR) through the forecast period.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager