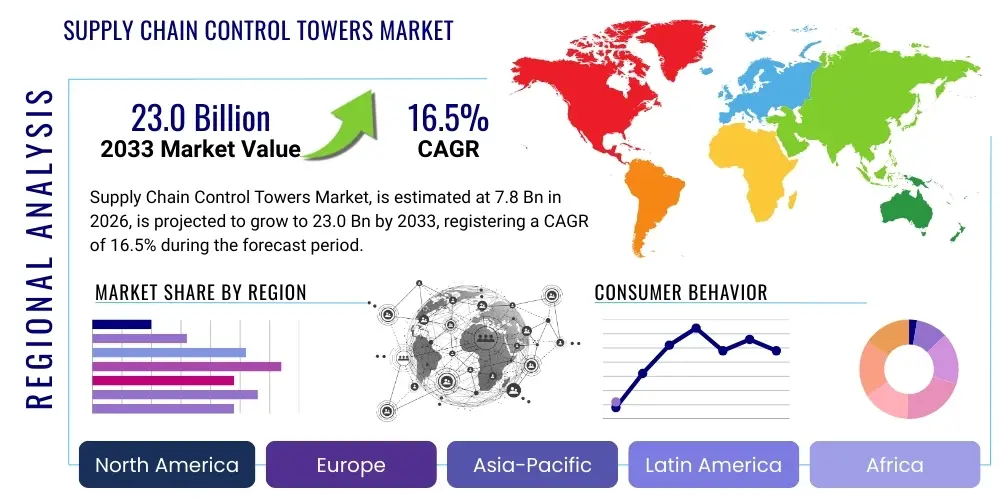

Supply Chain Control Towers Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 442064 | Date : Feb, 2026 | Pages : 258 | Region : Global | Publisher : MRU

Supply Chain Control Towers Market Size

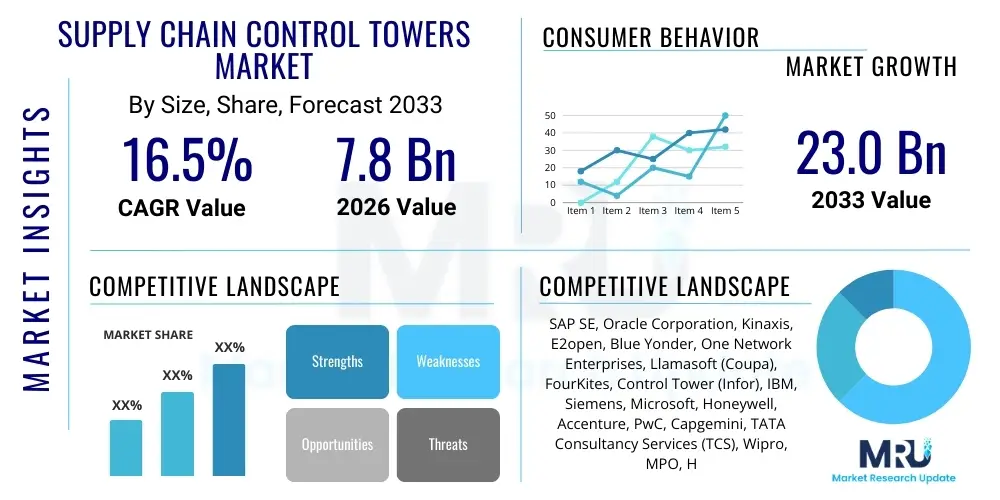

The Supply Chain Control Towers Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 16.5% between 2026 and 2033. The market is estimated at USD 7.8 Billion in 2026 and is projected to reach USD 23.0 Billion by the end of the forecast period in 2033.

Supply Chain Control Towers Market introduction

The Supply Chain Control Tower (SCCT) represents a sophisticated, centralized data hub that provides end-to-end visibility across the entire supply network, encompassing planning, execution, and monitoring functions. These platforms integrate data from disparate systems—including ERP, TMS, WMS, and external sources like weather data or geopolitical trackers—to create a single, unified view of the supply chain. The primary product description centers around providing real-time data aggregation, advanced analytics, and intelligent alerting capabilities, transforming reactive supply chain management into proactive, predictive management. This holistic approach allows organizations to detect bottlenecks, predict delays, and execute rapid, informed adjustments across global operations, thereby significantly minimizing risks and improving operational efficiency.

Major applications of SCCTs span across various functional domains, including optimizing inbound and outbound logistics, improving inventory positioning, enhancing demand forecasting accuracy, and streamlining order management processes. Specific vertical applications include managing complex manufacturing flows in the automotive industry, ensuring cold chain integrity in pharmaceuticals, and handling high-volume, quick-turnaround fulfillment in the retail and e-commerce sectors. The foundational benefit derived from implementing an SCCT is the capability for prescriptive decision-making, where the system not only identifies potential problems but also recommends optimal corrective actions based on predefined business rules and sophisticated analytical models. This shift from descriptive reporting to prescriptive guidance is critical for maintaining competitive advantage in today's volatile global marketplace.

The market expansion is fundamentally driven by the accelerating complexity inherent in modern, global supply chains, characterized by multi-tiered supplier networks, extensive geographic dispersion, and heightened consumer expectations for rapid delivery. Furthermore, the persistent need for resilience following major global disruptions, such as geopolitical conflicts and pandemics, has catalyzed investment in resilient planning tools like Control Towers. Organizations are increasingly digitalizing their operations, making the integration of IoT sensors, telematics, and big data analytical tools commonplace, which provides the necessary data foundation for Control Towers to function effectively. The imperative to achieve sustainability goals and comply with stringent regulatory requirements also necessitates the transparent, traceable visibility that SCCT solutions provide, forcing businesses across multiple industries to prioritize these sophisticated software implementations.

Supply Chain Control Towers Market Executive Summary

The Supply Chain Control Towers market is experiencing robust growth fueled by several converging business trends centered around digital transformation and operational resilience. A primary business trend involves the shift from traditional descriptive and diagnostic analytics towards highly advanced predictive and prescriptive capabilities, heavily leveraging Artificial Intelligence (AI) and Machine Learning (ML). Enterprises are moving beyond simple data visualization to demand platforms that automate decision-making for minor disruptions and provide scenario planning tools for major events. Furthermore, there is a pronounced consolidation in the vendor landscape as large enterprise resource planning (ERP) providers integrate dedicated control tower functionality, often through acquisitions, competing directly with niche pure-play software vendors who focus intensely on vertical-specific analytical depth.

Regionally, North America and Europe currently dominate the market share due to the early adoption of advanced supply chain technologies, the presence of major multinational corporations with intricate logistics networks, and substantial investment in cloud-based infrastructure. However, the Asia Pacific (APAC) region is projected to exhibit the highest Compound Annual Growth Rate (CAGR) throughout the forecast period. This rapid expansion in APAC is primarily attributed to fast-paced industrialization, the booming e-commerce sector, the expansion of manufacturing capabilities, and increasing governmental emphasis on developing robust national logistics infrastructure. The Middle East and Africa (MEA) and Latin America (LATAM) are emerging markets, primarily driven by investments in modernization of ports and logistics hubs, although the adoption rate is slower due to fragmented logistics infrastructure and resource constraints.

Segment trends highlight a clear dominance of the Cloud deployment model, favored for its flexibility, scalability, lower initial capital expenditure, and ease of deployment across global operations, aligning perfectly with the distributed nature of modern supply chains. Within the function segment, Logistics Management control towers—focused on transportation visibility and execution optimization—maintain a significant market share, though Inventory Management control towers are rapidly gaining prominence as companies strive to optimize working capital and minimize stock-outs. The Services component, encompassing implementation, integration, and managed services, is witnessing significant growth, driven by the complexity inherent in integrating Control Tower software with legacy systems and the ongoing need for expert maintenance and optimization services.

AI Impact Analysis on Supply Chain Control Towers Market

Common user inquiries regarding the impact of AI on Supply Chain Control Towers frequently revolve around implementation complexity, measurable return on investment (ROI), and the level of required human intervention. Users are highly concerned about how AI transitions the Control Tower from a monitoring tool to an autonomous decision-making engine, specifically asking how ML handles data quality issues, how quickly models adapt to unforeseen market shifts, and whether AI can truly deliver prescriptive recommendations that outperform human analysts. The key themes summarized from these inquiries underscore a strong expectation for AI to deliver proactive risk mitigation, automated optimization of routine processes, and superior forecasting accuracy, ultimately driving the adoption of Cognitive Control Towers capable of continuous self-learning and predictive supply chain management.

AI's integration fundamentally transforms the SCCT from a reporting platform into an intelligence center. Machine learning algorithms are crucial for processing the massive volumes of real-time data generated by IoT devices and disparate enterprise systems. These algorithms excel at pattern recognition, enabling the tower to identify subtle anomalies, predict potential disruptions (such as traffic delays, port congestion, or demand spikes), and quantify the probability of impact weeks or months in advance. This capability allows supply chain managers to shift from a reactive mode—where they respond to actual events—to a predictive mode, where preventative actions are implemented autonomously or guided by the system.

Furthermore, AI significantly enhances the prescriptive capabilities of the Control Tower. By utilizing reinforcement learning and optimization techniques, the system can automatically generate and evaluate multiple contingency plans simultaneously when a disruption is detected. For instance, if a raw material shipment is delayed, the AI can instantly analyze inventory levels, production schedules, alternative supplier costs, and transportation routes, recommending the financially optimal course of action. This automation reduces decision latency, which is critical in time-sensitive logistics environments, and ensures that corrective actions are executed with the highest degree of efficiency and adherence to overall business goals, solidifying the SCCT’s role as the central nervous system of the digitized enterprise.

- Enhanced Predictive Forecasting: AI/ML models improve demand sensing accuracy by integrating unstructured external data (e.g., social media trends, geopolitical news).

- Automated Anomaly Detection: Machine learning identifies abnormal patterns in operational data far quicker than traditional rule-based systems, enabling pre-emptive intervention.

- Prescriptive Decision Support: AI provides optimal, quantified recommendations for mitigating disruptions, reducing reliance on manual judgment.

- Cognitive Process Automation (CPA): Automation of routine tasks such as rescheduling shipments, reordering inventory, and adjusting capacity plans based on real-time insights.

- Dynamic Scenario Planning: AI models rapidly simulate the impact of various risks (e.g., natural disasters, economic shifts) on profitability and service levels.

DRO & Impact Forces Of Supply Chain Control Towers Market

The market for Supply Chain Control Towers is significantly influenced by powerful Drivers, facing specific Restraints, and presenting considerable Opportunities, which collectively define the overarching Impact Forces. Key drivers include the overwhelming need for end-to-end transparency across complex, multi-modal logistics networks and the increasing volatility of global trade, necessitating highly adaptive and agile supply chain structures. These drivers compel organizations, particularly those in manufacturing and retail, to invest heavily in advanced monitoring and execution tools. Conversely, the market faces significant restraints, primarily stemming from the high initial capital investment required for implementing sophisticated SCCT software and the immense complexity involved in integrating these new platforms with existing, often heterogeneous and decades-old legacy ERP systems. Overcoming these integration hurdles and securing executive sponsorship for the transformation are critical challenges.

Opportunities for market growth are vast and centered on leveraging emerging technologies such as the Industrial Internet of Things (IIoT) and Blockchain. The proliferation of IIoT devices provides Control Towers with granular, real-time data on asset location, condition, and environment, enabling hyper-accurate tracking and performance monitoring. Blockchain offers a secure, immutable ledger for verifying transactions and managing digital identities across the supply chain, significantly boosting trust and transparency, especially in critical areas like compliance and provenance tracking. These technological advancements open new avenues for service providers to offer highly specialized, industry-specific control tower solutions tailored to unique logistical and compliance requirements, such as cold chain management or hazardous materials tracking.

The collective impact forces favor accelerated adoption, driven by the undeniable competitive necessity of resilience. Post-pandemic operations have established that visibility is not a luxury but a fundamental requirement for business continuity. The pressure to reduce lead times, optimize working capital through precise inventory control, and achieve ambitious sustainability targets (e.g., carbon footprint reduction through optimized routing) are powerful external impact forces pushing companies toward Control Tower adoption. While financial and technical restraints remain valid, the overwhelming market pressure to manage complexity and minimize catastrophic disruption risk ensures that the investment in Control Towers will continue to be prioritized over manual or fragmented management solutions, ensuring sustained high growth throughout the forecast period.

- Drivers (D): Increasing supply chain complexity and globalization; need for operational resilience and risk mitigation; accelerated digitalization and IoT integration across logistics.

- Restraints (R): High implementation and maintenance costs; challenges in data standardization and integration across fragmented legacy IT systems; resistance to change management within large organizations.

- Opportunities (O): Adoption of prescriptive analytics and AI for automated decision-making; expansion into mid-market segments via scalable, cloud-based offerings; leveraging Blockchain for enhanced security and provenance tracking.

- Impact forces: Mandate for end-to-end visibility; competitive pressure for reduced lead times; regulatory demands for transparency and sustainability reporting.

Segmentation Analysis

The Supply Chain Control Towers Market is segmented across several critical dimensions, including Deployment Model, Functionality, Component, and Industry Vertical. Analyzing these segments provides crucial insights into the evolving preferences of end-users and the areas of highest investment concentration. The segmentation reflects the diverse needs of enterprises, ranging from small regional distributors requiring basic visibility tools to large multinational corporations demanding complex, highly integrated, and AI-driven platforms capable of managing global, multi-tier supplier networks. Understanding these segments is vital for vendors to tailor their product development and market strategies, ensuring alignment with specific operational and financial requirements across different customer profiles.

The Component segmentation, differentiating between software and services, highlights the growing importance of implementation and managed services. While the core software provides the essential framework for data aggregation and analytics, the complexity of integrating diverse operational systems (e.g., WMS, ERP, TMS) necessitates extensive professional services, which often account for a significant portion of the total project expenditure. The increasing adoption of the Cloud deployment model, dominating the market, is driven by the desire for rapid scalability, reduced upfront costs, and easier maintenance, particularly attractive to global organizations seeking standardized platforms without heavy localized IT infrastructure investment.

Furthermore, segmentation by Functionality—covering areas like Order Management, Inventory Management, and Logistics Management—shows where companies prioritize visibility improvements. While Logistics Management remains dominant due to the immediate financial impact of transportation optimization, the growth in Inventory Management Control Towers underscores the strategic focus on working capital optimization, especially in high-value manufacturing and retail. Finally, the vertical segmentation reveals varying levels of adoption maturity, with industries like Retail, Manufacturing, and Automotive leading the way due to their inherently complex supply chains, strict compliance requirements, and intense pressure for just-in-time operations.

- Deployment Model:

- Cloud (SaaS)

- On-Premise

- Functionality:

- Order Management Control Towers

- Inventory Management Control Towers

- Logistics Management Control Towers

- Component:

- Software (Platform and Applications)

- Services (Consulting, Implementation, Managed Services)

- Industry Vertical:

- Retail and E-commerce

- Manufacturing (Discrete and Process)

- Automotive

- Healthcare and Pharmaceuticals

- Food and Beverages

- Others (Oil & Gas, Telecommunications)

Value Chain Analysis For Supply Chain Control Towers Market

The value chain for the Supply Chain Control Towers market begins with upstream activities focused heavily on foundational technology development and intellectual property creation. This stage involves software developers, data scientists, and cloud infrastructure providers (like AWS, Azure, Google Cloud) who supply the critical algorithms, big data processing capabilities, and scalable computing environments necessary for the Control Tower architecture. Key upstream suppliers include specialized providers of AI/ML frameworks and IoT platforms, whose technology enables the real-time data ingestion and predictive analytical capabilities of the SCCT solutions. The quality and robustness of these upstream technological components directly influence the sophistication and performance metrics of the final Control Tower product offered to end-users.

Midstream activities in the value chain involve the core Control Tower vendors (the market players listed later) who are responsible for product development, system integration, customization, and deployment. These vendors invest substantially in integrating their proprietary software with existing enterprise systems (ERP, TMS, WMS) via sophisticated APIs and middleware solutions. Distribution channels are typically direct, particularly for large-scale enterprise implementations, involving extensive negotiation and tailored solution design. However, indirect channels, such as strategic partnerships with global system integrators (GSIs) like Accenture and TCS, are increasingly important. These GSIs play a crucial role in providing implementation expertise, change management support, and regional reach, extending the vendor's distribution network significantly.

Downstream analysis focuses on the end-users and the after-sales support ecosystem. End-users, who are the purchasers and operators of the SCCTs (e.g., supply chain directors, logistics managers), receive ongoing training, maintenance, and optimization services. The downstream success is measured by the tangible improvements in operational KPIs, such as order fulfillment rates, inventory accuracy, and transportation cost reduction. Post-sale services, including continuous monitoring, application management, and periodic upgrades, are essential for maximizing the long-term value derived from the Control Tower investment. Consulting firms specializing in supply chain optimization often operate downstream, advising clients on selection, implementation strategy, and post-go-live optimization of the Control Tower infrastructure.

Supply Chain Control Towers Market Potential Customers

Potential customers for Supply Chain Control Towers are predominantly large and medium-sized enterprises characterized by complex, geographically dispersed, and multi-modal logistics operations. The primary end-users or buyers of these solutions are often C-level executives—specifically Chief Supply Chain Officers (CSCOs) or Chief Operating Officers (COOs)—who prioritize strategic resilience and enterprise-wide efficiency gains over departmental optimization. Industries with high inventory costs, perishable goods, stringent regulatory compliance, or rapid demand variability represent the most immediate and valuable customer segments, as the financial and operational benefits of real-time visibility and proactive decision-making are immediate and substantial in these environments.

A significant customer base resides within the Third-Party Logistics (3PL) and Fourth-Party Logistics (4PL) providers. These organizations manage the logistics networks for multiple clients and, therefore, require highly sophisticated, multi-tenant control towers to oversee diverse and constantly changing operational parameters, ensuring service level agreements (SLAs) are met efficiently across various geographies and transportation modes. For 3PLs, the Control Tower is a crucial differentiator, allowing them to offer advanced reporting, proactive exception management, and superior risk management services to their client portfolio, thereby enhancing their competitive edge and service value proposition in a saturated market.

Furthermore, specific verticals such as automotive manufacturing, high-tech electronics, and pharmaceutical companies represent high-value potential customers. The automotive sector, reliant on complex global sourcing and just-in-time delivery schedules, utilizes SCCTs to track every component, manage supplier risk, and ensure uninterrupted production lines. Pharmaceutical companies leverage Control Towers specifically for regulatory compliance, managing temperature-sensitive cold chains, and tracking product provenance to prevent counterfeiting, making the SCCT an indispensable tool for maintaining both quality standards and compliance mandates across their distribution networks.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 7.8 Billion |

| Market Forecast in 2033 | USD 23.0 Billion |

| Growth Rate | 16.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | SAP SE, Oracle Corporation, Kinaxis, E2open, Blue Yonder, One Network Enterprises, Llamasoft (Coupa), FourKites, Control Tower (Infor), IBM, Siemens, Microsoft, Honeywell, Accenture, PwC, Capgemini, TATA Consultancy Services (TCS), Wipro, MPO, HighJump (Körber) |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Supply Chain Control Towers Market Key Technology Landscape

The technological backbone of the modern Supply Chain Control Tower is characterized by a synergistic blend of advanced data processing and connectivity technologies. Cloud computing forms the foundational layer, providing the necessary elasticity, scalability, and geographic distribution required to handle the massive and volatile data streams generated by global supply chains. SaaS models, hosted on major public cloud platforms, facilitate rapid deployment and integration, lowering the barrier to entry and enabling continuous software updates. Crucially, this cloud architecture supports the instantaneous processing of real-time data feeds, which is essential for providing true end-to-end visibility and achieving near-zero latency in disruption detection and response.

The operational intelligence within the Control Tower is driven by sophisticated Advanced Analytics, encompassing predictive, diagnostic, and prescriptive modeling. Machine Learning (ML) algorithms are integral here, allowing the system to learn from historical performance, identify complex causal relationships, and accurately forecast future events, such as demand surges or lead time variations. Furthermore, the integration of the Internet of Things (IoT) is fundamentally reshaping the data capture capability. IoT sensors deployed on assets, vehicles, and in warehouses provide granular data on location, temperature, humidity, and shock—feeding the Control Tower with the critical physical context needed for precision logistics management and quality assurance, particularly in sensitive supply chains like pharmaceuticals and perishable foods.

Beyond core analytics, emerging technologies like Blockchain are increasingly being explored for specific Control Tower functionalities, mainly related to improving transaction transparency and trust among multiple partners. Blockchain creates a decentralized, immutable record of product origin, quality checks, and ownership transfers, significantly simplifying regulatory compliance and reducing the administrative burden associated with verifying data integrity across multi-tiered supplier networks. Simultaneously, the development of Natural Language Processing (NLP) capabilities is allowing Control Towers to analyze unstructured data, such as news feeds, regulatory updates, and supplier emails, integrating contextual, qualitative intelligence into the quantitative operational models to provide a more comprehensive risk assessment.

Regional Highlights

- North America: This region holds the largest market share, characterized by high technological maturity, extensive cloud infrastructure, and the presence of numerous global enterprises demanding advanced, highly integrated Control Tower solutions. Early and aggressive adoption of predictive and prescriptive analytics driven by major US-based technology vendors solidifies its leadership.

- Europe: The European market is mature, driven by rigorous regulatory requirements (e.g., GDPR, sustainability mandates) and the need to manage complex cross-border logistics within the EU bloc. There is a strong emphasis on achieving sustainable supply chains, leading to high investment in SCCTs that provide granular visibility into carbon footprint tracking and ethical sourcing.

- Asia Pacific (APAC): APAC is the fastest-growing market, primarily fueled by the massive expansion of the manufacturing base, the exponential growth of e-commerce, and increasing investments in smart logistics infrastructure (e.g., smart ports). Countries like China, India, and Japan are rapidly adopting cloud-based control towers to overcome infrastructure deficiencies and manage increasingly complex intra-regional trade routes.

- Latin America (LATAM): This region shows moderate growth, primarily driven by large organizations in Brazil and Mexico seeking to improve visibility and mitigate risks associated with volatile macroeconomic conditions, fragmented logistics networks, and security challenges. Adoption is concentrated among multinational companies operating in the region.

- Middle East and Africa (MEA): Growth in MEA is spurred by significant government investment in becoming global logistics and trade hubs (e.g., UAE, Saudi Arabia). The focus is on leveraging Control Towers to manage large-scale infrastructure projects, energy logistics, and the increasing flow of goods through modern, technologically advanced ports.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Supply Chain Control Towers Market.- SAP SE

- Oracle Corporation

- Kinaxis

- E2open

- Blue Yonder

- One Network Enterprises

- Llamasoft (Coupa)

- FourKites

- Control Tower (Infor)

- IBM

- Siemens

- Microsoft

- Honeywell

- Accenture

- PwC

- Capgemini

- TATA Consultancy Services (TCS)

- Wipro

- MPO

- HighJump (Körber)

Frequently Asked Questions

Analyze common user questions about the Supply Chain Control Towers market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is a Supply Chain Control Tower (SCCT) and how does it differ from traditional supply chain management (SCM) systems?

An SCCT is a centralized, cloud-based platform providing end-to-end, real-time visibility across the entire supply chain, integrating data from various legacy systems (ERP, TMS, WMS). Unlike traditional SCM systems, which are often siloed and reactive, the SCCT leverages AI/ML for predictive and prescriptive analytics, enabling proactive disruption mitigation and automated decision-making across the network.

Which industries benefit most significantly from implementing a Control Tower?

Industries with high complexity, volatility, or strict regulatory requirements benefit the most. This includes Retail and E-commerce (due to high volume and rapid fulfillment demands), Automotive (JIT manufacturing and intricate supplier networks), and Healthcare/Pharmaceuticals (cold chain management and stringent compliance).

What are the primary challenges associated with Supply Chain Control Tower implementation?

The primary challenges include high initial implementation costs, difficulty integrating the new platform with existing legacy IT infrastructure, and securing high-quality, standardized data input from diverse and often fragmented supply chain partners. Effective change management is also critical for user adoption.

How does Artificial Intelligence (AI) enhance the functionality of a Control Tower?

AI significantly enhances SCCT functionality by enabling predictive forecasting, rapid automated anomaly detection, and prescriptive scenario planning. AI moves the system beyond mere monitoring to actively recommending optimal corrective actions for disruptions, drastically improving operational agility and reducing decision latency.

Is the Cloud deployment model essential for modern Control Towers?

While not strictly essential, the Cloud model (SaaS) is overwhelmingly preferred and dominant. Cloud deployment offers superior scalability, flexibility, global accessibility, and lower upfront capital expenditure compared to traditional on-premise installations, which aligns perfectly with the distributed nature of global supply chain operations.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager